warning LAND ROVER DISCOVERY 1999 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 925 of 1529

RESTRAINT SYSTEMS

75-22 REPAIRS

Airbag module - drivers

$% 76.74.01

WARNING: It is imperative that before any work

is undertaken on the SRS system the appropriate

information is read thoroughly.

WARNING: Always disconnect both battery leads

before beginning work on the SRS system.

Disconnect the negative battery lead first. Never

reverse connect the battery.

Remove

1.Remove the key from the starter switch.

Disconnect both battery leads, negative lead

first. Wait ten minutes before starting work.

2.Remove 2 Torx bolts securing air bag module

to steering wheel.

3.Release air bag module from steering wheel.

CAUTION: Do not allow the air bag module

to hang by the air bag harness.

4.Disconnect multiplug from air bag module. 5.Remove air bag module.

WARNING: Store the airbag module with the

deployment side uppermost. If it is stored

deployment side down, accidental

deployment will propel the airbag module

with enough force to cause serious injury.

WARNING: Store the airbag module or seat

belt pre-tensioner in a designated storage

area. If there is no designated storage area

available, store in the locked luggage

compartment/loadspace of the vehicle and

inform the workshop supervisor.

Refit

NOTE: If the airbag module is to be replaced,

the bar code of the new module must be

recorded.

1.Position air bag module and connect multiplug.

2.Fit air bag module to steering wheel and tighten

Torx bolts to 9 Nm (7 lbf.ft).

3.Connect battery leads, earth lead last.

Page 926 of 1529

RESTRAINT SYSTEMS

REPAIRS 75-23

Airbag module - passenger

$% 76.74.02

WARNING: It is imperative that before any work

is undertaken on the SRS system the appropriate

information is read thoroughly.

WARNING: Always disconnect both battery leads

before beginning work on the SRS system.

Disconnect the negative battery lead first. Never

reverse connect the battery.

Remove

1.Remove the key from the starter switch.

Disconnect both battery leads, negative lead

first. Wait ten minutes before starting work.

2.Release guides supporting glove box.

3.Lower glove box to gain access to air bag

module.4.Disconnect multiplug from air bag module.

5.Remove 4 Torx bolts securing air bag module

to fascia.

6.Remove air bag module from fascia panel.

WARNING: Store the air bag module with

the deployment side uppermost. If it is

stored deployment side down, accidental

deployment will propel the air bag module

with enough force to cause serious injury.

WARNING: Store the air bag module or seat

belt pre-tensioner in a designated storage

area. If there is no designated storage area

available, store in the luggage compartment

of the vehicle and inform the workshop

supervisor.

Refit

NOTE: If the air bag module is to be replaced,

the bar code of the new module must be

recorded.

1.Fit air bag module to fascia and tighten Torx

bolts to 8 Nm (6 lbf.ft).

2.Connect multiplug to air bag module.

3.Position glove box and engage supporting

guides. Close glove box.

4.Connect battery leads, earth lead last.

Page 927 of 1529

RESTRAINT SYSTEMS

75-24 REPAIRS

DCU

$% 76.74.06

WARNING: It is imperative that before any work

is undertaken on the SRS system the appropriate

information is read thoroughly.

WARNING: Always disconnect both battery leads

before beginning work on the SRS system.

Disconnect the negative battery lead first. Never

reverse connect the battery.

Remove

1.Remove the key from the starter switch.

Disconnect both battery leads, negative lead

first. Wait ten minutes before starting work.

2.Remove centre console.

lOn manual gearbox models:

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - centre - manual

models.

lOn automatic gearbox models:

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - centre - automatic

models.

3.Disconnect multiplug from DCU.

4.Remove 3 Torx bolts securing DCU to body and

remove DCU.

CAUTION: The SRS diagnostic control unit

is a non-serviceable component and no

attempt should be made to repair or modify

the unit.Refit

CAUTION: The SRS diagnostic control unit

is a shock sensitive device and must be

handled with extreme care.

1.Position DCU to body and connect multiplug.

2.Fit and tighten DCU Torx bolts to 10 Nm (7

lbf.ft).

3.Fit centre console.

lOn manual gearbox models:

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - centre - manual

models.

lOn automatic gearbox models:

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - centre - automatic

models.

4.Connect battery leads, earth lead last.

Page 928 of 1529

RESTRAINT SYSTEMS

REPAIRS 75-25

Air bag - steering wheel - deployment -

off vehicle

$% 76.74.16

These guidelines are written to aid authorised

personnel to carry out the safe disposal of air bag

modules when removed from the vehicle.

Deploy

It is imperative that before any work is

undertaken on the SRS system, the

appropriate information is read thoroughly.

1.Check condition of deployment tool LRT-86-

003 and associated fly leads.

2.Position LRT-86-007/02 in vice, ensuring that

vice jaws grip tool above the bottom flange to

prevent possibility of tool being forced upwards

during detonation. Tighten vice.

3.Fit and secure 2 off LRT-86-007/05 to LRT-86-

007/02.4.Fit and secure air bag to LRT-86-007/05.

5.Connect deployment tool fly lead LRT-86-003/

08 to air bag.

6.Connect deployment tool LRT-86-003 to

deployment tool fly lead LRT-86-003/08.

7.Connect deployment tool LRT-86-003 to

battery.

WARNING: Ensure all personnel are at least

15 metres (50 feet) away from the air bag

module.

8.Press deployment tool operating button to

deploy air bag module.

9.Disconnect deployment tool from battery.

WARNING: During deployment parts of the

air bag module become hot enough to burn

you. Wait 30 minutes after deployment

before touching the air bag module.

10.Disconnect deployment tool fly lead from air

bag.

11.Remove air bag module from holding tools and

place in a sealed bag, ready for disposal.

NOTE: Do not transport deployed SRS

components in the vehicle passenger

compartment.

12.Wipe down holding tools with a damp cloth and

remove from vice.

13.Transport deployed air bag module to

designated area for incineration.

14. Do not re-use or salvage any parts of the

SRS system.

Page 930 of 1529

RESTRAINT SYSTEMS

REPAIRS 75-27

6.Connect deployment tool fly lead LRT-86-003/

04 to air bag.

7.Connect deployment tool LRT-86-003 to

deployment tool fly lead LRT-86-003/04.

8.Connect deployment tool LRT-86-003 to

battery.

WARNING: Ensure all personnel are at least

15 metres (50 feet) away from the air bag

module.

9.Press deployment tool operating button to

deploy air bag module.

10.Disconnect deployment tool from battery.

WARNING: During deployment parts of the

air bag module become hot enough to burn

you. Wait 30 minutes after deployment

before touching the air bag module.

11.Disconnect deployment tool fly lead from air

bag.

12. Do not re-use or salvage any parts of the

SRS system.

NOTE: Do not transport deployed SRS

components in the vehicle passenger

compartment.

Air bag - fascia - passenger - deployment

- off vehicle

$% 76.74.18

These guidelines are written to aid authorised

personnel to carry out the safe disposal of air bag

modules when removed from the vehicle.

Deploy

It is imperative that before any work is

undertaken on the SRS system, the

appropriate information is read thoroughly.

1.Check condition of deployment tool LRT-86-

003 and associated fly leads.

2.Position LRT-86-007/03 in vice, ensuring that

vice jaws grip tool above the bottom flange to

prevent possibility of tool being forced upwards

during detonation. Tighten vice.

3.Fit and secure 2 off LRT-86-007/04 to LRT-86-

007/03.

Page 931 of 1529

RESTRAINT SYSTEMS

75-28 REPAIRS

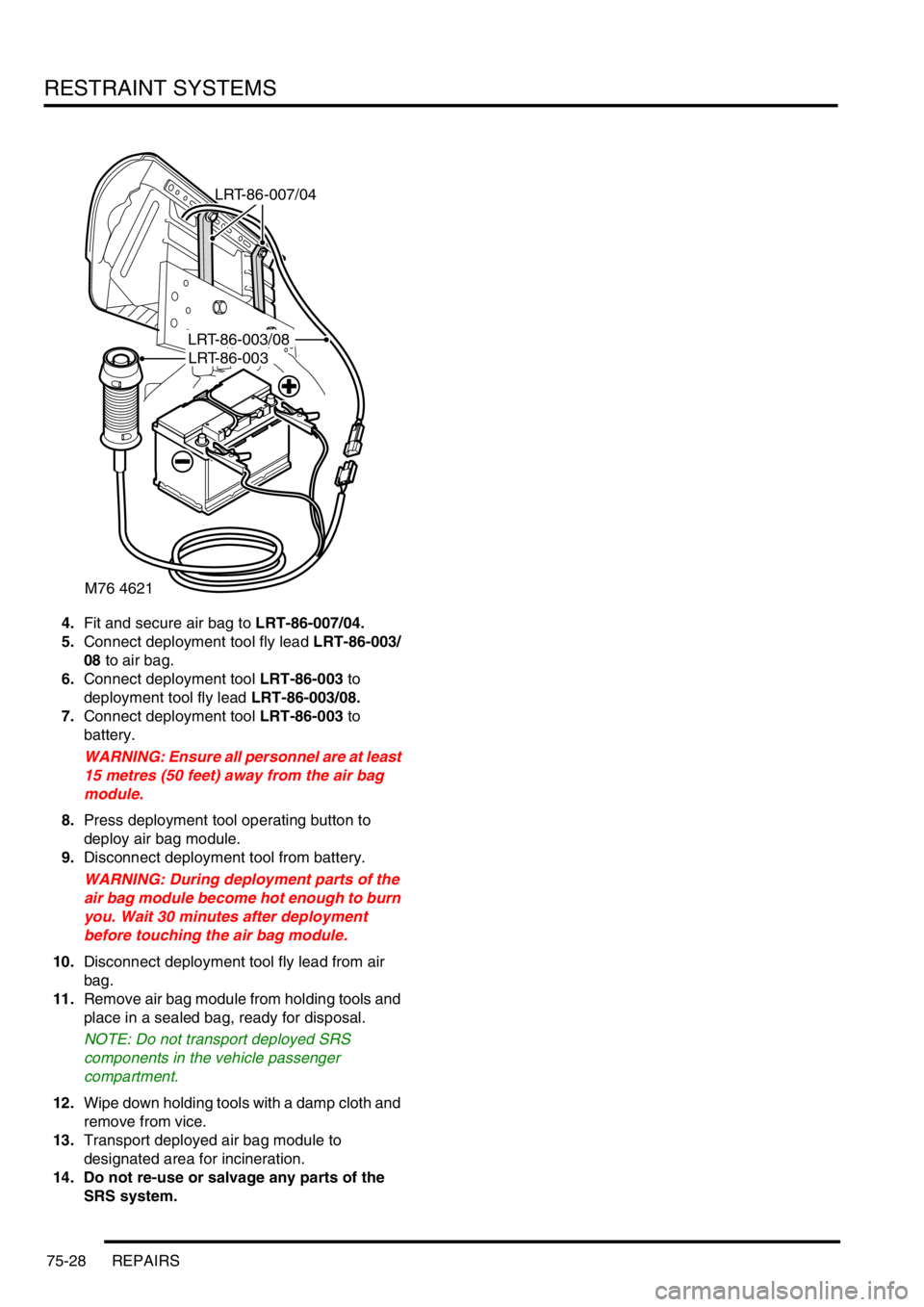

4.Fit and secure air bag to LRT-86-007/04.

5.Connect deployment tool fly lead LRT-86-003/

08 to air bag.

6.Connect deployment tool LRT-86-003 to

deployment tool fly lead LRT-86-003/08.

7.Connect deployment tool LRT-86-003 to

battery.

WARNING: Ensure all personnel are at least

15 metres (50 feet) away from the air bag

module.

8.Press deployment tool operating button to

deploy air bag module.

9.Disconnect deployment tool from battery.

WARNING: During deployment parts of the

air bag module become hot enough to burn

you. Wait 30 minutes after deployment

before touching the air bag module.

10.Disconnect deployment tool fly lead from air

bag.

11.Remove air bag module from holding tools and

place in a sealed bag, ready for disposal.

NOTE: Do not transport deployed SRS

components in the vehicle passenger

compartment.

12.Wipe down holding tools with a damp cloth and

remove from vice.

13.Transport deployed air bag module to

designated area for incineration.

14. Do not re-use or salvage any parts of the

SRS system.

M76 4621

LRT-86-007/04

LRT-86-003/08

LRT-86-003

Page 932 of 1529

RESTRAINT SYSTEMS

REPAIRS 75-29

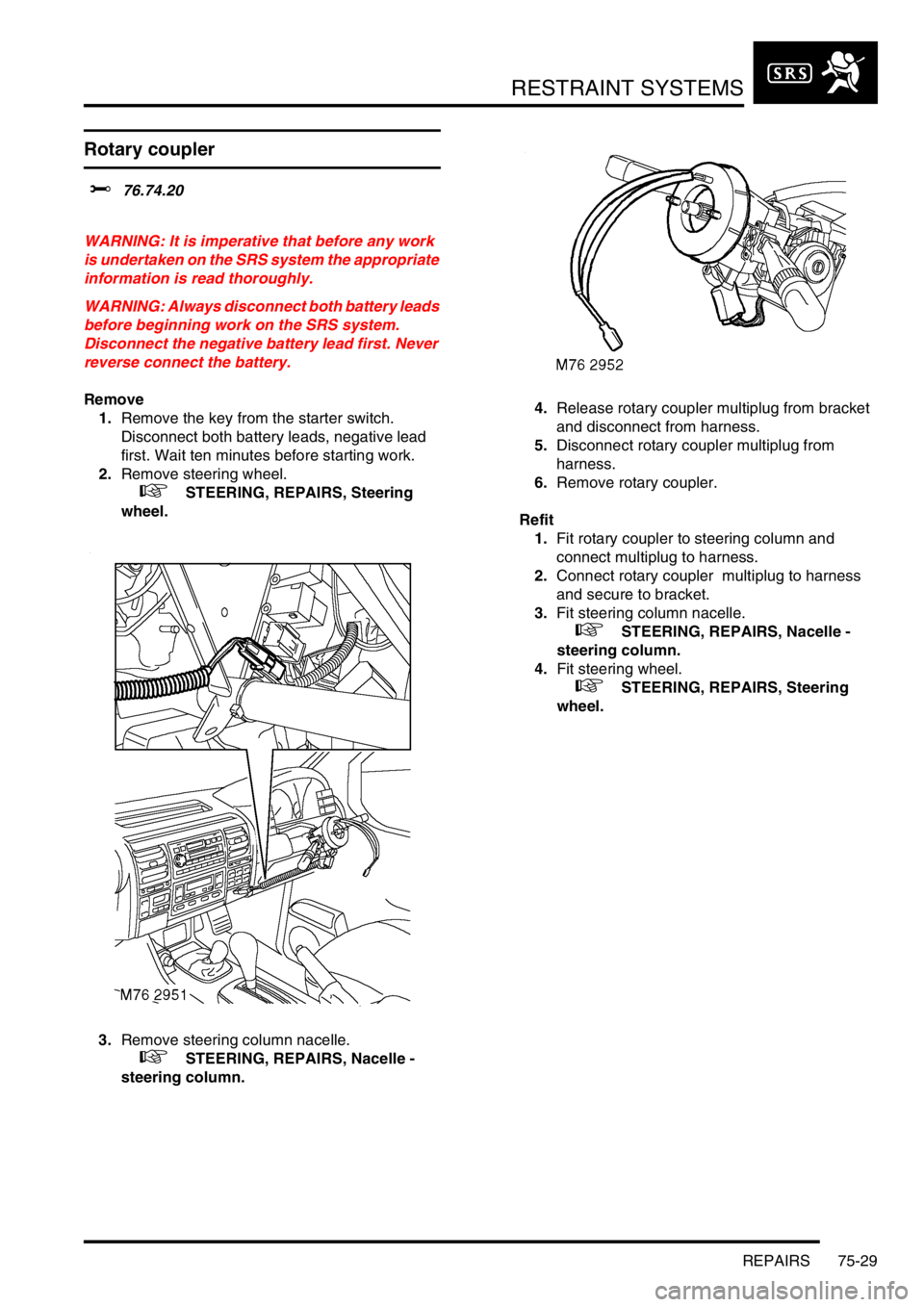

Rotary coupler

$% 76.74.20

WARNING: It is imperative that before any work

is undertaken on the SRS system the appropriate

information is read thoroughly.

WARNING: Always disconnect both battery leads

before beginning work on the SRS system.

Disconnect the negative battery lead first. Never

reverse connect the battery.

Remove

1.Remove the key from the starter switch.

Disconnect both battery leads, negative lead

first. Wait ten minutes before starting work.

2.Remove steering wheel.

+ STEERING, REPAIRS, Steering

wheel.

3.Remove steering column nacelle.

+ STEERING, REPAIRS, Nacelle -

steering column.4.Release rotary coupler multiplug from bracket

and disconnect from harness.

5.Disconnect rotary coupler multiplug from

harness.

6.Remove rotary coupler.

Refit

1.Fit rotary coupler to steering column and

connect multiplug to harness.

2.Connect rotary coupler multiplug to harness

and secure to bracket.

3.Fit steering column nacelle.

+ STEERING, REPAIRS, Nacelle -

steering column.

4.Fit steering wheel.

+ STEERING, REPAIRS, Steering

wheel.

Page 954 of 1529

EXTERIOR FITTINGS

REPAIRS 76-2-7

Panel - underbelly

$% 76.10.50

Remove

1.Raise front of vehicle, support underbody and

lower front axle

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove nut securing drag link to drop arm.

3.Using tool LRT-57-036 break taper joint and

release drag link from drop arm.

4.Remove nut and bolt securing steering damper

to chassis and remove damper.

5.Remove 7 screws securing underbelly panel.

6.Remove underbelly panel.

7.Remove 7 studs securing sound deadening to

underbelly panel.

8.Remove sound deadening.

Refit

1.Position sound deadening to underbelly panel

and secure with studs.

2.Fit underbelly panel and secure with screws.

3.Position steering damper, fit nut and bolt and

tighten to 125 Nm (92 lbf.ft)

4.Fit drag link to drop arm and tighten nut to 80

Nm (59 lbf.ft).

5.Lower front of vehicle.

Mirror - exterior - electric

$% 76.10.57

Remove

1.Release cheater panel from front door.

2.Remove anti-rattle foam pad from front door.

3.Release mirror multiplug from mounting plate.

4.Disconnect multiplug from mirror.

5.Remove 3 bolts securing mirror to door.

6.Remove mirror and collect mounting plate.

Refit

1.Fit mirror and mounting plate to door.

2.Fit bolts securing mirror to door and tighten to

4 Nm (3 lbf.ft).

3.Connect multiplug to mirror.

4.Secure multiplug to mounting plate.

5.Fit anti-rattle foam pad to front door.

6.Secure cheater panel to front door.

Page 991 of 1529

SCREENS

76-4-2 REPAIRS

Windscreen

$% 76.81.01

Introduction

The following equipment is required:

lCutting wire and handles.

lKent cutting knife.

lGlazing knife.

lWindscreen repair kit.

lSealant applicator gun.

lSuction cups.

lA felt covered table or stand to support glass.

WARNING: Wear protective gloves when

handling glass, solvents and primers.

WARNING: Wear suitable eye protection when

removing and refitting glass.

WARNING: If glass has splintered, protect eyes

and operate demister blower to remove glass

from heater ducts. Use a vacuum cleaner to

remove glass from fascia, carpet and seats.Remove

1.Remove air intake plenum.

+ HEATING AND VENTILATION,

REPAIRS, Plenum Air Intake.

2.If fitted, disconnect screen heater multiplugs.

3.Remove top corner trim finishers from body.

4.Remove windscreen top finisher and discard.

5.Release interior mirror from slug and tie aside.

6.Fit protection to exterior body work adjacent to

screen.

7.Cover body panels adjacent to glass.

8.Cover heater ducts with masking tape.

9.Cover interior of vehicle with protective sheet.

Page 993 of 1529

SCREENS

76-4-4 REPAIRS

15.Apply a continuous bead of sealant to sealant

face on screen as shown.

16.With assistance, lift screen into place and align

to screen supports and tape. Ensure top

finisher is located into correct position. Lightly

press glass to fully seat sealer.

CAUTION: Do not apply heavy pressure to

the sides of the windscreen. Lightly press

windscreen from centre outwards until

edges are to required gap. Pushing sides

into position can bend windscreen and lead

to cracking in service.

17.Remove protective covers and tape.

18.Test sealer for leaks, apply additional sealer if

necessary. If water is used, allow sealer to dry

before testing. Spray water around glass and

check for leaks. Mark any area that leaks. Dry

glass and sealer then apply additional sealer.

19.Fit interior mirror to slug.

20.If applicable, connect screen heater multiplugs.

21.Fit air intake plenum.

+ HEATING AND VENTILATION,

REPAIRS, Plenum Air Intake.

CAUTION: A curing time of 6 hours is

desirable. During this time leave a window

open to ventilate the vehicle interior. If the

vehicle must be used before the curing time

has elapsed, do not drive at speed or slam

the doors with the windows closed.

CAUTION: Vehicles fitted with a passenger

airbag should not be driven for 24 hours.

Glass - body side - rear

$% 76.81.18

Introduction

The following equipment is required:

lCutting wire and handles.

lKent cutting knife.

lGlazing knife.

lWindscreen repair kit.

lSealant applicator gun.

lSuction cups.

lA felt covered table or stand to support glass.

WARNING: Wear protective gloves when

handling glass, solvents and primers.

WARNING: Wear suitable eye protection when

removing and refitting glass.

Remove

1.If fitted, disconnect coaxial cable from terminal

on glass.

2.Fit protection to exterior body work adjacent to

glass.

3.Cover body panels adjacent to glass.

4.Fit protection to internal trim adjacent to glass.

5.Cover interior of vehicle with protective sheet.