oil temperature LAND ROVER DISCOVERY 2002 Owner's Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 608 of 1672

COOLING SYSTEM - V8

DESCRIPTION AND OPERATION 26-2-7

Inlet manifold - Cooling connections

Coolant leaves the cylinder block via an outlet pipe attached to the front of the air intake manifold. The pipe is

connected to the thermostat housing and the radiator by a branch hose off the radiator top hose.

Hot coolant from the engine is also directed from the inlet manifold via pipes and hoses into the heater matrix. Coolant

is circulated through the heater matrix at all times when the engine is running.

A further tapping from the inlet manifold supplies coolant to the throttle housing via a hose. The coolant circulates

through a plate attached to the bottom of the housing and is returned through a plastic bleed pipe to an expansion

tank. The hot coolant heats the air intake of the throttle housing preventing ice from forming.

An Engine Coolant Temperature (ECT) sensor is fitted in the inlet manifold adjacent to the manifold outlet pipe. The

sensor monitors coolant temperature emerging from the engine and sends signals to the ECM for engine

management and temperature gauge operation.

+ ENGINE MANAGEMENT SYSTEM - V8, DESCRIPTION AND OPERATION, Description - engine

management.

Expansion tank

The expansion tank is located in the engine compartment. The tank is made from moulded plastic and attached to

brackets on the right hand inner wing. A maximum coolant when cold level is moulded onto the tank.

Excess coolant created by heat expansion is returned to the expansion tank from the radiator bleed pipe at the top of

the radiator. An outlet pipe is connected into the pump feed hose and replaces the coolant displaced by heat

expansion into the system when the engine is cool.

The expansion tank is fitted with a sealed pressure cap. The cap contains a pressure relief valve which opens to allow

excessive pressure and coolant to vent through the overflow pipe. The relief valve opens at a pressure of 1.4 bar (20

lbf.in

2) and above.

Heater matrix

The heater matrix is fitted in the heater assembly inside the passenger compartment. Two pipes pass through the

bulkhead into the engine compartment and provide coolant flow to and from the matrix. The pipes from the bulkhead

are connected to the matrix, sealed with 'O' rings and clamped with circular rings.

The matrix is constructed from aluminium with two end tanks interconnected with tubes. Aluminium fins are located

between the tubes and conduct heat away from the hot coolant flowing through the tubes. Air from the heater

assembly is warmed as it passes through the matrix fins. The warm air is then distributed into the passenger

compartment as required.

+ HEATING AND VENTILATION, DESCRIPTION AND OPERATION, Description.When the engine is

running, coolant from the engine is constantly circulated through the heater matrix.

Radiator

The 45 row radiator is located at the front of the vehicle. The cross-flow type radiator is manufactured from aluminium

with moulded plastic end tanks interconnected with tubes. Aluminium fins are located between the tubes and conduct

heat from the hot coolant flowing through the tubes, reducing the cooling temperature as it flows through the radiator.

Air intake from the front of the vehicle when moving carries heat away from the fins. When the vehicle is stationary,

the viscous fan draws air through the radiator fins to prevent the engine from overheating.

Two connections at the top of the radiator provide for the attachment of the top hose and bleed pipe. A connection at

the bottom of the radiator allows for the attachment of the bottom hose to the thermostat housing.

Two smaller radiators are located in front of the cooling radiator. The lower radiator provides cooling of the gearbox

oil and the upper radiator provides cooling for the engine oil.

+ MANUAL GEARBOX - R380, DESCRIPTION AND OPERATION, Description.

+ AUTOMATIC GEARBOX - ZF4HP22 - 24, DESCRIPTION AND OPERATION, Description.

+ ENGINE - V8, DESCRIPTION AND OPERATION, Description.

Page 610 of 1672

COOLING SYSTEM - V8

DESCRIPTION AND OPERATION 26-2-9

Viscous fan

1Coolant pump pulley drive attachment

2Fan blades

3Bi-metallic coil

4Body

The viscous fan provides a means of controlling the speed of the fan relative to the operating temperature of the

engine. The fan rotation draws air through the radiator, reducing engine coolant temperatures when the vehicle is

stationary or moving slowly.

The viscous fan is attached to the coolant pump drive pulley and secured to the pulley by a nut. The nut is positively

attached to a spindle which is supported on bearings in the fan body. The viscous drive comprises a circular drive

plate attached to the spindle and driven from the coolant pump pulley and the coupling body. The drive plate and the

body have interlocking annular grooves with a small clearance which provides the drive when silicone fluid enters the

fluid chamber. A bi-metallic coil is fitted externally on the forward face of the body. The coil is connected to and

operates a valve in the body. The valve operates on a valve plate with ports that connect the reservoir to the fluid

chamber. The valve plate also has return ports which, when the valve is closed, scoop fluid from the fluid chamber

and push it into the reservoir under centrifugal force.

Silicone fluid is retained in a reservoir at the front of the body. When the engine is off and the fan is stationary, the

silicone fluid level stabilises between the reservoir and the fluid chamber. This will result in the fan operating when the

engine is started, but the drive will be removed quickly after the fan starts rotating and the fan will 'freewheel'.

At low radiator temperatures, the fan operation is not required and the bi-metallic coil keeps the valve closed,

separating the silicone fluid from the drive plate. This allows the fan to 'freewheel' reducing the load on the engine,

improving fuel consumption and reducing noise generated by the rotation of the fan.

When the radiator temperature increases, the bi-metallic coil reacts and moves the valve, allowing the silicone fluid

to flow into the fluid chamber. The resistance to shear of the silicone fluid creates drag on the drive plate and provides

drive to the body and the fan blades.

Page 612 of 1672

COOLING SYSTEM - V8

DESCRIPTION AND OPERATION 26-2-11

Viscous fan operation

A = Cold, B = Hot

1Drive plate

2Fan body

3Clearance

4Valve plate

5Valve

6Bi-metallic coil7Fluid seals

8Ball race

9Fluid chamber

10Reservoir

11Return port

When the engine is off and the fan is not rotating, the silicone fluid stabilises within the fluid chamber and the reservoir.

The fluid levels equalise due to the return port in the valve plate being open between the fluid chamber and the

reservoir. In this condition, when the engine is started, silicone fluid is present in the fluid chamber and causes drag

to occur between the drive plate and the body. This causes the fan to operate initially when the engine is started.

As the fan speed increases, centrifugal force and a scoop formed on the fluid chamber side of the valve plate, pushes

the silicone fluid through the return port in the valve plate into the reservoir. As the fluid chamber empties, the drag

between the drive plate and body is reduced, causing the drive plate to slip. This reduces the rotational speed of the

fan and allows it to 'freewheel'.

When the coolant temperature is low, the heat emitted from the radiator does not affect the bi-metallic coil. The valve

remains closed, preventing fluid escaping from the reservoir into the fluid chamber. In this condition the fan will

'freewheel' at a slow speed.

Page 613 of 1672

COOLING SYSTEM - V8

26-2-12 DESCRIPTION AND OPERATION

As the coolant temperature increases, the heat emitted from the radiator causes the bi-metallic coil to tighten. This

movement of the coil moves the valve to which it is attached. The rotation of the valve exposes ports in the valve plate

which allow silicone fluid to spill into the fluid chamber. As the fluid flows into the clearance between the annular

grooves in the drive plate and body, drag is created between the two components. The drag is due to the viscosity

and shear qualities of the silicone fluid and cause the drive plate to rotate the body and fan blades.

As the coolant temperature decreases, the bi-metallic coil expands, rotating the valve and closing off the ports in the

valve plate. When the valve is closed, centrifugal force pushes silicone fluid through the return port, emptying the fluid

chamber. As the fluid chamber empties, the drag between the drive plate and the body is reduced and the body slips

on the drive plate, slowing the rotational speed of the fan.

Page 617 of 1672

COOLING SYSTEM - V8

26-2-16 REPAIRS

8.Remove 6 scrivets and remove LH and RH air

deflectors from front panel. Disconnect

multiplug of gearbox oil temperature sensor

(arrowed).

9.Remove nut and move horn aside. 10.Remove 2 bolts securing radiator LH and RH

upper mounting brackets to body panel and

remove brackets.

11.Remove 4 screws securing air conditioning

condenser LH and RH upper mounting

brackets to condenser.

12.Remove brackets with rubber mounts from

radiator extension brackets.

13.Position absorbent cloth under each cooler

hose to collect oil spillage.

14.Push against coupling release rings and

disconnect hoses from gearbox oil cooler.

CAUTION: Always fit plugs to open

connections to prevent contamination.

15. If fitted: Push against coupling release rings

and disconnect hoses from engine oil cooler.

Page 618 of 1672

COOLING SYSTEM - V8

REPAIRS 26-2-17

16.Remove radiator assembly.

17.Release clip and remove bottom hose from

radiator.

18.Remove 2 bolts and remove extension

brackets from radiator.

19.Remove 2 captive nuts from radiator.

20.Remove 2 screws and remove gearbox oil

cooler from radiator.

21. If fitted: Remove 2 screws and remove engine

oil cooler from radiator.

22.Remove 2 rubber mountings from radiator.

23.Remove sealing strip from bottom of radiator.

24.Remove 2 cowl retaining clips from radiator. Refit

1.Fit cowl retaining clips to radiator.

2.Fit sealing strip to radiator.

3.Fit rubber mountings to radiator.

4.Fit gearbox oil cooler to radiator and secure

with screws.

5. If fitted: Fit engine oil cooler to radiator and

secure with screws.

6.Fit captive nuts to radiator.

7.Fit extension brackets to radiator and secure

with bolts.

8.Fit bottom hose to radiator and secure with clip.

9.Fit radiator and engage lower mountings in

chassis.

10.Ensure connections are clean, then secure

hoses to oil coolers.

11.Fit air conditioning condenser brackets and

secure with screws.

12.Fit radiator upper mounting brackets and

secure with bolts.

13.Fit LH horn and secure with nut.

14.Fit air deflectors and secure with scrivets.

15.Connect multiplug of gearbox oil temperature

sensor.

16.Fit front grille.

+ EXTERIOR FITTINGS, REPAIRS,

Grille - front - up to 03MY.

17.Connect bottom hose to thermostat housing

and secure with clip.

18.Connect top hose to radiator and secure with

clip.

19.Connect bleed hose to radiator and fit clip.

20.Fit lower fan cowl and secure with screws.

21.Fit viscous fan.

+ COOLING SYSTEM - V8, REPAIRS,

Fan - viscous.

22.Top up gearbox oil.

23.Top up engine oil.

24.Refill cooling system.

+ COOLING SYSTEM - V8,

ADJUSTMENTS, Drain and refill.

Page 697 of 1672

MANUAL GEARBOX - R380

37-14 REPAIRS

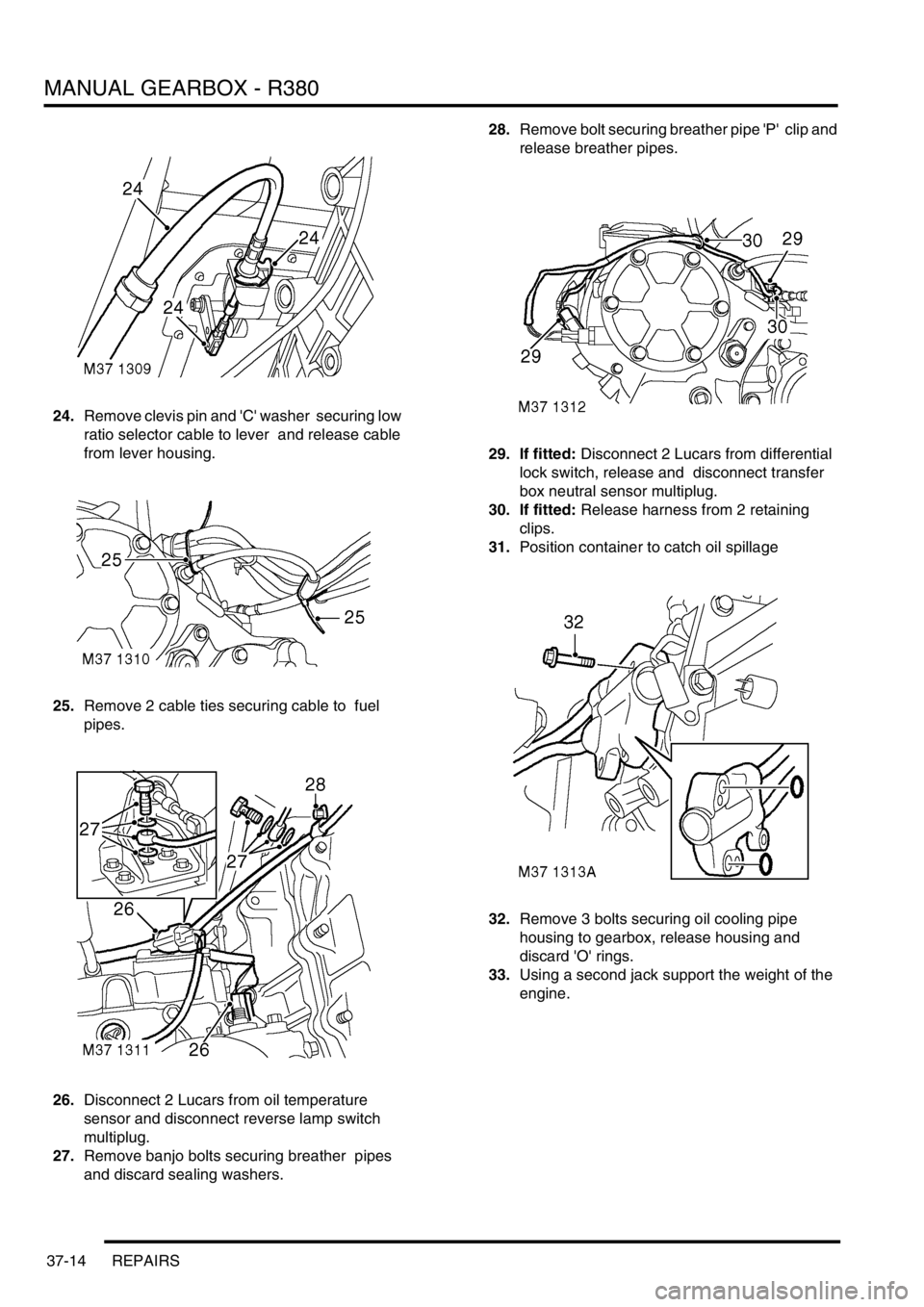

24.Remove clevis pin and 'C' washer securing low

ratio selector cable to lever and release cable

from lever housing.

25.Remove 2 cable ties securing cable to fuel

pipes.

26.Disconnect 2 Lucars from oil temperature

sensor and disconnect reverse lamp switch

multiplug.

27.Remove banjo bolts securing breather pipes

and discard sealing washers. 28.Remove bolt securing breather pipe 'P' clip and

release breather pipes.

29. If fitted: Disconnect 2 Lucars from differential

lock switch, release and disconnect transfer

box neutral sensor multiplug.

30. If fitted: Release harness from 2 retaining

clips.

31.Position container to catch oil spillage

32.Remove 3 bolts securing oil cooling pipe

housing to gearbox, release housing and

discard 'O' rings.

33.Using a second jack support the weight of the

engine.

Page 698 of 1672

MANUAL GEARBOX - R380

REPAIRS 37-15

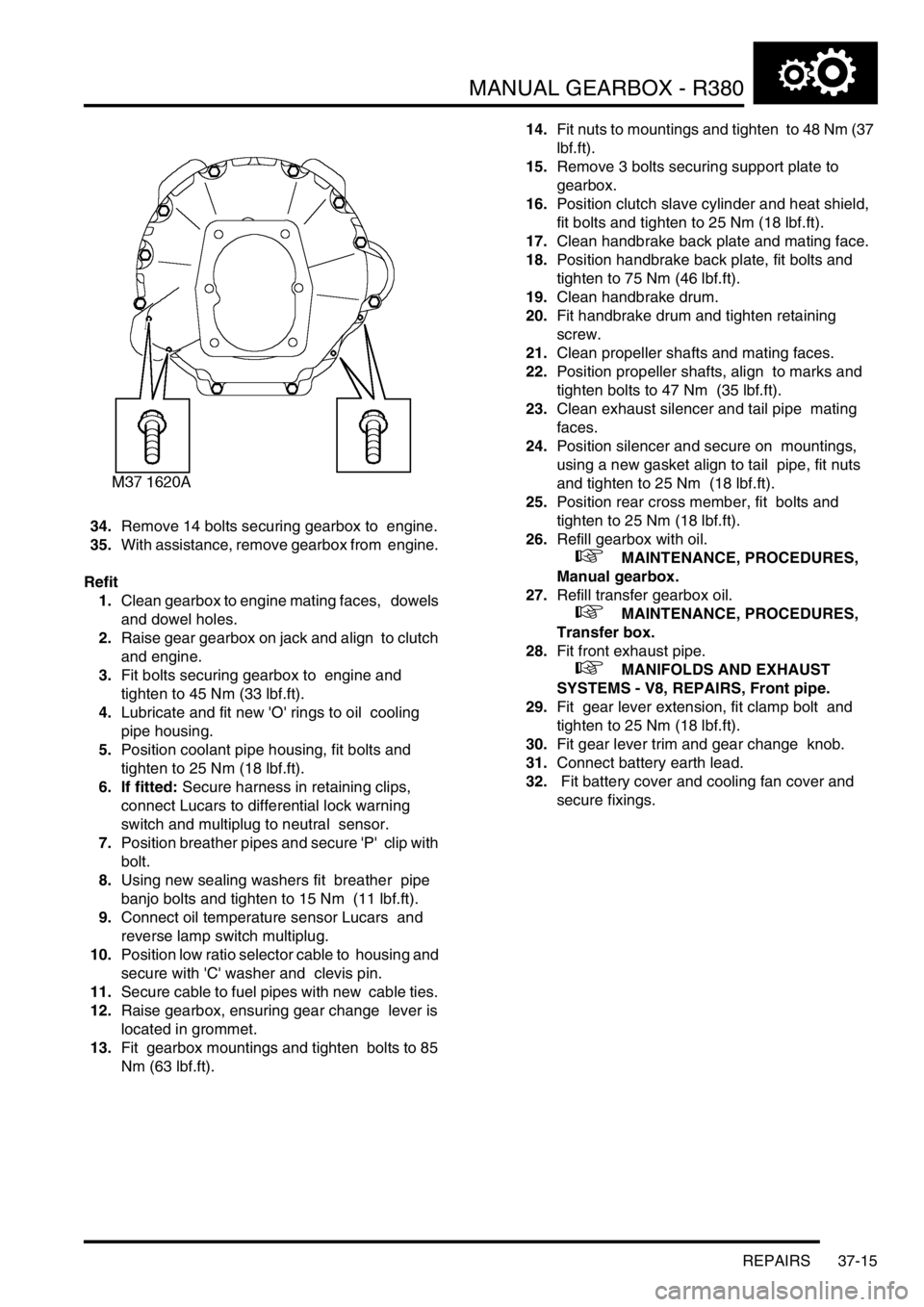

34.Remove 14 bolts securing gearbox to engine.

35.With assistance, remove gearbox from engine.

Refit

1.Clean gearbox to engine mating faces, dowels

and dowel holes.

2.Raise gear gearbox on jack and align to clutch

and engine.

3.Fit bolts securing gearbox to engine and

tighten to 45 Nm (33 lbf.ft).

4.Lubricate and fit new 'O' rings to oil cooling

pipe housing.

5.Position coolant pipe housing, fit bolts and

tighten to 25 Nm (18 lbf.ft).

6. If fitted: Secure harness in retaining clips,

connect Lucars to differential lock warning

switch and multiplug to neutral sensor.

7.Position breather pipes and secure 'P' clip with

bolt.

8.Using new sealing washers fit breather pipe

banjo bolts and tighten to 15 Nm (11 lbf.ft).

9.Connect oil temperature sensor Lucars and

reverse lamp switch multiplug.

10.Position low ratio selector cable to housing and

secure with 'C' washer and clevis pin.

11.Secure cable to fuel pipes with new cable ties.

12.Raise gearbox, ensuring gear change lever is

located in grommet.

13.Fit gearbox mountings and tighten bolts to 85

Nm (63 lbf.ft). 14.Fit nuts to mountings and tighten to 48 Nm (37

lbf.ft).

15.Remove 3 bolts securing support plate to

gearbox.

16.Position clutch slave cylinder and heat shield,

fit bolts and tighten to 25 Nm (18 lbf.ft).

17.Clean handbrake back plate and mating face.

18.Position handbrake back plate, fit bolts and

tighten to 75 Nm (46 lbf.ft).

19.Clean handbrake drum.

20.Fit handbrake drum and tighten retaining

screw.

21.Clean propeller shafts and mating faces.

22.Position propeller shafts, align to marks and

tighten bolts to 47 Nm (35 lbf.ft).

23.Clean exhaust silencer and tail pipe mating

faces.

24.Position silencer and secure on mountings,

using a new gasket align to tail pipe, fit nuts

and tighten to 25 Nm (18 lbf.ft).

25.Position rear cross member, fit bolts and

tighten to 25 Nm (18 lbf.ft).

26.Refill gearbox with oil.

+ MAINTENANCE, PROCEDURES,

Manual gearbox.

27.Refill transfer gearbox oil.

+ MAINTENANCE, PROCEDURES,

Transfer box.

28.Fit front exhaust pipe.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Front pipe.

29.Fit gear lever extension, fit clamp bolt and

tighten to 25 Nm (18 lbf.ft).

30.Fit gear lever trim and gear change knob.

31.Connect battery earth lead.

32. Fit battery cover and cooling fan cover and

secure fixings.

Page 701 of 1672

MANUAL GEARBOX - R380

37-18 REPAIRS

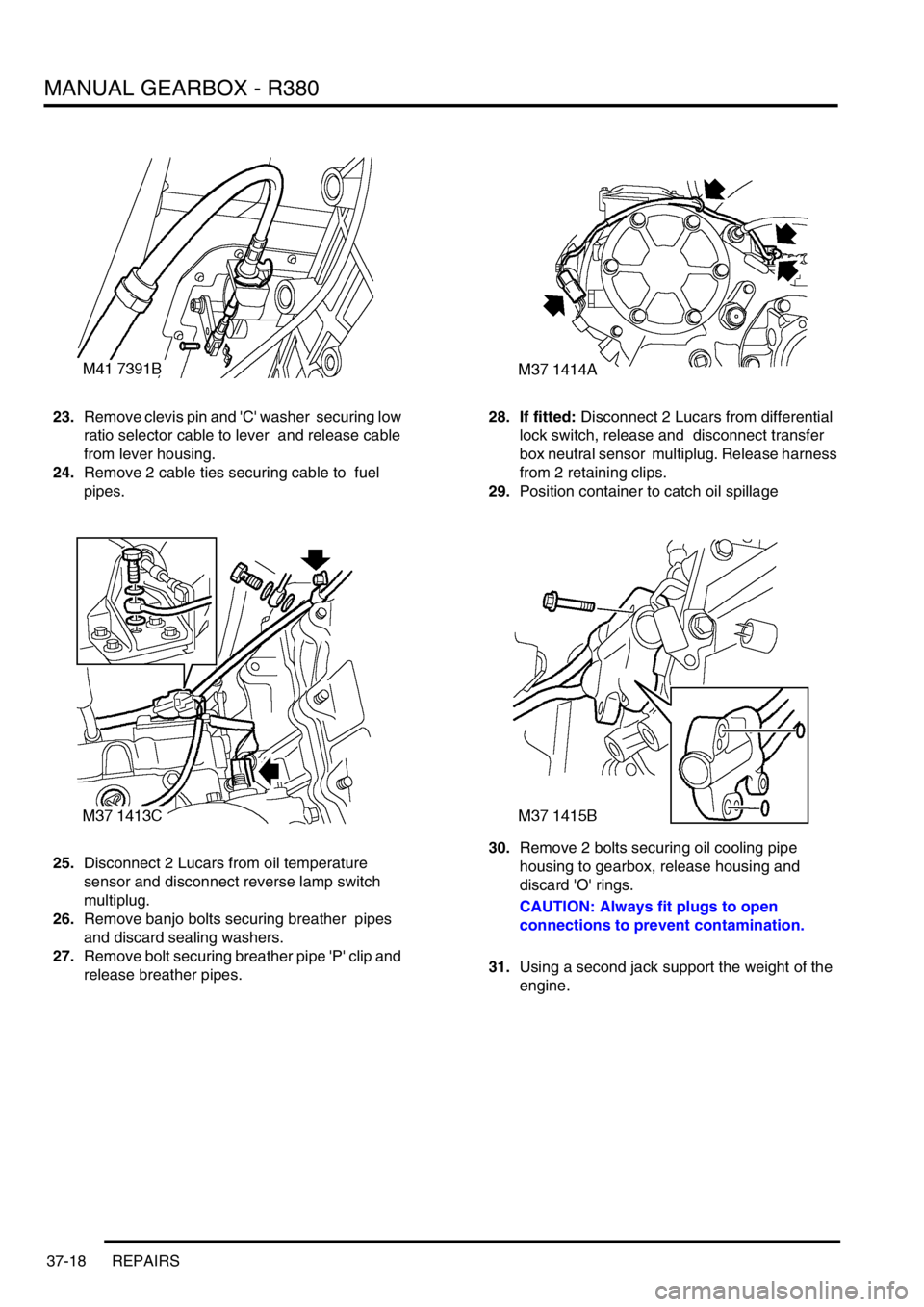

23.Remove clevis pin and 'C' washer securing low

ratio selector cable to lever and release cable

from lever housing.

24.Remove 2 cable ties securing cable to fuel

pipes.

25.Disconnect 2 Lucars from oil temperature

sensor and disconnect reverse lamp switch

multiplug.

26.Remove banjo bolts securing breather pipes

and discard sealing washers.

27.Remove bolt securing breather pipe 'P' clip and

release breather pipes. 28. If fitted: Disconnect 2 Lucars from differential

lock switch, release and disconnect transfer

box neutral sensor multiplug. Release harness

from 2 retaining clips.

29.Position container to catch oil spillage

30.Remove 2 bolts securing oil cooling pipe

housing to gearbox, release housing and

discard 'O' rings.

CAUTION: Always fit plugs to open

connections to prevent contamination.

31.Using a second jack support the weight of the

engine.

Page 702 of 1672

MANUAL GEARBOX - R380

REPAIRS 37-19

32.Remove 8 bolts securing gearbox to engine.

33.With assistance, remove gearbox from engine.

Refit

1.Clean gearbox to engine mating faces, dowels

and dowel holes.

2.With assistance raise gearbox on jack and

align to clutch and engine.

3.Fit bolts securing gearbox to engine and

tighten to 50 Nm (37 lbf.ft).

4.Clean oil cooling pipe housing mating faces.

5.Lubricate and fit new 'O' rings to oil cooling

pipe housing.

6.Position cooling pipe housing, fit bolts and

tighten to 25 Nm (18 lbf.ft).

7. If fitted: Secure harness in retaining clips,

connect Lucars to differential lock warning

switch and multiplug to transfer box neutral

switch.

8.Position breather pipes and secure 'P' clip with

bolt.

9.Using new sealing washers fit breather pipe

banjo bolts and tighten to 15 Nm (11 lbf.ft).

10.Connect oil temperature sensor Lucars and

reverse lamp switch multiplug.

11.Position low ratio selector cable to housing and

secure with 'C' washer and clevis pin.

12.Secure cable to fuel pipes with new cable ties. 13.Raise gearbox, ensuring gear change lever is

located in grommet.

14.Fit gearbox mountings and tighten bolts to 85

Nm (63 lbf.ft).

15.Fit nuts to gearbox mountings and tighten to 48

Nm (37 lbf.ft).

16.Remove 3 bolts securing support plate to

gearbox.

17.Position clutch slave cylinder and heat shield,

fit bolts and tighten to 25 Nm (18 lbf.ft).

18.Clean handbrake back plate and mating face.

19.Position handbrake back plate, fit bolts and

tighten to 75 Nm (55 lbf.ft).

20.Clean handbrake drum.

21.Fit handbrake drum and tighten retaining

screw.

22.Fit front propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - front..

23.Fit rear propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - rear.

24.Clean exhaust silencer and tail pipe mating

faces.

25.Position silencer and secure on mountings,

using a new gasket align to tail pipe, fit nuts

and tighten to 25 Nm (18 lbf.ft).

26.Fit exhaust front pipe.

+ MANIFOLDS AND EXHAUST

SYSTEMS - Td5, REPAIRS, Pipe - front.

27.Refit starter motor.

+ CHARGING AND STARTING,

REPAIRS, Starter motor - diesel.

28.Refill gearbox with oil.

+ MAINTENANCE, PROCEDURES,

Manual gearbox.

29.Refill transfer gearbox with oil.

+ MAINTENANCE, PROCEDURES,

Transfer box.

30.Fit gear lever extension, fit clamp bolt and

tighten to 25 Nm (18 lbf.ft).

31.Fit gear lever trim and gear change knob.

32.Connect battery earth lead.

33.Fit cooling fan cowl and battery cover and

secure fixings.