warning LAND ROVER DISCOVERY 2002 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 1113 of 1672

RESTRAINT SYSTEMS

75-18 REPAIRS

Pre-tensioner - front seat belt

$% 76.73.30

WARNING: It is imperative that before any work

is undertaken on the SRS system the appropriate

information is read thoroughly.

WARNING: Always disconnect both battery leads

before beginning work on the SRS system.

Disconnect the negative battery lead first. Never

reverse connect the battery.

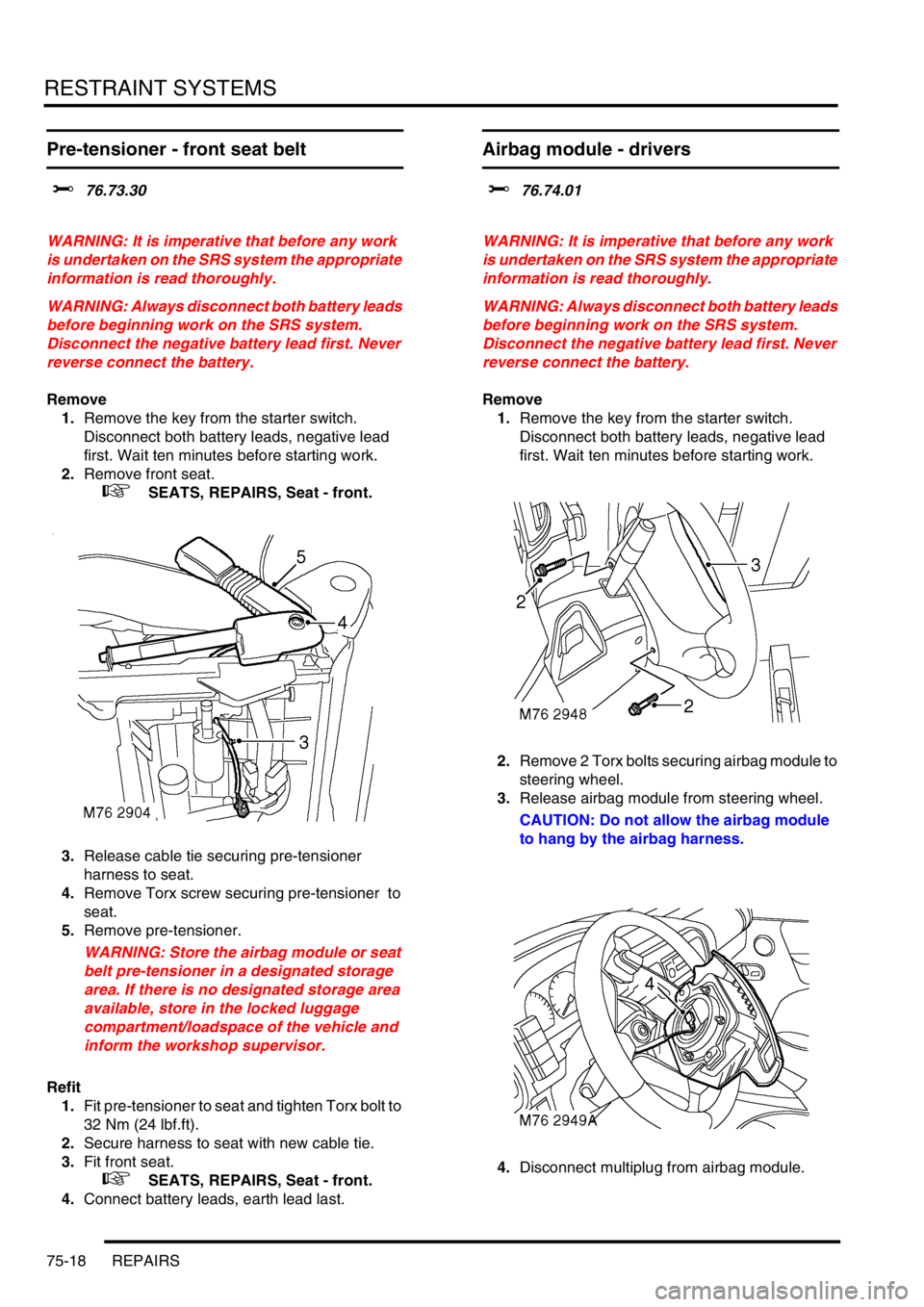

Remove

1.Remove the key from the starter switch.

Disconnect both battery leads, negative lead

first. Wait ten minutes before starting work.

2.Remove front seat.

+ SEATS, REPAIRS, Seat - front.

3.Release cable tie securing pre-tensioner

harness to seat.

4.Remove Torx screw securing pre-tensioner to

seat.

5.Remove pre-tensioner.

WARNING: Store the airbag module or seat

belt pre-tensioner in a designated storage

area. If there is no designated storage area

available, store in the locked luggage

compartment/loadspace of the vehicle and

inform the workshop supervisor.

Refit

1.Fit pre-tensioner to seat and tighten Torx bolt to

32 Nm (24 lbf.ft).

2.Secure harness to seat with new cable tie.

3.Fit front seat.

+ SEATS, REPAIRS, Seat - front.

4.Connect battery leads, earth lead last.

Airbag module - drivers

$% 76.74.01

WARNING: It is imperative that before any work

is undertaken on the SRS system the appropriate

information is read thoroughly.

WARNING: Always disconnect both battery leads

before beginning work on the SRS system.

Disconnect the negative battery lead first. Never

reverse connect the battery.

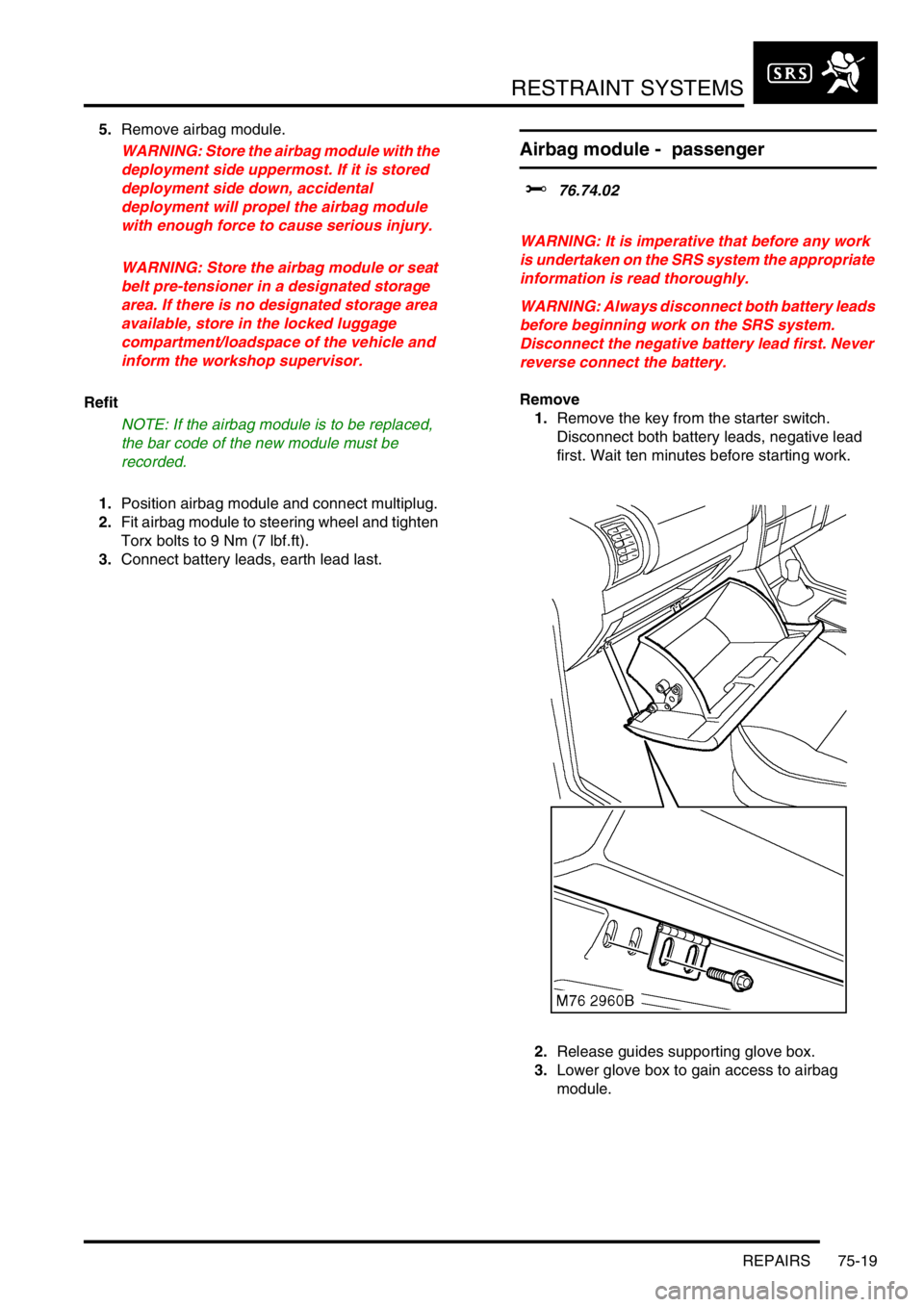

Remove

1.Remove the key from the starter switch.

Disconnect both battery leads, negative lead

first. Wait ten minutes before starting work.

2.Remove 2 Torx bolts securing airbag module to

steering wheel.

3.Release airbag module from steering wheel.

CAUTION: Do not allow the airbag module

to hang by the airbag harness.

4.Disconnect multiplug from airbag module.

Page 1114 of 1672

RESTRAINT SYSTEMS

REPAIRS 75-19

5.Remove airbag module.

WARNING: Store the airbag module with the

deployment side uppermost. If it is stored

deployment side down, accidental

deployment will propel the airbag module

with enough force to cause serious injury.

WARNING: Store the airbag module or seat

belt pre-tensioner in a designated storage

area. If there is no designated storage area

available, store in the locked luggage

compartment/loadspace of the vehicle and

inform the workshop supervisor.

Refit

NOTE: If the airbag module is to be replaced,

the bar code of the new module must be

recorded.

1.Position airbag module and connect multiplug.

2.Fit airbag module to steering wheel and tighten

Torx bolts to 9 Nm (7 lbf.ft).

3.Connect battery leads, earth lead last.

Airbag module - passenger

$% 76.74.02

WARNING: It is imperative that before any work

is undertaken on the SRS system the appropriate

information is read thoroughly.

WARNING: Always disconnect both battery leads

before beginning work on the SRS system.

Disconnect the negative battery lead first. Never

reverse connect the battery.

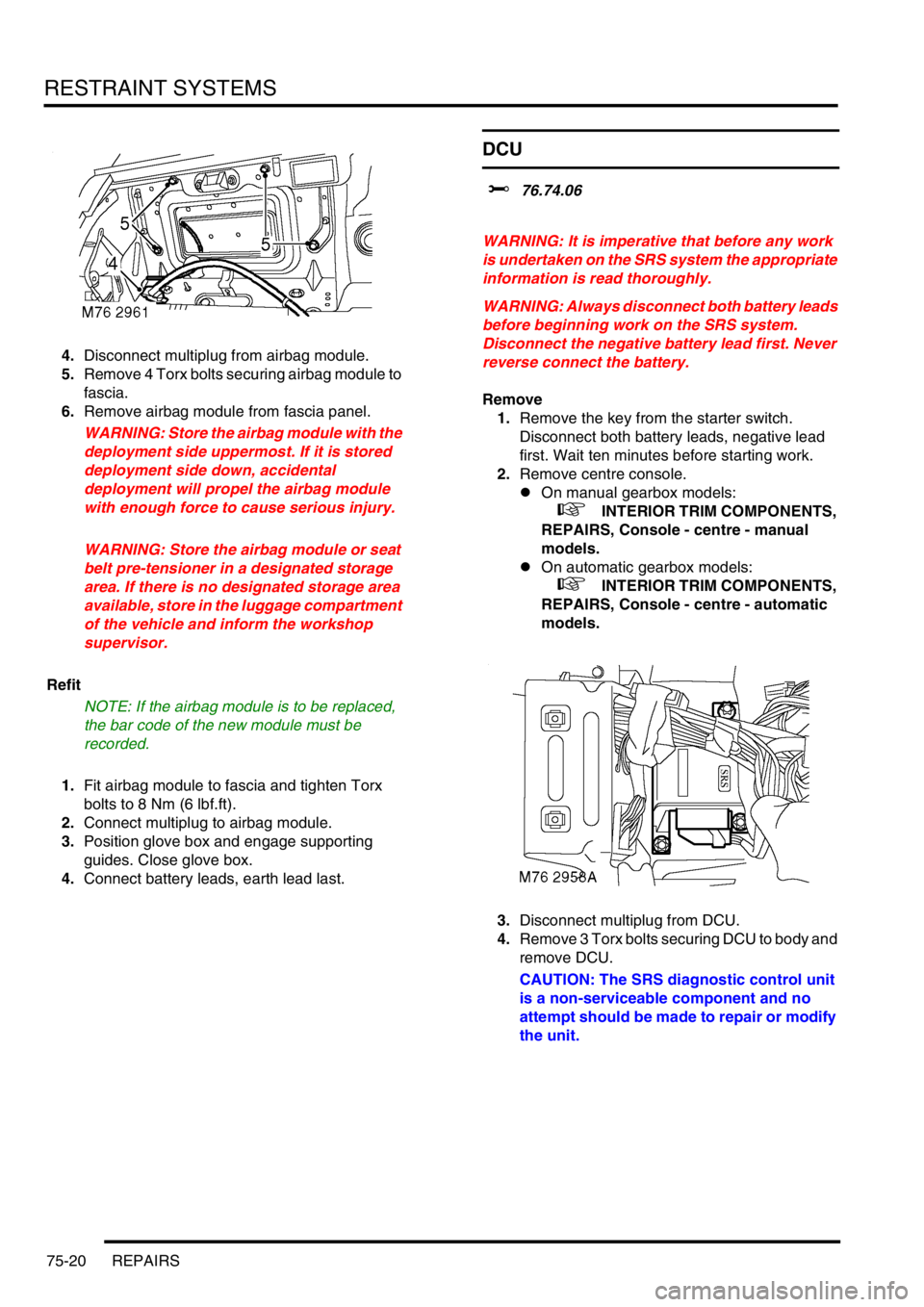

Remove

1.Remove the key from the starter switch.

Disconnect both battery leads, negative lead

first. Wait ten minutes before starting work.

2.Release guides supporting glove box.

3.Lower glove box to gain access to airbag

module.

Page 1115 of 1672

RESTRAINT SYSTEMS

75-20 REPAIRS

4.Disconnect multiplug from airbag module.

5.Remove 4 Torx bolts securing airbag module to

fascia.

6.Remove airbag module from fascia panel.

WARNING: Store the airbag module with the

deployment side uppermost. If it is stored

deployment side down, accidental

deployment will propel the airbag module

with enough force to cause serious injury.

WARNING: Store the airbag module or seat

belt pre-tensioner in a designated storage

area. If there is no designated storage area

available, store in the luggage compartment

of the vehicle and inform the workshop

supervisor.

Refit

NOTE: If the airbag module is to be replaced,

the bar code of the new module must be

recorded.

1.Fit airbag module to fascia and tighten Torx

bolts to 8 Nm (6 lbf.ft).

2.Connect multiplug to airbag module.

3.Position glove box and engage supporting

guides. Close glove box.

4.Connect battery leads, earth lead last.

DCU

$% 76.74.06

WARNING: It is imperative that before any work

is undertaken on the SRS system the appropriate

information is read thoroughly.

WARNING: Always disconnect both battery leads

before beginning work on the SRS system.

Disconnect the negative battery lead first. Never

reverse connect the battery.

Remove

1.Remove the key from the starter switch.

Disconnect both battery leads, negative lead

first. Wait ten minutes before starting work.

2.Remove centre console.

lOn manual gearbox models:

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - centre - manual

models.

lOn automatic gearbox models:

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - centre - automatic

models.

3.Disconnect multiplug from DCU.

4.Remove 3 Torx bolts securing DCU to body and

remove DCU.

CAUTION: The SRS diagnostic control unit

is a non-serviceable component and no

attempt should be made to repair or modify

the unit.

Page 1116 of 1672

RESTRAINT SYSTEMS

REPAIRS 75-21

Refit

CAUTION: The SRS diagnostic control unit

is a shock sensitive device and must be

handled with extreme care.

1.Position DCU to body and connect multiplug.

2.Fit and tighten DCU Torx bolts to 10 Nm (7

lbf.ft).

3.Fit centre console.

lOn manual gearbox models:

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - centre - manual

models.

lOn automatic gearbox models:

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - centre - automatic

models.

4.Connect battery leads, earth lead last.

Rotary coupler

$% 76.74.20

WARNING: It is imperative that before any work

is undertaken on the SRS system the appropriate

information is read thoroughly.

WARNING: Always disconnect both battery leads

before beginning work on the SRS system.

Disconnect the negative battery lead first. Never

reverse connect the battery.

Remove

1.Remove the key from the starter switch.

Disconnect both battery leads, negative lead

first. Wait ten minutes before starting work.

2.Remove steering wheel.

+ STEERING, REPAIRS, Steering

wheel.

3.Remove steering column nacelle.

+ STEERING, REPAIRS, Nacelle -

steering column.

Page 1118 of 1672

RESTRAINT SYSTEMS

REPAIRS 75-23

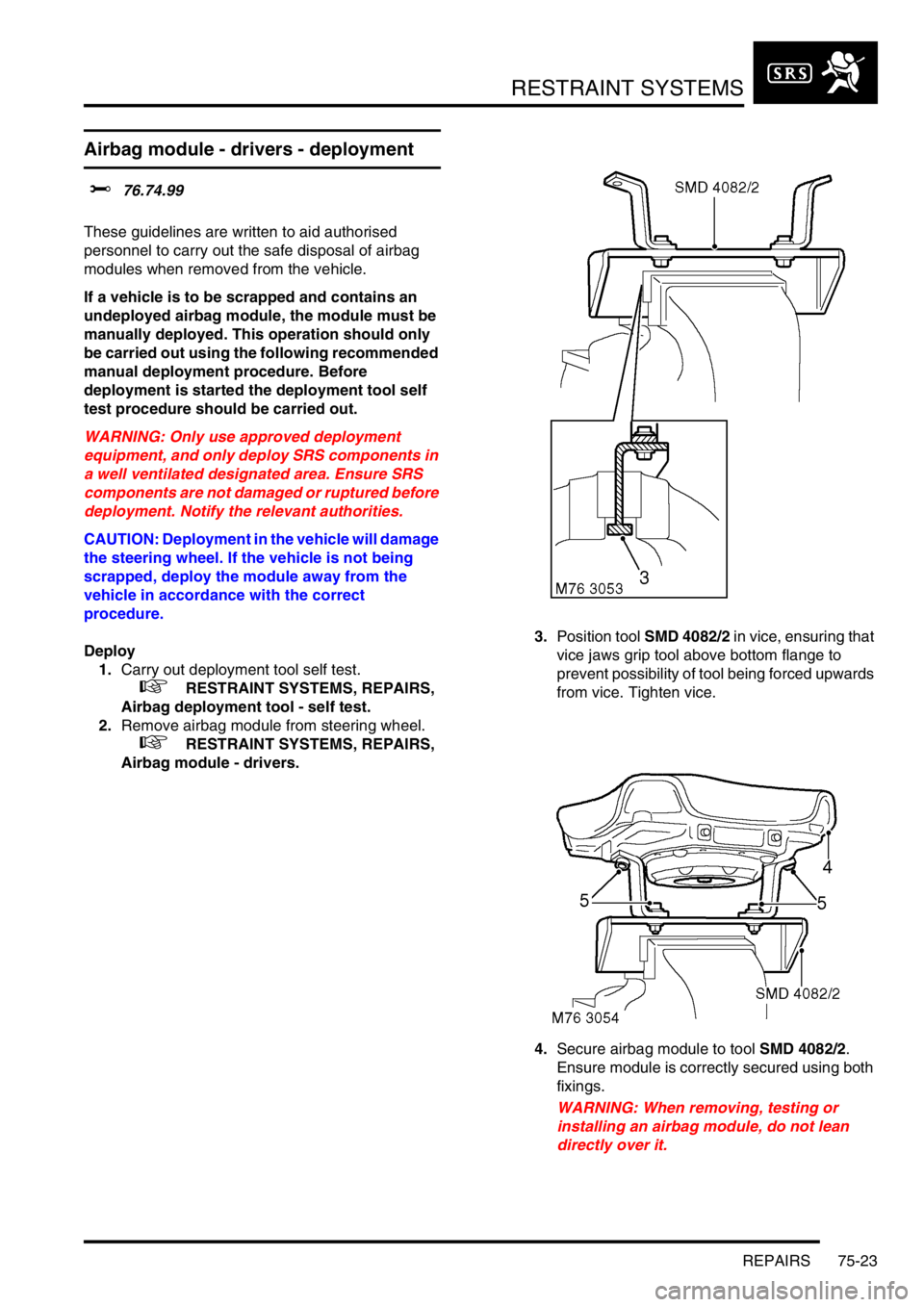

Airbag module - drivers - deployment

$% 76.74.99

These guidelines are written to aid authorised

personnel to carry out the safe disposal of airbag

modules when removed from the vehicle.

If a vehicle is to be scrapped and contains an

undeployed airbag module, the module must be

manually deployed. This operation should only

be carried out using the following recommended

manual deployment procedure. Before

deployment is started the deployment tool self

test procedure should be carried out.

WARNING: Only use approved deployment

equipment, and only deploy SRS components in

a well ventilated designated area. Ensure SRS

components are not damaged or ruptured before

deployment. Notify the relevant authorities.

CAUTION: Deployment in the vehicle will damage

the steering wheel. If the vehicle is not being

scrapped, deploy the module away from the

vehicle in accordance with the correct

procedure.

Deploy

1.Carry out deployment tool self test.

+ RESTRAINT SYSTEMS, REPAIRS,

Airbag deployment tool - self test.

2.Remove airbag module from steering wheel.

+ RESTRAINT SYSTEMS, REPAIRS,

Airbag module - drivers.3.Position tool SMD 4082/2 in vice, ensuring that

vice jaws grip tool above bottom flange to

prevent possibility of tool being forced upwards

from vice. Tighten vice.

4.Secure airbag module to tool SMD 4082/2.

Ensure module is correctly secured using both

fixings.

WARNING: When removing, testing or

installing an airbag module, do not lean

directly over it.

Page 1119 of 1672

RESTRAINT SYSTEMS

75-24 REPAIRS

5.Ensure airbag module mounting brackets are

secure.

6.Connect flylead SMD 4082/4 to airbag module.

WARNING: Ensure the deployment tool is

not connected to the battery.

7.Connect flylead SMD 4082/4 to tool SMD 4082/

1.

WARNING: Do not lean over module whilst

connecting.

8.Connect tool SMD 4082/1 to battery.

WARNING: Ensure all personnel are at least

15 metres (50 ft) away from the airbag

module.9.Press both operating buttons to deploy airbag

module.

10.DO NOT return to airbag module for 30

minutes.

11.Using gloves and face mask, remove airbag

module from tool, place airbag module in

plastic bag and seal bag.

12.Wipe down tool with damp cloth.

13.Transport deployed airbag module to

designated area for incineration.

NOTE: DO NOT re-use or salvage any parts of

the airbag system including steering wheel or

steering column. Do not transport deployed

SRS components in the vehicle passenger

compartment.

Page 1120 of 1672

RESTRAINT SYSTEMS

REPAIRS 75-25

Airbag module - passenger - deployment

$% 76.74.99

These guidelines are written to aid authorised

personnel to carry out the safe disposal of airbag

modules when removed from the vehicle.

If a vehicle is to be scrapped and contains an

undeployed airbag module, the module must be

manually deployed. This operation should only

be carried out using the following recommended

manual deployment procedure. Before

deployment is started the deployment tool self

test procedure should be carried out.

WARNING: Only use approved deployment

equipment, and only deploy SRS components in

a well ventilated designated area. Ensure SRS

components are not damaged or ruptured before

deployment. Notify the relevant authorities.

Deploy

1.Carry out deployment tool self test.

+ RESTRAINT SYSTEMS, REPAIRS,

Airbag deployment tool - self test.

2.Remove airbag module from fascia.

+ RESTRAINT SYSTEMS, REPAIRS,

Airbag module - passenger.3.Position tool SMD 4082/6 in vice, ensuring that

vice jaws grip tool above bottom flange to

prevent possibility of tool being forced upwards

from vice. Tighten vice.

4.Position brackets SMD 4082/7 to tool; lightly

tighten bolts.

5.Position airbag module to tool SMD 4082/6.

Ensure module is correctly secured using all

fixings.

WARNING: When removing, testing or

installing an airbag module, do not lean

directly over it.

Page 1121 of 1672

RESTRAINT SYSTEMS

75-26 REPAIRS

6.Ensure airbag module mounting brackets are

secure.

7.Connect flylead SMD 4082/5 to airbag module.

WARNING: Ensure the deployment tool is

not connected to the battery.

8.Connect flylead SMD 4082/5 to tool SMD 4082/

1.

9.Connect tool SMD 4082/1 to battery.

WARNING: Ensure all personnel are at least

15 metres (50 ft) away from the airbag

module.10.Press both operating buttons to deploy airbag

module.

11.DO NOT return to airbag module for 30

minutes.

12.Using gloves and face mask, remove airbag

module from tool, place airbag module in

plastic bag and seal bag.

13.Wipe down tool with damp cloth.

14.Transport deployed airbag module to

designated area for incineration.

NOTE: DO NOT re-use or salvage any parts of

the airbag system.Do not transport deployed

SRS components in the vehicle passenger

compartment.

Page 1122 of 1672

RESTRAINT SYSTEMS

REPAIRS 75-27

Pre-tensioner - deployment

$% 76.74.99

These guidelines are written to aid authorised

personnel to carry out the safe disposal of pre-

tensioners.

If a vehicle is to be scrapped and contains an

undeployed pre-tensioner, the pre-tensioner

must be manually deployed. This operation

should only be carried out using the following

recommended manual deployment procedure.

Before deployment is started the deployment

tool self test procedure should be carried out.

WARNING: Only use approved deployment

equipment, and only deploy SRS components in

a well ventilated designated area. Ensure SRS

components are not damaged or ruptured before

deployment. Notify the relevant authorities.

Deploy

1.Carry out deployment tool self test.

+ RESTRAINT SYSTEMS, REPAIRS,

Airbag deployment tool - self test.

2.Slide seat fully rearwards to access pre-

tensioner harness connector.

3.Disconnect pre-tensioner harness connector.

Ensure deployment tool SMD 4082/1 is not

connected to battery.

4.Connect flylead SMD 4082/30 to pre-tensioner

connector.

5.Connect flylead SMD 4082/30 to tool SMD

4082/1

WARNING: Ensure pre-tensioner is secured

tightly to seat.

6.Connect tool SMD 4082/1 to battery.

WARNING: Ensure all personnel are

standing at least 15 metres 50 (ft) away from

vehicle.

7.Press both operating buttons to deploy pre-

tensioner.

8.Wearing gloves, disconnect flylead SMD 4082/

30 from pre-tensioner connector and remove

pre-tensioner from seat. Place pre-tensioner in

plastic bag and seal bag.

Page 1143 of 1672

EXTERIOR FITTINGS

76-2-6 REPAIRS

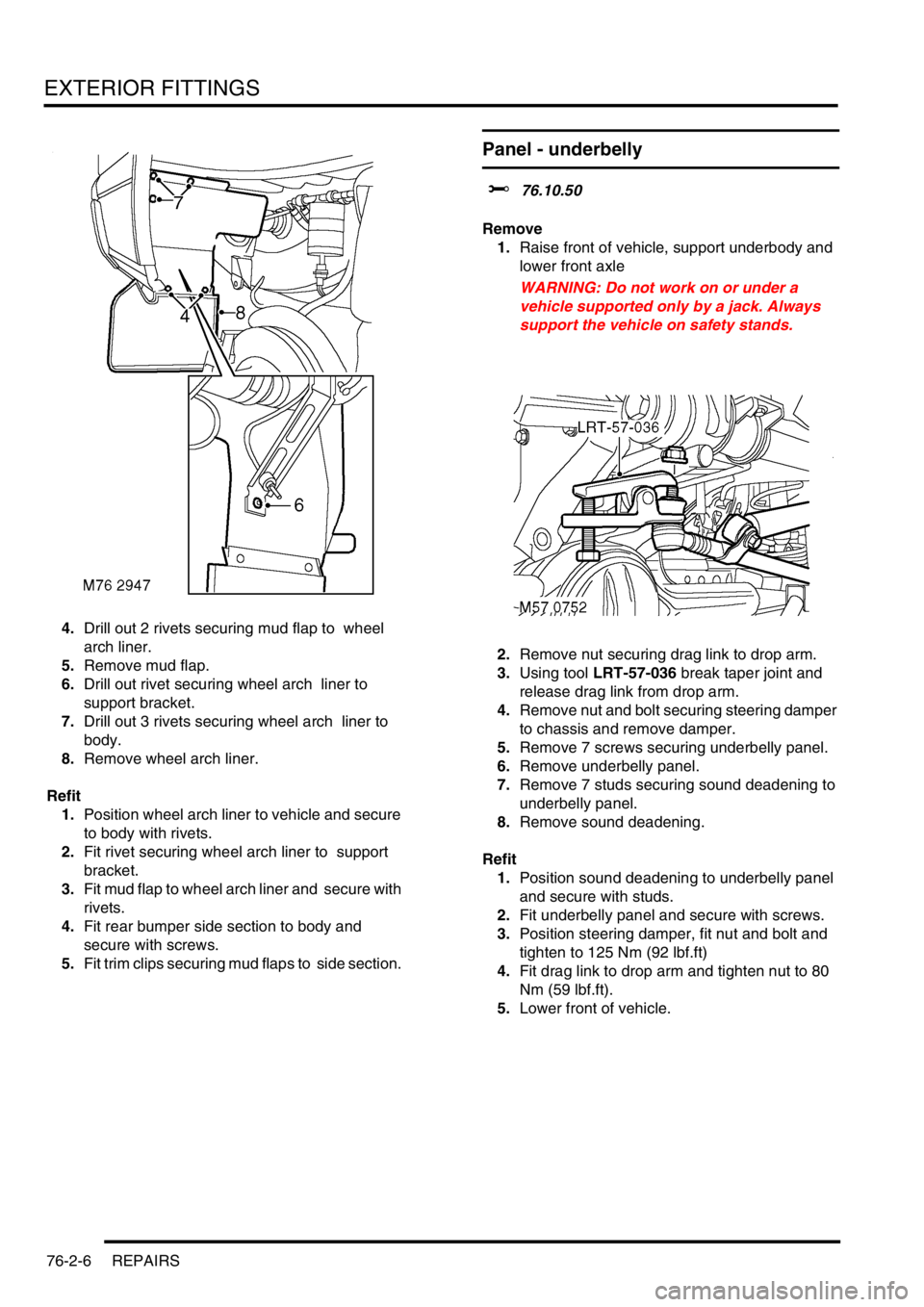

4.Drill out 2 rivets securing mud flap to wheel

arch liner.

5.Remove mud flap.

6.Drill out rivet securing wheel arch liner to

support bracket.

7.Drill out 3 rivets securing wheel arch liner to

body.

8.Remove wheel arch liner.

Refit

1.Position wheel arch liner to vehicle and secure

to body with rivets.

2.Fit rivet securing wheel arch liner to support

bracket.

3.Fit mud flap to wheel arch liner and secure with

rivets.

4.Fit rear bumper side section to body and

secure with screws.

5.Fit trim clips securing mud flaps to side section.

Panel - underbelly

$% 76.10.50

Remove

1.Raise front of vehicle, support underbody and

lower front axle

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove nut securing drag link to drop arm.

3.Using tool LRT-57-036 break taper joint and

release drag link from drop arm.

4.Remove nut and bolt securing steering damper

to chassis and remove damper.

5.Remove 7 screws securing underbelly panel.

6.Remove underbelly panel.

7.Remove 7 studs securing sound deadening to

underbelly panel.

8.Remove sound deadening.

Refit

1.Position sound deadening to underbelly panel

and secure with studs.

2.Fit underbelly panel and secure with screws.

3.Position steering damper, fit nut and bolt and

tighten to 125 Nm (92 lbf.ft)

4.Fit drag link to drop arm and tighten nut to 80

Nm (59 lbf.ft).

5.Lower front of vehicle.