suspension LAND ROVER DISCOVERY 1999 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 149 of 1529

MAINTENANCE

10-26 PROCEDURES

2.Check/tighten front suspension RH radius arm

fixings.

3.Check/tighten front suspension Panhard rod

fixingsCheck rear axle suspension fixings

1.Check and tighten if necessary all rear axle

suspension fixings.

+ TORQUE WRENCH SETTINGS, Rear

suspension.

Page 151 of 1529

MAINTENANCE

10-28 PROCEDURES

Check – Height sensors

SLS height sensors

1.Check height sensors for condition and

security.

2.Check electrical harness for chafing and

damage.

Front and rear axle suspension links

Check

Rear suspension

Front suspension

1.Check condition of front and rear axle

suspension link mounting rubbers.

2.Check security of fixings.

+ TORQUE WRENCH SETTINGS,

Front suspension.

+ TORQUE WRENCH SETTINGS, Rear

suspension.

Page 154 of 1529

MAINTENANCE

PROCEDURES 10-31

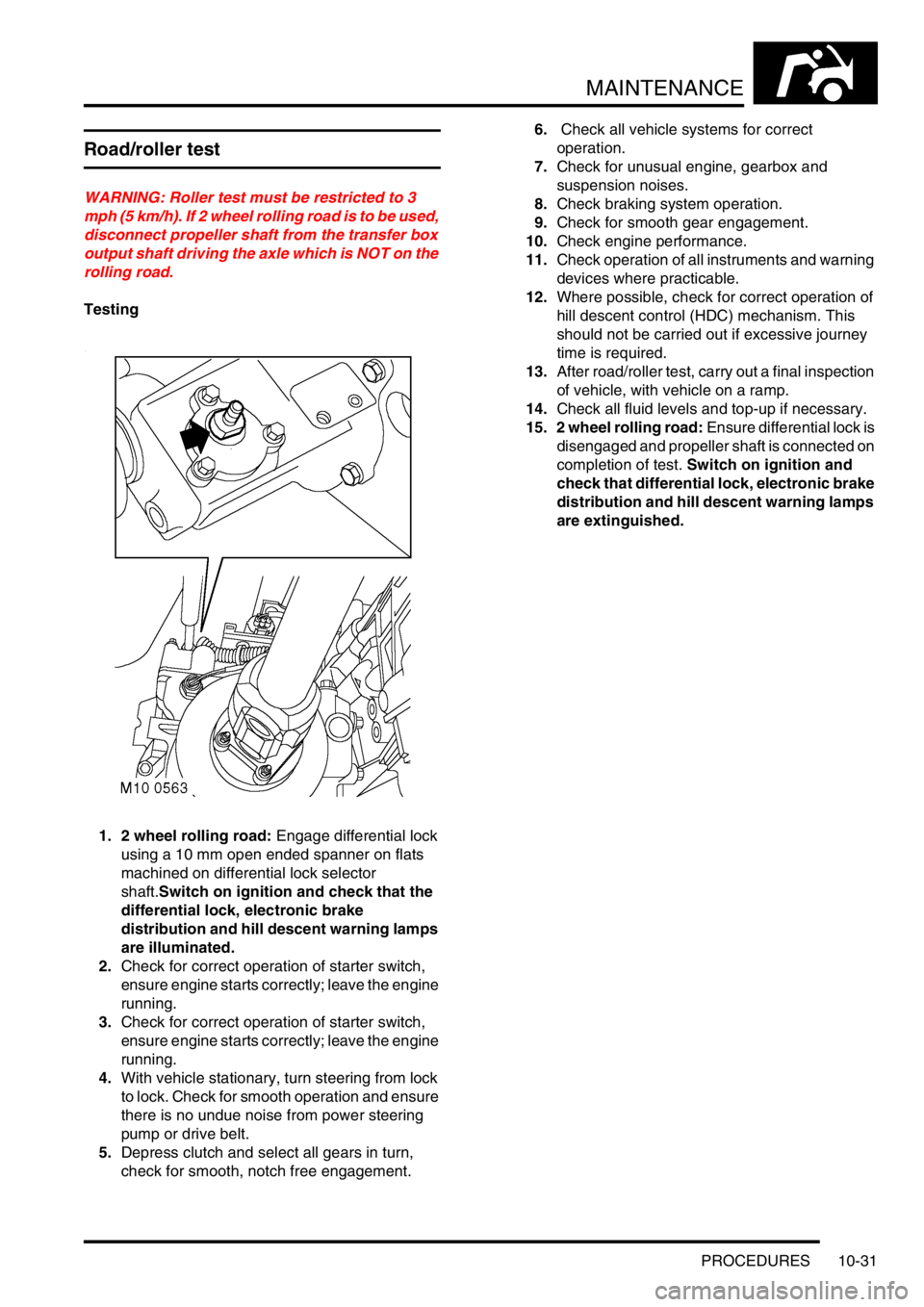

Road/roller test

WARNING: Roller test must be restricted to 3

mph (5 km/h). If 2 wheel rolling road is to be used,

disconnect propeller shaft from the transfer box

output shaft driving the axle which is NOT on the

rolling road.

Testing

1. 2 wheel rolling road: Engage differential lock

using a 10 mm open ended spanner on flats

machined on differential lock selector

shaft.Switch on ignition and check that the

differential lock, electronic brake

distribution and hill descent warning lamps

are illuminated.

2.Check for correct operation of starter switch,

ensure engine starts correctly; leave the engine

running.

3.Check for correct operation of starter switch,

ensure engine starts correctly; leave the engine

running.

4.With vehicle stationary, turn steering from lock

to lock. Check for smooth operation and ensure

there is no undue noise from power steering

pump or drive belt.

5.Depress clutch and select all gears in turn,

check for smooth, notch free engagement.6. Check all vehicle systems for correct

operation.

7.Check for unusual engine, gearbox and

suspension noises.

8.Check braking system operation.

9.Check for smooth gear engagement.

10.Check engine performance.

11.Check operation of all instruments and warning

devices where practicable.

12.Where possible, check for correct operation of

hill descent control (HDC) mechanism. This

should not be carried out if excessive journey

time is required.

13.After road/roller test, carry out a final inspection

of vehicle, with vehicle on a ramp.

14.Check all fluid levels and top-up if necessary.

15. 2 wheel rolling road: Ensure differential lock is

disengaged and propeller shaft is connected on

completion of test. Switch on ignition and

check that differential lock, electronic brake

distribution and hill descent warning lamps

are extinguished.

Page 667 of 1529

REAR AXLE

51-2 DESCRIPTION AND OPERATION

Description

General

The rear axle consists of an axle casing with a differential unit attached to the right of the vehicle centre line. A wheel

hub is installed in each end of the axle casing and connected to the differential unit by a drive shaft.

Axle casing

The axle casing is of welded construction, with brackets on the casing exterior for attachment to the rear suspension.

A differential cover on the rear of the axle casing contains an oil level plug for checking and replenishment of the

differential unit lubricating oil. A magnetic drain plug is installed on the underside of the axle casing.

The interior of the axle casing is ventilated through a breather tube inserted in a red plastic sleeve in the top of the

casing. The open end of the breather tube is located between the chassis and the left rear wheelarch.

Differential unit

The differential unit is of the spiral bevel type, lubricated by splash oil. The unit consists of a differential carrier

attached to a pinion housing. In the pinion housing, the pinion is splined to a pinion flange which is secured with a bolt

and washer. An oil seal prevents leakage past the pinion flange.

Centralising peg

The centralising peg is a press fit in the centre of the pinion flange and provides a positive location for the rear

propellor shaft to ensure it is centralised with the flange.

Page 681 of 1529

FRONT AXLE

54-2 DESCRIPTION AND OPERATION

Description

General

The front axle consists of an axle casing with a differential unit attached to the right of the vehicle centre line. A wheel

hub is installed in a steering knuckle at each end of the axle casing and connected to the differential unit by a drive

shaft.

Axle casing

The axle casing is of welded construction, with brackets on the casing exterior for attachment to the front suspension.

Yokes at each end of the casing incorporate upper and lower ball joints for attachment of the steering knuckles.

A differential cover on the front of the axle casing contains an oil level plug for checking and replenishment of the

differential lubricating oil. A magnetic drain plug is installed on the underside of the casing. An oil seal is installed in

each end of the axle casing to prevent leakage past the drive shafts.

The interior of the axle casing is ventilated through a breather tube inserted in a red plastic sleeve in the top of the

casing. The open end of the breather tube is located in the left rear corner of the engine compartment.

Differential unit

The differential unit is of the spiral bevel type, lubricated by splash oil. The unit consists of a differential carrier

attached to a pinion housing. In the pinion housing, the pinion is splined to a drive flange which is secured with a bolt

and washer. An oil seal prevents leakage past the drive flange.

Steering knuckle

The steering knuckles are mounted on upper and lower ball joints in the yokes at the end of the axle casing. A tension

collet, in the lower mounting point of each steering knuckle, accommodates manufacturing tolerances to enable the

correct tightening of both ball joints. Lugs are incorporated on the steering knuckles for attachment of the steering

system drag link and track rod.

Page 690 of 1529

FRONT AXLE

REPAIRS 54-11

Constant velocity joint - drive shaft

$% 54.20.21

Remove

1.Remove wheel hub.

+ FRONT SUSPENSION, REPAIRS,

Wheel hub.

2.Place drive shaft in vice.

3.Release both securing bands from gaiter and

discard.

4.Compress gaiter to gain access to joint.

5.Using a suitable drift against the inner part of

the joint, remove joint from shaft.

6.Remove circlip from shaft and discard.

7.Remove spacer from shaft.

8.Remove gaiter from shaft and inspect for

damage. Renew if necessary. Refit

1.Clean drive shaft and gaiter.

2.Clean spacer.

3.Fit new inner securing band to gaiter.

4.Fit gaiter to shaft.

5.Fit spacer to shaft.

6.Fit new circlip to shaft.

7.Position joint to shaft. Use a screwdriver to

press circlip into its groove and push joint fully

onto shaft.

8.Apply grease from the sachet to the joint.

9.Position gaiter to joint and fit new outer

securing band.

10.Use a Band-it thriftool to secure inner and outer

securing bands.

11.Fit wheel hub.

+ FRONT SUSPENSION, REPAIRS,

Wheel hub.

Page 712 of 1529

STEERING

ADJUSTMENTS 57-19

5.Adjust drag link so that taper joint is centralised

in drop arm, then tighten drag link clamp bolts:

Tighten M8 bolts to 22 Nm (16 lbf.ft) and M10

bolts to 33 Nm (24 lbf.ft).

6.Connect drag link to drop arm and tighten nut to

80 Nm (59 lbf.ft).

7.Remove steering box centralising bolt.

8.Remove stand(s) and lower vehicle.

9.Road test the vehicle and check that the

steering wheel is centralised. If steering wheel

is not centralised, proceed as follows.

10.Slacken drag link adjuster clamp bolts.

11.Without disconnecting drag link from drop arm,

adjust the length of the drag link to bring the

steering wheel to the central position.

CAUTION: Repositioning the steering wheel

on its splines cannot correct small (less

than 5°) errors in steering wheel alignment.

Always rectify small errors in alignment by

adjusting the drag link as detailed above,

ensuring that steering box centralisation is

maintained.

12.Tighten drag link clamp bolts: Tighten M8 bolts

to 22 Nm (16 lbf.ft) and M10 bolts to 33 Nm (24

lbf.ft)

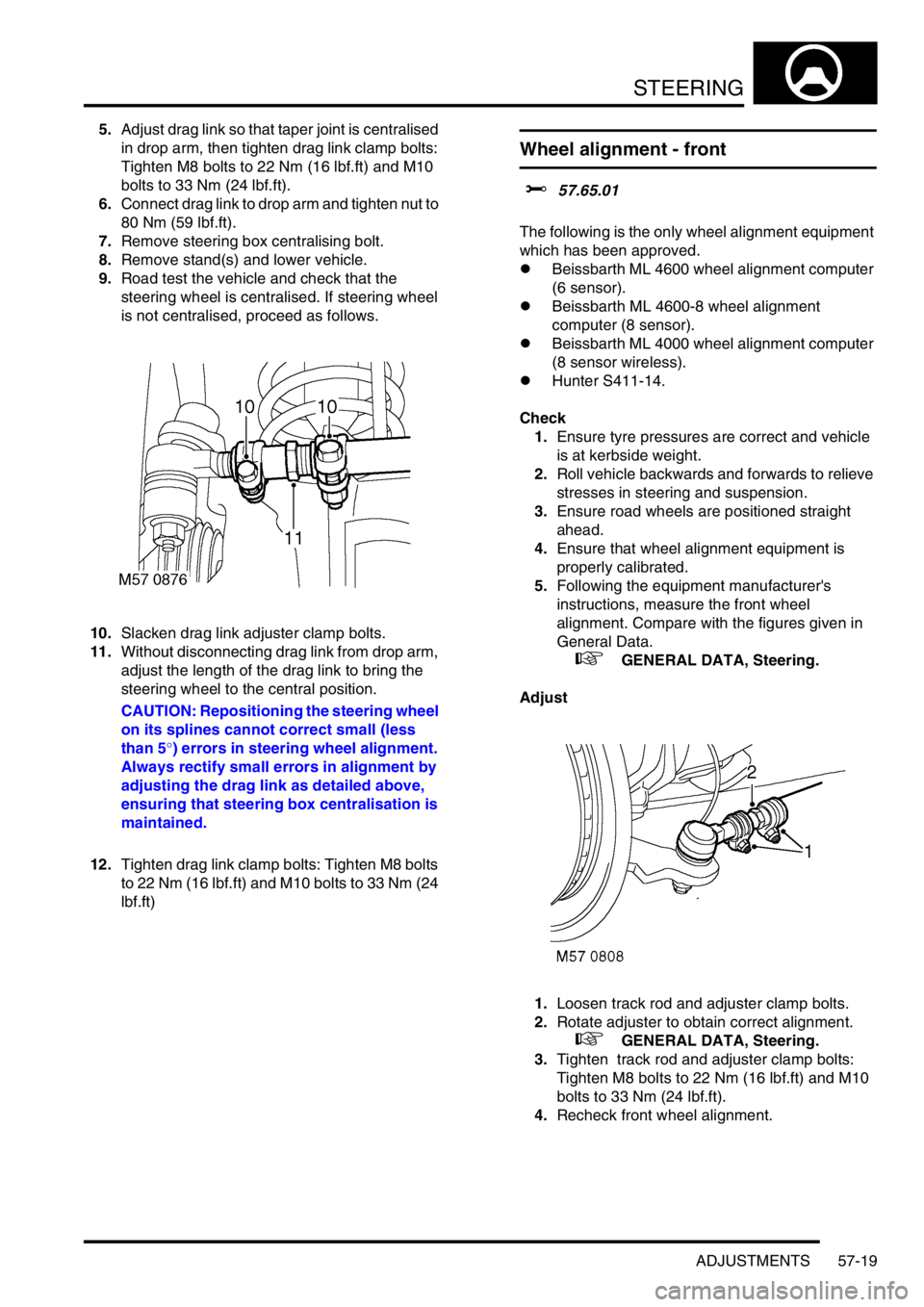

Wheel alignment - front

$% 57.65.01

The following is the only wheel alignment equipment

which has been approved.

lBeissbarth ML 4600 wheel alignment computer

(6 sensor).

lBeissbarth ML 4600-8 wheel alignment

computer (8 sensor).

lBeissbarth ML 4000 wheel alignment computer

(8 sensor wireless).

lHunter S411-14.

Check

1.Ensure tyre pressures are correct and vehicle

is at kerbside weight.

2.Roll vehicle backwards and forwards to relieve

stresses in steering and suspension.

3.Ensure road wheels are positioned straight

ahead.

4.Ensure that wheel alignment equipment is

properly calibrated.

5.Following the equipment manufacturer's

instructions, measure the front wheel

alignment. Compare with the figures given in

General Data.

+ GENERAL DATA, Steering.

Adjust

1.Loosen track rod and adjuster clamp bolts.

2.Rotate adjuster to obtain correct alignment.

+ GENERAL DATA, Steering.

3.Tighten track rod and adjuster clamp bolts:

Tighten M8 bolts to 22 Nm (16 lbf.ft) and M10

bolts to 33 Nm (24 lbf.ft).

4.Recheck front wheel alignment.

Page 746 of 1529

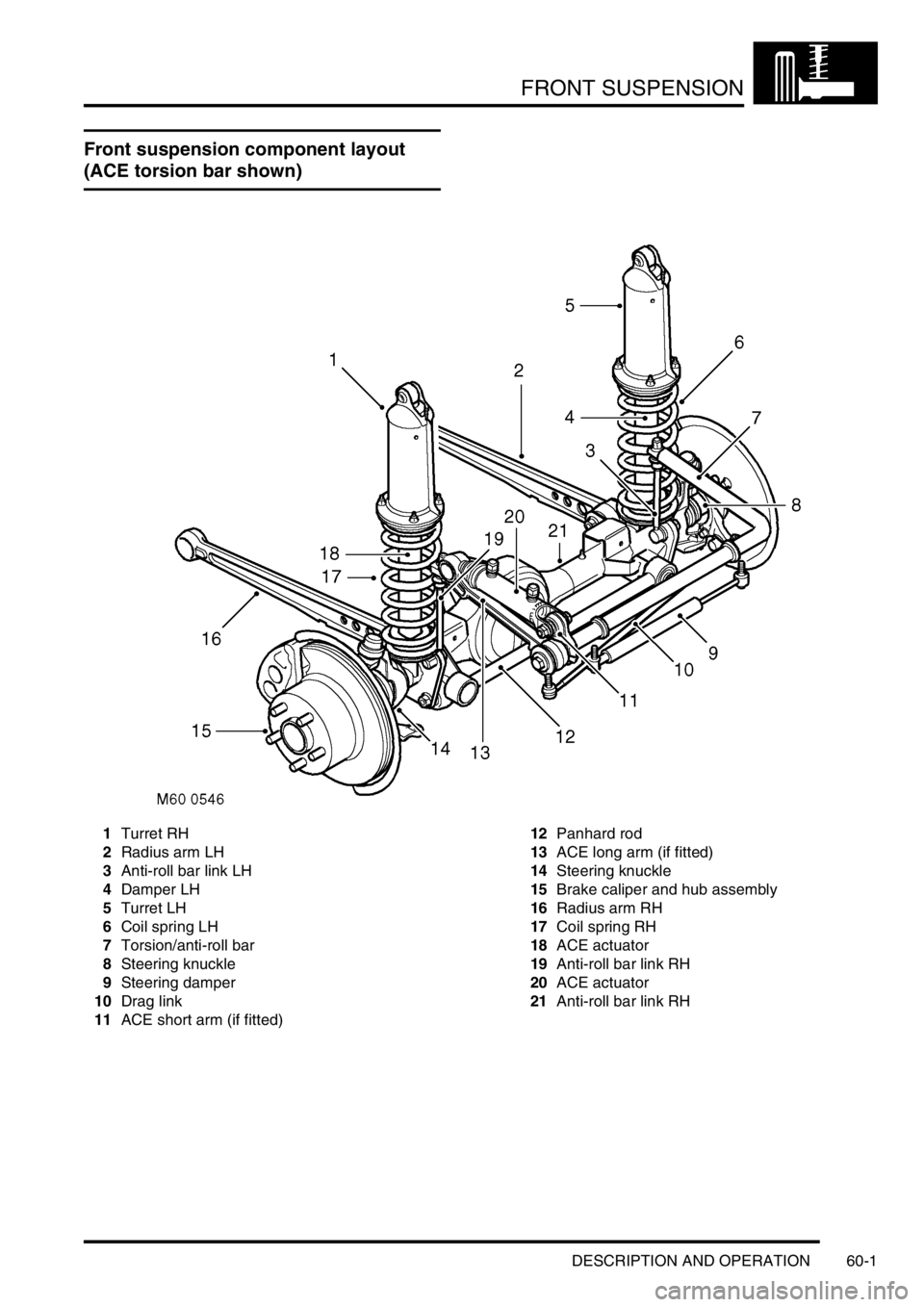

FRONT SUSPENSION

DESCRIPTION AND OPERATION 60-1

FRONT SUSPENSION DESCRIPTION AND OPERAT ION

Front suspension component layout

(ACE torsion bar shown)

1Turret RH

2Radius arm LH

3Anti-roll bar link LH

4Damper LH

5Turret LH

6Coil spring LH

7Torsion/anti-roll bar

8Steering knuckle

9Steering damper

10Drag link

11ACE short arm (if fitted)12Panhard rod

13ACE long arm (if fitted)

14Steering knuckle

15Brake caliper and hub assembly

16Radius arm RH

17Coil spring RH

18ACE actuator

19Anti-roll bar link RH

20ACE actuator

21Anti-roll bar link RH

Page 747 of 1529

FRONT SUSPENSION

60-2 DESCRIPTION AND OPERATION

Front suspension components (ACE

torsion bar shown)

Page 748 of 1529

FRONT SUSPENSION

DESCRIPTION AND OPERATION 60-3

1Damper 2 off

2Bolt 2 off

3Turret 2 off

4Nut 8 off

5Nut

6Bolt 4 off

7Nut

8Washer

9Anti-roll bar link RH

10Torsion/Anti-roll bar assembly

11Anti-roll bar link LH

12Washer

13Nut

14Nut

15Mounting rubber 2 off

16Clamp plate 2 off

17Bolt 2 off

18Lower spring seat LH

19Front axle20Nut

21Bush

22Panhard rod

23Bolt

24Radius arm LH

25Bolt

26Bush

27Nut

28Nut

29Bush

30Bolt

31Radius arm RH

32Bolt

33Bush

34Nut

35Lower spring seat RH

36Coil spring 2 off

37Upper spring seat 2 off