turn signal LAND ROVER DISCOVERY 1995 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 206 of 873

Tdi

1

DESCRIPTION AND OPERATION DESCRIPTION

Air intake

The air cleaner is positioned to the right of the engine

and connected by hoses to a cold air intake duct and

the turbocharger inlet. A crankcase breather hose is

fitted between the air cleaner and the separator.

A single stage turbocharger, fitted between the

exhaust manifold and exhaust pipe, is connected by

hoses to the air cleaner and to an intercooler mounted

on the right of the radiator. The intercooler is

connected by a hose to the inlet manifold.

Fuel system

A 89 litre fuel tank is mounted at the rear of the

vehicle beneath the load space floor. The tank is

vented by a 2 way valve in the filler cap.

A mechanical lift pump, driven by the camshaft, is

mounted on the side of the engine.

A fuel filter, fitted with a replaceable element and

incorporating a water separator, is positioned on the

LH side of the bulkhead.

A Bosch Type injection pump, incorporating a cold

start advance unit and a high idle setting is mounted

on the LH side of the engine and is directly driven by

gears from the crankshaft. The pump meters and

distributes fuel to 4 pintle type injectors located in

pre-combustion chambers in the cylinder heads.

A return line passes excess fuel from the injection

pump and injectors back to the fuel tank.

Glow plugs

Four glow plugs are located in the cylinder head,

directly below each injector.Exhaust gas recirculation (EGR)

Exhaust gas recirculation is controlled by the EGR

control unit mounted in the passenger compartment

on the RH 'A' post behind the fascia and receives the

following inputs:

a. Engine temperature from coolant temperature

transmitter in No. 4 cylinder head.

b. Throttle position from the sensor on the injection

pump.

c. Engine speed from the tachometer.

d. EGR valve lift position.

When all correct signals are received, the EGR

solenoid allows vacuum to open the EGR valve and

recirculate a portion of the exhaust gas.

Page 210 of 873

Tdi

5

DESCRIPTION AND OPERATION Exhaust Gas Recirculation (EGR)

Operation of the EGR system is dependent on the

following:

a. Engine temperature - must be between 20°C

and 100°C approx.

b. Engine speed - must be between 630 and 2850

rev/min.

c. Engine load - calculated by throttle position

sensor.

d. EGR valve lift position.

e. Duration of engine idling.

Under varying engine speed and load conditions the

control unit sends a signal to open the vacuum

modulator which allows a vacuum to be applied above

the EGR valve diaphragm, the vacuum supply being

taken from a 'T' connector in the brake servo hose.

This process is controlled by an engine speed/load

map stored in the EGR control unit memory.

Engine speed is measured by monitoring the

waveform present on one phase of the generator.

Throttle position is measured via a sensor mounted on

the fuel injection pump throttle lever. Closed loop

control is achieved by allowing the control unit to

continually monitor EGR valve lift via a position sensor

mounted on the valve; this valve lift is compared with

the actual valve lift required on the control unit map

and adjusted if necessary.

With coolant temperature between 20°C and 100°C;

the engine having just returned to idle, EGR will shut

off after 25-30 seconds idling.

Page 215 of 873

19FUEL SYSTEM

10

DESCRIPTION AND OPERATION Vehicle speed sensor

The vehicle speed sensor is located on the transfer

box behind the transmission brake. The unit has a

multirole as the vehicle electronic speedometer

sensor and as a sensor for 'surge damping', (a

function which smooths out engine response to sharp

accelerator movement and reduces vehicle 'bucking').

The sensor is an additional input for engine overheat

protection.

Brake and clutch switches

The brake and clutch switches are located on the

pedal box and serve as safety features to the system.

They return information to the ECM which limits

maximum fuel quantity under braking.

Throttle position sensor

The accelerator pedal is connected directly to a

sensor mounted in the pedal box. Driver demand is

relayed back to the ECM to increase or decrease

injected fuel quantity.

Incorporated in the sensor is a backup idle switch

which the system will default to in the event of sensor

failure.

Boost pressure sensor

The boost pressure sensor is mounted on the

bulkhead. It relays boost pressure information to the

ECM which compensates fuel quantity to reduce

smoke during acceleration.

Electro-pneumatic modulator

The electro-pneumatic modulator is located on the

inner wing just forward of the air cleaner. It regulates

vacuum signals from the source to the EGR valve.

The ECM controls the modulator to open the EGR

valve according to required airflow.Exhaust gas recirculation valve

The EGR valve is located on the engine exhaust

manifold and is controlled by vacuum from the

electro-pneumatic modulator.

Once open the EGR valve directs a quantity of

exhaust gas back into the inlet manifold to be burnt

inside the engine. This reduces NOx (Oxides of

nitrogen) emissions of the engine.

Temperature sensors

Water, Fuel and Air temperature sensors monitor

engine conditions and relay their information back to

the ECM which makes adjustments to injected fuel

quantity, injection timing, EGR and corrections to

measured boost pressure and airflow.

Page 229 of 873

19FUEL SYSTEM

12

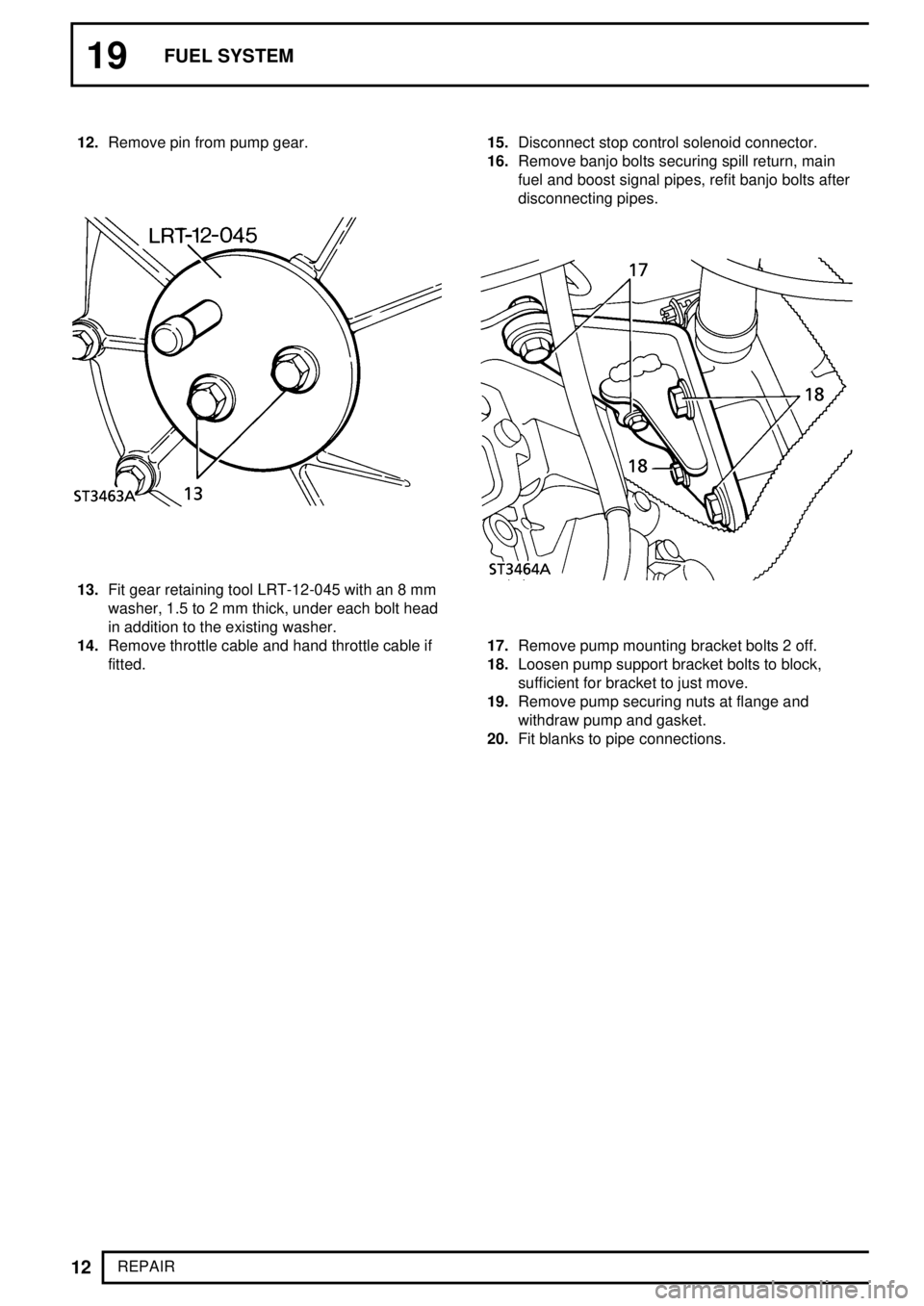

REPAIR 12.Remove pin from pump gear.

13.Fit gear retaining tool LRT-12-045 with an 8 mm

washer, 1.5 to 2 mm thick, under each bolt head

in addition to the existing washer.

14.Remove throttle cable and hand throttle cable if

fitted.15.Disconnect stop control solenoid connector.

16.Remove banjo bolts securing spill return, main

fuel and boost signal pipes, refit banjo bolts after

disconnecting pipes.

17.Remove pump mounting bracket bolts 2 off.

18.Loosen pump support bracket bolts to block,

sufficient for bracket to just move.

19.Remove pump securing nuts at flange and

withdraw pump and gasket.

20.Fit blanks to pipe connections.

Page 230 of 873

Tdi

13

REPAIR Refit

21.Remove blanks from pump.

22.Remove special tool pin from pump.

23.Clean mating faces of pump and front cover.

24.Fit pump to cover with a new gasket and secure

with nuts. Tighten to

25 Nm.

25.Attach pump to bracket and finger tighten nuts

and bolts

26.First tighten bolts securing bracket to block and

then bolts securing pump to bracket.

27.Connect spill return, main fuel pipes. Tighten to

25 Nm.

28.Connect boost signal pipe and secure with banjo

bolts. Tighten to

10 Nm.

29.Connect stop control solenoid lead.

30.Connect throttle cable and where applicable

hand throttle cable.

31.Remove special tool LRT-12-045.

32.Fit gear lock plate.

33.Fit pin from special tool LRT-12-045.

34.Secure gear with bolts.

35.Remove special tool pin.

36.Turn crankshaft two complete revolutions, check

timing pin from LRT-12-045 can be fully and

easily inserted into the pump. At the same time

check flywheel timing pin LST-12-044 can also

be inserted in the flywheel slot.

37.If, with the flywheel timing pin located, the timing

pin cannot be inserted cleanly into the injection

pump, carry out the following:

(a) Ensure flywheel timing pin is disengaged

from slot in flywheel.

(b) Turn the crankshaft the small amount

necessary to enable the timing pin to be

inserted into the pump.

(c) Loosen the three pump gear retaining

bolts.

(d) Turn the crankshaft to T.D.C..

(e) Check that the timing pin is an easy fit in

the pump and that the flywheel timing pin

locates.

(f) Tighten the pump gear retaining bolts to

the correct torque.

(g) Remove the timing pin from the pump and

the timing tool from the flywheel housing.

38.Using antisieze compound, fit the blanking plug

to flywheel housing. Tighten to

12 Nm.

39.Fit access plate with gasket to front cover plate.

Tighten to

25 Nm.

40.Refit injector pipes. Tighten to29 Nm.

Page 238 of 873

19FUEL SYSTEM

2

DESCRIPTION AND OPERATION Fuel pressure regulator

The fuel pressure regulator is mounted in the fuel rail

at the rear of the plenum chamber. The regulator is a

mechanical device controlled by plenum chamber

vacuum, it ensures that fuel rail pressure is

maintained at a constant pressure difference of 2.5

bar above that of the manifold.

When pressure exceeds the regulator setting excess

fuel is returned to the fuel tank.

Fuel pump

The electric fuel pump is located in the fuel tank, and

is a self priming 'wet' pump, the motor is immersed in

the fuel within the tank.

Air flow sensor

The hot-wire air flow sensor is mounted on a bracket

attached to the left hand valance, rigidly connected to

the air cleaner and by hose to the plenum chamber

inlet neck.

The air flow sensor consists of a cast alloy body

through which air flows. A proportion of this air flows

through a bypass in which two wire elements are

situated: one is a sensing wire and the other is a

compensating wire. Under the control of an electronic

module which is mounted on the air flow sensor body,

a small current is passed through the sensing wire to

produce a heating effect. The compensating wire is

also connected to the module but is not heated, but

reacts to the temperature of the air taken in, as engine

intake air passes over the wires a cooling effect takes

place.

The electronic module monitors the reaction of the

wires in proportion to the air stream and provides

output signals in proportion to the air mass flow rate

which are compatible with the requirements of the

ECM.Throttle position sensor

The throttle position sensor is mounted on the side of

the plenum chamber inlet neck and is directly coupled

to the throttle butterfly shaft.

The throttle position sensor is a resistive device

supplied with a voltage from the ECM. Movement of

the accelerator pedal causes the throttle valve to

open, thus rotating the wiper arm within the throttle

position sensor which in turn varies the resistance in

proportion to the valve position. The ECM lengthens

the injector open time when it detects a change in

output voltage (rising) from the throttle position

sensor.

In addition the ECM will weaken the mixture when it

detects the throttle position sensor output voltage is

decreasing under deceleration and will shorten the

length of time the injectors are open.

When the throttle is fully open, the ECM will detect the

corresponding throttle position sensor voltage and will

apply full load enrichment. This is a fixed percentage

and is independent of temperature. Full load

enrichment is also achieved by adjusting the length of

the injector open time.

When the throttle is closed, overrun fuel cut off or idle

speed control may be facilitated dependant on other

inputs to the ECM.

The throttle position sensor is 'self adaptive', which

means that adjustment is not possible. It also means

the throttle position sensor setting is not lost, for

example, when throttle stop wear occurs.

CAUTION: Do not attempt to adjust throttle

position sensor.

Page 272 of 873

SFI

1

DESCRIPTION AND OPERATION ENGINE MANAGEMENT SYSTEM

Description

The engine management system (EMS) maintains

optimum engine performance over the entire

operating range. The correct amount of fuel is

metered into each cylinder inlet tract and the ignition

timing is adjusted at each spark plug.

The system is controlled by the ENGINE CONTROL

MODULE (ECM) which receives data from sensors

located on and around the engine. From this

information it provides the correct fuel requirements

and ignition timing at all engine loads and speeds.

The fuel injection system uses a hot wire Mass Air

Flow Sensor to calculate the amount of air flowing into

the engine.

The ignition system does not use a distributor. It is a

direct ignition system (DIS), using four double ended

coils. The circuit to each coil is completed by

switching inside the ECM.

The on board diagnostic system detects any faults

which may occur within the EMS. Fault diagnosis

includes failure of all EMS sensors and actuators,

emissions related items, fuel supply and exhaust

systems.

The system incorporates certain default strategies to

enable the vehicle to be driven in case of sensor

failure. This may mean that a fault is not detected by

the driver. The fault is indicated by illumination of the

malfunction indicator light (MIL) on North American

specification vehicles.

A further feature of the system is 'robust

immobilisation'.Crankshaft position sensor (CKP Sensor)

The crankshaft position sensor is the most important

sensor on the engine. It is located in the left hand side

of the flywheel housing and uses a different thickness

of spacer for manual and automatic gearboxes. The

signal it produces informs the ECM:

- the engine is turning

- how fast the engine is turning

- which stage the engine is at in the cycle.

As there is no default strategy, failure of the

crankshaft sensor will result in the engine failing to

start. The fault is indicated by illumination of the

malfunction indicator light (MIL) on North American

specification vehicles.

Camshaft position sensor (CMP Sensor)

The camshaft position sensor is located in the engine

front cover. It produces one pulse every two

revolutions. The signal is used in two areas, injector

timing corrections for fully sequential fuelling and

active knock control.

If the camshaft sensor fails, default operation is to

continue normal ignition timing. The fuel injectors will

be actuated sequentially, timing the injection with

respect to top dead centre. Injection will either be

correct or one revolution out of synchronisation. The

fault is not easily detected by the driver. The fault is

indicated by illumination of the malfunction indicator

light (MIL) on North American specification vehicles.

Mass air flow sensor (MAF Sensor)

The 'hot wire' type mass air flow sensor is mounted

rigidly to the air filter and connected by flexible hose to

the plenum chamber inlet. The sensing element of the

MAF Sensor is a hot wire anenometer consisting of

two wires, a sensing wire which is heated and a

compensating wire which is not heated. Air flows

across the wires cooling the heated one, changing its

resistance. The ECM measures this change in

resistance and calculates the amount of air flowing

into the engine.

As there is no default strategy, failure will result in the

engine starting, and dying when it reaches 550

rev/min, when the ECM detects no MAF Sensor

signal. The fault is indicated by illumination of the

malfunction indicator light (MIL) on North American

specification vehicles.

Page 314 of 873

19FUEL SYSTEM

2

DESCRIPTION AND OPERATION Basic ignition timing

MEMS provides the optimum ignition timing for the

relevant engine speed and load. The speed and

position of the engine is detected by the crankshaft

sensor which is bolted to, and projects through the

engine adapter plate.

The sensor incorporates an armature which runs

adjacent to a reluctor insert in the flywheel, the insert

consisting of 34 poles spaced at 10°intervals, with

two missing poles 180°apart to identify the T.D.C.

positions.

The sensor 'reads' these poles to provide a constant

up-date of engine speed and crankshaft position to

the ECM

The load signal is provided by the manifold absolute

pressure sensor mounted inside the ECM casing

which detects manifold pressure via a hose connected

to the manifold chamber. The sensor converts

pressure variations into graduated electrical signals

which can be read by the ECMIgnition timing compensation

Coolant temperature sensor

When the ECM receives a low engine temperature

signal from the coolant sensor, it provides optimum

driveability and emissions by advancing or retarding

the ignition timing.

Knock sensor

The knock sensor is a capacitive device mounted in

the cylinder block between nos. 2 and 3 cylinders

below the inlet manifold. The sensor monitors noise

and vibration in the engine and passes this

information to the ECM which is able to identify the

characteristics of the knocking and make the

necessary corrections to the ignition timing of

individual cylinders.

Idle speed control

When the throttle pedal is released and the engine is

at idle, the ECM uses the fast response of ignition

timing to assist idle speed control.

When loads are placed on, or removed from the

engine the ECM senses the change in engine speed

and in conjuction with the opening of the throttle disc

by the stepper motor, advances or retards the ignition

timing to maintain the specified idle speed. When load

is removed from the engine and the stepper motor

returns to it's original position, the ignition timing

returns to the idle setting.

NOTE: Due to the sensitivity of this system

the ignition timing will be constantly

changing at idle speed.

Page 316 of 873

19FUEL SYSTEM

4

DESCRIPTION AND OPERATION

Injectors

The four fuel injectors are fitted between the

pressurised fuel rail and inlet manifold. Each injector

comprises of a solenoid operated needle valve and a

specially designed nozzle to ensure good fuel

atomisation.

Engine coolant temperature sensor

The coolant temperature sensor is mounted in the

thermostat housing and is immersed in the engine

coolant. The sensor is a resistive device in which the

resistance varies with temperature

Throttle housing

The throttle housing is attached to the inlet manifold

via a rubber sandwich plate and incorporates a throttle

disc which is connected to the throttle pedal via the

throttle lever and a cable.

There are two breather pipes; one either side of the

throttle disc. When the engine is running with the

throttle disc open, both pipes are subject to manifold

depression and draw crankcase fumes into the

manifold. When the throttle disc is closed, only the

pipe on the inlet manifold side of the disc is subject to

manifold depression. This pipe incorporates a

restrictor to prevent engine oil being drawn into the

engine by the substantially greater manifold

depression.

Also incorporated in the throttle housing are the

throttle potentiometer and stepper motor.

Throttle potentiometer

The throttle potentiometer is mounted in front of the

throttle housing and is directly coupled to the throttle

disc shaft.

Three wires connect the throttle potentiometer to the

ECM; a 5 volt supply to the potentiometer, an earth

return to the ECM and an output voltage to the ECM

which indicates the rate of throttle disc movement.

Stepper motor

The stepper motor is contained within the throttle

housing and operates a cam and push rod via a

reduction gear. The push rod is in direct contact with

the throttle lever and moves the throttle disc to control

idle and fast idle speed. The stepper motor maximum

movement is 3.75 revolutions accomplished in steps

of 7.5°. The reduction gear converts this into 180°of

cam movement.

The throttle lever has a throttle position setting screw

which rests on the stepper motor operating pin when

the throttle pedal is released and is used to set the

relationship between engine speed and stepper motor

position.

In the side of the throttle housing is a throttle air

bypass bleed screw to provide easier and more

sensitive setting of the stepper motor position at idle.

The stepper motor position is checked using Testbook

and should be within the range of 20 to 40 steps when

the engine is run in. If it is identified as being outside

this range it can be adjusted to within range by turning

the throttle air bypass bleed screw. It is important to

follow Testbook setting procedure when adjusting this

screw to prevent mismatching of throttle body

settings. This ensures that the stepper motor is at the

optimum position within its range for providing further

movement to compensate for changes in engine load

or temperature in accordance with signals from the

ECM

NOTE: The stepper motor and throttle

position setting screws must only be

adjusted when Testbook identifies the

requirement.

Page 317 of 873

Mpi

5

DESCRIPTION AND OPERATION

Fuel pump

The electric fuel pump, located inside the fuel tank, is

a self-priming centrifugal 'wet' pump, the motor and

pump are filled with fuel.

The fuel pump supplies more fuel than the maximum

load requirement for the engine, so that pressure in

the fuel system can be maintained under all

conditions.

Fuel pressure regulator

The pressure regulator is a mechanical device

controlled by manifold depression and is mounted in

the fuel rail. The regulator ensures that fuel rail

pressure is maintained at a constant pressure

difference to that in the inlet manifold, as manifold

depression increases the regulated fuel pressure is

reduced in direct proportion.

When pressure exceeds the regulator setting excess

fuel is spill returned to the fuel tank swirl pot which

contains the fuel pick-up strainer.

Relay module

The relay module contains the main relay, fuel pump

relay, starter relay and oxygen sensor relay and is

mounted on the ECM mounting bracket.

The main relay is energised when the ignition is

switched on and supplies current to the ECM

The fuel pump relay is energised by the ECM for a

short period when the ignition is switched on, during

cranking and while the engine is running.

The starter relay is energised by the cranking signal

from the ignition switch.

This oxygen sensor relay is energised when the

ignition is switched on and supplies current to the

ECM

Intake air temperature sensor

The intake air temperature sensor is fitted in the side

of the inlet manifold and sends the ECM a signal

relating to air temperature. The ECM uses this signal

in its calculations on air flow.

Inertia switch

The fuel pump circuit incorporates an inertia switch

which in the event of sudden deceleration isolates the

power supply to the fuel pump. The inertia switch is

situated in the engine compartment on the bulkhead

and can, if tripped, be reset by depressing the central

plunger.

WARNING: Check the integrity of the fuel

system before the inertia switch is reset.

Diagnostic connector

A diagnostic connector is provided to enable

diagnosis to be carried out without disturbing the

system electrical connections and to allow the ECM's

ability to store certain faults to be utilised.

Oxygen sensor - Closed-loop emission control

The MEMS Mpi system operates a closed loop

emission system to ensure the most efficient level of

exhaust gas conversion.

An oxygen sensor fitted in the exhaust manifold

monitors the exhaust gases. It then supplies a small

voltage proportional to exhaust oxygen content to the

ECM As the air/fuel mixture weakens, the exhaust

oxygen content increases and so the voltage to the

ECM decreases. If the mixture becomes richer so the

oxygen content decreases and the voltage increases.

The ECM uses this signal voltage to determine the

air/fuel mixture being delivered to the engine, and

adjusts the injector duration to maintain the ratio

necessary for efficient gas conversion by the catalyst.

The oxygen sensor has an integral heating element to

ensure an efficient operating temperature is quickly

reached from cold. The electrical supply for the heater

element is controlled by the oxygen sensor relay.

Fuel temperature sensor

The fuel temperature sensor is inserted in the fuel rail

and measures fuel and fuel rail temperatures. During

engine cranking at high temperatures, the ECM

increases fuel supply, and opens the throttle disc via

the stepper motor to aid hot starting.