cooling system - v8 LAND ROVER DISCOVERY 1999 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 797 of 1529

FRONT SUSPENSION

60-52 REPAIRS

Pipe assembly - pump or reservoir to

valve block - ACE - V8

$% 60.60.32

Introduction

CAUTION: The ACE hydraulic system is

extremely sensitive to the ingress of dirt or

debris. The smallest amount could render the

system unserviceable. It is imperative that the

following precautions are taken.

lACE components are thoroughly cleaned

externally before work commences;

lall opened pipe and module ports are

capped immediately;

lall fluid is stored in and administered

through clean containers.

Remove

1.To avoid any possibility of swarf ingress,

remove the valve block.

+ FRONT SUSPENSION, REPAIRS,

Valve block - ACE.

2.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

3.Remove RH front road wheel.

4.Remove 3 screws and remove splash shield.

5.Remove viscous fan.

+ COOLING SYSTEM - V8, REPAIRS,

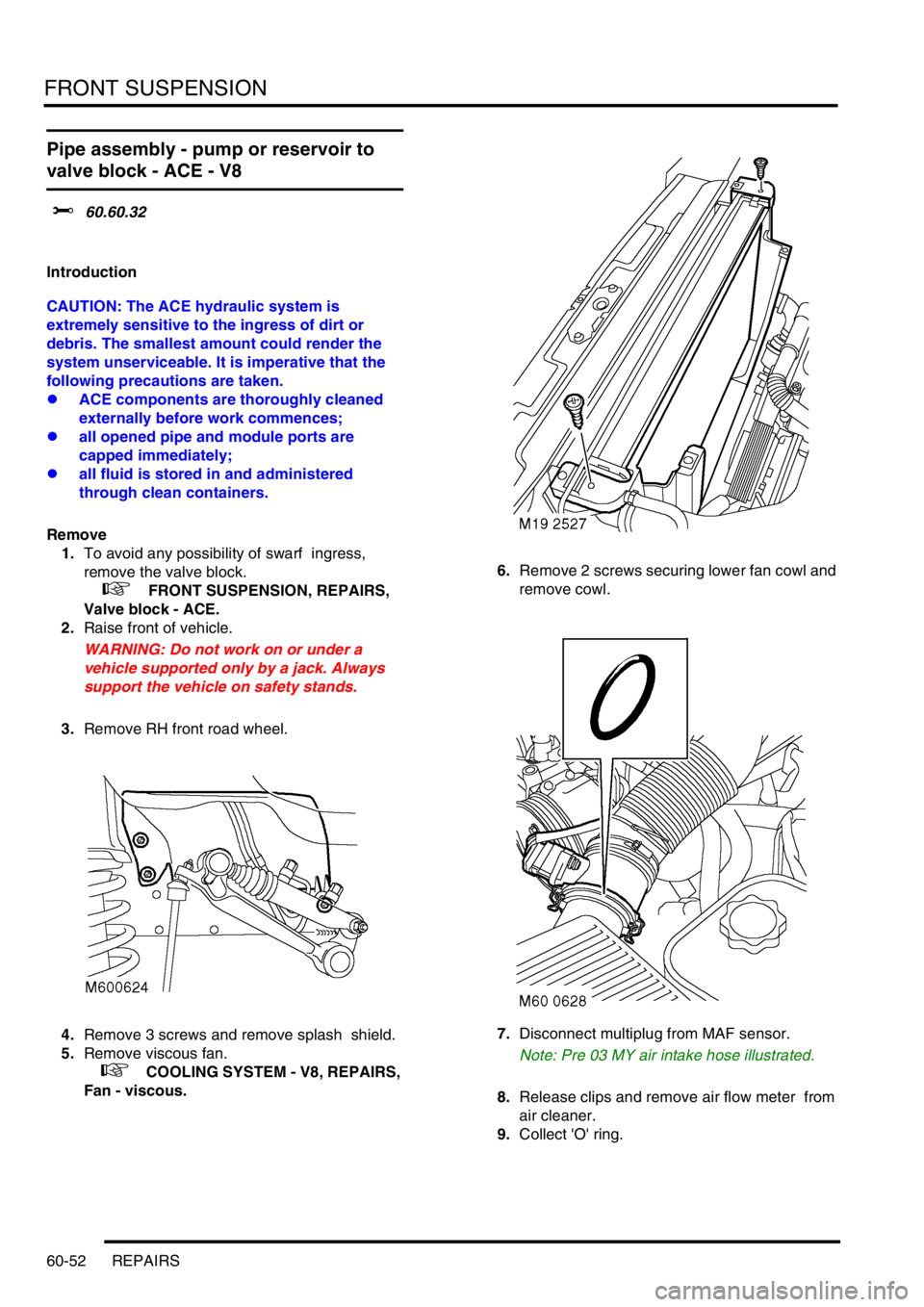

Fan - viscous.6.Remove 2 screws securing lower fan cowl and

remove cowl.

7.Disconnect multiplug from MAF sensor.

Note: Pre 03 MY air intake hose illustrated.

8.Release clips and remove air flow meter from

air cleaner.

9.Collect 'O' ring.

Page 799 of 1529

FRONT SUSPENSION

60-54 REPAIRS

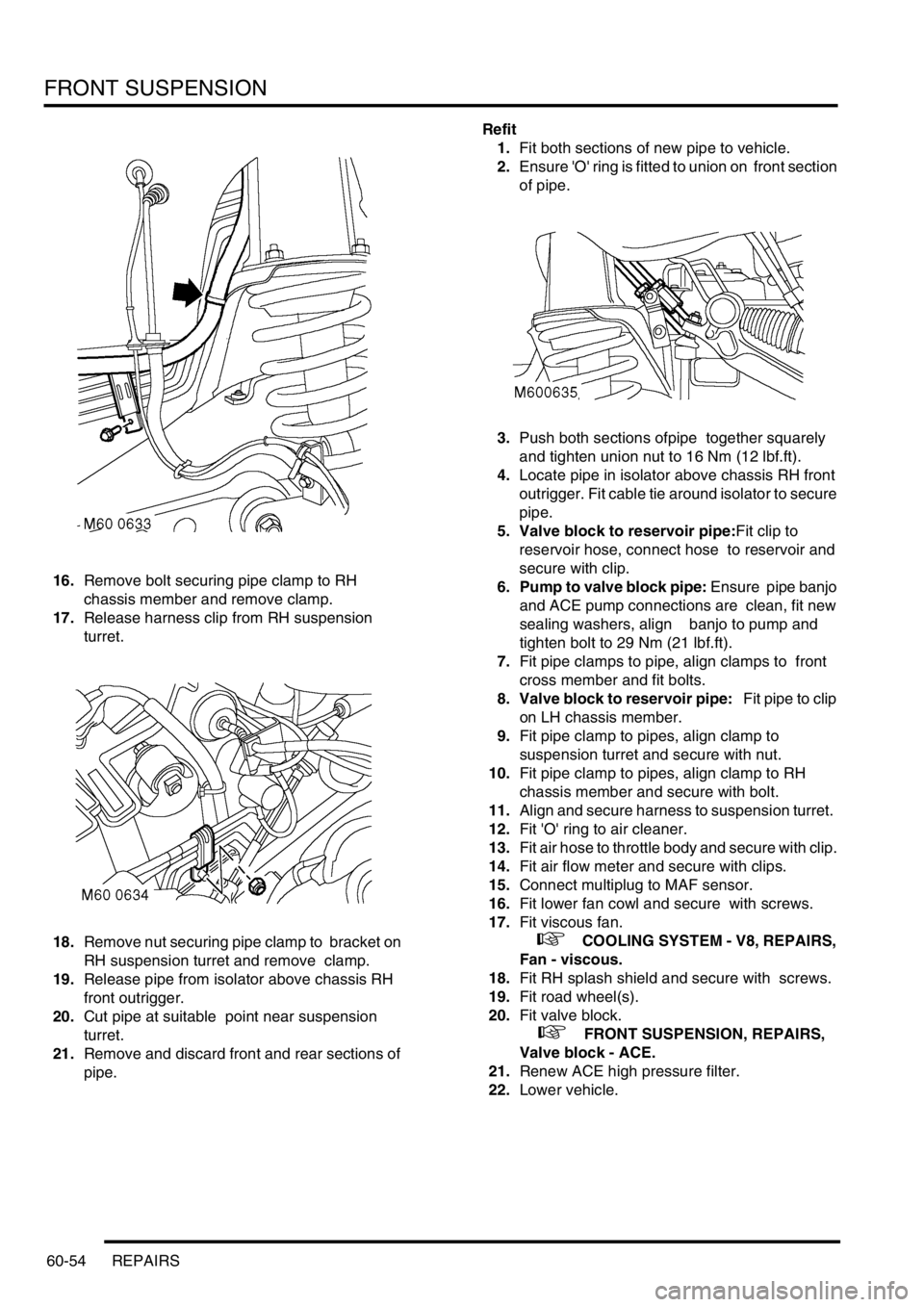

16.Remove bolt securing pipe clamp to RH

chassis member and remove clamp.

17.Release harness clip from RH suspension

turret.

18.Remove nut securing pipe clamp to bracket on

RH suspension turret and remove clamp.

19.Release pipe from isolator above chassis RH

front outrigger.

20.Cut pipe at suitable point near suspension

turret.

21.Remove and discard front and rear sections of

pipe. Refit

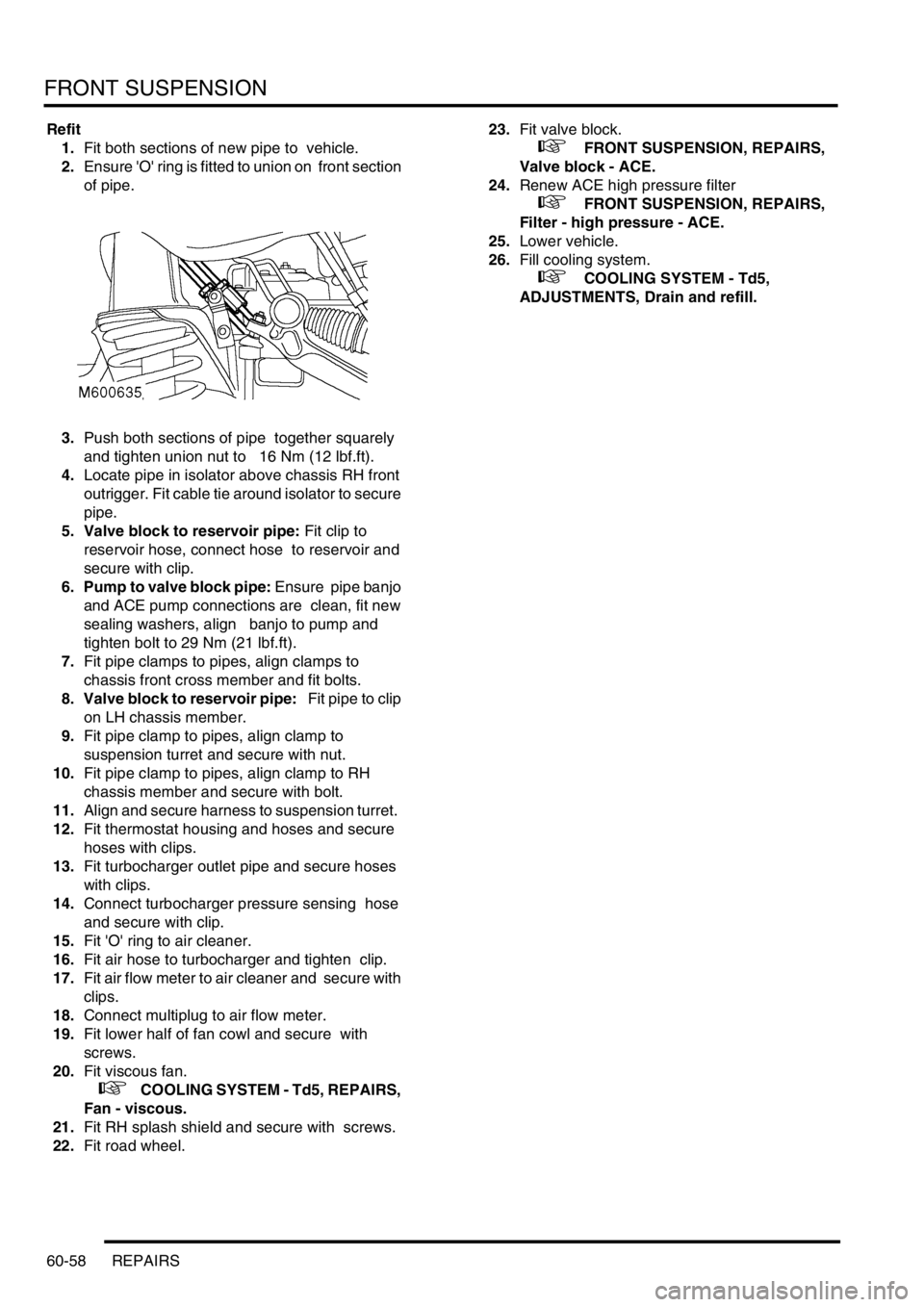

1.Fit both sections of new pipe to vehicle.

2.Ensure 'O' ring is fitted to union on front section

of pipe.

3.Push both sections ofpipe together squarely

and tighten union nut to 16 Nm (12 lbf.ft).

4.Locate pipe in isolator above chassis RH front

outrigger. Fit cable tie around isolator to secure

pipe.

5. Valve block to reservoir pipe:Fit clip to

reservoir hose, connect hose to reservoir and

secure with clip.

6. Pump to valve block pipe: Ensure pipe banjo

and ACE pump connections are clean, fit new

sealing washers, align banjo to pump and

tighten bolt to 29 Nm (21 lbf.ft).

7.Fit pipe clamps to pipe, align clamps to front

cross member and fit bolts.

8. Valve block to reservoir pipe: Fit pipe to clip

on LH chassis member.

9.Fit pipe clamp to pipes, align clamp to

suspension turret and secure with nut.

10.Fit pipe clamp to pipes, align clamp to RH

chassis member and secure with bolt.

11.Align and secure harness to suspension turret.

12.Fit 'O' ring to air cleaner.

13.Fit air hose to throttle body and secure with clip.

14.Fit air flow meter and secure with clips.

15.Connect multiplug to MAF sensor.

16.Fit lower fan cowl and secure with screws.

17.Fit viscous fan.

+ COOLING SYSTEM - V8, REPAIRS,

Fan - viscous.

18.Fit RH splash shield and secure with screws.

19.Fit road wheel(s).

20.Fit valve block.

+ FRONT SUSPENSION, REPAIRS,

Valve block - ACE.

21.Renew ACE high pressure filter.

22.Lower vehicle.

Page 800 of 1529

FRONT SUSPENSION

REPAIRS 60-55

Pipe assembly - pump or reservoir to

valve block - ACE - diesel

$% 60.60.32

CAUTION: The ACE hydraulic system is

extremely sensitive to the ingress of dirt or

debris. The smallest amount could render the

system unserviceable. It is imperative that the

following precautions are taken.

lACE components are thoroughly cleaned

externally before work commences;

lall opened pipe and module ports are

capped immediately;

lall fluid is stored in and administered

through clean containers.

Remove

1.To avoid any possibility of swarf ingress,

remove valve block.

+ FRONT SUSPENSION, REPAIRS,

Valve block - ACE.

2.Drain cooling system.

+ COOLING SYSTEM - Td5,

ADJUSTMENTS, Drain and refill.

3.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

4.Remove RH front road wheel.

5.Remove 3 screws and remove splash shield.

6.Remove viscous fan.

+ COOLING SYSTEM - Td5, REPAIRS,

Fan - viscous.7.Remove 2 screws securing lower half of fan

cowl and remove cowl.

8.Disconnect multiplug from air flow meter.

9.Release clips and remove air flow meter from

air cleaner.

10.Collect 'O' ring.

Page 803 of 1529

FRONT SUSPENSION

60-58 REPAIRS

Refit

1.Fit both sections of new pipe to vehicle.

2.Ensure 'O' ring is fitted to union on front section

of pipe.

3.Push both sections of pipe together squarely

and tighten union nut to 16 Nm (12 lbf.ft).

4.Locate pipe in isolator above chassis RH front

outrigger. Fit cable tie around isolator to secure

pipe.

5. Valve block to reservoir pipe: Fit clip to

reservoir hose, connect hose to reservoir and

secure with clip.

6. Pump to valve block pipe: Ensure pipe banjo

and ACE pump connections are clean, fit new

sealing washers, align banjo to pump and

tighten bolt to 29 Nm (21 lbf.ft).

7.Fit pipe clamps to pipes, align clamps to

chassis front cross member and fit bolts.

8. Valve block to reservoir pipe: F it pi pe to c li p

on LH chassis member.

9.Fit pipe clamp to pipes, align clamp to

suspension turret and secure with nut.

10.Fit pipe clamp to pipes, align clamp to RH

chassis member and secure with bolt.

11.Align and secure harness to suspension turret.

12.Fit thermostat housing and hoses and secure

hoses with clips.

13.Fit turbocharger outlet pipe and secure hoses

with clips.

14.Connect turbocharger pressure sensing hose

and secure with clip.

15.Fit 'O' ring to air cleaner.

16.Fit air hose to turbocharger and tighten clip.

17.Fit air flow meter to air cleaner and secure with

clips.

18.Connect multiplug to air flow meter.

19.Fit lower half of fan cowl and secure with

screws.

20.Fit viscous fan.

+ COOLING SYSTEM - Td5, REPAIRS,

Fan - viscous.

21.Fit RH splash shield and secure with screws.

22.Fit road wheel.23.Fit valve block.

+ FRONT SUSPENSION, REPAIRS,

Valve block - ACE.

24.Renew ACE high pressure filter

+ FRONT SUSPENSION, REPAIRS,

Filter - high pressure - ACE.

25.Lower vehicle.

26.Fill cooling system.

+ COOLING SYSTEM - Td5,

ADJUSTMENTS, Drain and refill.

Page 1179 of 1529

HEATING AND VENTILATION

80-22REPAIRS

Heater assembly - models without air

conditioning

$% 80.20.01.99

Remove

1.Drain cooling system.

l

+ COOLING SYSTEM - Td5,

ADJUSTMENTS, Drain and refill.

l

+ COOLING SYSTEM - V8,

ADJUSTMENTS, Drain and refill.

2. Diesel models: Remove 3 bolts and remove

engine cover.

3.Release clips and disconnect coolant hoses

from heater pipes.

CAUTION: Always fit plugs to open

connections to prevent contamination.

4.Remove facia assembly.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Fascia.5.Disconnect harness multiplug from heater

blower motor.

6.Remove bolt and 2 nuts securing heater

blower housing assembly to body and remove

blower.

7.Disconnect 2 drain tubes from base of heater.

Page 1180 of 1529

HEATING AND VENTILATION

REPAIRS 80-23

8.Remove 2 screws securing console bracket to

tunnel and remove bracket.

9.Release radio coaxial cable from behind heater

pipes.

10.Protect the carpet from coolant spillage.

11.Remove 4 nuts and 1 bolt securing heater to

body.

12.Remove heater from vehicle.

13.Remove 2 screws securing heater RH and LH

footwell outlet duct to heater casing and

remove ducts. 14.Remove 2 screws securing matrix pipe bracket

to heater casing.

15.Remove screw securing pipe clamp to heater

casing and remove clamp.

16.Carefully remove matrix from heater.

Refit

1.Fit matrix into heater casing.

2.Fit screws securing pipe bracket to heater

casing.

3.Fit pipe clamp and secure with screw.

4.Fit heater ducts and secure with screws.

5.Position heater assembly to vehicle, ensure

heater coolant pipe grommet is correctly

located in bulkhead and secure with nuts and

bolt.

6.Fit radio coaxial cable behind heater pipes.

7.Fit console bracket and secure with screws.

8.Connect drain tubes to base of heater.

9.Fit blower unit to heater and secure to body

with nuts and bolt.

10.Connect harness multiplug to blower motor.

11.Fit facia assembly

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Fascia.

12.Connect heater hoses and secure with clips.

13. Diesel models: Fit engine cover and secure

with bolts.

14.Refill cooling system

l

+ COOLING SYSTEM - Td5,

ADJUSTMENTS, Drain and refill.

l

+ COOLING SYSTEM - V8,

ADJUSTMENTS, Drain and refill.

Page 1181 of 1529

HEATING AND VENTILATION

80-24REPAIRS

Heater assembly - models with air

conditioning

$% 80.20.01.98

Remove

1.Drain cooling system.

l

+ COOLING SYSTEM - V8,

ADJUSTMENTS, Drain and refill.

l

+ COOLING SYSTEM - Td5,

ADJUSTMENTS, Drain and refill.

2.Evacuate air conditioning system.

+ AIR CONDITIONING, REFRIGERANT

RECOVERY, RECYCLING AND

RECHARGING, Refrigerant recovery,

recycling and recharging.

3.Release 2 clips securing heater hoses to

heater and release hoses.

4.Remove 2 bolts securing air conditioning pipes

to evaporator, release pipes and discard 'O'

rings.

CAUTION: Always fit plugs to open

connections to prevent contamination.

5.Remove fascia.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Fascia.6.Remove screws securing rear heater ducting

and remove ducting.

7.Disconnect multiplug from heater motor.

8.Remove 2 nuts and bolt securing heater motor

assembly and remove motor assembly from

heater casing.

Page 1182 of 1529

HEATING AND VENTILATION

REPAIRS 80-25

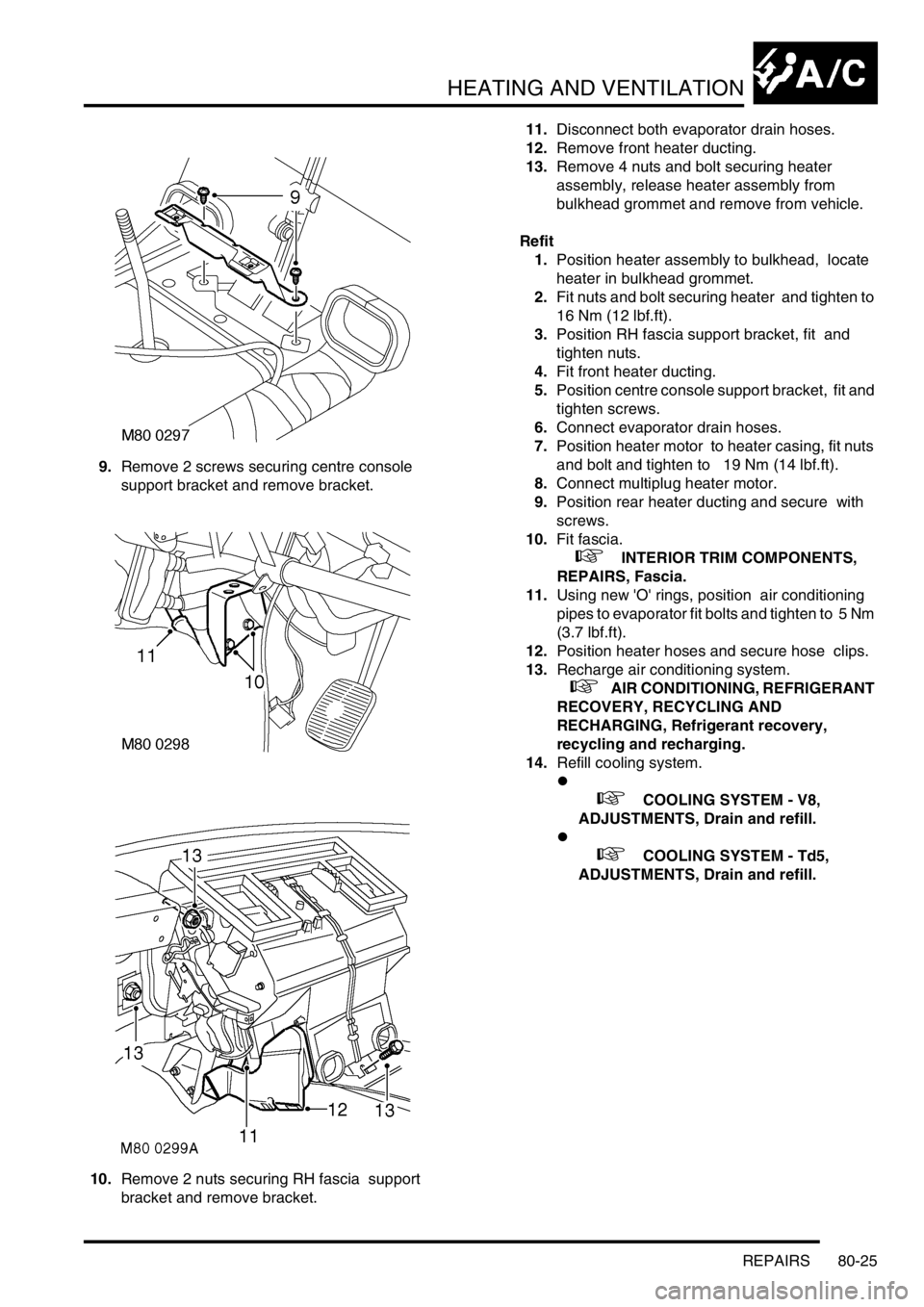

9.Remove 2 screws securing centre console

support bracket and remove bracket.

10.Remove 2 nuts securing RH fascia support

bracket and remove bracket. 11.Disconnect both evaporator drain hoses.

12.Remove front heater ducting.

13.Remove 4 nuts and bolt securing heater

assembly, release heater assembly from

bulkhead grommet and remove from vehicle.

Refit

1.Position heater assembly to bulkhead, locate

heater in bulkhead grommet.

2.Fit nuts and bolt securing heater and tighten to

16 Nm (12 lbf.ft).

3.Position RH fascia support bracket, fit and

tighten nuts.

4.Fit front heater ducting.

5.Position centre console support bracket, fit and

tighten screws.

6.Connect evaporator drain hoses.

7.Position heater motor to heater casing, fit nuts

and bolt and tighten to 19 Nm (14 lbf.ft).

8.Connect multiplug heater motor.

9.Position rear heater ducting and secure with

screws.

10.Fit fascia.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Fascia.

11.Using new 'O' rings, position air conditioning

pipes to evaporator fit bolts and tighten to 5 Nm

(3.7 lbf.ft).

12.Position heater hoses and secure hose clips.

13.Recharge air conditioning system.

+ AIR CONDITIONING, REFRIGERANT

RECOVERY, RECYCLING AND

RECHARGING, Refrigerant recovery,

recycling and recharging.

14.Refill cooling system.

l

+ COOLING SYSTEM - V8,

ADJUSTMENTS, Drain and refill.

l

+ COOLING SYSTEM - Td5,

ADJUSTMENTS, Drain and refill.

Page 1187 of 1529

HEATING AND VENTILATION

80-30REPAIRS

Pipe - Heater - Return

$% 80.25.12

Remove

1.Drain engine coolant.

+ COOLING SYSTEM - V8,

ADJUSTMENTS, Drain and refill.

2.Release clip securing heater return hose to

heater return pipe and disconnect hose from

pipe.

3.Remove bolt securing heater return pipe to

heater feed pipe.

4.Release clips securing engine harness and

vacuum pipe to heater return pipe.

5.Remove bolt securing heater return pipe to

cylinder head.

6.Release clip securing engine coolant hose to

heater return pipe.

7.Release engine coolant hose from heater

return pipe and collect pipe.Refit

1.Connect engine coolant hose to heater return

pipe and secure with clip.

2.Position heater return pipe to cylinder block and

secure with bolt.

3.Secure engine harness and vacuum pipe to

heater return pipe and secure with clips.

4.Fit and tighten bolt securing heater return pipe

to heater feed pipe.

5.Connect heater return hose to heater return

pipe and secure with clip.

6.Refill engine coolant.

+ COOLING SYSTEM - V8,

ADJUSTMENTS, Drain and refill.

M80 0437

M80 0438

4

46

7

5

Page 1188 of 1529

HEATING AND VENTILATION

REPAIRS 80-31

Fuel burning heater - (FBH) - Td5

$% 80.40.01.99

Remove

1.Release fixings and remove battery cover.

2.Disconnect battery earth lead.

3.Clamp feed and return coolant hoses at FBH.

4.Position container to collect spillage.

5.Release clips, disconnect coolant feed and

return hoses from FBH.

CAUTION: Before disconnecting or

removing components, ensure the

immediate area around joint faces and

connections are clean. Plug open

connections to prevent contamination.

6.Disconnect 2 multiplugs from FBH.7.Position container to collect spillage and

disconnect quick release fuel pipe from FBH.

CAUTION: Before disconnecting any part of

the fuel system, it is imperative that all dust,

dirt and debris is removed from around

components to prevent ingress of foreign

matter into fuel system.

8.Remove Torx bolt securing FBH to bulkhead

mounting bracket.

9.Release and remove FBH.

10.Collect locating bushes from pegs.

Refit

1.Fit bushes to pegs.

2.Align FBH to pegs, fit Torx bolt and tighten to 25

Nm (18 lbf.ft).

3.Clean quick release connection and fit fuel pipe

to FBH.

4.Connect multiplugs to FBH.

5.Connect coolant hoses to FBH and secure with

clips.

6.Release clamps from hoses.

7.Connect battery earth lead.

8.Fit and secure battery cover.

9.Top-up cooling system.

+ MAINTENANCE, PROCEDURES,

Cooling system.