length LAND ROVER FREELANDER 2001 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 91 of 1007

GENERAL DATA

04-28

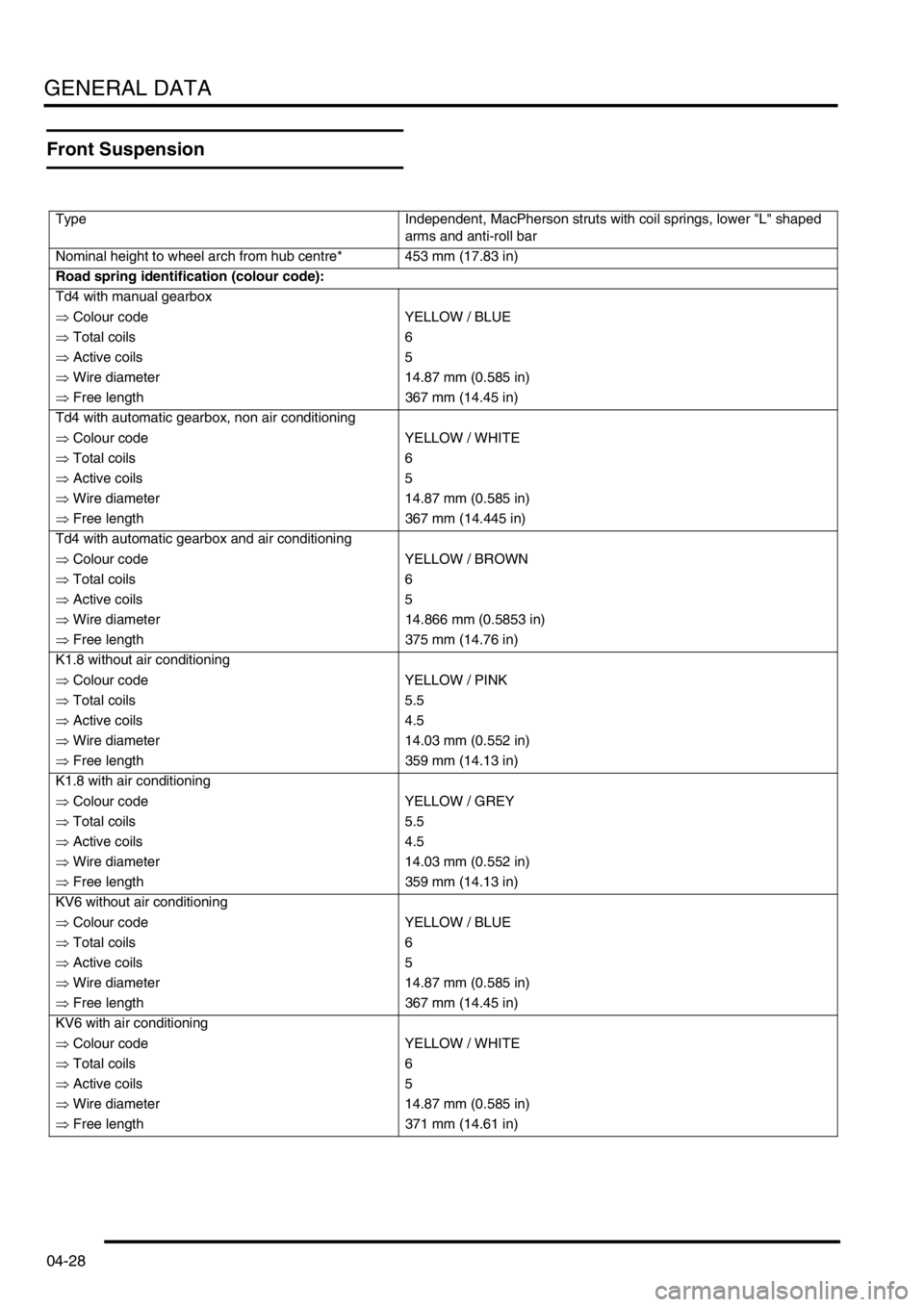

Front Suspension

Type Independent, MacPherson struts with coil springs, lower "L" shaped

arms and anti-roll bar

Nominal height to wheel arch from hub centre* 453 mm (17.83 in)

Road spring identification (colour code):

Td4 with manual gearbox

⇒ Colour code YELLOW / BLUE

⇒ Total coils 6

⇒ Active coils 5

⇒ Wire diameter 14.87 mm (0.585 in)

⇒ Free length 367 mm (14.45 in)

Td4 with automatic gearbox, non air conditioning

⇒ Colour code YELLOW / WHITE

⇒ Total coils 6

⇒ Active coils 5

⇒ Wire diameter 14.87 mm (0.585 in)

⇒ Free length 367 mm (14.445 in)

Td4 with automatic gearbox and air conditioning

⇒ Colour code YELLOW / BROWN

⇒ Total coils 6

⇒ Active coils 5

⇒ Wire diameter 14.866 mm (0.5853 in)

⇒ Free length 375 mm (14.76 in)

K1.8 without air conditioning

⇒ Colour code YELLOW / PINK

⇒ Total coils 5.5

⇒ Active coils 4.5

⇒ Wire diameter 14.03 mm (0.552 in)

⇒ Free length 359 mm (14.13 in)

K1.8 with air conditioning

⇒ Colour code YELLOW / GREY

⇒ Total coils 5.5

⇒ Active coils 4.5

⇒ Wire diameter 14.03 mm (0.552 in)

⇒ Free length 359 mm (14.13 in)

KV6 without air conditioning

⇒ Colour code YELLOW / BLUE

⇒ Total coils 6

⇒ Active coils 5

⇒ Wire diameter 14.87 mm (0.585 in)

⇒ Free length 367 mm (14.45 in)

KV6 with air conditioning

⇒ Colour code YELLOW / WHITE

⇒ Total coils 6

⇒ Active coils 5

⇒ Wire diameter 14.87 mm (0.585 in)

⇒ Free length 371 mm (14.61 in)

Page 92 of 1007

GENERAL DATA

04-29

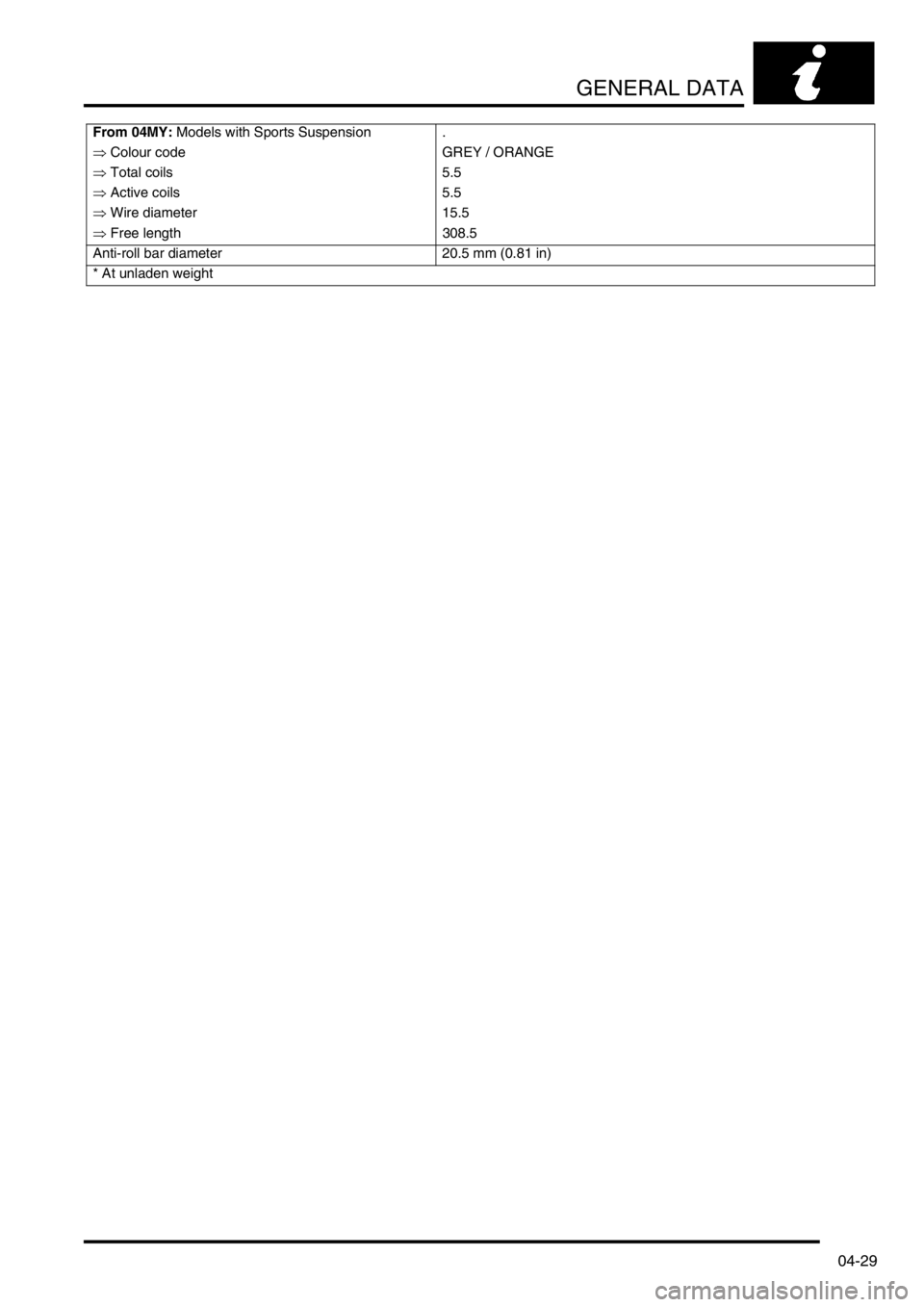

From 04MY: Models with Sports Suspension .

⇒ Colour code GREY / ORANGE

⇒ Total coils 5.5

⇒ Active coils 5.5

⇒ Wire diameter 15.5

⇒ Free length 308.5

Anti-roll bar diameter 20.5 mm (0.81 in)

* At unladen weight

Page 93 of 1007

GENERAL DATA

04-30

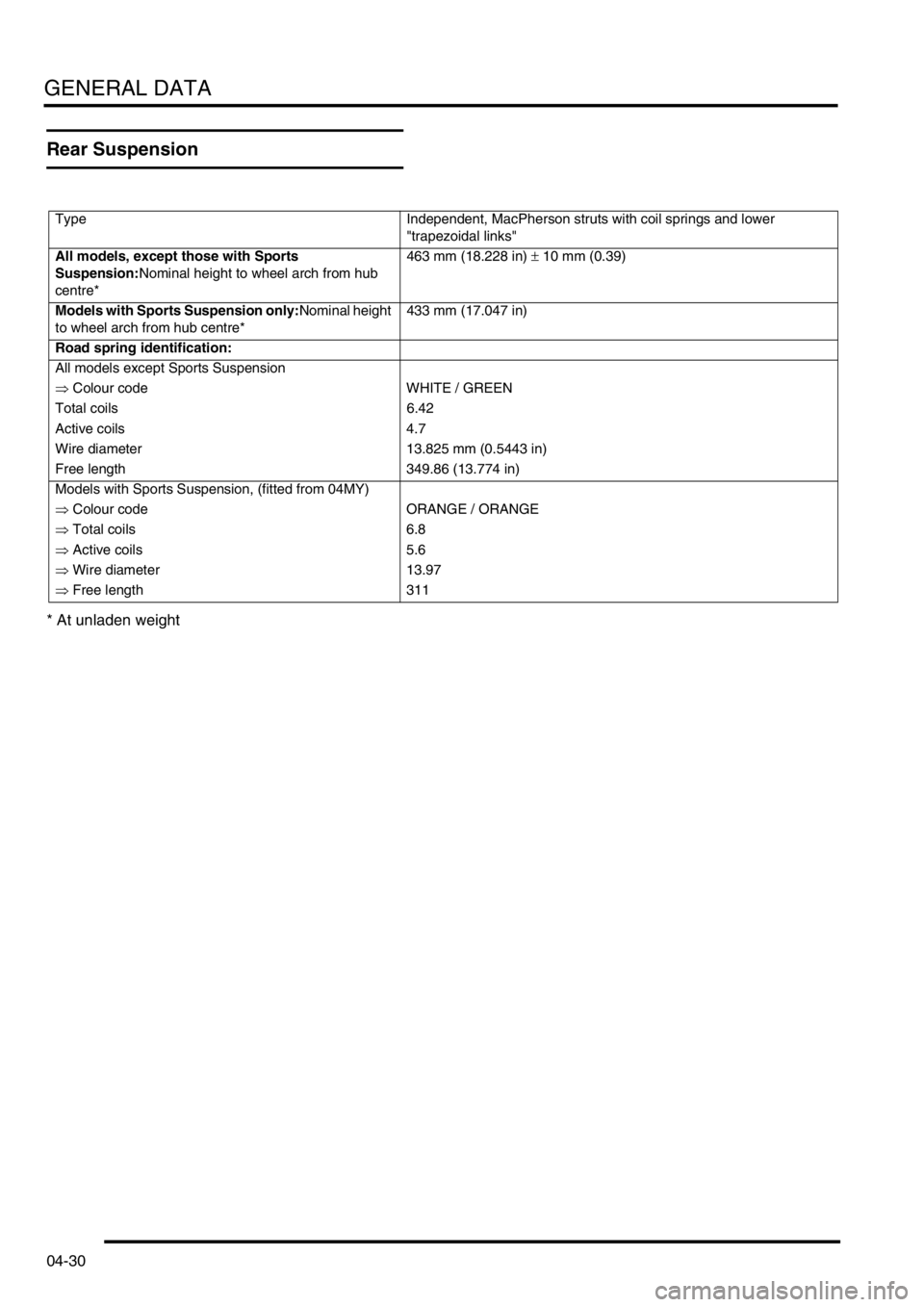

Rear Suspension

* At unladen weight

Type Independent, MacPherson struts with coil springs and lower

"trapezoidal links"

All models, except those with Sports

Suspension:Nominal height to wheel arch from hub

centre*463 mm (18.228 in) ± 10 mm (0.39)

Models with Sports Suspension only:Nominal height

to wheel arch from hub centre*433 mm (17.047 in)

Road spring identification:

All models except Sports Suspension

⇒ Colour code WHITE / GREEN

Total coils 6.42

Active coils 4.7

Wire diameter 13.825 mm (0.5443 in)

Free length 349.86 (13.774 in)

Models with Sports Suspension, (fitted from 04MY)

⇒ Colour code ORANGE / ORANGE

⇒ Total coils 6.8

⇒ Active coils 5.6

⇒ Wire diameter 13.97

⇒ Free length 311

Page 98 of 1007

GENERAL DATA

04-35

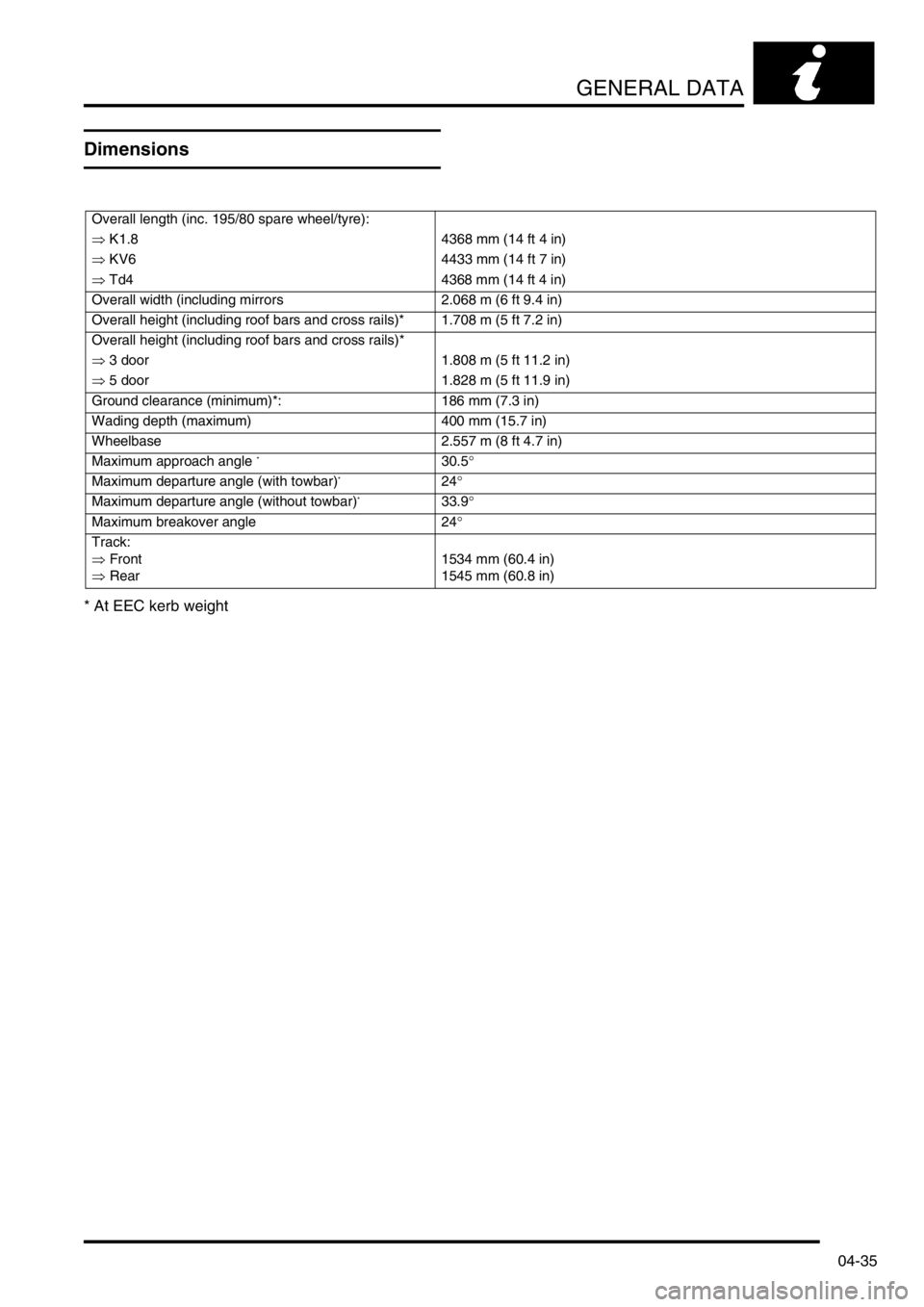

Dimensions

* At EEC kerb weight

Overall length (inc. 195/80 spare wheel/tyre):

⇒ K1.8 4368 mm (14 ft 4 in)

⇒ KV6 4433 mm (14 ft 7 in)

⇒ Td4 4368 mm (14 ft 4 in)

Overall width (including mirrors 2.068 m (6 ft 9.4 in)

Overall height (including roof bars and cross rails)* 1.708 m (5 ft 7.2 in)

Overall height (including roof bars and cross rails)*

⇒ 3 door 1.808 m (5 ft 11.2 in)

⇒ 5 door 1.828 m (5 ft 11.9 in)

Ground clearance (minimum)*: 186 mm (7.3 in)

Wading depth (maximum) 400 mm (15.7 in)

Wheelbase 2.557 m (8 ft 4.7 in)

Maximum approach angle

*30.5°

Maximum departure angle (with towbar)

*24°

Maximum departure angle (without towbar)

*33.9°

Maximum breakover angle 24°

Track:

⇒ Front

⇒ Rear1534 mm (60.4 in)

1545 mm (60.8 in)

Page 151 of 1007

MAINTENANCE

10-4 MAINTENANCE

Seats and Seat Belts

Check

1.Check seat frames are secured to floor and

show no signs of movement.

2.Check operation of seat slide and tilt

mechanisms, ensuring there is no excessive

play between seat cushion and seat back.

3.Check tightness of accessible seat fixings.

4.Fully extract seat belt and allow it to return

under its own recoil mechanism.

5.Check entire length of seat belt webbing for

signs of fraying or damage. Repeat for all belts.

6.Check security of seat belt upper mountings.

7.Check for correct operation of seat belt height

adjusters.

8.Check security of seat belt buckle mountings.

9.Connect each belt to the correct buckle, check

seat belt buckle and tongue are secure.

Release seat belt buckle and check for correct

operation.

10.Check tightness of accessible seat belt

mountings.

Lamps, Horns and Warning Indicators

Check

1.Switch on side, head and tail lights and check

operation.

2.Check headlamp dim/dip operation.

3.Check headlamp levelling operation.

4.Check turn signals and hazard warning lights

operation.

5.Press brake pedal and check operation of

brake lights.

6.Check all exterior lamp lenses for clarity and

condition. Pay particular attention to head lamp

lenses for signs of stone chips or damage.

7.Check horn for loud clear sound.

8.Check operation of all instrument pack warning

and indicator lights.

9.Check for correct operation of interior courtesy

lights.

10.Switch on headlamps (with ignition switch at 'O'

position) and check light reminder warning

operates when door is opened.

Page 233 of 1007

ENGINE - K SERIES KV6

12-3-56 REPAIRS

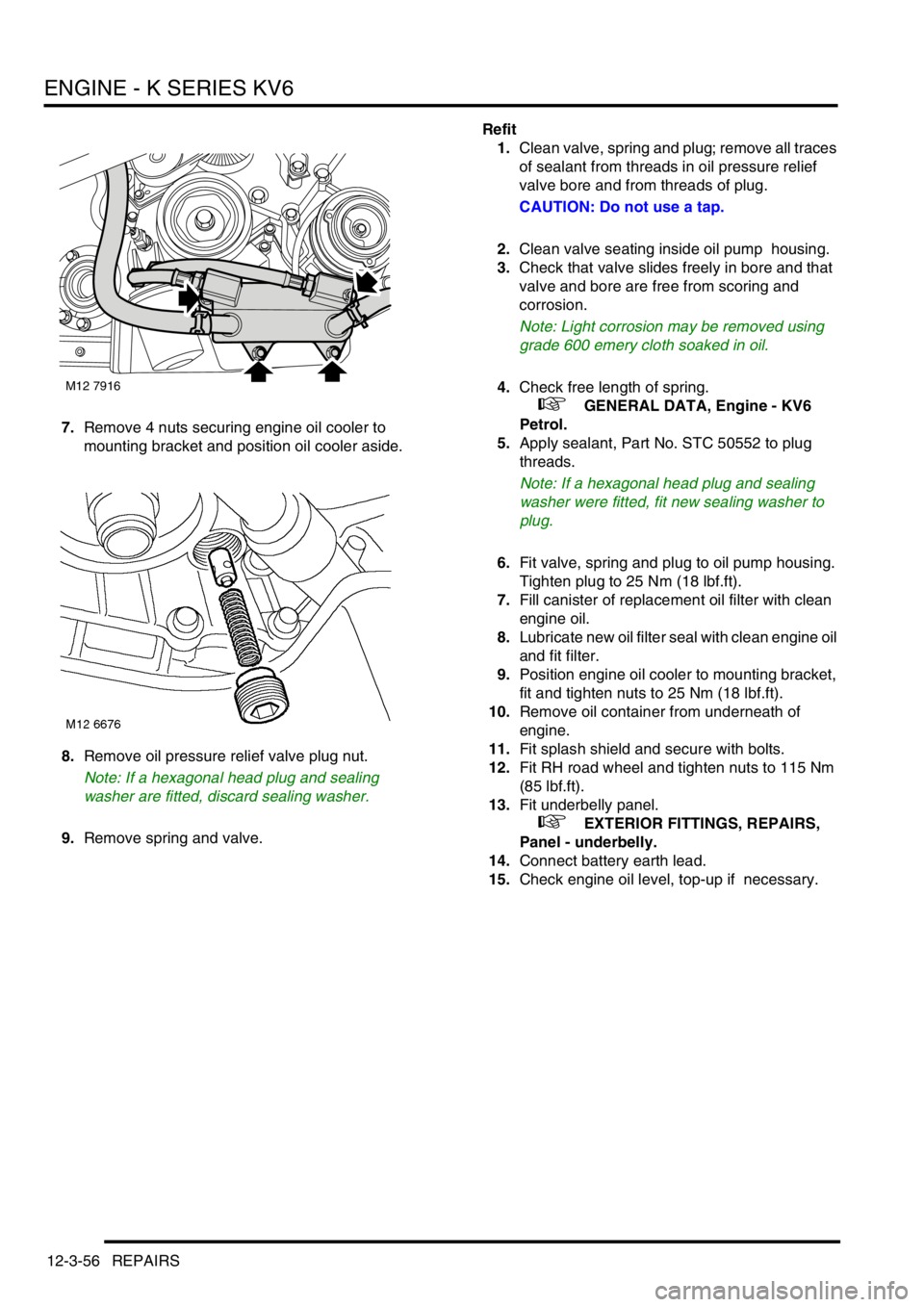

7.Remove 4 nuts securing engine oil cooler to

mounting bracket and position oil cooler aside.

8.Remove oil pressure relief valve plug nut.

Note: If a hexagonal head plug and sealing

washer are fitted, discard sealing washer.

9.Remove spring and valve.Refit

1.Clean valve, spring and plug; remove all traces

of sealant from threads in oil pressure relief

valve bore and from threads of plug.

CAUTION: Do not use a tap.

2.Clean valve seating inside oil pump housing.

3.Check that valve slides freely in bore and that

valve and bore are free from scoring and

corrosion.

Note: Light corrosion may be removed using

grade 600 emery cloth soaked in oil.

4.Check free length of spring.

+ GENERAL DATA, Engine - KV6

Petrol.

5.Apply sealant, Part No. STC 50552 to plug

threads.

Note: If a hexagonal head plug and sealing

washer were fitted, fit new sealing washer to

plug.

6.Fit valve, spring and plug to oil pump housing.

Tighten plug to 25 Nm (18 lbf.ft).

7.Fill canister of replacement oil filter with clean

engine oil.

8.Lubricate new oil filter seal with clean engine oil

and fit filter.

9.Position engine oil cooler to mounting bracket,

fit and tighten nuts to 25 Nm (18 lbf.ft).

10.Remove oil container from underneath of

engine.

11.Fit splash shield and secure with bolts.

12.Fit RH road wheel and tighten nuts to 115 Nm

(85 lbf.ft).

13.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

14.Connect battery earth lead.

15.Check engine oil level, top-up if necessary.

M12 7916

Page 260 of 1007

ENGINE - K SERIES KV6

OVERHAUL 12-3-83

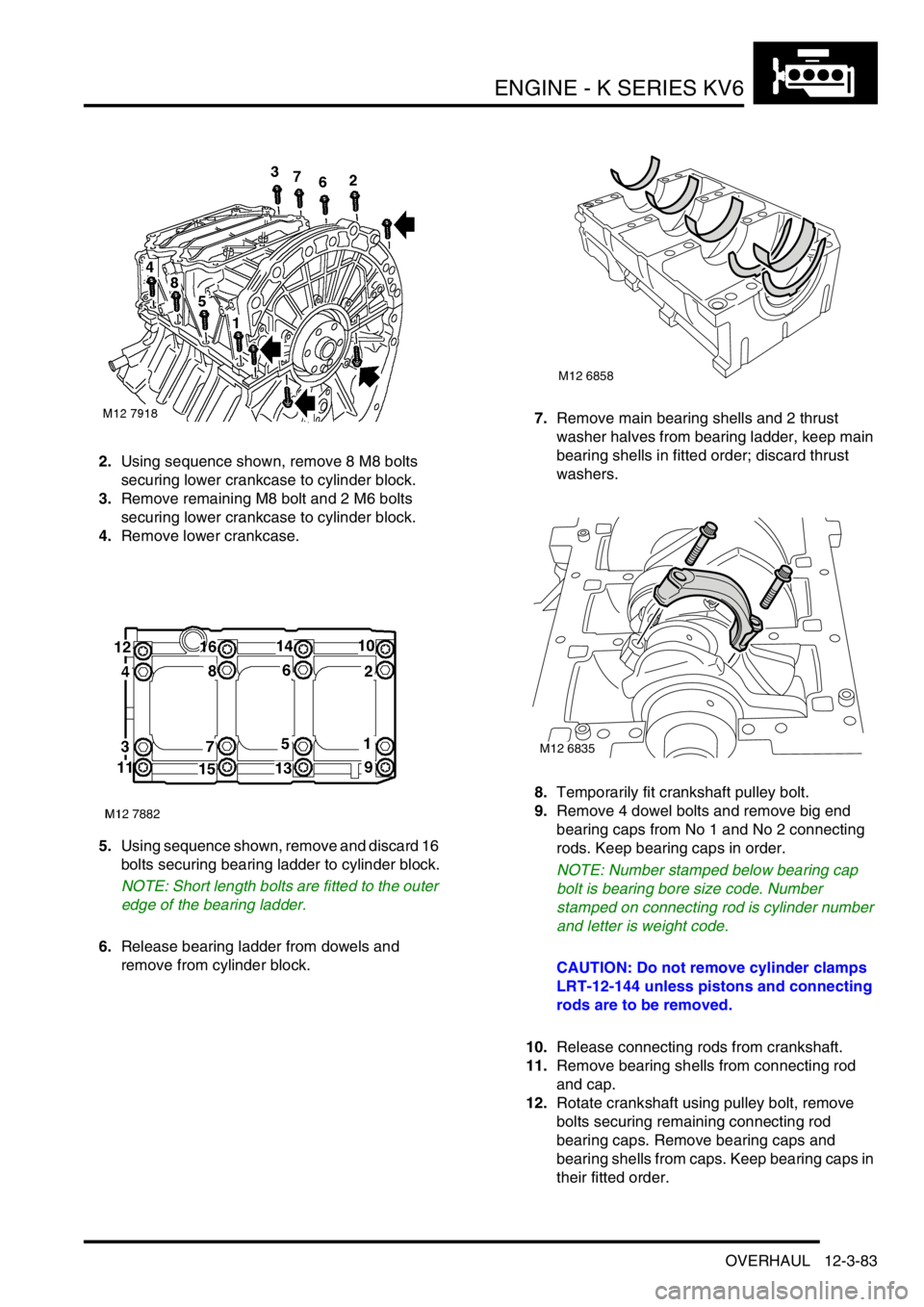

2.Using sequence shown, remove 8 M8 bolts

securing lower crankcase to cylinder block.

3.Remove remaining M8 bolt and 2 M6 bolts

securing lower crankcase to cylinder block.

4.Remove lower crankcase.

5.Using sequence shown, remove and discard 16

bolts securing bearing ladder to cylinder block.

NOTE: Short length bolts are fitted to the outer

edge of the bearing ladder.

6.Release bearing ladder from dowels and

remove from cylinder block.7.Remove main bearing shells and 2 thrust

washer halves from bearing ladder, keep main

bearing shells in fitted order; discard thrust

washers.

8.Temporarily fit crankshaft pulley bolt.

9.Remove 4 dowel bolts and remove big end

bearing caps from No 1 and No 2 connecting

rods. Keep bearing caps in order.

NOTE: Number stamped below bearing cap

bolt is bearing bore size code. Number

stamped on connecting rod is cylinder number

and letter is weight code.

CAUTION: Do not remove cylinder clamps

LRT-12-144 unless pistons and connecting

rods are to be removed.

10.Release connecting rods from crankshaft.

11.Remove bearing shells from connecting rod

and cap.

12.Rotate crankshaft using pulley bolt, remove

bolts securing remaining connecting rod

bearing caps. Remove bearing caps and

bearing shells from caps. Keep bearing caps in

their fitted order.

M12 6858

M12 6835

Page 275 of 1007

ENGINE - K SERIES KV6

12-3-98 OVERHAUL

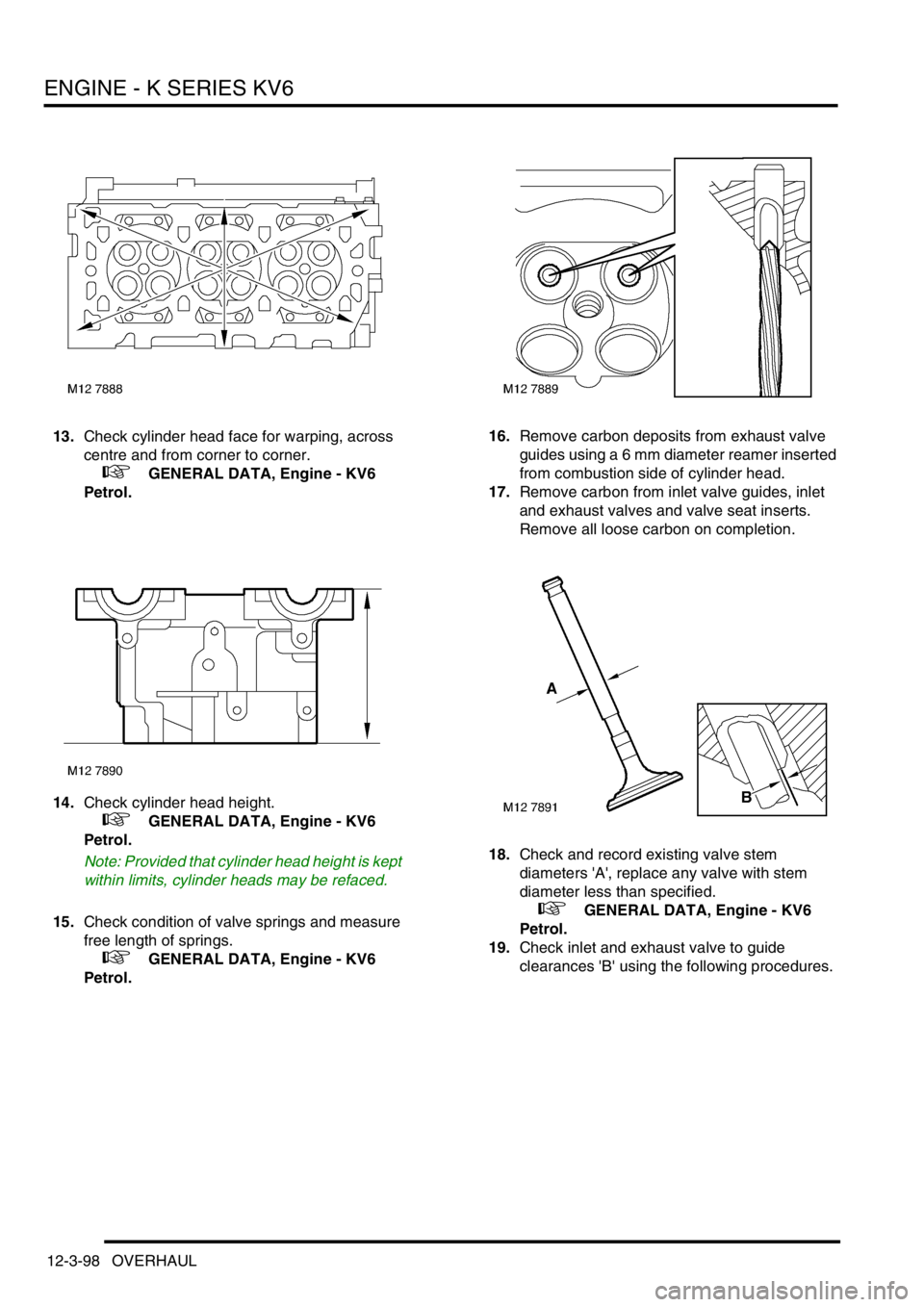

13.Check cylinder head face for warping, across

centre and from corner to corner.

+ GENERAL DATA, Engine - KV6

Petrol.

14.Check cylinder head height.

+ GENERAL DATA, Engine - KV6

Petrol.

Note: Provided that cylinder head height is kept

within limits, cylinder heads may be refaced.

15.Check condition of valve springs and measure

free length of springs.

+ GENERAL DATA, Engine - KV6

Petrol.16.Remove carbon deposits from exhaust valve

guides using a 6 mm diameter reamer inserted

from combustion side of cylinder head.

17.Remove carbon from inlet valve guides, inlet

and exhaust valves and valve seat inserts.

Remove all loose carbon on completion.

18.Check and record existing valve stem

diameters 'A', replace any valve with stem

diameter less than specified.

+ GENERAL DATA, Engine - KV6

Petrol.

19.Check inlet and exhaust valve to guide

clearances 'B' using the following procedures.

Page 282 of 1007

ENGINE - K SERIES KV6

OVERHAUL 12-3-105

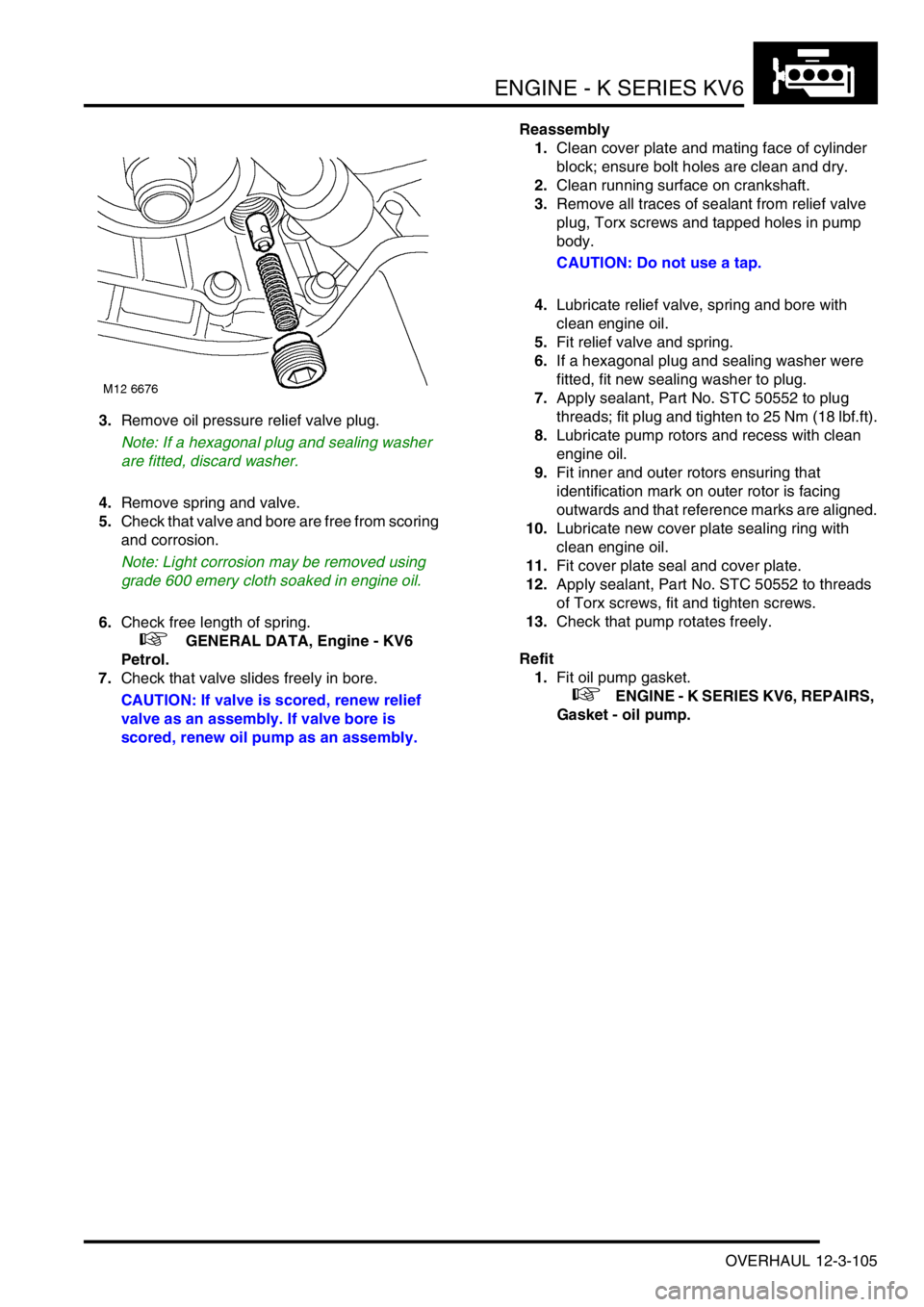

3.Remove oil pressure relief valve plug.

Note: If a hexagonal plug and sealing washer

are fitted, discard washer.

4.Remove spring and valve.

5.Check that valve and bore are free from scoring

and corrosion.

Note: Light corrosion may be removed using

grade 600 emery cloth soaked in engine oil.

6.Check free length of spring.

+ GENERAL DATA, Engine - KV6

Petrol.

7.Check that valve slides freely in bore.

CAUTION: If valve is scored, renew relief

valve as an assembly. If valve bore is

scored, renew oil pump as an assembly.Reassembly

1.Clean cover plate and mating face of cylinder

block; ensure bolt holes are clean and dry.

2.Clean running surface on crankshaft.

3.Remove all traces of sealant from relief valve

plug, Torx screws and tapped holes in pump

body.

CAUTION: Do not use a tap.

4.Lubricate relief valve, spring and bore with

clean engine oil.

5.Fit relief valve and spring.

6.If a hexagonal plug and sealing washer were

fitted, fit new sealing washer to plug.

7.Apply sealant, Part No. STC 50552 to plug

threads; fit plug and tighten to 25 Nm (18 lbf.ft).

8.Lubricate pump rotors and recess with clean

engine oil.

9.Fit inner and outer rotors ensuring that

identification mark on outer rotor is facing

outwards and that reference marks are aligned.

10.Lubricate new cover plate sealing ring with

clean engine oil.

11.Fit cover plate seal and cover plate.

12.Apply sealant, Part No. STC 50552 to threads

of Torx screws, fit and tighten screws.

13.Check that pump rotates freely.

Refit

1.Fit oil pump gasket.

+ ENGINE - K SERIES KV6, REPAIRS,

Gasket - oil pump.

Page 613 of 1007

DOORS

76-1-8 REPAIRS

Rubber/felt - glass channel - front door

$% 76.31.13

Remove

1.Remove exterior mirror.

+ EXTERIOR FITTINGS, REPAIRS,

Mirror - exterior - electric.

2.Lower door glass.

3.Remove inner seal.

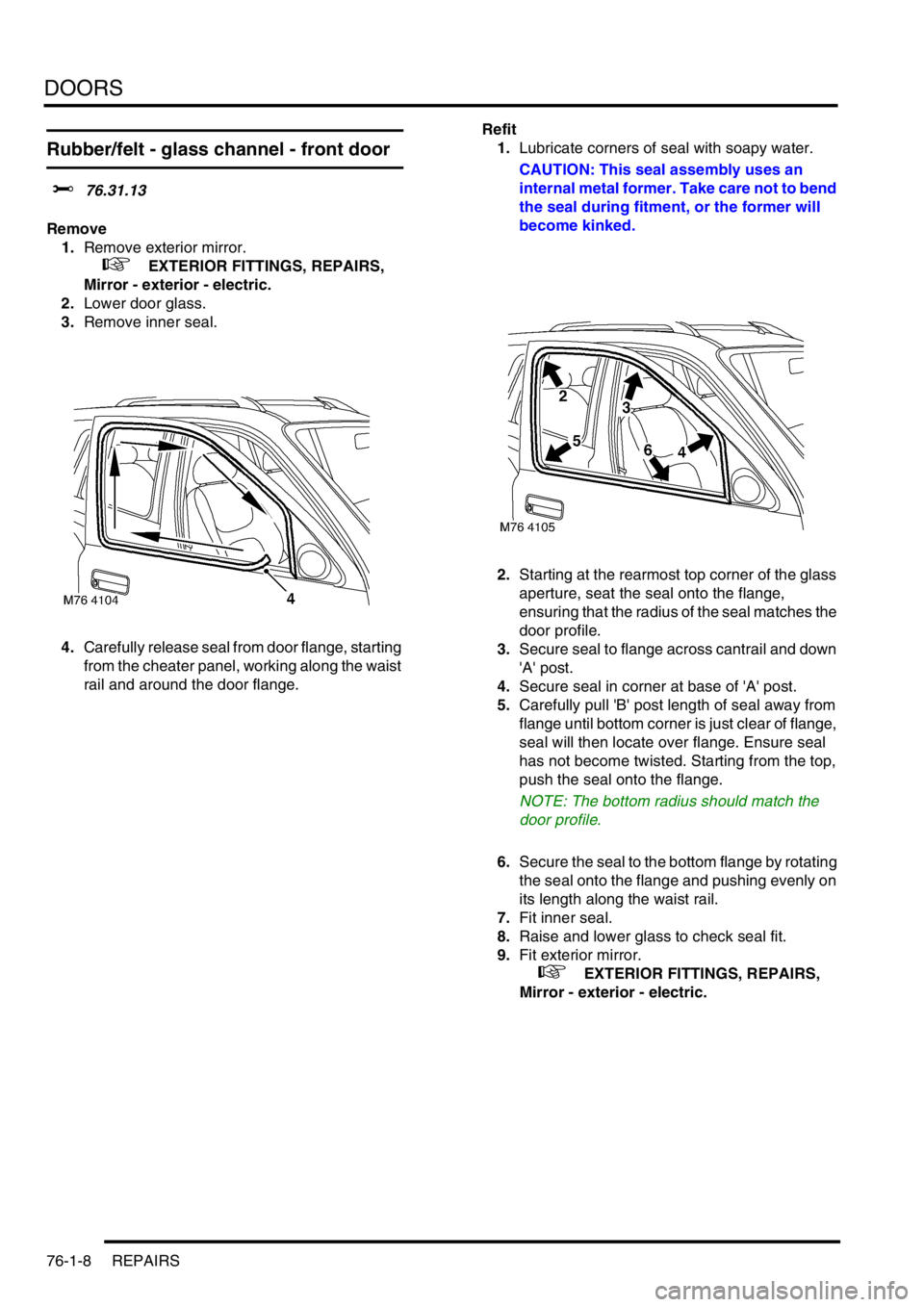

4.Carefully release seal from door flange, starting

from the cheater panel, working along the waist

rail and around the door flange.Refit

1.Lubricate corners of seal with soapy water.

CAUTION: This seal assembly uses an

internal metal former. Take care not to bend

the seal during fitment, or the former will

become kinked.

2.Starting at the rearmost top corner of the glass

aperture, seat the seal onto the flange,

ensuring that the radius of the seal matches the

door profile.

3.Secure seal to flange across cantrail and down

'A' post.

4.Secure seal in corner at base of 'A' post.

5.Carefully pull 'B' post length of seal away from

flange until bottom corner is just clear of flange,

seal will then locate over flange. Ensure seal

has not become twisted. Starting from the top,

push the seal onto the flange.

NOTE: The bottom radius should match the

door profile.

6.Secure the seal to the bottom flange by rotating

the seal onto the flange and pushing evenly on

its length along the waist rail.

7.Fit inner seal.

8.Raise and lower glass to check seal fit.

9.Fit exterior mirror.

+ EXTERIOR FITTINGS, REPAIRS,

Mirror - exterior - electric.