tow bar LAND ROVER DISCOVERY 1995 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 379 of 873

![LAND ROVER DISCOVERY 1995 Workshop Manual MANIFOLD AND EXHAUST SYSTEM

3

REPAIR MANIFOLD AND EXHAUST SYSTEM - Tdi

Remove

1.Raise vehicle on a ramp [hoist].

2.Remove anti-roll[sway] bar bolts to chassis and

allow to swing down clear of axle.

Se LAND ROVER DISCOVERY 1995 Workshop Manual MANIFOLD AND EXHAUST SYSTEM

3

REPAIR MANIFOLD AND EXHAUST SYSTEM - Tdi

Remove

1.Raise vehicle on a ramp [hoist].

2.Remove anti-roll[sway] bar bolts to chassis and

allow to swing down clear of axle.

Se](/img/64/57248/w960_57248-378.png)

MANIFOLD AND EXHAUST SYSTEM

3

REPAIR MANIFOLD AND EXHAUST SYSTEM - Tdi

Remove

1.Raise vehicle on a ramp [hoist].

2.Remove anti-roll[sway] bar bolts to chassis and

allow to swing down clear of axle.

See REAR

SUSPENSION, Repair, Anti-roll [sway] Bar

Assembly Rear

3.Remove exhaust support bracket behind

catalyst.

4.Disconnect exhaust at manifold.

5.Disconnect flange between rear and front

exhaust.

6.Fit axle stands in suitable place on chassis.

7.Allow hoist to lower until front suspension is fully

extended.

8.Manoeuvre front exhaust section fron

underneath vehicle.

9.Remove bolts securing three hanger brackets to

chassis. Lower rear exhaust assembly onto rear

axle. Detach rubbers from hanging brackets.

10.Place extended axle stands underneath chassis

in front of chassis mounted rear towing brackets.11.Lower hoist until vehicle weight is supported

securely on stands.

12.Lower hoist until rear suspension is almost fully

extended.

13.Move rear exhaust to a diagonal position, centre

silencer to right of vehicle.

14.Facing rear of vehicle, twist assembly

anti-clockwise clear of rear axle.

15.Remove rear exhaust assembly from vehicle.

Refit

16.Position rear exhaust assembly over rear axle in

a diagonal position, as for removing.

17.Twist assembly clockwise until it is in mounting

position.

18.Reverse removal procedure instructions 1 to 15

using a new manifold gasket and applying

exhaust sealer to system joints.

19.Examine system for leaks, ensuring that system

does not foul under body components. Rectify if

necessary.

Page 582 of 873

![LAND ROVER DISCOVERY 1995 Workshop Manual FRONT SUSPENSION

5

REPAIR ANTI-ROLL[SWAY] BAR ASSEMBLY FRONT

Service repair no - 60.10.01

KEY

1. Anti-roll[sway] bar

2. Rubber bush

3. Strap

4. Nut, bolt, washer5. Nut and washer

6. Castellated nut an LAND ROVER DISCOVERY 1995 Workshop Manual FRONT SUSPENSION

5

REPAIR ANTI-ROLL[SWAY] BAR ASSEMBLY FRONT

Service repair no - 60.10.01

KEY

1. Anti-roll[sway] bar

2. Rubber bush

3. Strap

4. Nut, bolt, washer5. Nut and washer

6. Castellated nut an](/img/64/57248/w960_57248-581.png)

FRONT SUSPENSION

5

REPAIR ANTI-ROLL[SWAY] BAR ASSEMBLY FRONT

Service repair no - 60.10.01

KEY

1. Anti-roll[sway] bar

2. Rubber bush

3. Strap

4. Nut, bolt, washer5. Nut and washer

6. Castellated nut and cotter pin

7. Ball joint link arm

Remove

1.Mark for reassembly position of rubber bushes

on anti- roll[sway] bar.

2.Remove four nuts, bolts and washers securing

two bush straps.

3.Remove nuts, bolts, washers and rubber bushes

from ball joint links and remove anti-roll[sway]

bar.Refit

4.Position bushes on anti-roll[sway] bar. Ensure

split points towards axle on RH bush and away

from axle on LH bush.

5.Fit anti-roll[sway] bar with two straps. To ensure

correct fit angled sides of bar should point down

as shown. Loosely fit the bolts, washers and

nyloc nuts.

6.Fit bolt, washers and rubber bushes. Using new

nuts fit anti-roll[sway] bar to ball joint links.

Tighten to

68Nm.

7.Tighten nuts securing straps to30Nm

Page 589 of 873

![LAND ROVER DISCOVERY 1995 Workshop Manual 64REAR SUSPENSION

4

REPAIR ANTI-ROLL[SWAY] BAR ASSEMBLY REAR

Service repair no - 64.35.08.

KEY

1. Anti-roll[sway] bar

2. Rubber bush

3. Strap

4. Nut, bolt, washer5. Nut and washer

6. Ball joint link a LAND ROVER DISCOVERY 1995 Workshop Manual 64REAR SUSPENSION

4

REPAIR ANTI-ROLL[SWAY] BAR ASSEMBLY REAR

Service repair no - 64.35.08.

KEY

1. Anti-roll[sway] bar

2. Rubber bush

3. Strap

4. Nut, bolt, washer5. Nut and washer

6. Ball joint link a](/img/64/57248/w960_57248-588.png)

64REAR SUSPENSION

4

REPAIR ANTI-ROLL[SWAY] BAR ASSEMBLY REAR

Service repair no - 64.35.08.

KEY

1. Anti-roll[sway] bar

2. Rubber bush

3. Strap

4. Nut, bolt, washer5. Nut and washer

6. Ball joint link arm

7. Bolt and washer

8. Castellated nut and cotter pin

Remove

1.Note for reassembly, position of rubber bushes

on anti-roll bar.

2.Remove four nuts, bolts and washers securing

two bush straps.

3.Remove nuts, bolts, washers and rubber bushes

from the ball joint links and remove anti-roll bar.Refit

4.Position rubber bushes on anti-roll bar. Fit joint

towards axle.

5.Fit anti-roll bar with two straps. Ensure ball joint

link arms point down as shown. Loosely fit, bolts,

washers and new nyloc nuts.

6.Fit bolt, washers and rubber bushes. Fit anti-roll

bar to ball joint links. Tighten to

68Nm.

7.Tighten nuts securing straps to30Nm.

Page 679 of 873

76CHASSIS AND BODY

12

REPAIR REAR DOOR TRIM PANEL

Service repair no - 76.34.09

Remove

1.Remove the two screws securing the door pull

and remove it from the door.

2.Remove the finisher from the inner door handle.

3.Using a trim panel removing tool release the

seventeen trim panel fasteners and withdraw the

panel from the door.

4.If necessary remove the sixteen screws securing

the stowage bins to the trim panel and detach

the bins.

Refit

5.Reverse removal procedure.REAR DOOR LOCK AND INNER AND OUTER

RELEASE HANDLES

Service repair no - 76.37.16/74/77/78

Remove

1.Disconnect battery negative lead.

2.Remove the door pull, the trim panel and the

vapour protective sheet, to allow access to the

door handles and lock mechanisms.

3.Disconnect the inner release handle connecting

rod at the lock.

4.Remove the two screws securing the inner

handle and withdraw the handle complete with

connecting rod.

NOTE: Two identical 'Y' shaped levers

(bellcranks) are fitted to the rear door lock

mechanism and are referred to as inner

and outer 'Y' levers; the inner one being the

nearest to the inner door panel.

5.If fitted, remove the central locking actuator

control rod link from the actuator and from the

inner 'Y' lever.

6.Detach the remote button connecting rod at the

inner 'Y' lever and withdraw from inside the door.

7.Detach the lock and barrel connecting rods from

the upper leg of the inner 'Y' lever.

Page 867 of 873

ELECTRICAL

47

REPAIR

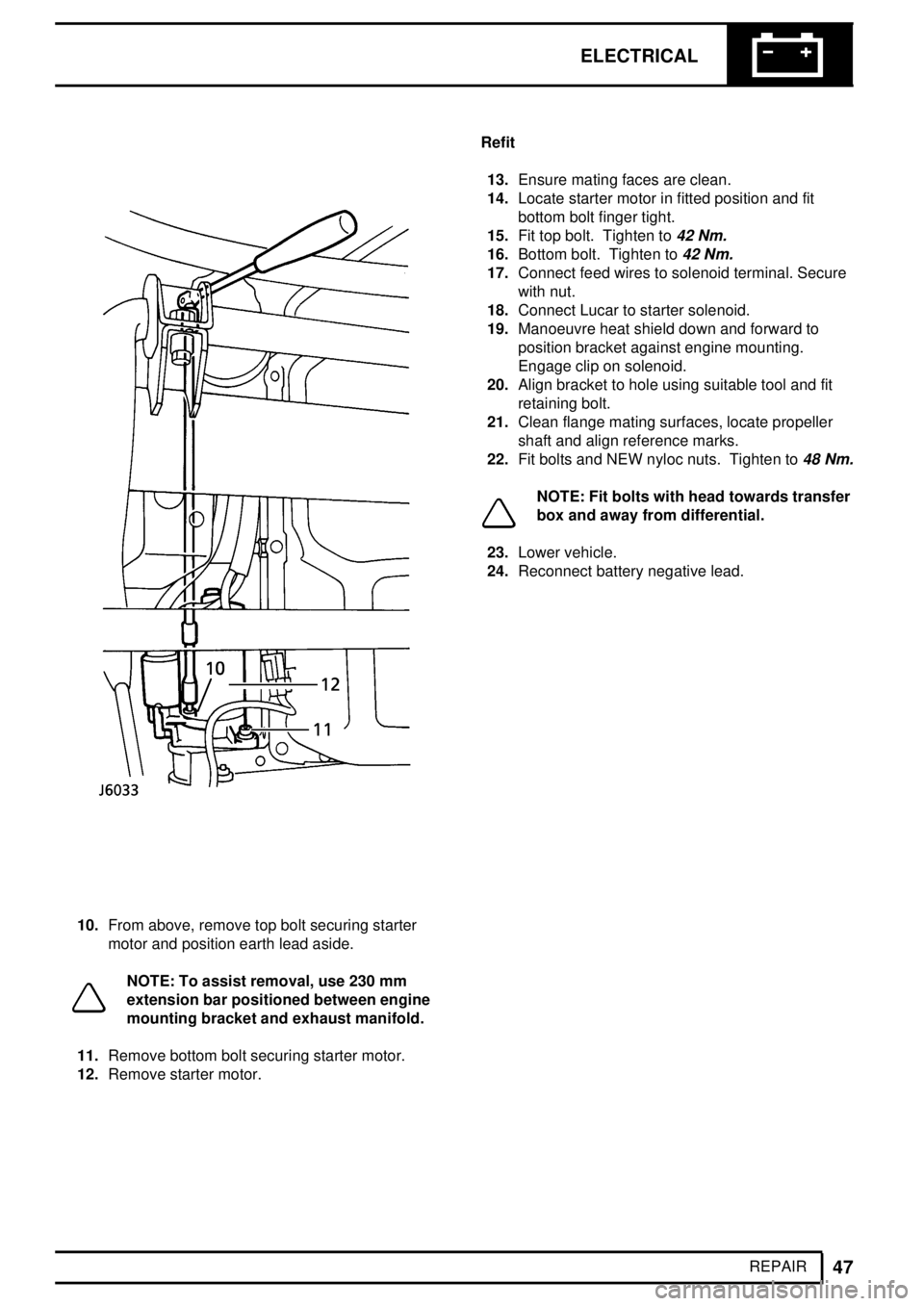

10.From above, remove top bolt securing starter

motor and position earth lead aside.

NOTE: To assist removal, use 230 mm

extension bar positioned between engine

mounting bracket and exhaust manifold.

11.Remove bottom bolt securing starter motor.

12.Remove starter motor.Refit

13.Ensure mating faces are clean.

14.Locate starter motor in fitted position and fit

bottom bolt finger tight.

15.Fit top bolt. Tighten to

42 Nm.

16.Bottom bolt. Tighten to42 Nm.

17.Connect feed wires to solenoid terminal. Secure

with nut.

18.Connect Lucar to starter solenoid.

19.Manoeuvre heat shield down and forward to

position bracket against engine mounting.

Engage clip on solenoid.

20.Align bracket to hole using suitable tool and fit

retaining bolt.

21.Clean flange mating surfaces, locate propeller

shaft and align reference marks.

22.Fit bolts and NEW nyloc nuts. Tighten to

48 Nm.

NOTE: Fit bolts with head towards transfer

box and away from differential.

23.Lower vehicle.

24.Reconnect battery negative lead.