warning LAND ROVER DISCOVERY 1999 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 122 of 1529

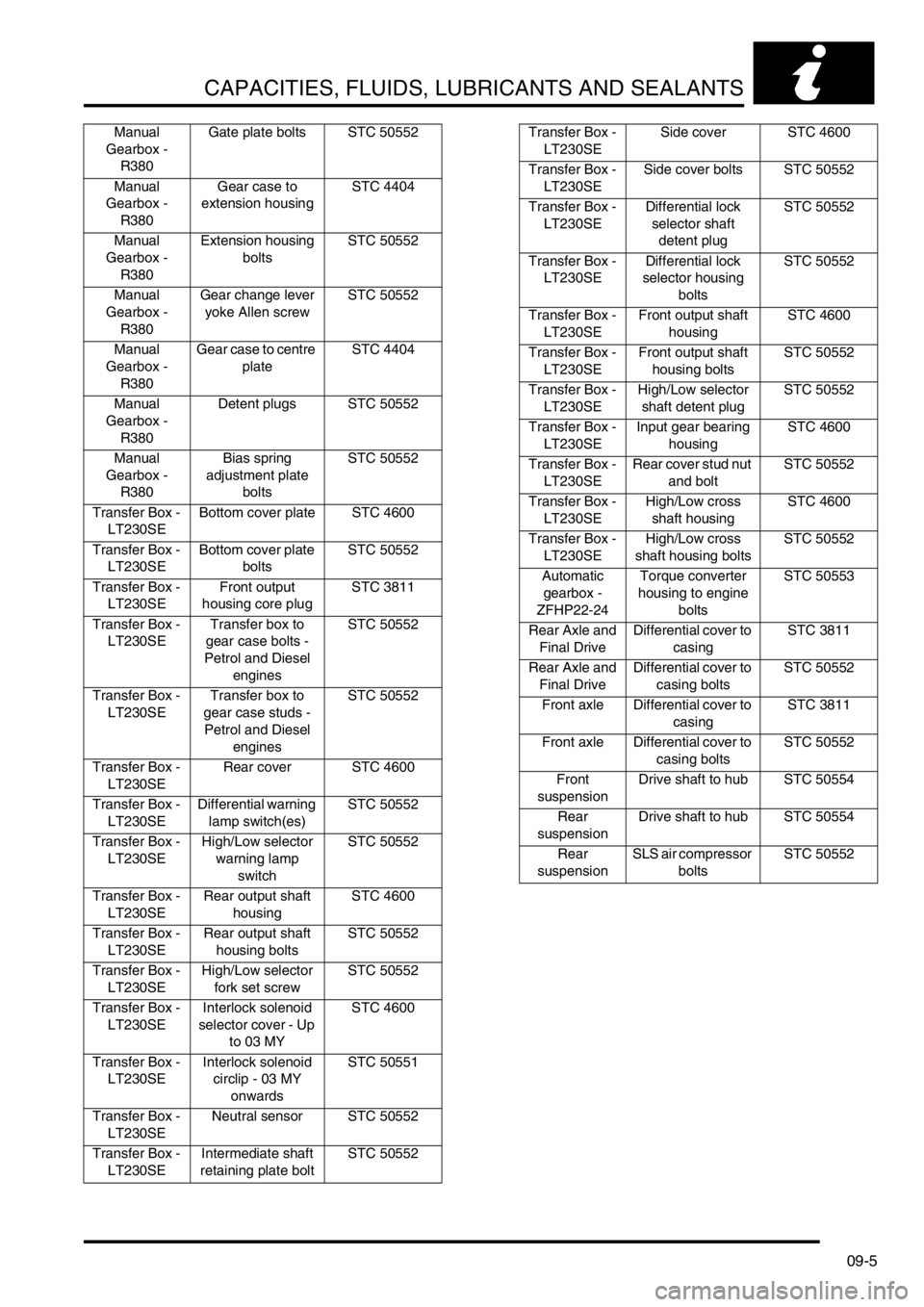

CAPACITIES, FLUIDS, LUBRICANTS AND SEALANTS

09-5

Manual

Gearbox -

R380Gate plate bolts STC 50552

Manual

Gearbox -

R380Gear case to

extension housingSTC 4404

Manual

Gearbox -

R380Extension housing

boltsSTC 50552

Manual

Gearbox -

R380Gear change lever

yoke Allen screwSTC 50552

Manual

Gearbox -

R380Gear case to centre

plateSTC 4404

Manual

Gearbox -

R380Detent plugs STC 50552

Manual

Gearbox -

R380Bias spring

adjustment plate

boltsSTC 50552

Transfer Box -

LT230SEBottom cover plate STC 4600

Transfer Box -

LT230SEBottom cover plate

boltsSTC 50552

Transfer Box -

LT230SEFront output

housing core plugSTC 3811

Transfer Box -

LT230SETransfer box to

gear case bolts -

Petrol and Diesel

enginesSTC 50552

Transfer Box -

LT230SETransfer box to

gear case studs -

Petrol and Diesel

enginesSTC 50552

Transfer Box -

LT230SERear cover STC 4600

Transfer Box -

LT230SEDifferential warning

lamp switch(es)STC 50552

Transfer Box -

LT230SEHigh/Low selector

warning lamp

switchSTC 50552

Transfer Box -

LT230SERear output shaft

housingSTC 4600

Transfer Box -

LT230SERear output shaft

housing boltsSTC 50552

Transfer Box -

LT230SEHigh/Low selector

fork set screwSTC 50552

Transfer Box -

LT230SEInterlock solenoid

selector cover - Up

to 03 MYSTC 4600

Transfer Box -

LT230SEInterlock solenoid

circlip - 03 MY

onwardsSTC 50551

Transfer Box -

LT230SENeutral sensor STC 50552

Transfer Box -

LT230SEIntermediate shaft

retaining plate boltSTC 50552Transfer Box -

LT230SESide cover STC 4600

Transfer Box -

LT230SESide cover bolts STC 50552

Transfer Box -

LT230SEDifferential lock

selector shaft

detent plugSTC 50552

Transfer Box -

LT230SEDifferential lock

selector housing

boltsSTC 50552

Transfer Box -

LT230SEFront output shaft

housingSTC 4600

Transfer Box -

LT230SEFront output shaft

housing boltsSTC 50552

Transfer Box -

LT230SEHigh/Low selector

shaft detent plugSTC 50552

Transfer Box -

LT230SEInput gear bearing

housingSTC 4600

Transfer Box -

LT230SERear cover stud nut

and boltSTC 50552

Transfer Box -

LT230SEHigh/Low cross

shaft housingSTC 4600

Transfer Box -

LT230SEHigh/Low cross

shaft housing boltsSTC 50552

Automatic

gearbox -

ZFHP22-24Torque converter

housing to engine

boltsSTC 50553

Rear Axle and

Final DriveDifferential cover to

casingSTC 3811

Rear Axle and

Final DriveDifferential cover to

casing boltsSTC 50552

Front axle Differential cover to

casingSTC 3811

Front axle Differential cover to

casing boltsSTC 50552

Front

suspensionDrive shaft to hub STC 50554

Rear

suspensionDrive shaft to hub STC 50554

Rear

suspensionSLS air compressor

boltsSTC 50552

Page 128 of 1529

MAINTENANCE

PROCEDURES 10-5

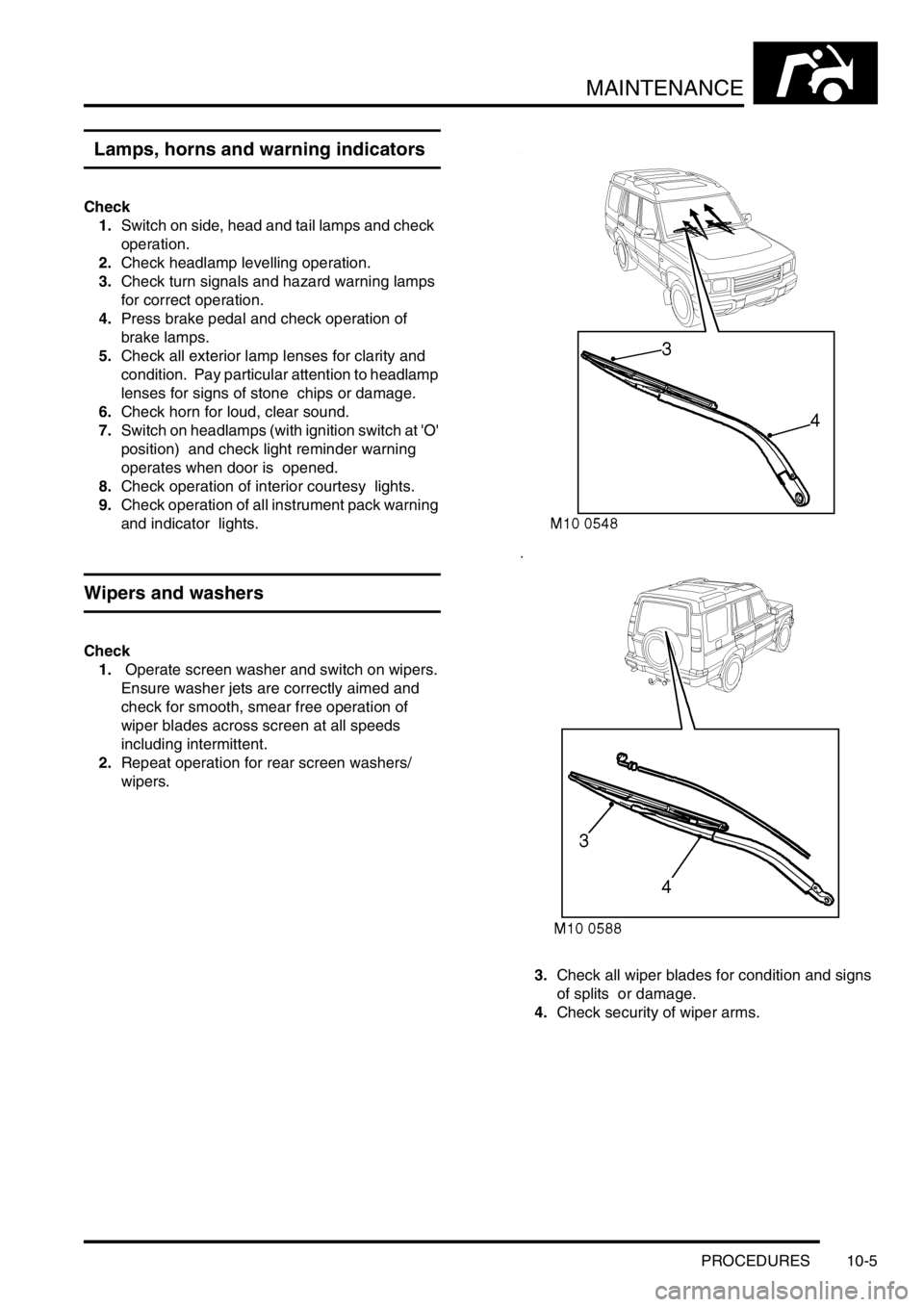

Lamps, horns and warning indicators

Check

1.Switch on side, head and tail lamps and check

operation.

2.Check headlamp levelling operation.

3.Check turn signals and hazard warning lamps

for correct operation.

4.Press brake pedal and check operation of

brake lamps.

5.Check all exterior lamp lenses for clarity and

condition. Pay particular attention to headlamp

lenses for signs of stone chips or damage.

6.Check horn for loud, clear sound.

7.Switch on headlamps (with ignition switch at 'O'

position) and check light reminder warning

operates when door is opened.

8.Check operation of interior courtesy lights.

9.Check operation of all instrument pack warning

and indicator lights.

Wipers and washers

Check

1. Operate screen washer and switch on wipers.

Ensure washer jets are correctly aimed and

check for smooth, smear free operation of

wiper blades across screen at all speeds

including intermittent.

2.Repeat operation for rear screen washers/

wipers.

3.Check all wiper blades for condition and signs

of splits or damage.

4.Check security of wiper arms.

Page 137 of 1529

MAINTENANCE

10-14 PROCEDURES

Intercooler - diesel engine

Remove

1.Remove intercooler.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Intercooler.

Flush

1.Flush intercooler element using Flushing

Solvent Part No. STC 9713, following the

manufacturer's instructions.

2.Thoroughly dry intercooler ensuring that no

trace of solvent remains in the element.

3.Refit intercooler on completion.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Intercooler.

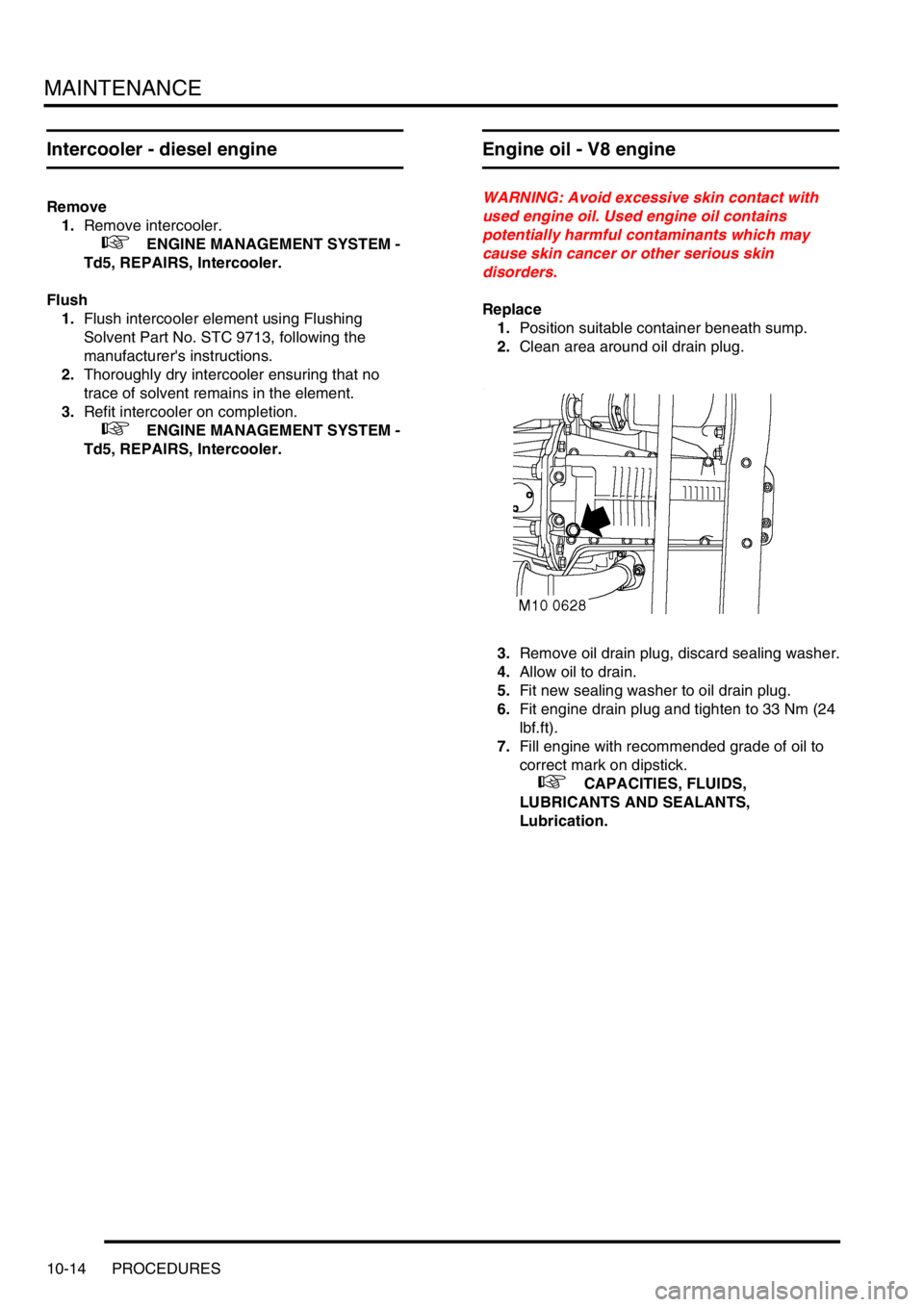

Engine oil - V8 engine

WARNING: Avoid excessive skin contact with

used engine oil. Used engine oil contains

potentially harmful contaminants which may

cause skin cancer or other serious skin

disorders.

Replace

1.Position suitable container beneath sump.

2.Clean area around oil drain plug.

3.Remove oil drain plug, discard sealing washer.

4.Allow oil to drain.

5.Fit new sealing washer to oil drain plug.

6.Fit engine drain plug and tighten to 33 Nm (24

lbf.ft).

7.Fill engine with recommended grade of oil to

correct mark on dipstick.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

Page 138 of 1529

MAINTENANCE

PROCEDURES 10-15

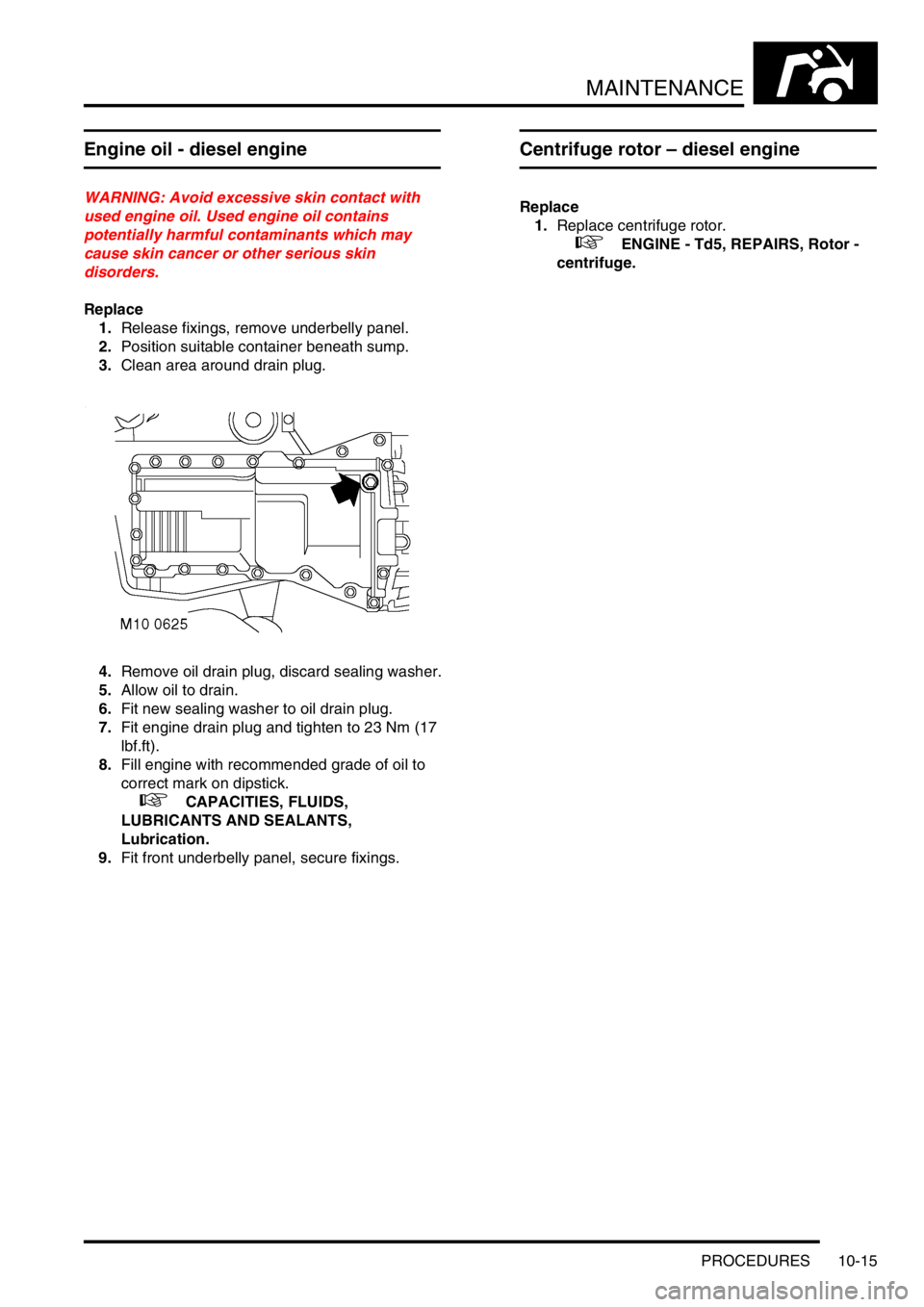

Engine oil - diesel engine

WARNING: Avoid excessive skin contact with

used engine oil. Used engine oil contains

potentially harmful contaminants which may

cause skin cancer or other serious skin

disorders.

Replace

1.Release fixings, remove underbelly panel.

2.Position suitable container beneath sump.

3.Clean area around drain plug.

4.Remove oil drain plug, discard sealing washer.

5.Allow oil to drain.

6.Fit new sealing washer to oil drain plug.

7.Fit engine drain plug and tighten to 23 Nm (17

lbf.ft).

8.Fill engine with recommended grade of oil to

correct mark on dipstick.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

9.Fit front underbelly panel, secure fixings.

Centrifuge rotor – diesel engine

Replace

1.Replace centrifuge rotor.

+ ENGINE - Td5, REPAIRS, Rotor -

centrifuge.

Page 139 of 1529

MAINTENANCE

10-16 PROCEDURES

Engine oil filter - diesel engine

Replace

1.Replace oil filter.

+ ENGINE - Td5, REPAIRS, Filter - oil.

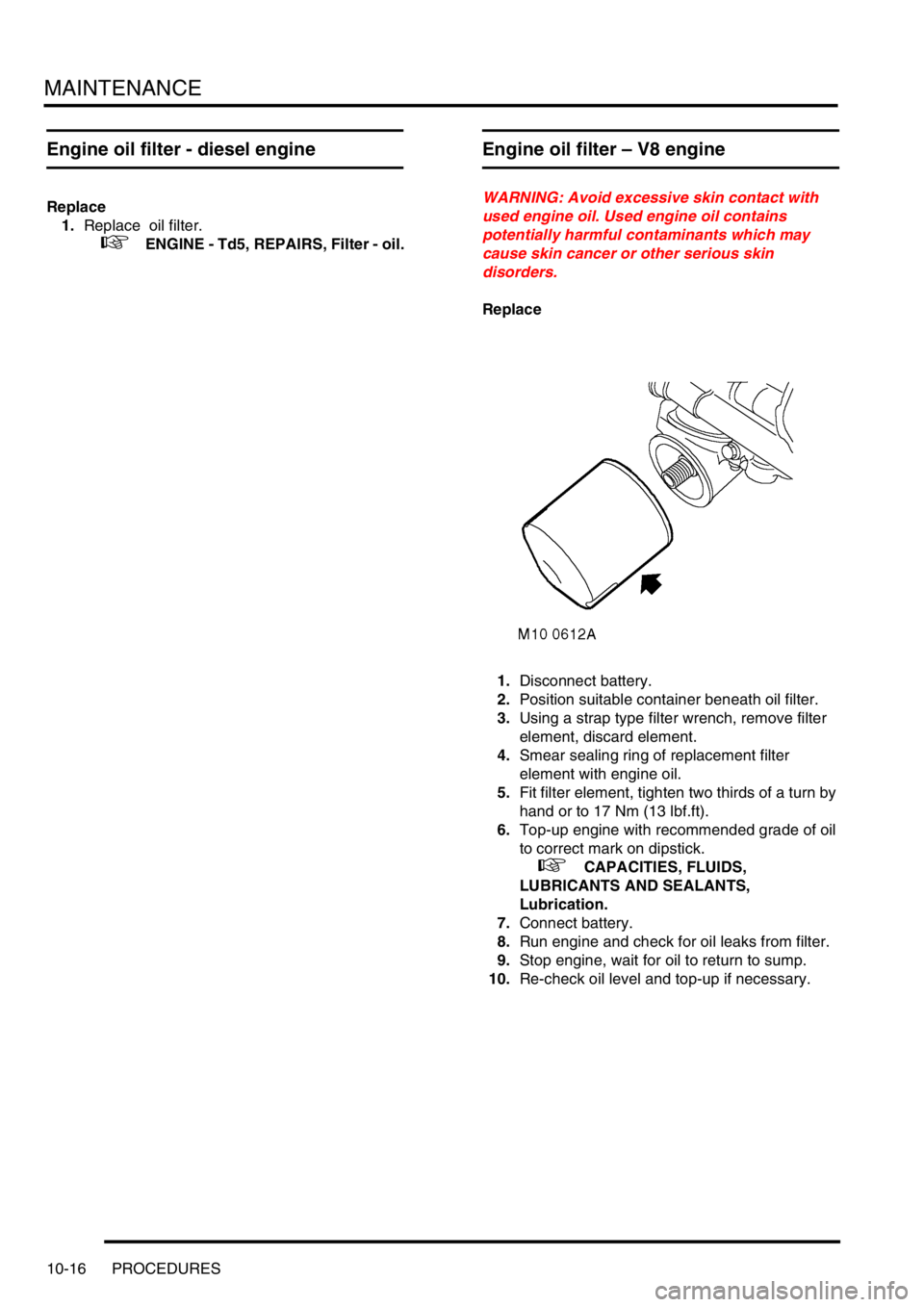

Engine oil filter – V8 engine

WARNING: Avoid excessive skin contact with

used engine oil. Used engine oil contains

potentially harmful contaminants which may

cause skin cancer or other serious skin

disorders.

Replace

1.Disconnect battery.

2.Position suitable container beneath oil filter.

3.Using a strap type filter wrench, remove filter

element, discard element.

4.Smear sealing ring of replacement filter

element with engine oil.

5.Fit filter element, tighten two thirds of a turn by

hand or to 17 Nm (13 lbf.ft).

6.Top-up engine with recommended grade of oil

to correct mark on dipstick.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

7.Connect battery.

8.Run engine and check for oil leaks from filter.

9.Stop engine, wait for oil to return to sump.

10.Re-check oil level and top-up if necessary.

Page 140 of 1529

MAINTENANCE

PROCEDURES 10-17

Manual gearbox

WARNING: Avoid excessive skin contact with

mineral oil. Mineral oils remove the natural fats

from the skin, leading to dryness, irritation and

dermatitis.

Check/top-up oil level

1.Release fixings, remove rear underbelly panel.

2.Clean area around oil filler/level plug.

3.Remove oil filler/level plug.

4.Check that oil level is to bottom of oil filler/level

plug hole.

5.Top-up level (if required) with recommended oil

to bottom of filler/level plug hole.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

6.Remove all traces of sealant from threads of oil

filler/level plug.

7.Apply Loctite 290 to threads of oil filler/level

plug.

8. Fit manual gearbox filler/level plug and tighten

to 30 Nm (22 lbf.ft).

9.Remove all traces of oil from gearcase.

10.Fit rear underbelly panel, secure fixings.Replace oil

1.Release fixings, remove rear underbelly panel.

2.Place a suitable container beneath gearbox

drain plug.

3.Clean area around oil filler/level and drain

plugs.

4.Remove oil filler/level plug.

5.Remove oil drain plug, remove and discard

sealing washer.

6.Allow oil to drain.

7.Clean magnet in oil drain plug.

8.Fit new sealing washer to oil drain plug.

9.Fit manual gearbox drain plug and tighten to 50

Nm (37 lbf.ft).

10.Fill gearbox with recommended oil to bottom of

filler/level plug hole.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

11.Remove all traces of sealant from threads of oil

filler/level plug.

12.Apply Loctite 290 to threads of oil filler/level

plug.

13. Fit manual gearbox filler/level plug and tighten

to 30 Nm (22 lbf.ft).

14.Remove all traces of oil from gearcase.

15.Fit rear underbelly panel, secure fixings.

Page 141 of 1529

MAINTENANCE

10-18 PROCEDURES

Automatic gearbox

WARNING: Avoid excessive skin contact with

mineral oil. Mineral oils remove the natural fats

from the skin, leading to dryness, irritation and

dermatitis.

Replace oil filter

1.Replace oil filter.

+ AUTOMATIC GEARBOX - ZF4HP22

- 24, REPAIRS, Filter - oil.

Replace oil

1. Ensure that gearbox is cool. Apply

handbrake and securely chock front and rear

wheels.

2.Place a suitable container beneath gearbox.

3.Clean area around oil filler/level and drain

plugs.

4.Remove oil drain plug, remove and discard

sealing washer.

5.Allow oil to drain.

6.Fit new sealing washer to oil drain plug.

7.Fit automatic gearbox drain plug and tighten to

15 Nm (11 lbf.ft).

8.Remove oil filler/level plug, remove and discard

sealing washer.

9.Fill gearbox with recommended oil to bottom of

oil level/filler plug hole.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

10.Select 'P' (Park).

11.Ensure handbrake is applied.

12.Start engine and allow it to idle.

13.Apply footbrake. 14.Move selector lever through all gear positions,

while continuing to fill the gearbox. Select 'P'

(Park).

15.With engine idling, continue filling gearbox until

a 2 mm bead of oil runs from oil filler/level plug

hole.

16.Fit new sealing washer to automatic gearbox

filler/level plug, fit plug and tighten to 30 Nm (22

l b f . f t ) .

17.Stop engine.

18.Remove all traces of oil from gearbox casing.

Page 142 of 1529

MAINTENANCE

PROCEDURES 10-19

Transfer box

WARNING: Avoid excessive skin contact with

mineral oil. Mineral oils remove the natural fats

from the skin, leading to dryness, irritation and

dermatitis.

Check/top-up oil level

1.Release fixings, remove rear underbelly panel.

2.Clean area around oil filler/level plug.

3.Remove oil filler/level plug.

4.Check that oil level is to bottom of filler/level

plug hole.

5.Top-up level (if required) with recommended oil

to bottom of oil filler/level plug hole.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

6. Fit transfer box filler/level plug and tighten to 25

Nm (18 lbf.ft).

7.Remove all traces of oil from main casing.

8.Fit rear underbelly panel (if fitted), secure

fixings.Replace oil

1. Release fixings, remove rear underbelly panel.

2.Place a suitable container beneath transfer box

drain plug.

3.Clean area around oil filler/level and drain

plugs.

4.Remove oil filler/level plug.

5.Remove oil drain plug.

6.Allow oil to drain.

7. Fit transfer box drain plug and tighten to 30

Nm (22 lbf.ft).

8.Fill transfer box with recommended oil to

bottom of oil filler/level plug hole.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

9. Fit transfer box filler/level plug and tighten to 25

Nm (18 lbf.ft).

10. Remove all traces of oil from transfer box.

11.Fit rear underbelly panel (if fitted), secure

fixings.

Page 143 of 1529

MAINTENANCE

10-20 PROCEDURES

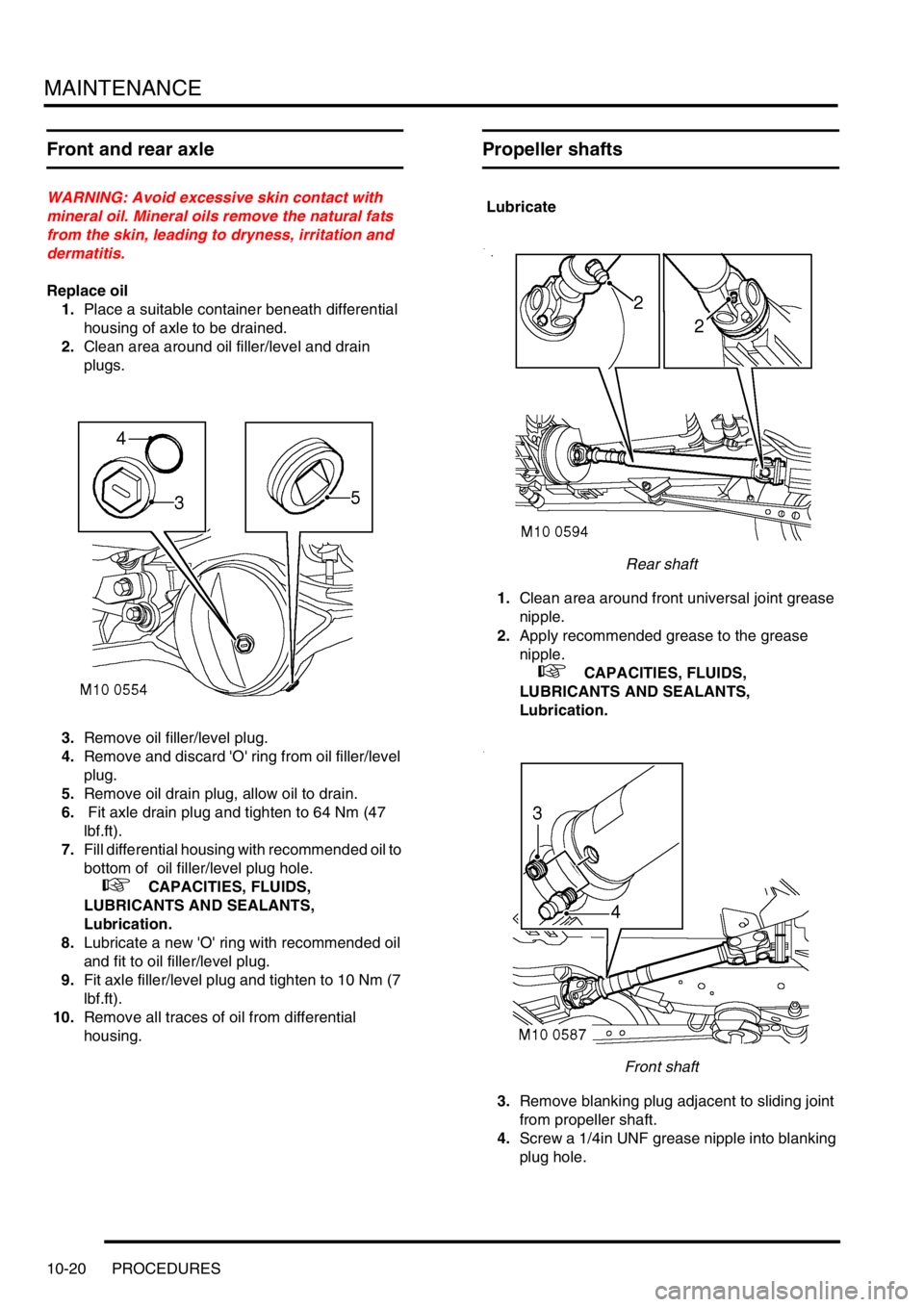

Front and rear axle

WARNING: Avoid excessive skin contact with

mineral oil. Mineral oils remove the natural fats

from the skin, leading to dryness, irritation and

dermatitis.

Replace oil

1.Place a suitable container beneath differential

housing of axle to be drained.

2.Clean area around oil filler/level and drain

plugs.

3.Remove oil filler/level plug.

4.Remove and discard 'O' ring from oil filler/level

plug.

5.Remove oil drain plug, allow oil to drain.

6. Fit axle drain plug and tighten to 64 Nm (47

lbf.ft).

7.Fill differential housing with recommended oil to

bottom of oil filler/level plug hole.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

8.Lubricate a new 'O' ring with recommended oil

and fit to oil filler/level plug.

9.Fit axle filler/level plug and tighten to 10 Nm (7

lbf.ft).

10.Remove all traces of oil from differential

housing.

Propeller shafts

Lubricate

Rear shaft

1.Clean area around front universal joint grease

nipple.

2.Apply recommended grease to the grease

nipple.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

Front shaft

3.Remove blanking plug adjacent to sliding joint

from propeller shaft.

4.Screw a 1/4in UNF grease nipple into blanking

plug hole.

Page 154 of 1529

MAINTENANCE

PROCEDURES 10-31

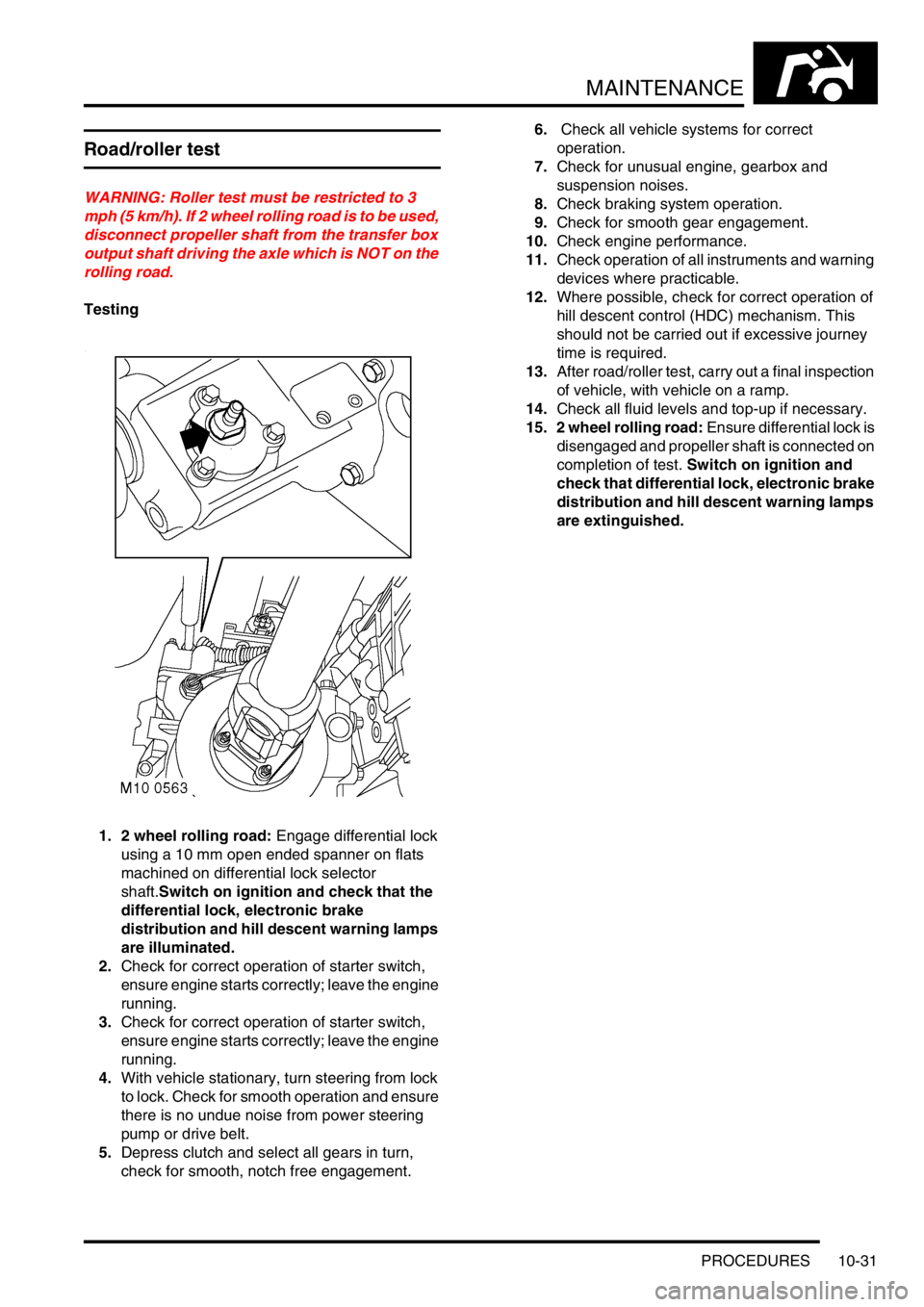

Road/roller test

WARNING: Roller test must be restricted to 3

mph (5 km/h). If 2 wheel rolling road is to be used,

disconnect propeller shaft from the transfer box

output shaft driving the axle which is NOT on the

rolling road.

Testing

1. 2 wheel rolling road: Engage differential lock

using a 10 mm open ended spanner on flats

machined on differential lock selector

shaft.Switch on ignition and check that the

differential lock, electronic brake

distribution and hill descent warning lamps

are illuminated.

2.Check for correct operation of starter switch,

ensure engine starts correctly; leave the engine

running.

3.Check for correct operation of starter switch,

ensure engine starts correctly; leave the engine

running.

4.With vehicle stationary, turn steering from lock

to lock. Check for smooth operation and ensure

there is no undue noise from power steering

pump or drive belt.

5.Depress clutch and select all gears in turn,

check for smooth, notch free engagement.6. Check all vehicle systems for correct

operation.

7.Check for unusual engine, gearbox and

suspension noises.

8.Check braking system operation.

9.Check for smooth gear engagement.

10.Check engine performance.

11.Check operation of all instruments and warning

devices where practicable.

12.Where possible, check for correct operation of

hill descent control (HDC) mechanism. This

should not be carried out if excessive journey

time is required.

13.After road/roller test, carry out a final inspection

of vehicle, with vehicle on a ramp.

14.Check all fluid levels and top-up if necessary.

15. 2 wheel rolling road: Ensure differential lock is

disengaged and propeller shaft is connected on

completion of test. Switch on ignition and

check that differential lock, electronic brake

distribution and hill descent warning lamps

are extinguished.