torque LAND ROVER DISCOVERY 1999 Manual PDF

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 637 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

44-40 REPAIRS

Refit

1.Clean intermediate plate and mating face on

gearbox casing.

2.Apply Petroleum Jelly to new gasket and

position on gearbox casing.

3.Apply Petroleum Jelly to thrust washer and

Torrington race.

4.Correctly position Torrington race and thrust

washer to forward clutch hub.

5.Position converter housing and intermediate

plate assembly to gearbox casing.

6.Clean bolts and plain washers and old sealant

from 4 bolt threads.

7.Apply sealant, Part No. STC 50553 to 4 longer

bolt threads and fit bolts in position shown.

8.Fit remaining bolts and tighten progressively in

a diagonal sequence to 46 Nm (34 lbf.ft).

9.Place LRT-44-003/1 into pump housing, tighten

screws to secure LRT-44-003/1 to input shaft.

10.Clamp a suitable steel base to converter

housing flange.11.Mount DTI gauge and position gauge probe

onto LRT-44-003/1 and zero gauge.

12.Check that the axial end-float is between 0.2 to

0.4 mm (0.008 to 0.016 in). If end-float in not

within limits, replace existing thrust washer,

positioned at rear of intermediate plate, with a

suitable thickness thrust washer to give the

required end-float.

13.Remove DTI gauge and base plate.

14.Fit torque converter oil seal.

+ AUTOMATIC GEARBOX - ZF4HP22

- 24, REPAIRS, Torque converter and oil

seal.

M44 1344

M44 1358

LRT-44-003/1

Page 677 of 1529

REAR AXLE

51-12 OVERHAUL

Inspect

1.Clean and inspect all components for wear and

damage.

2.Fit planet gears and rotate to align cross shaft

holes.

3.Fit cross shaft, ensure roll pin hole is aligned.

4.Secure cross shaft with new roll pin.

5.Fit crown wheel to carrier, fit new bolts and

tighten to 60 Nm (44 lbf.ft).

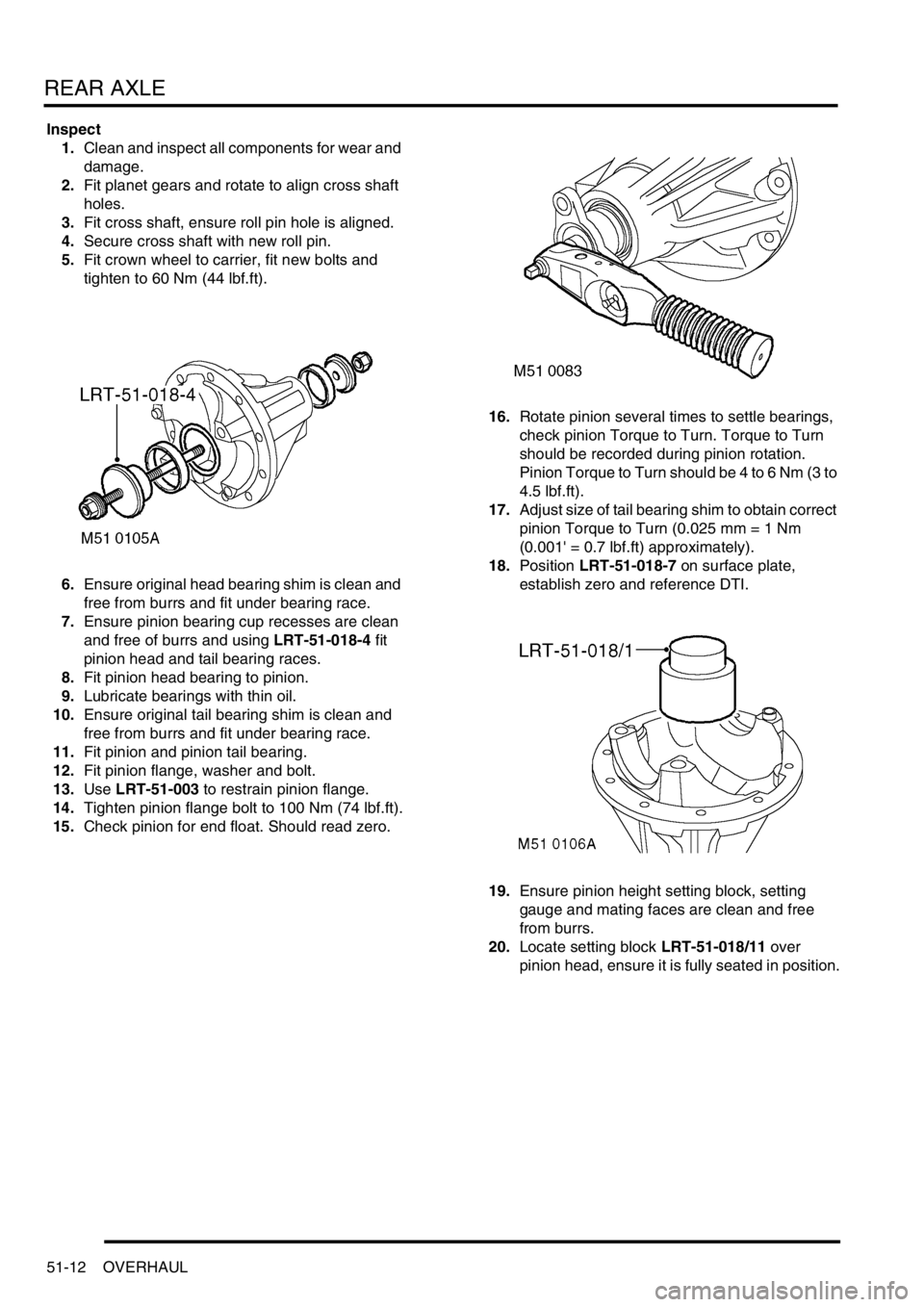

6.Ensure original head bearing shim is clean and

free from burrs and fit under bearing race.

7.Ensure pinion bearing cup recesses are clean

and free of burrs and using LRT-51-018-4 fit

pinion head and tail bearing races.

8.Fit pinion head bearing to pinion.

9.Lubricate bearings with thin oil.

10.Ensure original tail bearing shim is clean and

free from burrs and fit under bearing race.

11.Fit pinion and pinion tail bearing.

12.Fit pinion flange, washer and bolt.

13.Use LRT-51-003 to restrain pinion flange.

14.Tighten pinion flange bolt to 100 Nm (74 lbf.ft).

15.Check pinion for end float. Should read zero.16.Rotate pinion several times to settle bearings,

check pinion Torque to Turn. Torque to Turn

should be recorded during pinion rotation.

Pinion Torque to Turn should be 4 to 6 Nm (3 to

4.5 lbf.ft).

17.Adjust size of tail bearing shim to obtain correct

pinion Torque to Turn (0.025 mm = 1 Nm

(0.001' = 0.7 lbf.ft) approximately).

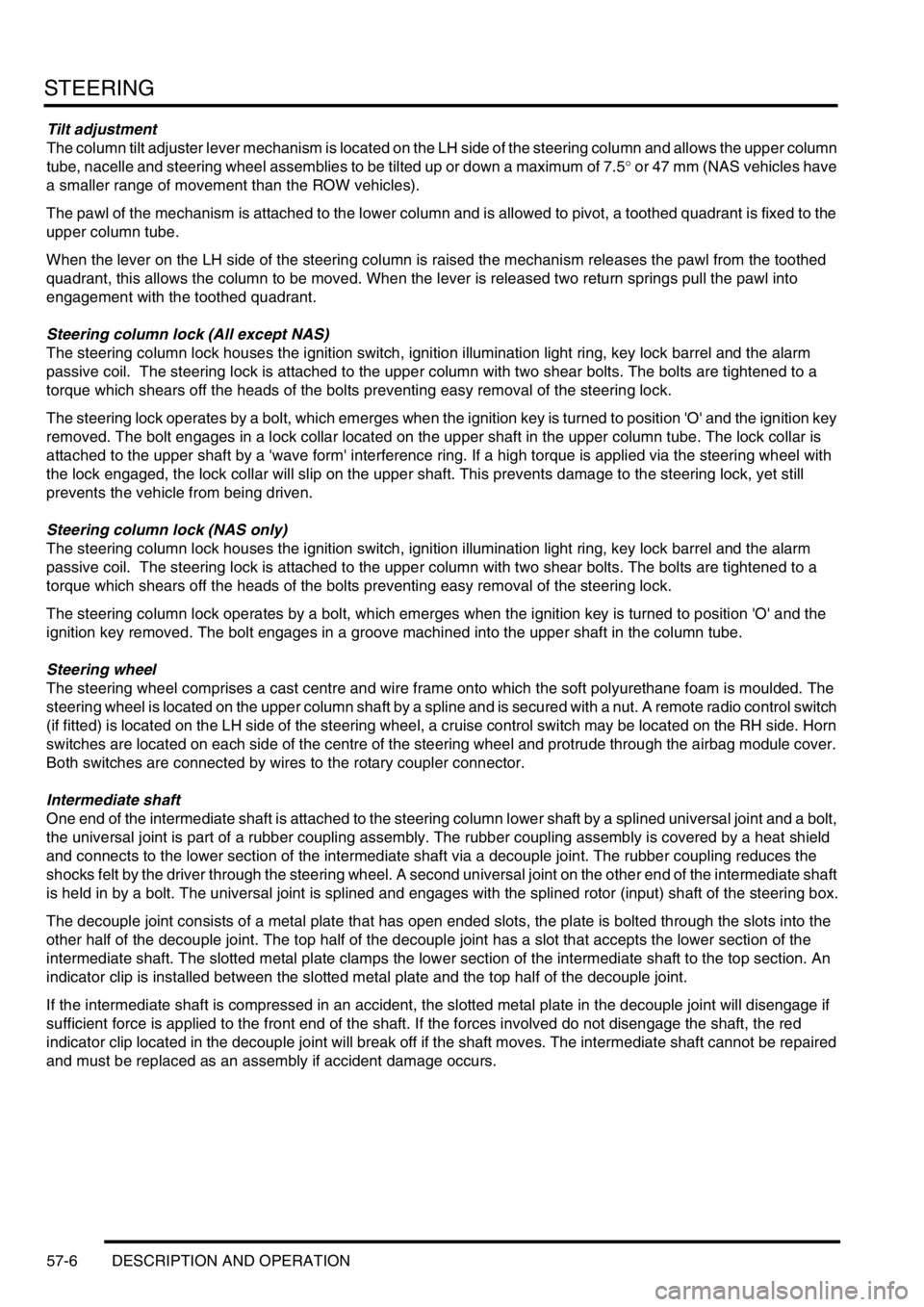

18.Position LRT-51-018-7 on surface plate,

establish zero and reference DTI.

19.Ensure pinion height setting block, setting

gauge and mating faces are clean and free

from burrs.

20.Locate setting block LRT-51-018/11 over

pinion head, ensure it is fully seated in position.

Page 678 of 1529

REAR AXLE

OVERHAUL 51-13

21. Pinion height setting procedure:

l'A' = Nominal pinion height setting, 74.390.

l'B' = Setting block height.

l'C' = Head height setting.

l'C' = 'A' - 'B'. Subtract nominal pinion height

'A' from setting block height 'B' (on side of

setting block).

lExample: 74.390 - 73.130 = 1.26 mm

(2.929' - 2.88' = 0.049'). Therefore pinion

head height reading is 1.260 mm ± 0.025

mm (0.049' ± 0.001').

CAUTION: Setting block height must be

checked using figures on side of block.

22.Align setting gauge LRT-51-018/7 to setting

block, rock gauge to obtain minimum reading. If

reading is lower than required reading,

decrease shim size. If reading is higher than

required reading, increase shim size.

23.Using LRT-51-003 to restrain pinion flange,

remove bolt and washer. Remove pinion

flange.

24.Remove pinion, collect tail bearing and tail

bearing shim.

25.Remove pinion head bearing outer race and

shim. Discard shim. Ensure bearing race

recess is clean and free from burrs.26.Fit calculated shim, and using LRT-51-018/4 fit

head bearing outer race.

27.Fit pinion, pinion tail bearing and tail bearing

shim.

28.Fit pinion flange and bolt and washer. Using

LRT-51-003 to restrain pinion flange, tighten

bolt to 100 Nm (74 lbf.ft).

29.Rotate pinion in both directions to settle

bearings.

30.Recheck pinion Torque to Turn, adjust if

necessary.

31.Recheck pinion head height.

32.Using LRT-51-003 to restrain pinion flange,

remove bolt and washer. Remove pinion

flange.

33.Discard bolt.

34.Using LRT-51-010 fit pinion seal.

35.Ensure spacer and tail bearing are correctly

located.

36.Fit pinion, pinion flange and washer.

37.Fit new pinion flange bolt and tighten to 100 Nm

(74 lbf.ft).

38.Lightly oil differential bearings.

39.Ensure spring dowels are fitted in bearing caps.

40.Fit differential bearing outer races and locate

differential assembly into housing.

41.Fit bearing caps and tighten bolts to 10 Nm (7.5

lbf.ft).

Page 679 of 1529

REAR AXLE

51-14 OVERHAUL

42.Fit adjusting nuts, tighten crown wheel side nut

to 22 Nm (16 lbf.ft). Ensure opposing nut is

loose.

43.Position DTI to check crown wheel backlash.

Adjust opposing nut to obtain correct crown

wheel backlash.

44.Rotate pinion in both directions to settle

bearings.

45.Measure in 3 places to obtain correct crown

wheel backlash.

NOTE: Crown wheel backlash should be within

0.076 mm - 0.177 mm (0.003' - 0.007').

46.Align adjusting nuts to next roll pin slot, do not

loosen nuts to align slots.

47.Tighten bearing cap bolts to 90 Nm (66.5 lbf.ft).

48.Secure adjusting nuts with new roll pins.

49.Apply Prussian Blue to crown wheel teeth to

check tooth contact.50.Rotate pinion several times to obtain full tooth

contact.

51.A = Normal pattern, the drive pattern should be

centred on the gear teeth. The coast pattern

should be centred on the gear teeth but may be

towards the toe. There should be some

clearance between the pattern and the top of

the gear teeth.

52.B = Backlash correct, thinner pinion shim

required.

53.C = Backlash correct, thicker pinion shim

required.

54.D = Pinion shim correct, decrease backlash.

55.E = Pinion shim correct, increase backlash.

56.Note assembly Torque to Turn when checking

tooth contact. Total Torque to Turn should not

exceed 10.85 Nm (8 lbf.ft).

Reassembly

1.Fit differential assembly.

Page 699 of 1529

STEERING

57-6 DESCRIPTION AND OPERATION

Tilt adjustment

The column tilt adjuster lever mechanism is located on the LH side of the steering column and allows the upper column

tube, nacelle and steering wheel assemblies to be tilted up or down a maximum of 7.5° or 47 mm (NAS vehicles have

a smaller range of movement than the ROW vehicles).

The pawl of the mechanism is attached to the lower column and is allowed to pivot, a toothed quadrant is fixed to the

upper column tube.

When the lever on the LH side of the steering column is raised the mechanism releases the pawl from the toothed

quadrant, this allows the column to be moved. When the lever is released two return springs pull the pawl into

engagement with the toothed quadrant.

Steering column lock (All except NAS)

The steering column lock houses the ignition switch, ignition illumination light ring, key lock barrel and the alarm

passive coil. The steering lock is attached to the upper column with two shear bolts. The bolts are tightened to a

torque which shears off the heads of the bolts preventing easy removal of the steering lock.

The steering lock operates by a bolt, which emerges when the ignition key is turned to position 'O' and the ignition key

removed. The bolt engages in a lock collar located on the upper shaft in the upper column tube. The lock collar is

attached to the upper shaft by a 'wave form' interference ring. If a high torque is applied via the steering wheel with

the lock engaged, the lock collar will slip on the upper shaft. This prevents damage to the steering lock, yet still

prevents the vehicle from being driven.

Steering column lock (NAS only)

The steering column lock houses the ignition switch, ignition illumination light ring, key lock barrel and the alarm

passive coil. The steering lock is attached to the upper column with two shear bolts. The bolts are tightened to a

torque which shears off the heads of the bolts preventing easy removal of the steering lock.

The steering column lock operates by a bolt, which emerges when the ignition key is turned to position 'O' and the

ignition key removed. The bolt engages in a groove machined into the upper shaft in the column tube.

Steering wheel

The steering wheel comprises a cast centre and wire frame onto which the soft polyurethane foam is moulded. The

steering wheel is located on the upper column shaft by a spline and is secured with a nut. A remote radio control switch

(if fitted) is located on the LH side of the steering wheel, a cruise control switch may be located on the RH side. Horn

switches are located on each side of the centre of the steering wheel and protrude through the airbag module cover.

Both switches are connected by wires to the rotary coupler connector.

Intermediate shaft

One end of the intermediate shaft is attached to the steering column lower shaft by a splined universal joint and a bolt,

the universal joint is part of a rubber coupling assembly. The rubber coupling assembly is covered by a heat shield

and connects to the lower section of the intermediate shaft via a decouple joint. The rubber coupling reduces the

shocks felt by the driver through the steering wheel. A second universal joint on the other end of the intermediate shaft

is held in by a bolt. The universal joint is splined and engages with the splined rotor (input) shaft of the steering box.

The decouple joint consists of a metal plate that has open ended slots, the plate is bolted through the slots into the

other half of the decouple joint. The top half of the decouple joint has a slot that accepts the lower section of the

intermediate shaft. The slotted metal plate clamps the lower section of the intermediate shaft to the top section. An

indicator clip is installed between the slotted metal plate and the top half of the decouple joint.

If the intermediate shaft is compressed in an accident, the slotted metal plate in the decouple joint will disengage if

sufficient force is applied to the front end of the shaft. If the forces involved do not disengage the shaft, the red

indicator clip located in the decouple joint will break off if the shaft moves. The intermediate shaft cannot be repaired

and must be replaced as an assembly if accident damage occurs.

Page 702 of 1529

STEERING

DESCRIPTION AND OPERATION 57-9

Principle of operation

Movement of the input shaft is transferred through the pin to the torsion bar and valve rotor on the input shaft. As the

input shaft turns, the spline of the torsion bar turns the worm gear. This action causes the roller to rotate on its bearings

and move. As the roller is located by a pin to a yoke on the output shaft, the output shaft rotates in the steering box

housing. As the amount of torque acting on the input shaft increases the torsion bar starts to twist. As the torsion bar

twists the valve rotor turns in the valve sleeve. When the ports in the valve rotor and valve sleeve are turned, hydraulic

fluid is directed to chamber 'A' or 'B' in the power cylinder.

With hydraulic fluid in one chamber under high pressure, the piston moves. The return line ports in the rotary valve,

aligned by the movement of the valve rotor, allow the fluid in the opposite chamber to flow to return. The teeth of the

rack move and transfer the force from the piston to the output shaft, giving assistance to move the drop arm. As the

output shaft rotates the torsion bar load is decreased. The rotor on the input shaft will return as the torsion bar

unwinds, the rotary valve will then be in a neutral position and the pressure in chambers 'A' and 'B' will equalise. With

no high pressure acting on the piston, force on the piston and rack is released.

To prevent heat accumulation at full steering lock due to excessive pressure, a relief valve inside the steering box is

opened as the box approaches full lock. The relief valve pins are located in the cylinder cover and housing and are

not to be adjusted.

The steering box design ensures a mechanical link through the course spline on the control valve rotor, the spline will

become engaged if:

lThe hydraulic pressure fails.

lThe steering box rotary control valve fails.

The coarse spline may also engage in some full lock situations if sufficient torque is applied to the input shaft.

Page 703 of 1529

STEERING

57-10 DESCRIPTION AND OPERATION

Rotary control valve

The rotary valve assembly comprises of three parts. The valve sleeve is fixed inside one end of the worm gear, the

valve sleeve has ports through it to allow the passage of hydraulic fluid. The input shaft has a valve rotor machined

on one end, the valve rotor also has ports through it and can rotate in the valve sleeve. A torsion bar is attached to

the input shaft by a pin, the torsion bar goes through the input shaft and valve rotor and is engaged by a spline into

the worm gear.

The coarse spline on the end of the valve rotor is loosely engaged in the worm gear, the coarse spline can make

contact and drive the worm gear in some full lock and in no pressure conditions. In the event of a torsion bar failure,

power assistance will be lost, the coarse spline will drive the worm gear and enable the vehicle to be steered and

driver control maintained.

Rotary control valve at neutral

1Worm gear

2Torsion bar

3Valve sleeve

4Pin5Input shaft and valve rotor

6Piston/rack

7Coarse spline

8Spline (torque shaft to worm gear)

When there is no demand for assistance the torsion bar holds the ports in the valve sleeve and valve rotor in a neutral

relationship to one another. The ports in the valve sleeve and the valve rotor are so aligned to allow equal (low) fluid

pressure on each side of the piston. Excess fluid flows through ports in the valve rotor through the valve sleeve and

back to the reservoir.

Page 704 of 1529

STEERING

DESCRIPTION AND OPERATION 57-11

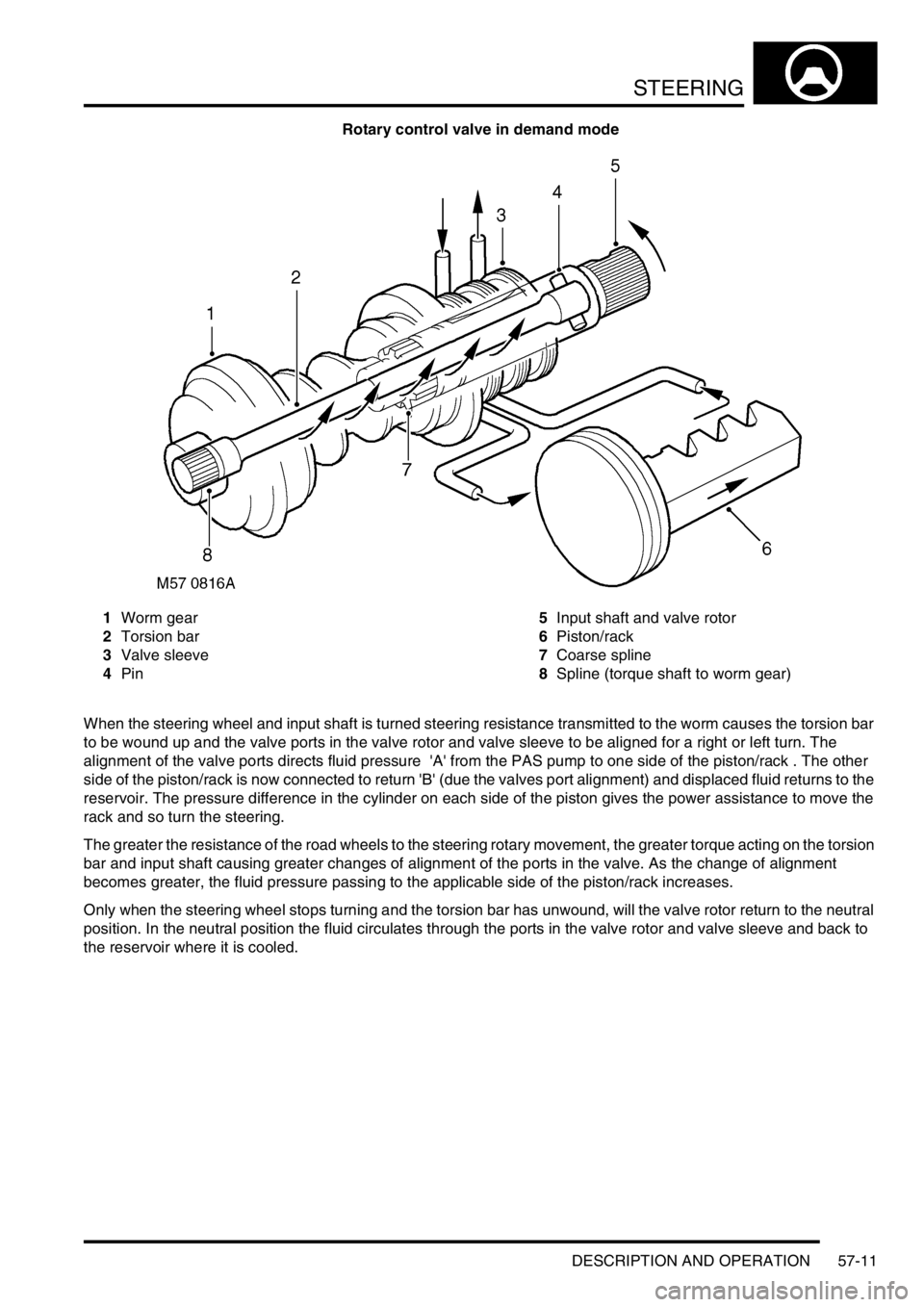

Rotary control valve in demand mode

1Worm gear

2Torsion bar

3Valve sleeve

4Pin5Input shaft and valve rotor

6Piston/rack

7Coarse spline

8Spline (torque shaft to worm gear)

When the steering wheel and input shaft is turned steering resistance transmitted to the worm causes the torsion bar

to be wound up and the valve ports in the valve rotor and valve sleeve to be aligned for a right or left turn. The

alignment of the valve ports directs fluid pressure 'A' from the PAS pump to one side of the piston/rack . The other

side of the piston/rack is now connected to return 'B' (due the valves port alignment) and displaced fluid returns to the

reservoir. The pressure difference in the cylinder on each side of the piston gives the power assistance to move the

rack and so turn the steering.

The greater the resistance of the road wheels to the steering rotary movement, the greater torque acting on the torsion

bar and input shaft causing greater changes of alignment of the ports in the valve. As the change of alignment

becomes greater, the fluid pressure passing to the applicable side of the piston/rack increases.

Only when the steering wheel stops turning and the torsion bar has unwound, will the valve rotor return to the neutral

position. In the neutral position the fluid circulates through the ports in the valve rotor and valve sleeve and back to

the reservoir where it is cooled.

Page 751 of 1529

FRONT SUSPENSION

60-6 DESCRIPTION AND OPERATION

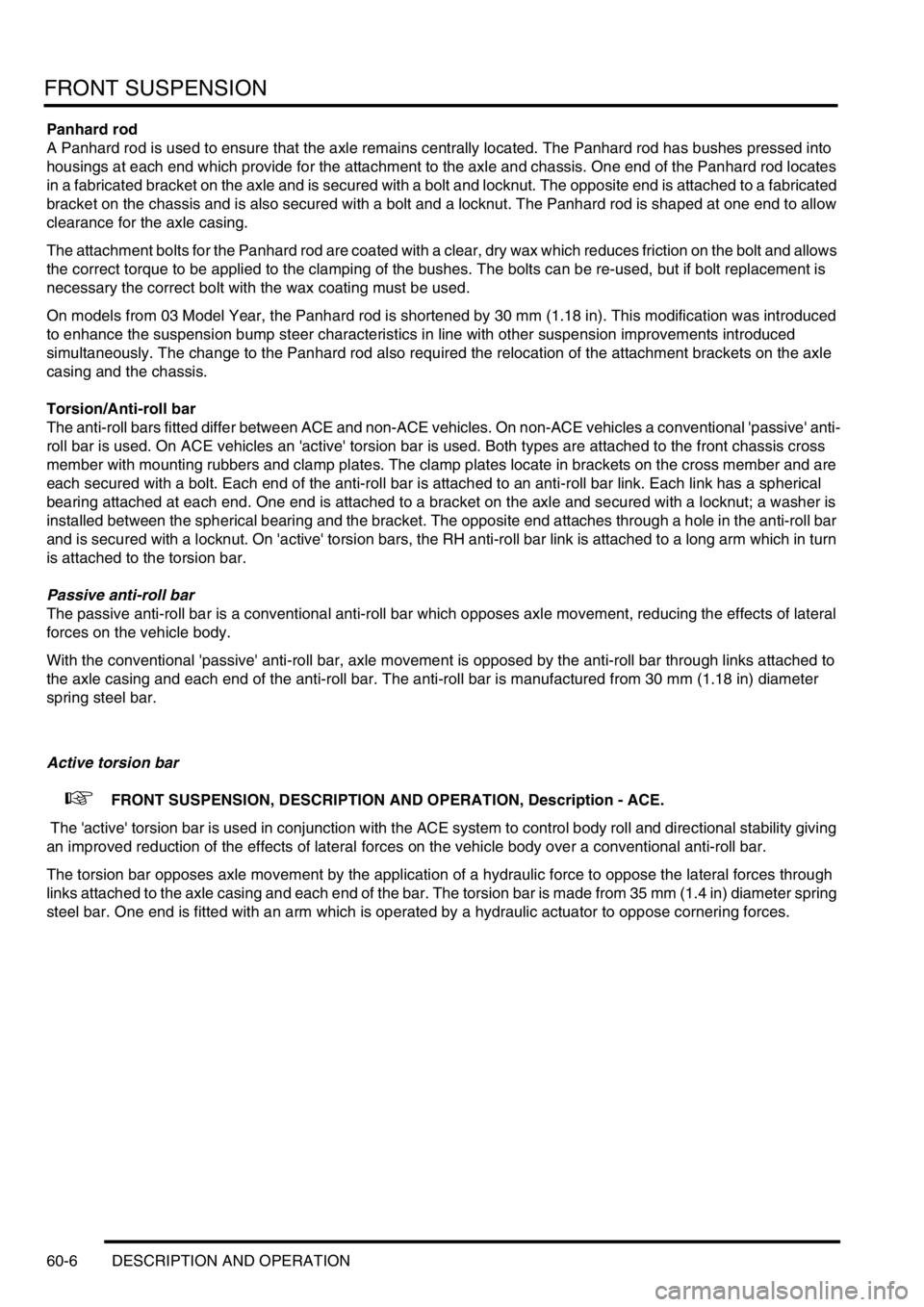

Panhard rod

A Panhard rod is used to ensure that the axle remains centrally located. The Panhard rod has bushes pressed into

housings at each end which provide for the attachment to the axle and chassis. One end of the Panhard rod locates

in a fabricated bracket on the axle and is secured with a bolt and locknut. The opposite end is attached to a fabricated

bracket on the chassis and is also secured with a bolt and a locknut. The Panhard rod is shaped at one end to allow

clearance for the axle casing.

The attachment bolts for the Panhard rod are coated with a clear, dry wax which reduces friction on the bolt and allows

the correct torque to be applied to the clamping of the bushes. The bolts can be re-used, but if bolt replacement is

necessary the correct bolt with the wax coating must be used.

On models from 03 Model Year, the Panhard rod is shortened by 30 mm (1.18 in). This modification was introduced

to enhance the suspension bump steer characteristics in line with other suspension improvements introduced

simultaneously. The change to the Panhard rod also required the relocation of the attachment brackets on the axle

casing and the chassis.

Torsion/Anti-roll bar

The anti-roll bars fitted differ between ACE and non-ACE vehicles. On non-ACE vehicles a conventional 'passive' anti-

roll bar is used. On ACE vehicles an 'active' torsion bar is used. Both types are attached to the front chassis cross

member with mounting rubbers and clamp plates. The clamp plates locate in brackets on the cross member and are

each secured with a bolt. Each end of the anti-roll bar is attached to an anti-roll bar link. Each link has a spherical

bearing attached at each end. One end is attached to a bracket on the axle and secured with a locknut; a washer is

installed between the spherical bearing and the bracket. The opposite end attaches through a hole in the anti-roll bar

and is secured with a locknut. On 'active' torsion bars, the RH anti-roll bar link is attached to a long arm which in turn

is attached to the torsion bar.

Passive anti-roll bar

The passive anti-roll bar is a conventional anti-roll bar which opposes axle movement, reducing the effects of lateral

forces on the vehicle body.

With the conventional 'passive' anti-roll bar, axle movement is opposed by the anti-roll bar through links attached to

the axle casing and each end of the anti-roll bar. The anti-roll bar is manufactured from 30 mm (1.18 in) diameter

spring steel bar.

Active torsion bar

+ FRONT SUSPENSION, DESCRIPTION AND OPERATION, Description - ACE.

The 'active' torsion bar is used in conjunction with the ACE system to control body roll and directional stability giving

an improved reduction of the effects of lateral forces on the vehicle body over a conventional anti-roll bar.

The torsion bar opposes axle movement by the application of a hydraulic force to oppose the lateral forces through

links attached to the axle casing and each end of the bar. The torsion bar is made from 35 mm (1.4 in) diameter spring

steel bar. One end is fitted with an arm which is operated by a hydraulic actuator to oppose cornering forces.

Page 755 of 1529

FRONT SUSPENSION

60-10 DESCRIPTION AND OPERATION

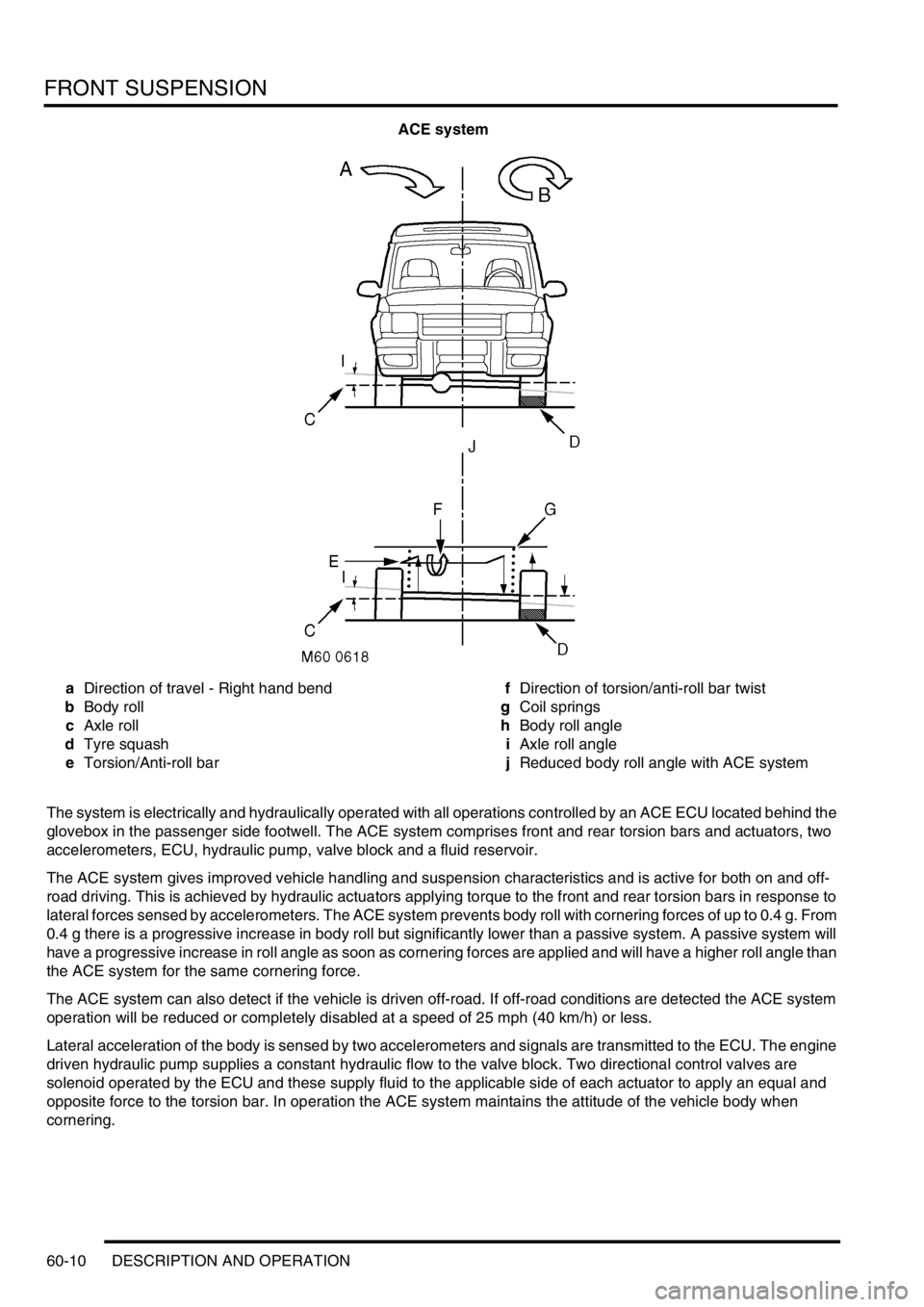

ACE system

aDirection of travel - Right hand bend

bBody roll

cAxle roll

dTyre squash

eTorsion/Anti-roll barfDirection of torsion/anti-roll bar twist

gCoil springs

hBody roll angle

iAxle roll angle

jReduced body roll angle with ACE system

The system is electrically and hydraulically operated with all operations controlled by an ACE ECU located behind the

glovebox in the passenger side footwell. The ACE system comprises front and rear torsion bars and actuators, two

accelerometers, ECU, hydraulic pump, valve block and a fluid reservoir.

The ACE system gives improved vehicle handling and suspension characteristics and is active for both on and off-

road driving. This is achieved by hydraulic actuators applying torque to the front and rear torsion bars in response to

lateral forces sensed by accelerometers. The ACE system prevents body roll with cornering forces of up to 0.4 g. From

0.4 g there is a progressive increase in body roll but significantly lower than a passive system. A passive system will

have a progressive increase in roll angle as soon as cornering forces are applied and will have a higher roll angle than

the ACE system for the same cornering force.

The ACE system can also detect if the vehicle is driven off-road. If off-road conditions are detected the ACE system

operation will be reduced or completely disabled at a speed of 25 mph (40 km/h) or less.

Lateral acceleration of the body is sensed by two accelerometers and signals are transmitted to the ECU. The engine

driven hydraulic pump supplies a constant hydraulic flow to the valve block. Two directional control valves are

solenoid operated by the ECU and these supply fluid to the applicable side of each actuator to apply an equal and

opposite force to the torsion bar. In operation the ACE system maintains the attitude of the vehicle body when

cornering.