power steering fluid LAND ROVER DISCOVERY 1999 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 715 of 1529

STEERING

57-22 ADJUSTMENTS

38.Fit new seal, connect PAS cooler pipe and

tighten union nut to 24 Nm (18 lbf ft).

39. LHD only: Fit turbocharger intercooler feed

pipe and vacuum connection. Fit new seal to air

cleaner. Connect air intake hose and secure

clips. Connect multiplug to MAF sensor.

40.Clean chassis and surrounding area.

41.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

42.Remove adaptor and hose set from tool LRT-

57-041.

43.Check PAS fluid level.

44.Connect battery earth lead.

Power steering pressure check - V8 LHD

models

$% 57.90.10.01

Check

1.Disconnect battery earth lead.

2.Syphon PAS fluid from reservoir.

3.Raise front of vehicle and support on stands.

4.Turn steering on LH lock.

5.Remove 3 screws securing LH splash shield

and remove shield.

6.Release clip securing PAS pipes.

7.Position absorbent cloth to catch spillage.

8.Position container to collect PAS fluid spillage.

Page 717 of 1529

STEERING

57-24 ADJUSTMENTS

33.On completion stop engine, disconnect battery

earth lead and syphon fluid from PAS reservoir.

34.Remove test equipment from LRT-57-002.

35.Clean PAS pump and pipe union.

36.Fit new 'O' ring to high pressure pipe, align to

PAS pump and tighten union to 25 Nm (18

lbf.ft).

37.Secure PAS pipes in clip.

38.Using new 'O' ring fit intake hose to air cleaner

and secure clips.

39.Remove PAS reservoir filler cap, fill to level

indicator and refit cap.

40.Connect battery earth lead.

41.Start engine and allow air to bleed from PAS

system, by turning steering from lock to lock.

42.Visually check PAS system for leaks.

43.Clean chassis member.

44.Check power steering fluid, if aerated, wait until

fluid is free from bubbles then top-up reservoir

to 'UPPER' level mark.

45.Lower vehicle.

46.Dismantle test equipment.

Power steering pressure check - V8 RHD

models

$% 57.90.10.01

Check

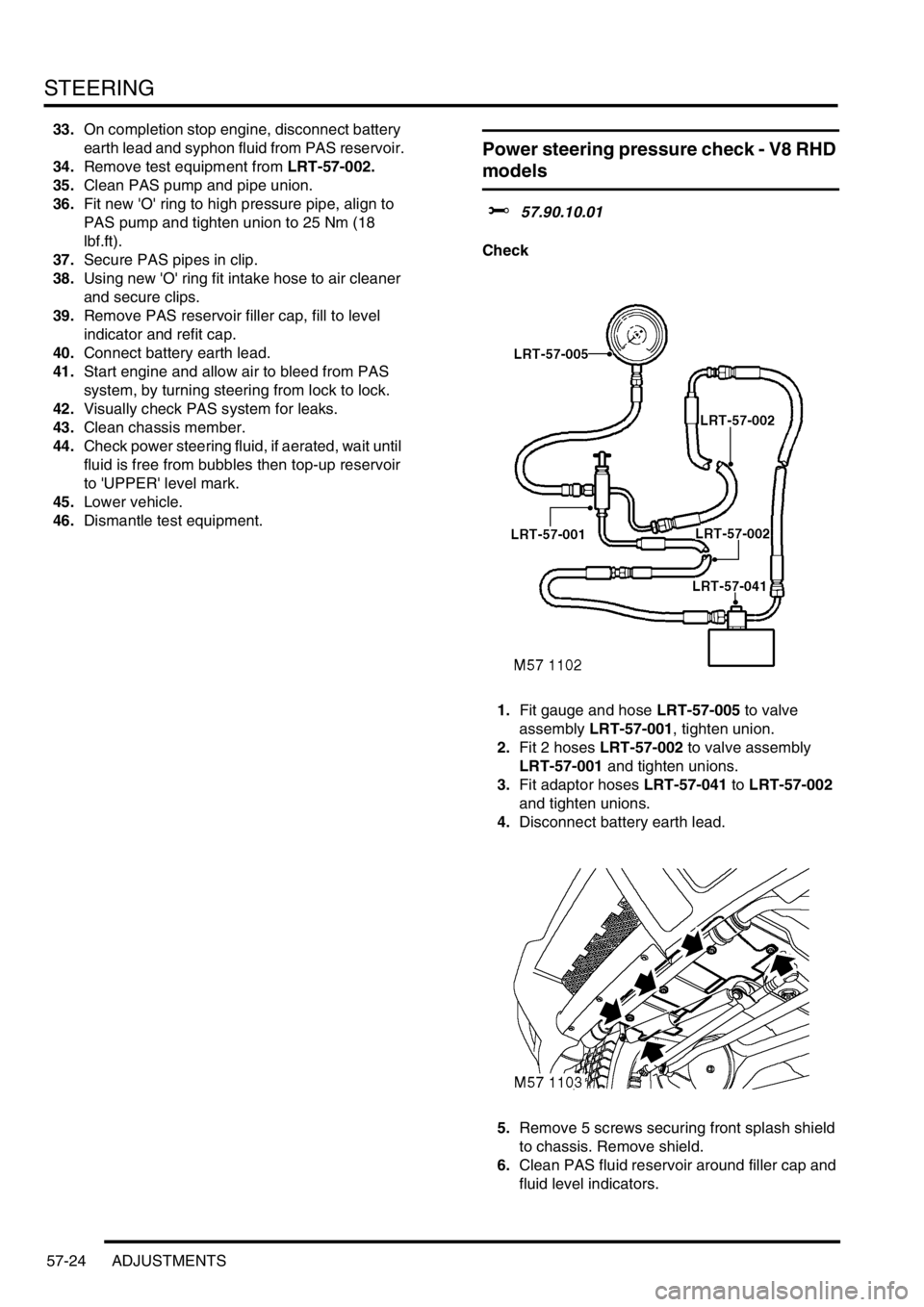

1.Fit gauge and hose LRT-57-005 to valve

assembly LRT-57-001, tighten union.

2.Fit 2 hoses LRT-57-002 to valve assembly

LRT-57-001 and tighten unions.

3.Fit adaptor hoses LRT-57-041 to LRT-57-002

and tighten unions.

4.Disconnect battery earth lead.

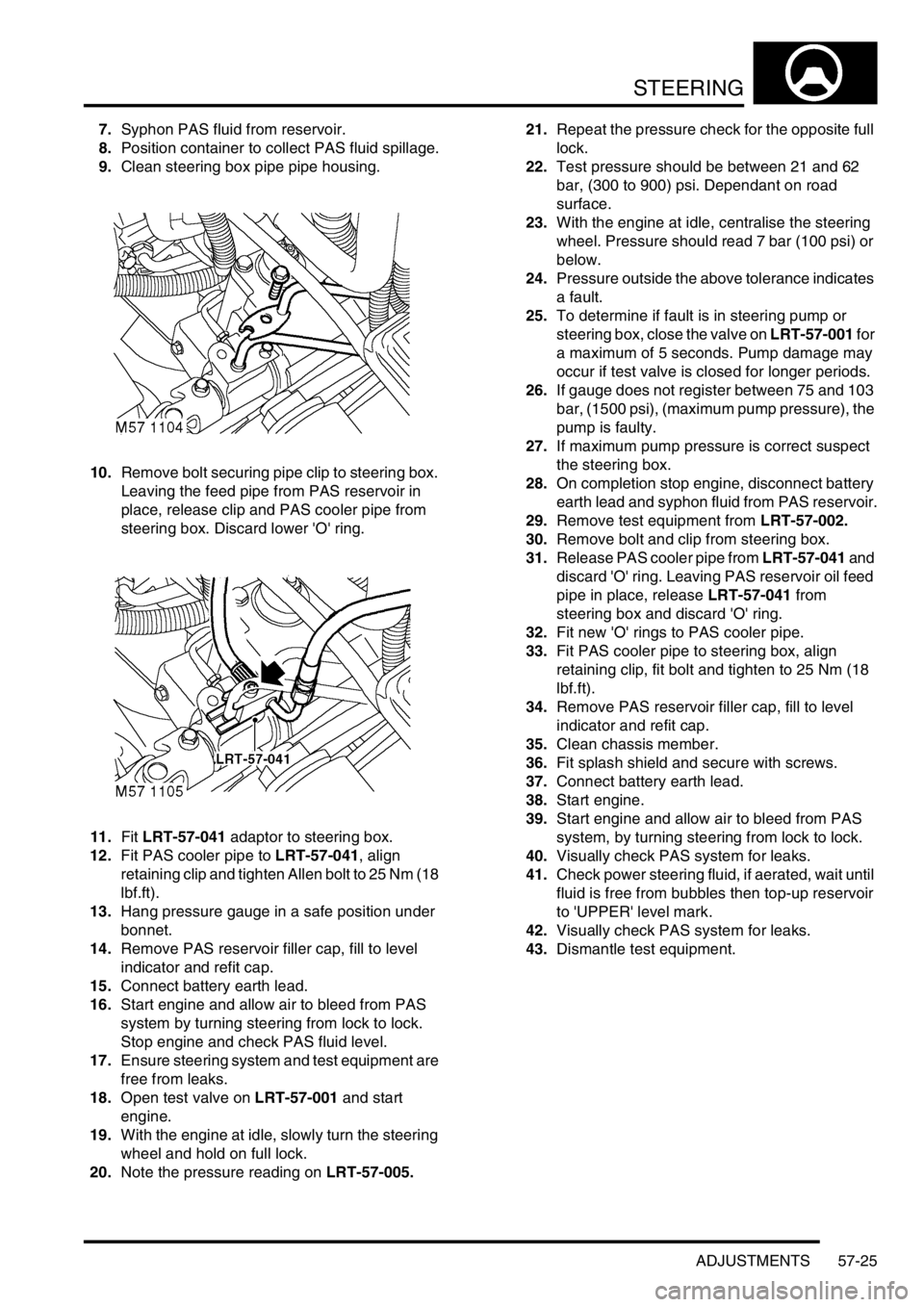

5.Remove 5 screws securing front splash shield

to chassis. Remove shield.

6.Clean PAS fluid reservoir around filler cap and

fluid level indicators.

Page 718 of 1529

STEERING

ADJUSTMENTS 57-25

7.Syphon PAS fluid from reservoir.

8.Position container to collect PAS fluid spillage.

9.Clean steering box pipe pipe housing.

10.Remove bolt securing pipe clip to steering box.

Leaving the feed pipe from PAS reservoir in

place, release clip and PAS cooler pipe from

steering box. Discard lower 'O' ring.

11.Fit LRT-57-041 adaptor to steering box.

12.Fit PAS cooler pipe to LRT-57-041, align

retaining clip and tighten Allen bolt to 25 Nm (18

lbf.ft).

13.Hang pressure gauge in a safe position under

bonnet.

14.Remove PAS reservoir filler cap, fill to level

indicator and refit cap.

15.Connect battery earth lead.

16.Start engine and allow air to bleed from PAS

system by turning steering from lock to lock.

Stop engine and check PAS fluid level.

17.Ensure steering system and test equipment are

free from leaks.

18.Open test valve on LRT-57-001 and start

engine.

19.With the engine at idle, slowly turn the steering

wheel and hold on full lock.

20.Note the pressure reading on LRT-57-005.21.Repeat the pressure check for the opposite full

lock.

22.Test pressure should be between 21 and 62

bar, (300 to 900) psi. Dependant on road

surface.

23.With the engine at idle, centralise the steering

wheel. Pressure should read 7 bar (100 psi) or

below.

24.Pressure outside the above tolerance indicates

a fault.

25.To determine if fault is in steering pump or

steering box, close the valve on LRT-57-001 for

a maximum of 5 seconds. Pump damage may

occur if test valve is closed for longer periods.

26.If gauge does not register between 75 and 103

bar, (1500 psi), (maximum pump pressure), the

pump is faulty.

27.If maximum pump pressure is correct suspect

the steering box.

28.On completion stop engine, disconnect battery

earth lead and syphon fluid from PAS reservoir.

29.Remove test equipment from LRT-57-002.

30.Remove bolt and clip from steering box.

31.Release PAS cooler pipe from LRT-57-041 and

discard 'O' ring. Leaving PAS reservoir oil feed

pipe in place, release LRT-57-041 from

steering box and discard 'O' ring.

32.Fit new 'O' rings to PAS cooler pipe.

33.Fit PAS cooler pipe to steering box, align

retaining clip, fit bolt and tighten to 25 Nm (18

lbf.ft).

34.Remove PAS reservoir filler cap, fill to level

indicator and refit cap.

35.Clean chassis member.

36.Fit splash shield and secure with screws.

37.Connect battery earth lead.

38.Start engine.

39.Start engine and allow air to bleed from PAS

system, by turning steering from lock to lock.

40.Visually check PAS system for leaks.

41.Check power steering fluid, if aerated, wait until

fluid is free from bubbles then top-up reservoir

to 'UPPER' level mark.

42.Visually check PAS system for leaks.

43.Dismantle test equipment.

Page 723 of 1529

STEERING

57-30 REPAIRS

Power steering box - LHD - diesel

$% 57.10.01

Remove

1.Remove battery cover.

2.Disconnect battery earth lead.

3.Drain cooling system.

+ COOLING SYSTEM - Td5,

ADJUSTMENTS, Drain and refill.

4.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

5.Remove LH front road wheel.

6.Ensure steering wheel is centralised, remove

key from steering lock and engage column lock.

7.Fit centralising bolt to steering box.

8.Loosen 2 clips securing intercooler to turbo

hose. Remove hose.9.Remove 3 bolts securing intermediate shaft

and universal joint.

10.Push intermediate shaft upwards, release and

remove universal joint.

CAUTION: Do not turn the steering wheel

with the intermediate shaft or universal joint

disconnected as damage to the rotary

coupler and the steering wheel switches

may occur.

11.Position container below PAS pipes to catch

fluid spillage.

Page 730 of 1529

STEERING

REPAIRS 57-37

Refit

1.Fit centralising bolt to steering box.

2.With assistance, position steering box to

chassis, fit bolts and tighten to 90 Nm (66 lbf.ft).

3. Models with ACE: Ensure washer is in place

on lower ball joint of anti-roll bar link, then

connect lower ball joint to axle and tighten nut

to 100 Nm (74 lbf.ft).

4.Position drag link, fit nut and tighten to 80 Nm

(59 lbf.ft).

5.Position Panhard rod, fit bolt and nut and

tighten to 230 Nm (170 lbf.ft).

6.Position coolant rail and secure with clips and

bolt.

7.Fit coolant hoses and secure with clips.

8. Models with ACE: Fit and tighten bolt

securing ACE pipes to chassis.

9.Clean PAS pipes ends and 'O' ring recess.

10.Lubricate new 'O' rings for PAS pipes with

clean PAS fluid.

11.Fit 'O' rings to PAS pipes and position pipes in

steering box. Fit PAS pipe bracket and tighten

bolt to 22 Nm 16 lbf.ft).

12.Ensure steering wheel is centralised. Fit

universal joint between steering box and

intermediate shaft and tighten bolts to 25 Nm

(18 lbf.ft).

13.Remove centralising bolt from steering box.

14.Fit road wheel(s) and tighten nuts to 140 Nm

(103 lbf.ft).

15.Remove stand(s) and lower vehicle.

16.Connect battery earth lead.

17.Fit battery cover.

18.Refill cooling system.

+ COOLING SYSTEM - Td5,

ADJUSTMENTS, Drain and refill.

19.Bleed PAS system.

+ STEERING, ADJUSTMENTS,

Hydraulic system - bleed.

20.Centralise steering linkage

+ STEERING, ADJUSTMENTS,

Steering linkage - centralise.

Seal - input shaft - steering box

$% 57.10.16

Remove

1.Remove steering box:

lFor V8 models:

+ STEERING, REPAIRS, Power

steering box - V8.

lFor LHD diesel models:

+ STEERING, REPAIRS, Power

steering box - LHD - diesel.

lFor RHD diesel models:

+ STEERING, REPAIRS, Steering

box - RHD - diesel.

2.Secure steering box in vice.

3.Remove circlip and extract oil seal from

steering box. Take care not to damage

surface of the shaft.

Refit

1.Clean oil seal recess and input shaft.

2.Lubricate new seal with clean PAS fluid.

3.Fit seal using LRT-57-503.

4.Fit circlip.

5.Fit steering box.

lFor V8 models:

+ STEERING, REPAIRS, Power

steering box - V8.

lFor LHD diesel models:

+ STEERING, REPAIRS, Power

steering box - LHD - diesel.

lFor RHD diesel models:

+ STEERING, REPAIRS, Steering

box - RHD - diesel.

Page 732 of 1529

STEERING

REPAIRS 57-39

Refit

1.Clean seal recess, output shaft, end cover and

mating face.

2.Lubricate new end cover 'O' ring with clean

PAS fluid. Fit 'O' ring to end cover.

3.Position output shaft, fit bolts and tighten to 88

Nm (65 lbf.ft).

4.Tighten rack adjuster one turn, align marks and

secure with Allen screw.

5.Lubricate new output shaft seal with clean PAS

fluid.

6.Fit seal using LRT-57-504.

7.Fit spacer, circlip and seal shield.

8.Clean drop arm and steering box splines.

9.Ensure steering box is in the central position.

Align and fit drop arm to output shaft and

secure with new lock washer and nut. Tighten

nut to 240 Nm (177 lbf.ft).

10.Secure lock washer to drop arm nut.

11.Fit steering box.

lFor V8 models:

+ STEERING, REPAIRS, Power

steering box - V8.

lFor LHD diesel models:

+ STEERING, REPAIRS, Power

steering box - LHD - diesel.

lFor RHD diesel models:

+ STEERING, REPAIRS, Steering

box - RHD - diesel.

Pump - power steering - V8

$% 57.20.14

Remove

1.Remove auxiliary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Belt - auxiliary drive.

2.Remove cable tie securing harness to air intake

hose.

3.Loosen 3 clips securing air intake hose, release

and remove hose.

Note: Pre 03 MY air intake hose illustrated.

4. Models with ACE: Remove 3 bolts securing

ACE pump, release pump and position aside.

Page 1243 of 1529

WIPERS AND WASHERS

84-8 DESCRIPTION AND OPERATION

Description

General

All markets have a common wiper system with headlamp powerwash as an option.

The wipers system comprises two front wipers and one rear wiper which are powered by electric motors. A washer

reservoir is located in the front left hand wheel arch and is fitted with two electric pumps. Each pump supplies washer

fluid to either the front or rear screens. On certain models, a third pump can be fitted to operate a headlamp power

wash function. Operation of the front and rear wipers and washers is controlled by the driver using switches located

on a steering column stalk and push button switches on the fascia.

Control of the wipers and washers is achieved by the following components:

lBCU.

lIDM.

lFront wiper relay.

lFront wash/ wipe switch.

lVariable delay switch.

lFront wiper motor assembly.

lFront washer pump motor.

lRear wiper relay.

lRear wiper switch.

lRear washer switch.

lRear wiper motor.

lRear washer pump motor.

Both the Body Control Unit (BCU) and the Intelligent Driver Module (IDM) control the wiper system. The BCU controls

the time delay function of the wiper system and is located below and behind the passenger glovebox. During engine

cranking the BCU prevents wiper functions. Two relays are located in the passenger compartment fusebox. The

relays control the delay operation of the front and rear wipers. The relays are an integral part of the fusebox and

cannot be renewed separately.

Power for the wiper system is supplied by the IDM, which is integral with the passenger fusebox and cannot be

renewed as a component. A serial communication link allows communication between the IDM and the BCU.

The system has diagnostic capabilities through TestBook.

Front wipers

The two front windscreen wipers are operated by a linkage assembly and an electric motor located under the plenum

grill below the windscreen. The linkage and motor assembly is handed for left and right hand drive vehicles. The motor

is an integral part of the linkage and cannot be replaced separately.

The linkage comprises a pressed steel mounting plate which provides for the attachment of a wheel box at each end.

The mounting plate is secured to the bulkhead with flanged nuts which attach to a stud plate located behind the

bulkhead. A link arm is attached to each wheel box by a short link and secured with circlips. The link arm has an

attachment hole centrally located along its length for the electric motor drive link.

The electric motor is mounted in a recess in the bulkhead below a sealed cover plate. The drive spindle of the motor

protrudes through the cover plate and is fitted with a link. The link is attached to a tapered spline on the motor spindle

and is secured with a lock washer and nut. The opposite end of the link is attached to the central attachment point on

the link arm and secured with a circlip.

Each wheel box has a taper splined shaft which allows for the attachment of the wiper arm which is secured with a

washer and nut. The shaft of each wheel box is passed through a rubber sealed aperture in the plenum. The wiper

arm attachment to the splined shaft has a pivot to which the remainder of the arm is attached. The two parts of the

arm are connected by a spring which controls the pressure of the blade on the screen to a predetermined amount.

The wiper blades are attached to the wiper arms with a clips that allow the blade to pivot. Each wiper blade comprises

a number of levers and yokes to which the rubber wiper is attached. The levers and yokes ensure that the pressure

applied by the arm spring is distributed evenly along the full length of the blade. The rubber wiper is held in the yokes

by a pair of stainless steel strips which also contribute to the even distribution of spring pressure along the blade. The

driver's side wiper blade is fitted with an aerofoil which presses the blade onto the screen at high speed. This prevents

the blade from lifting off the screen and maintains the wiping performance.

Page 1248 of 1529

WIPERS AND WASHERS

DESCRIPTION AND OPERATION 84-13

Rear wiper motor

The DC motor contains two permanent magnets and a park switch. An earth braid attached between the motor casing

and the brush pack is utilised to minimise radio interference during wiper functions.

The rear wiper switch provides an earth signal to the BCU, which determines the delay interval, if appropriate. The

BCU then signals the IDM to activate the rear wiper motor relay, which provides power to the rear wiper motor.

To allow the rear wiper to park when the rear wiper is switched off, power flows through the park switch until a cam

in the wiper motor assembly breaks the contact of the park switch. Triggering the park switch grounds the positive

side of the wiper motor causing it to stop abruptly

Washers

The washer system comprises a reservoir, washer pumps, hoses and washer jets. The front washers are controlled

from a stalk switch on the steering column and the rear washers are operated by a non-latching pushbutton switch on

the fascia adjacent to the instrument pack.

Reservoir

The reservoir is located behind the front bumper in the inner wheel arch and has a capacity of 6.0 litres (12.5 US pints).

A filler neck tube is connected to the reservoir with a seal and extends into the engine compartment on the front left

hand side. The filler neck tube contains a removable filter to prevent particle contamination and a yellow float to show

reservoir contents. The washer filler neck tube is sealed with a cap which is coloured blue for identification.

Two electric washer pumps are located on the rear face of the reservoir and supply washer fluid to the front

windscreen and the tail door window. Each pump is sealed to the reservoir with a rubber sealing grommet.

On vehicles with headlamp powerwash fitted, a third pump is fitted with a sealing grommet to the front face of the

reservoir.

The reservoir and filler neck tube are manufactured from moulded opaque nylon. The reservoir has moulded lugs for

attachment to the vehicle body. A bracket is attached to the top of the filler neck tube and locates in a hole in the body

to secure the top of the tube.

Front screen washer jets

Two washer jets for the front windscreen are fitted to the top surface of the bonnet and held in place with plastic clips.

Each washer jet is connected via a hose to an in-line valve. The in-line valve prevents the washer fluid draining back

to the reservoir and ensures that the washers operate immediately the washer pump is operated. From each in-line

valve the washers are connected via a short hose to a 'T' connector. From the 'T' connector a single hose connects

to the outlet of the front washer pump. Each jet has two jets which can be adjusted to allow full fluid coverage of the

windscreen.