alternator LAND ROVER DISCOVERY 1999 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 1171 of 1529

HEATING AND VENTILATION

80-14DESCRIPTION AND OPERATION

Coolant temperature control

When the ECU first enters the active mode, it initiates a start to full load combustion. Full load combustion continues

until the heat exchanger casing temperature reaches 60 °C (140 °F), when the ECU decreases the speed of the FBH

fuel pump and the combustion air fan to half speed, to produce part load combustion. The ECU maintains part load

combustion while the heat exchanger casing temperature remains between 54 and 65 °C (129 and 149 °F). If the heat

exchanger casing temperature decreases to 54 °C (129 °F), the ECU switches the system to full load combustion

again. If the heat exchanger casing temperature increases to 65 °C (149 °F), the ECU enters a control idle phase of

operation.

On entering the control idle phase, the ECU immediately switches the FBH fuel pump off, to stop combustion, and

starts a timer for the combustion air fan. After a 2 minute cooldown period, the ECU switches the combustion air fan

off and then remains in the control idle phase while the heat exchanger casing temperature remains above 59 °C (138

°F). If the heat exchanger casing temperature decreases to 59 °C (138 °F), within 15 minutes of the ECU entering the

control idle phase, the ECU initiates a start to part load combustion. If more than 15 minutes elapse before the heat

exchanger casing temperature decreases to 59 °C (138 °F), the ECU initiates a start to full load combustion.

In order to limit the build-up of carbon deposits on the glow plug/flame sensor, the ECU also enters the control idle

phase if the continuous part and/or full load combustion time exceeds 72 minutes. After the cooldown period, if the

heat exchanger casing is still in the temperature range that requires additional heat, the ECU initiates an immediate

restart to part or full load combustion, as appropriate.

Shutdown

The FBH system is de-activated when the alternator power supply to the FBH unit is disconnected, either by the

engine stopping or, if the ambient temperature increases to 5 °C (41 °F) or above, by the contacts in the air

temperature sensor opening. If the system is active when the alternator power supply is disconnected, the ECU de-

energises the FBH fuel pump to stop combustion, but continues operation of the combustion air fan and the circulation

pump to cool down the FBH unit. The cool down time depends on the combustion load at the time the alternator power

input is disconnected.

Cool down times

Diagnostics

The ECU in the FBH unit monitors the system for faults. Any faults detected are stored in a volatile memory in the the

ECU, which can be interrogated by Testbook. A maximum of three faults and associated freeze frame data can be

stored at any one time. If a further fault is detected, the oldest fault is overwritten by the new fault.

The ECU also incorporates an error lockout mode of operation that inhibits system operation to prevent serious faults

from causing further damage to the system. In the error lockout mode, the ECU immediately stops the FBH fuel pump,

and stops the combustion air fan and circulation pump after a cool down time of approximately 2 minutes. Error lockout

occurs for start sequence failures and/or combustion flameouts, heat exchanger casing overheat and out of limit input

voltage. The error lockout mode can be cleared using Testbook, or by disconnecting the battery power supply for a

minimum of 10 seconds.

Start failure/flameout. If a start sequence fails to establish combustion, or a flameout occurs after combustion is

established, the ECU immediately initiates another start sequence. The start failure or flameout is also recorded by

an event timer in the ECU. The event timer is increased by one after each start failure or flameout, and decreased by

one if a subsequent start is successful. If the event timer increases to three (over any number of drive cycles), the

ECU enters the error lockout mode.

Heat exchanger casing overheat. To protect the system from excessive temperatures, the ECU enters the error

lockout mode if the heat exchanger casing temperature exceeds 105 °C (221 °F).

Out of limit voltage. The ECU enters the error lockout mode if the battery or alternator power input is less than 10.5 ±

0.3 V for more than 20 seconds, or more than 15.5 ± 0.5 V for more than 6 seconds.

Combustion load Cool down time, seconds

Part 100

Full 175

Page 1266 of 1529

CHARGING AND STARTING

REPAIRS 86-1-1

CHARGING AND STARTING REPAIRS

Alternator - diesel

$% 86.10.02

Remove

1.Remove auxiliary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Belt - auxiliary drive.

2.Release cover and remove nut securing lead

to alternator.

3.Disconnect alternator multiplug.

4.Remove bolt (LH thread) and remove auxiliary

drive belt tensioner. 5.Remove bolt securing support stay to

alternator.

6.Release clip and disconnect oil drain hose from

vacuum pump.

7.Disconnect vacuum pump oil supply pipe from

cylinder head and discard 'O' ring.

8.Remove bolt securing alternator and release

from mounting bracket.

9.Disconnect vacuum hose from vacuum pump.

10.Remove alternator. Take care not to damage

radiator cooling fins.

11.Remove 4 bolts, and remove vacuum pump

from alternator.

CAUTION: Always fit plugs to open

connections to prevent contamination.

Page 1267 of 1529

CHARGING AND STARTING

86-1-2 REPAIRS

Refit

1.Clean mating faces of alternator and vacuum

pump.

2.Fit vacuum pump to alternator and tighten

bolts to 8 Nm (6 lbf.ft).

3.Position alternator to engine and connect

multiplug.

4.Connect vacuum hose and oil drain hose to

vacuum pump and secure clips.

5.With assistance align alternator to mounting

bracket and fit but do not tighten bolt.

6.Fit bolt securing support stay to alternator and

tighten to 25 Nm (18 lbf.ft) .

7.Tighten bolt securing alternator to mounting

bracket to 45 Nm (33 lbf.ft).

8.Using new 'O' ring, connect oil supply pipe to

cylinder head and tighten to 10 Nm (7 lbf.ft).

9.Connect lead to alternator and tighten nut to 6

Nm (4.4 lbf.ft).

10.Fit auxiliary drive belt tensioner and tighten bolt

to 50 Nm (37 lbf.ft).

11.Fit auxiliary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Belt - auxiliary drive.

Page 1268 of 1529

CHARGING AND STARTING

REPAIRS 86-1-3

Alternator - V8

$% 86.10.02

Remove

1.Remove auxiliary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Belt - auxiliary drive.

2.Remove 2 bolts securing alternator to

mounting bracket.

3.Release alternator from mounting bracket

4.Remove nuts securing alternator cables, and

release cables. 5.Remove alternator from mounting bracket.

6.Remove pulley from alternator.

Refit

1.Fit alternator pulley and tighten nut to 80 Nm

(59 lbf.ft).

2.Position alternator to mounting bracket.

3.Connect alternator cables and tighten B+ nut to

18 Nm (13 lbf.ft), and D+ nut to 5 Nm (3.7 lbf.ft).

4.Locate alternator in mounting bracket.

5.Fit alternator mounting bolts and tighten to 45

Nm (33 lbf.ft).

6.Fit auxiliary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Belt - auxiliary drive.

Page 1414 of 1529

HARNESSES

REPAIRS 86-7-9

6.Disconnect air conditioning compressor

multiplug.

7.Remove 2 nuts securing alternator cables and

release cables. 8.Disconnect coolant temperature sensor

multiplug.

9.Release 2 harness clips from coolant rail.

10.Remove nut securing engine harness positive

lead to battery, release lead and position

aside.

Page 1417 of 1529

HARNESSES

86-7-12 REPAIRS

Refit

1.Position engine harness around engine.

2.Connect oil pressure switch and camshaft

sensor multiplugs.

3.Fit and tighten bolt securing harness to LH side

of engine.

4.Connect both knock sensor multiplugs.

5.Connect battery cable and solenoid cable to

starter motor.

6.Position starter heat shield and secure with

bolt.

7.Clean exhaust flange mating faces, using a

new gasket align exhaust fit nuts and tighten to

60 Nm (44 lbf.ft).

8.Remove stand(s) and lower vehicle.

9.Position harness into footwell and secure

grommet.

10.Connect ECM multiplugs.

11.Position toe board and secure with trim fixings.

12.Connect engine harness to main harness

multiplug and secure earth lead.

13.Connect EVAP solenoid multiplug.

14.Connect both fuse box multiplugs.

15.Position starter lead to fuse box and secure

screw.

16.Fit fuse box cover.

17.Position battery positive lead to battery and

secure nut.

18.Secure harness to coolant rail.

19.Position alternator cables and tighten terminal

B+ to 18 Nm (13 lbf.ft) and terminal D+ to 5 Nm

(3.7 lbf.ft)

20.Connect coolant temperature sensor multiplug.

21.Connect A/C compressor multiplug.

22.Secure harness clip to rear of LH cylinder head.

23.Connect CKP sensor multiplug.

24.Secure injector harness and connect injector

multiplugs.

25.Connect coil multiplugs.

26.Connect and secure HS

2O sensor multiplug

27.Fit upper inlet manifold.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Gasket - inlet

manifold - upper - Without Secondary Air

Injection.

28.Connect battery earth lead.

Harness - engine - diesel

$% 86.70.17

Remove

1.Remove engine acoustic cover.

2.Remove battery carrier.

+ CHARGING AND STARTING,

REPAIRS, Battery carrier.

3.Remove engine compartment fuse box cover.

4.Remove bolts securing battery and alternator

leads to fuse box.

5.Remove bolt securing heater plug lead to fuse

box.

6.Disconnect 2 engine harness multiplugs from

fuse box.

Page 1419 of 1529

HARNESSES

86-7-14 REPAIRS

13.Disconnect multiplug from fuel temperature

sensor.

14.Release harness clip from coolant pipe. 15.Disconnect multiplug from MAP sensor.

16.Disconnect 4 glow plug connectors.

17.Release nut securing battery lead to alternator

and disconnect multiplug from alternator.

18.Disconnect injector multiplug.

19.Remove 2 bolts securing harness to front of

cylinder head.

20.Disconnect multiplug from ECT sensor.

Page 1420 of 1529

HARNESSES

REPAIRS 86-7-15

21.Disconnect multiplugs from A/C compressor,

turbocharger solenoid valve, AAP sensor and

MAF sensor.

22.Release harness clips from coolant hose and

PAS hose.

23.Note the route of the engine harness, release

from underneath of inlet manifold and remove

from engine.

Refit

1.Position harness on engine.

2.Connect multiplugs to A/C compressor,

turbocharger solenoid valve, AAP and MAF

sensors.

3.Position harness clips to coolant and PAS

hoses.

4.Connect multiplug to ECT sensor.

5.Position harness to front of cylinder head and

tighten bolts to 10 Nm (7 lbf.ft).

6.Connect injector multiplug.

7.Connect multiplug and position battery cable to

alternator and tighten nut.

8.Connect multiplug to fuel temperature sensor.

9.Connect multiplug to MAP sensor.

10.Connect glow plugs.

11.Connect CKP sensor multiplug.

12.Connect Lucar to starter solenoid.

13.Connect battery lead to starter solenoid and

tighten nut to 10 Nm (7 lbf.ft).

14.Position harness clip to coolant pipe.

15.Locate harness over bell housing and connect

multiplug to oil pressure switch.

16.Connect 2 multiplugs to EGR solenoids.

17.Connect engine harness multiplug to ECM and

main harness.

18.Connect engine harness multiplugs to fuse

box.

19.Position glow plug lead to fuse box and tighten

bolt to 3.5 Nm (2.6 lbf.ft).

20.Position battery and alternator leads to fuse

box and tighten bolts to 6 Nm (4.4 lbf.ft).

21.Fit engine compartment fuse box cover.

22.Fit battery carrier.

23.Fit engine acoustic cover.

Harness - main

$% 86.70.07

Remove

1.Remove heater assembly.

+ HEATING AND VENTILATION,

REPAIRS, Heater assembly - models with

air conditioning.

+ HEATING AND VENTILATION,

REPAIRS, Heater assembly - models

without air conditioning.

2.Remove 4 clips securing LH and RH trim

panels to lower 'A' post.

3.Remove both lower 'A' post trim panels.

4.Remove air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

V8, REPAIRS, Air cleaner assembly.

5.Remove battery tray.

6.Remove front bumper.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper assembly - front.

Page 1484 of 1529

INSTRUMENTS

DESCRIPTION AND OPERATION 88-1

INS TRUMENTS DESCRIPTION AND OPERAT ION

Instrument pack

1Hill descent control information warning lamp

2Overspeed warning lamp

3Brake system warning lamp

4Malfunction Indicator Lamp (MIL)

5Tachometer

6Direction indicator warning lamp

7Main beam warning lamp

8Direction indicator warning lamp

9Speedometer

10SRS warning lamp

11Off road mode warning lamp

12Glow plug warning lamp

13Trailer warning lamp

14Water in fuel filter warning lamp

15Transmission high temperature warning lamp

16Seat belt warning lamp17Fuel tank level gauge

18Low fuel level warning lamp

19LCD odometer/trip meter

20Anti-theft status warning lamp

21ABS warning lamp

22Gearbox manual/sport mode warning lamp

23Alternator charge warning lamp

24ACE warning lamp

25Oil pressure warning lamp

26SLS warning lamp

27Hill descent control warning lamp

28Engine coolant temperature gauge

29High coolant temperature warning lamp

30Traction control warning lamp

31Differential lock warning lamp

32Transfer box neutral warning lamp

Page 1485 of 1529

INSTRUMENTS

88-2 DESCRIPTION AND OPERATION

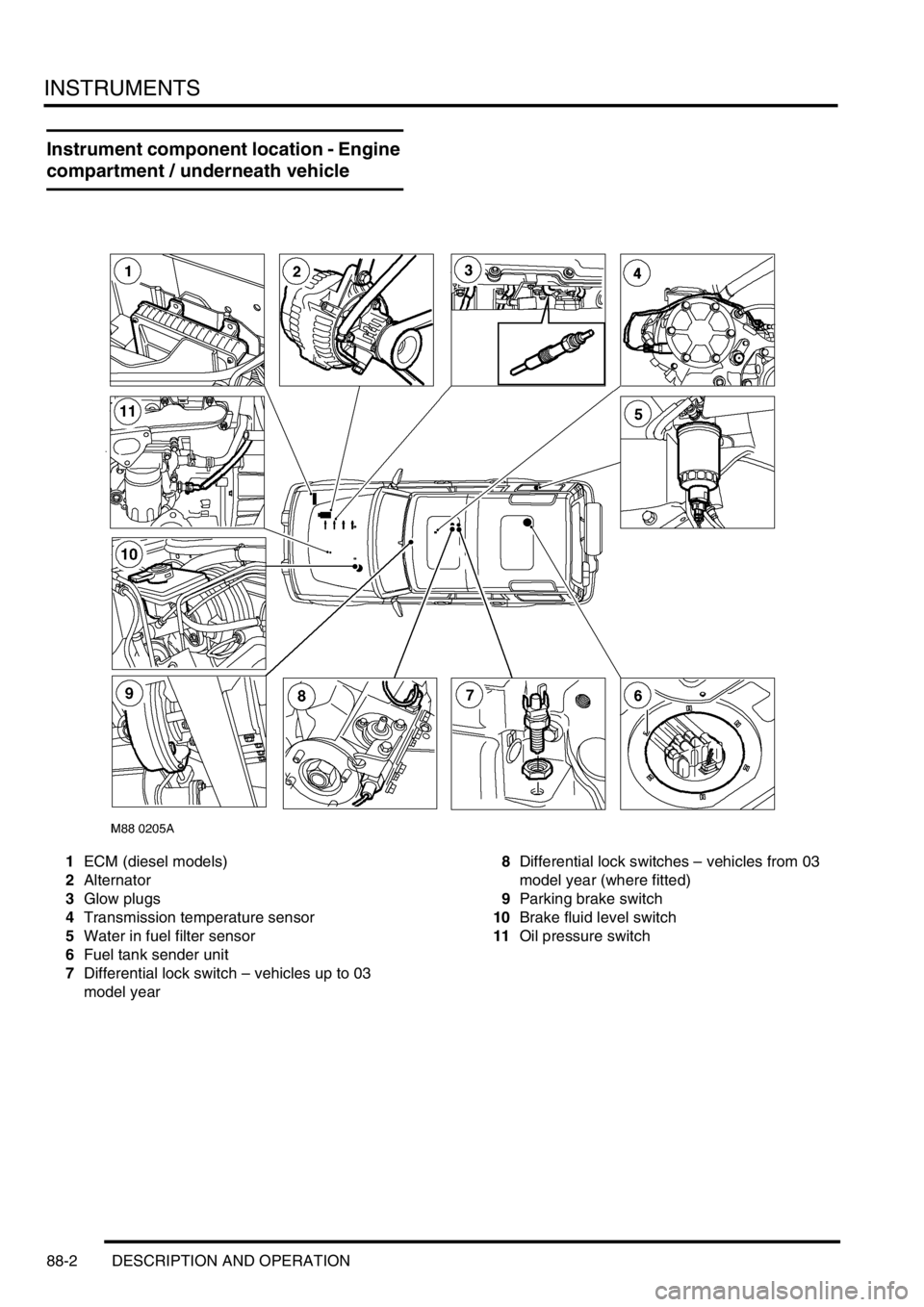

Instrument component location - Engine

compartment / underneath vehicle

1ECM (diesel models)

2Alternator

3Glow plugs

4Transmission temperature sensor

5Water in fuel filter sensor

6Fuel tank sender unit

7Differential lock switch – vehicles up to 03

model year8Differential lock switches – vehicles from 03

model year (where fitted)

9Parking brake switch

10Brake fluid level switch

11Oil pressure switch