warning LAND ROVER DISCOVERY 1999 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 1347 of 1529

ALARM SYSTEM AND HORN

86-4-24 DESCRIPTION AND OPERATION

The theft deterrent LED utilises a particular flash to show the status of the following:

lAlarm armed.

lEngine immobilised.

lAlarm tampered.

lHandset low battery warning.

Transit mode

To prevent excessive battery drain during transportation to overseas markets, the vehicle is placed in a transit mode

at the end of line test.

The following functions are disabled when the vehicle is in transit mode:

lVolumetric sensors.

lPassive immobilisation.

lMobilisation of the vehicle by use of door lock.

lIgnition key interlock.

lElectric seat enable time-out with drivers door open.

To exit this mode, switch on the ignition and simultaneously hold down the heated rear window and the rear fog lamp

switch for 2 seconds.

Transit mode can be entered using Testbook.

Page 1348 of 1529

ALARM SYSTEM AND HORN

REPAIR 86-4-25

REPAIR

Switch - central door locking

$% 86.26.30

Remove

1.Carefully remove clock assembly from louvre

panel.

2.Disconnect multiplug from door lock switch.

3.Remove door lock switch from clock.

Refit

1.Fit door lock switch to clock assembly.

2.Connect multiplug to door lock switch.

3.Position clock assembly and push to secure in

position.

Switches - horn

$% 86.30.01

Remove

WARNING: It is imperative that before any

work is undertaken on the SRS system the

appropriate information is read thoroughly.

1.Disconnect both battery leads, negative lead

first, and wait 10 minutes.

2.Remove driver's airbag module.

+ RESTRAINT SYSTEMS, REPAIRS,

Airbag module - drivers.

3.Release horn switch multiplugs and leads from

steering wheel base.

4.Disconnect horn switch multiplugs from

harness.

5.Disconnect horn switch multiplug from rotary

coupler harness.

6.Remove screw securing earth leads to steering

wheel.

7.Using a broad round edged tool, carefully prise

horn switches from steering wheel.

Refit

1.Fit to steering wheel and connect multiplugs.

2.Fit earth leads and secure with screw.

3.Secure leads and multiplugs to base of steering

wheel.

4.Fit driver's airbag module.

+ RESTRAINT SYSTEMS, REPAIRS,

Airbag module - drivers.

Page 1415 of 1529

HARNESSES

86-7-10 REPAIRS

11.Release clips and remove fuse box cover.

12.Remove bolt securing starter lead to fuse box,

release lead and position aside.

13.Disconnect 2 engine harness multiplugs from

fuse box.

14.Disconnect EVAP solenoid multiplug.

15.Remove nut securing engine harness earth to

body and disconnect engine harness to main

harness multiplug. 16.Remove trim fixings securing toe board and

remove toe board.

17.Disconnect 5 multiplugs connecting engine

harness to ECM.

18.Release engine harness, pull into engine bay.

19.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

Page 1441 of 1529

DRIVING AIDS

86-8-4 DESCRIPTION AND OPERATION

Description

General

Park Distance Control (PDC) is introduced on vehicles from 03 model year. PDC provides an audible warning to the

driver when any obstacles are in the path of the vehicle during a reversing manoeuvre. The purpose of the system is

to assist the driver when parking and is not designed as a crash avoidance system or a replacement for visual

interpretation by the driver.

The system comprises four ultrasonic sensors in the rear bumper, an ECU, a fascia mounted momentary switch and

a sounder unit. The system operates using ultrasonic signals which are transmitted by the sensors. The reflected echo

from this output is received by the sensors and used by the PDC ECU to calculate the distance from an object.

The fascia mounted switch allows the driver to de-activate the PDC system if operation is not required or the vehicle

has a trailer attached.

Page 1448 of 1529

DRIVING AIDS

DESCRIPTION AND OPERATION 86-8-11

Operation

PDC System Operation

When the ignition switch is in position II and reverse gear is selected, the PDC sensors are automatically activated.

The PDC ECU only activates the system if reverse is selected for more than 1 second. This avoids nuisance audible

warnings when the gear selector lever is being moved between Drive and Park on vehicles with automatic

transmission.

When the system is activated, the PDC ECU illuminates the indicator LED in the PDC switch, switches on the

ultrasonic sensors and generates a single chime on the PDC sounder to indicate the system is active. If an object is

range of the sensors when the system is activated, a series of audible warnings are emitted by the PDC sounder

immediately.

If PDC operation is not required, it can be suspended temporarily by pressing the PDC switch. When reverse is

deselected and subsequently reselected, PDC will automatically become active again.

PDC can also be manually selected when not in reverse gear by pressing the PDC switch. A second press of the

switch is required to turn off the PDC or the PDC will be deactivated if reverse is selected and then deselected.

Sensor Operation

The PDC ECU processes the distance readings from the ultrasonic sensors to determine if there are any objects

within the detection areas. If there are no objects in the detection areas, there are no further audible warnings. If an

object is detected, repeated audible warnings are produced on the PDC sounder.

The maximum detection range is 1800 mm (70 in). When an object is detected, the time delay between the audible

warning tones decreases as the distance between the detected object and the vehicle decreases until, at

approximately 450 mm (17 in), the audible warning tone is continuous.

After the initial detection of an object, if there is no decrease in the distance between an object and the central sensors,

the time delay between the audible warnings remains constant. If an object is detected by one of the corner sensors

only, the audible warnings stop after about 5 seconds if there is no change in the distance between the object and the

corner sensor.

Page 1449 of 1529

DRIVING AIDS

86-8-12 DESCRIPTION AND OPERATION

Park Distance Control Detection Areas

aIntermittent Warning Tone

bContinuous Warning Tone

Detection Calculation

When operating in the combined transmitter and receiver mode, the sensor outputs a number ultrasonic pulses and

receives the reflected echo signal. The ECU amplifies the received echo signals and compares them with a

preprogrammed threshold to calculate the distance to the object. This is achieved by determining the elapsed time

between the transmission and reception of the ultrasonic signal.

When operating in receiver mode, the sensor receives echo signals transmitted by an adjacent sensor. This mode is

used to improve the accuracy of the system.

The detection cycle consists of the ECU operating one sensor in the combined transmitter and receiver mode and

transmitting a number of ultrasonic pulses. The ECU then switches the transmitting sensor and the adjacent sensor(s)

to receiver mode. After a short time delay, this sequence is repeated using a different sensor to transmit the ultrasonic

pulse and continues until all four sensors have output an ultrasonic signal. This sequence is completed in 100ms. The

ECU uses several measurements of the same sensors to remove errors from the calculation.

If the object is directly behind a sensor, the distance is calculated using the time between the transmission and

reception of the signal. If the object is positioned between two sensors, the ECU uses both signals to determine the

correct distance using triangulation.

To perform the triangulation calculation, the ECU must know the distance between the individual sensors in the

bumper. This information is stored in the ECU memory. From the received distance from each sensor and using the

known distance between adjacent sensors, the ECU can calculate the minimum distance from the vehicle to the

object.

When approaching several objects, the ECU recognises the distance from the vehicle to the nearest object.

A

Y- Y

1800mm (70in)

450mm (17in)

600mm (23.5in)

YY

B

M86 5917

Page 1484 of 1529

INSTRUMENTS

DESCRIPTION AND OPERATION 88-1

INS TRUMENTS DESCRIPTION AND OPERAT ION

Instrument pack

1Hill descent control information warning lamp

2Overspeed warning lamp

3Brake system warning lamp

4Malfunction Indicator Lamp (MIL)

5Tachometer

6Direction indicator warning lamp

7Main beam warning lamp

8Direction indicator warning lamp

9Speedometer

10SRS warning lamp

11Off road mode warning lamp

12Glow plug warning lamp

13Trailer warning lamp

14Water in fuel filter warning lamp

15Transmission high temperature warning lamp

16Seat belt warning lamp17Fuel tank level gauge

18Low fuel level warning lamp

19LCD odometer/trip meter

20Anti-theft status warning lamp

21ABS warning lamp

22Gearbox manual/sport mode warning lamp

23Alternator charge warning lamp

24ACE warning lamp

25Oil pressure warning lamp

26SLS warning lamp

27Hill descent control warning lamp

28Engine coolant temperature gauge

29High coolant temperature warning lamp

30Traction control warning lamp

31Differential lock warning lamp

32Transfer box neutral warning lamp

Page 1487 of 1529

INSTRUMENTS

88-4 DESCRIPTION AND OPERATION

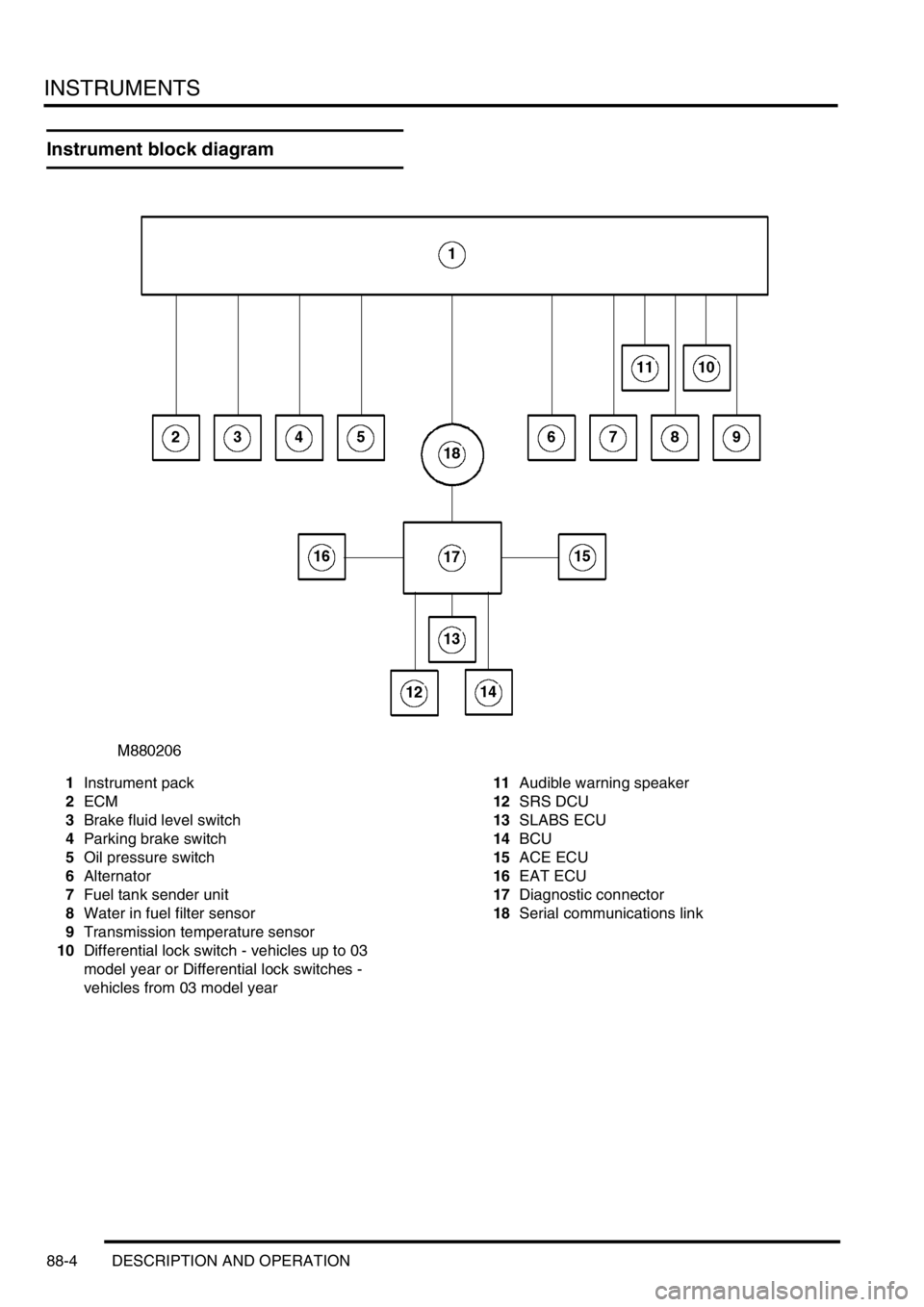

Instrument block diagram

1Instrument pack

2ECM

3Brake fluid level switch

4Parking brake switch

5Oil pressure switch

6Alternator

7Fuel tank sender unit

8Water in fuel filter sensor

9Transmission temperature sensor

10Differential lock switch - vehicles up to 03

model year or Differential lock switches -

vehicles from 03 model year11Audible warning speaker

12SRS DCU

13SLABS ECU

14BCU

15ACE ECU

16EAT ECU

17Diagnostic connector

18Serial communications link

Page 1488 of 1529

INSTRUMENTS

DESCRIPTION AND OPERATION 88-5

Description

General

The instrument pack consists of four analogue dials, four warning lamp packs and a Liquid Crystal Display (LCD)

odometer.

The four dials are used to indicate:

lRoad speed.

lEngine speed.

lFuel tank level.

lEngine coolant temperature.

The dials are driven by a microprocessor from information received from the serial communication link. Information

input is received as either:

lDigital.

lAnalogue.

lPulse train.

lPulse Width Modulation (PWM).

The LCD provides information for:

lOdometer.

lTrip distance.

lSelected gear (on vehicles fitted with an automatic gearbox).

A trip reset button is provided to zero the trip display, this button also allows the selection of "miles" or "kilometres"

for the display. A photocell controls the illumination of the LCD, maintaining contrast of the display during ambient light

changes.

Within the four warning lamp packs there are 28 lamps. A long life bulb illuminates the high beam warning lamp and

the rest of the warning lamps are illuminated by Light Emitting Diodes (LED's). All warning lamp legends are invisible

until lit. When lit the symbols are illuminated on a black background.

The warning lamps illuminate in one of four colours. The colour indicates the level of importance to the driver, as

follows:

lRed = warning.

lAmber = caution.

lGreen = system operative.

lBlue = main beam operative.

The first warning lamp pack is located in the top left-hand side of the instrument pack and contains the following

warning lamps:

lTraction control warning lamp.

lTransfer box in neutral warning lamp.

lDifferential lock warning lamp

lOverspeed warning lamp (activated for gulf market only).

lBrake system warning lamp.

lHill Descent Control (HDC) information warning lamp.

lMalfunction Indicator Lamp (MIL)/ SERVICE ENGINE SOON warning lamp.

The second warning lamp pack is located in the centre of the instrument pack and contains the following warning

lamps:

lDirection indicator warning lamps.

lHigh beam warning lamp.

lAnti-lock brake system warning lamp.

Page 1489 of 1529

INSTRUMENTS

88-6 DESCRIPTION AND OPERATION

The third warning lamp pack is located in the top right-hand side of the instrument pack and contains the following

warning lamps:

lSRS warning lamp.

lSLS off road mode warning lamp.

lTrailer warning lamp.

lGlow plug warning lamp.

lWater in fuel filter warning lamp.

lSeat belt warning lamp.

lTransmission high temperature warning lamp.

The fourth warning lamp pack is located underneath the tachometer of the instrument pack contains the following

warning lamps:

lOil pressure warning lamp.

lAlternator charge warning lamp.

lHDC fault warning lamp.

lSelf Levelling Suspension (SLS) warning lamp.

lActive Cornering Enhancement (ACE) warning lamp.

lGearbox manual/sport mode warning lamps.

The serial communication link is used to allow information to travel to and from the instrument pack, and it provides

the ability to configure the instrument pack to a specific market. It also allows the instrument pack to be controlled by

TestBook for diagnostics.

There are five market specific variants of the instrument pack:

lUnited Kingdom (UK).

lNorth American Specification (NAS).

lCanada.

lAustralia.

lRest Of the World (ROW), Gulf and Japan.

The main difference between the five markets is that the speedometer will indicate road speed in mph as major figures

and km/h as minor figures, km/h as major figures and mph as minor figures or km/h only.

When TestBook is used to diagnose the instrument pack it demands each of the dials and warning lamps to operate

in-turn so a visual check of their operation can be made.

CAUTION: The instrument pack must not be stored on its face side at any time. This is because the dials have

damping fluid within them to ensure smooth operation of the dials' indicator needles. This fluid will leak out.

Speedometer

The speedometer informs the driver of the current vehicle road speed. It has a Liquid Crystal Display (LCD) to show

odometer, trip meter and, on automatic gearbox models, the selected gear. The speedometer will not show speeds

of less than 1.5 mph (2.5 km/h).

There are three different market configurations:

lNAS and UK = mph as major figures km/h as minor figures.

lCanada = km/h as major figures mph as minor figures.

lROW and Australia = km/h only.

The Self Levelling and Anti-Lock Brake System (SLABS) ECU provides the signal input for the road speed. The signal

is at 8000 pulses per mile (1.6 kilometres).