oil LAND ROVER DISCOVERY 2002 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 721 of 1672

MANUAL GEARBOX - R380

37-38 OVERHAUL

Filter - gearbox oil

$% 37.12.38

Disassembly

1.Remove gearbox extension.

+ MANUAL GEARBOX - R380,

OVERHAUL, Extension - gearbox rear.

2.Remove oil filter from gearbox.

Reassembly

1.Clean filter recess in gearbox.

2.Fit filter.

3.Fit gearbox extension.

+ MANUAL GEARBOX - R380,

OVERHAUL, Extension - gearbox rear.

Gear - 5th gear set

$% 37.20.36

Disassembly

1.Remove 5th gear - layshaft.

+ MANUAL GEARBOX - R380,

OVERHAUL, 5th gear - layshaft.

2.Using tool LRT-37-001/2, LRT-37-009 and

LRT-37-010, remove output shaft support

bearing track.

3.Remove 5th gear and baulk ring from output

shaft.

Page 725 of 1672

MANUAL GEARBOX - R380

37-42 OVERHAUL

Bearing - layshaft rear support

$% 37.20.58

Disassembly

1.Remove extension housing.

+ MANUAL GEARBOX - R380,

OVERHAUL, Extension - gearbox rear.

2.Remove 3 Torx screws, remove oil pump and

discard 'O' ring.

3.Drift out layshaft support bearing.

4.Using a suitable two legged puller remove 5th

gear layshaft support bearing track from end of

layshaft. Reassembly

1.Clean layshaft and bearing recess in extension

housing.

2.Fit layshaft support bearing.

3.Clean oil pump recess in extension housing,

ensure screw holes are clean and dry.

4.Lubricate oil pump recess in housing with

gearbox oil.

5.Lubricate a new 'O' ring with gearbox oil and fit

to oil pump.

6.Locate oil pump in extension housing with word

'TOP' towards top of housing.

7.Align fixing screw holes and tap pump lightly

around edges until pump is fully in housing. Do

not pull pump into housing by tightening

screws.

8.Fit Torx screws and tighten to 6 Nm (4.5 lbf.ft).

9.Apply a small amount of heat and fit support

bearing track to layshaft.

10.Fit extension housing.

+ MANUAL GEARBOX - R380,

OVERHAUL, Extension - gearbox rear.

Page 726 of 1672

MANUAL GEARBOX - R380

OVERHAUL 37-43

Bearing - output shaft rear support

$% 37.20.55

Disassembly

1.Remove extension housing.

+ MANUAL GEARBOX - R380,

OVERHAUL, Extension - gearbox rear.

2.Using tool LRT-37-001/2, LRT-37-009 and

LRT-37-010, remove output shaft support

bearing track.

3.Remove output shaft rear oil seal. 4.Remove output shaft support bearing and oil

pick-up ring.

Reassembly

1.Clean output shaft and bearing recess in

extension housing.

2.Fit output shaft support bearing and oil pick-up

ring. (Align tag with centre of drain slot).

3.Fit new output shaft oil seal using LRT-37-014.

Page 727 of 1672

MANUAL GEARBOX - R380

37-44 OVERHAUL

4.Using tool LRT-37-015 and LRT-37-021, fit

support bearing track to output shaft.

5.Fit extension housing.

+ MANUAL GEARBOX - R380,

OVERHAUL, Extension - gearbox rear.

Shaft - reverse idler

$% 37.20.13

Disassembly

1.Remove 5th / reverse gear synchroniser.

+ MANUAL GEARBOX - R380,

OVERHAUL, Synchronizer assembly - 5th/

reverse.

2.Remove reverse gear complete with needle

roller bearing and collar noting selective spacer

between collar and centre plate bearing.

3.Remove layshaft reverse gear noting oil groove

faces centre plate bearing.

4.Remove detent screw from centre plate and

collect upper detent ball and spring.

Page 728 of 1672

MANUAL GEARBOX - R380

OVERHAUL 37-45

5.Remove 2 bolts securing spool retainer to

gearbox case. Remove retainer, remove and

discard 'O' ring - if fitted.

6.Remove interlock spool from selector shaft.

7.Remove filter from gearbox case.

8.Align selector shaft pin with slot in centre plate

and using wooden blocks and hide mallet,

release centre plate and collect lower detent

ball and spring. 9.Press out reverse idler shaft using a suitable

press.

10.Remove idler gear, needle roller bearing and

spacer.

Reassembly

1.Clean centre plate and reverse gear

components.

2.Lubricate gearbox components with clean gear

oil.

3.Position idler gear, bearing and spacer to idler

shaft.

4.Using a suitable press fit idler shaft to centre

plate.

5.Using feeler gauges, check clearance between

reverse idler and shaft flange; fit a thicker or

thinner spacer if necessary in order to achieve

correct clearance:

lNew clearance = 0.04 - 0.38 mm (0.002 -

0.015 in)

lService limit = 0.38 mm (0.015 in)

6.Apply sealant, Part No. STC 3254 to gearbox

casing.

7.Fit lower spring and detent ball into centre

plate, retain using a dummy shaft.

8.Align selector shaft pin with slot in centre plate.

9.Fit centre plate and fit 2 off 8x35 mm slave bolts

to retain centre plate in position on gearbox

case; recover dummy shaft.

Page 730 of 1672

MANUAL GEARBOX - R380

OVERHAUL 37-47

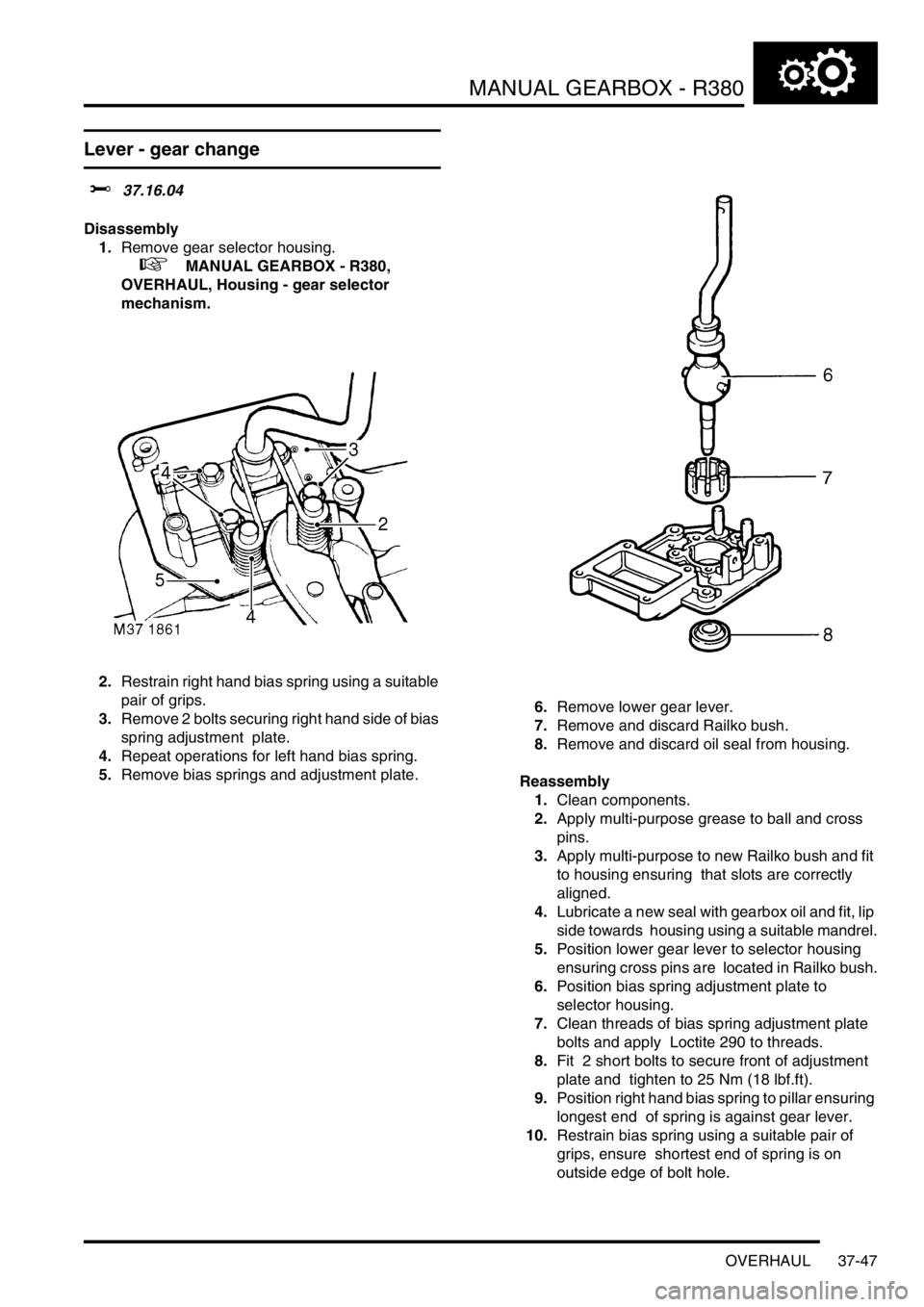

Lever - gear change

$% 37.16.04

Disassembly

1.Remove gear selector housing.

+ MANUAL GEARBOX - R380,

OVERHAUL, Housing - gear selector

mechanism.

2.Restrain right hand bias spring using a suitable

pair of grips.

3.Remove 2 bolts securing right hand side of bias

spring adjustment plate.

4.Repeat operations for left hand bias spring.

5.Remove bias springs and adjustment plate.6.Remove lower gear lever.

7.Remove and discard Railko bush.

8.Remove and discard oil seal from housing.

Reassembly

1.Clean components.

2.Apply multi-purpose grease to ball and cross

pins.

3.Apply multi-purpose to new Railko bush and fit

to housing ensuring that slots are correctly

aligned.

4.Lubricate a new seal with gearbox oil and fit, lip

side towards housing using a suitable mandrel.

5.Position lower gear lever to selector housing

ensuring cross pins are located in Railko bush.

6.Position bias spring adjustment plate to

selector housing.

7.Clean threads of bias spring adjustment plate

bolts and apply Loctite 290 to threads.

8.Fit 2 short bolts to secure front of adjustment

plate and tighten to 25 Nm (18 lbf.ft).

9.Position right hand bias spring to pillar ensuring

longest end of spring is against gear lever.

10.Restrain bias spring using a suitable pair of

grips, ensure shortest end of spring is on

outside edge of bolt hole.

Page 732 of 1672

MANUAL GEARBOX - R380

OVERHAUL 37-49

Cover - front

$% 37.12.33.01

Disassembly

1.Remove retaining peg and remove release

bearing.

2.Remove bolt securing clutch release fork,

remove retaining clip and remove clutch

release fork.

3.Remove 2 bolts securing release bearing

sleeve and remove bearing sleeve. 4.Remove 6 bolts securing clutch housing and

remove clutch housing.

5.Remove and discard 6 bolts securing oil seal

housing.

6.Remove oil seal housing.

7.Using a soft metal drift, carefully remove input

shaft front bearing track from housing.

8.Remove oil seal from housing, discard seal.

Page 733 of 1672

MANUAL GEARBOX - R380

37-50 OVERHAUL

Reassembly

1.Using a suitable solvent cleaner, clean seal

housing mating faces.

2.Clean seal recess, bearings and bearing

races.

3.Lubricate new oil seal and fit using a suitable

mandrel into housing.

4.Fit input shaft front bearing track using a press

and suitable mandrel.

5.Apply sealant, Part No. STC 4404 to seal

housing, fit new bolts and tighten by diagonal

selection to 25 Nm (18 lbf.ft).

6.Clean clutch housing mating faces, dowels and

dowel holes.

7.Position clutch housing, fit bolts and tighten to

75 Nm (55 lbf.ft).

8.Clean release bearing sleeve mating faces,

dowel and dowel holes.

9.Position release bearing sleeve, fit bolts and

tighten to 25 Nm (18 lbf.ft).

10.Examine clutch release fork pivot points for

wear and replace as required.

11.Apply a smear of Molybdenum disulphide

grease to pivot points and position release fork.

12.Fit retaining clip ensuring it locates over pivot

point washer, fit bolt to release fork and tighten

to 10 Nm (7 lbf.ft).

13.Clean release bearing and bearing sleeve

mating faces.

14.Apply smear of Molybdenum disulphide grease

to release bearing sleeve.

15.Fit release bearing and secure with retaining

peg.

Page 737 of 1672

TRANSFER BOX - LT230SE

41-4 DESCRIPTION AND OPERATION

Main casing components – Vehicles up

to 03 model year

1Retaining plate

2Stake nut - intermediate shaft

3Bolt - retaining plate

4'O' rings - intermediate shaft

5Bearings and outer tracks - mainshaft input

gear

6Mainshaft input gear bearing housing

7Cover plate

8Bolt - cover plate

9Selective shim

10Mainshaft input gear

11Oil filler/level plug

12Oil temperature switch - if fitted

13Bearings and outer tracks - intermediate gears

14Circlips

15Intermediate gears

16Bottom cover plate

17Bolt - bottom cover plate

18Selective spacer

19Mainshaft oil seal20Oil drain plug

21Main casing

22Intermediate shaft

23Locating dowel

24Detent ball - high/low selector

25Detent spring - high/low selector

26Detent plug - high/low selector

27Neutral warning switch - Automatic gearbox

only - North America and Japan

28Bolt - interlock solenoid cover - Automatic

gearbox only - North America and Japan

29Cover - interlock solenoid - Automatic gearbox

only - North America and Japan

30Belleville washer - Automatic gearbox only -

North America and Japan

31Interlock solenoid - Automatic gearbox only -

North America and Japan

Page 738 of 1672

TRANSFER BOX - LT230SE

DESCRIPTION AND OPERATION 41-5

Main casing components – Vehicles

from 03 model year

1Retaining plate

2Stake nut - intermediate shaft

3Bolt - retaining plate

4'O' rings - intermediate shaft

5Bearings and outer tracks - mainshaft input

gear

6Mainshaft input gear bearing housing

7Cover plate

8Bolt - cover plate

9Selective shim

10Mainshaft input gear

11Oil filler/level plug

12Oil temperature switch - if fitted

13Bearings and outer tracks - intermediate gears14Intermediate gears

15Bottom cover plate

16Bolt - bottom cover plate

17Selective spacer

18Mainshaft oil seal

19Oil drain plug

20Main casing

21Intermediate shaft

22Locating dowel

23Detent ball - high/low selector

24Detent spring - high/low selector

25Detent plug - high/low selector

26Neutral warning switch - Automatic gearbox

only - North America and Japan