air condition LAND ROVER FREELANDER 2001 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 141 of 1007

LIFTING AND TOWING

08-2

Raising the front of a vehicle

Position the cup of the hydraulic arm under the

centre of the front body crossmember assembly.

Use jack to raise front road wheels to enable safety

stands to be installed under the front end of each

longitudinal member.

Carefully lower jack until vehicle sits securely on

safety stands.

Before working on the underside of a vehicle re-

check the stability of the vehicle on the stands.

Use the reverse procedure when removing a vehicle

from stands.

NOTE: For some repair operations it may be

necessary to use a jack to support the engine under

the sump. In this case, a block of wood should be

used on the jack to protect the sump.

Raising the rear of a vehicle

Position cup of hydraulic arm under the centre of the

rear subframe crossmember at the position

identified by the embossed arrows.

Use jack to raise rear road wheels to enable safety

stands to be installed under the rear ends of the

body longitudinal members.

Carefully lower jack until vehicle sits securely on

safety stands.

Before working on the underside of a vehicle, re-

check the stability of the vehicle on the stands.

Use the reverse procedure when removing a vehicle

from stands.

Wheel-free lift

Locate the lifting pads under the ends of the body

longitudinal members. Raise the ramp to support the

weight of the vehicle, ensure the vehicle is secure on

the lifting pads, then raise the ramp to the required

height.

Towing

General

The vehicle has permanent four wheel drive. The

following instructions must be adhered to:

Towing the vehicle on all four wheels with driver

operating steering and brakes

lTurn ignition key to position '1' to release

steering lock and then to position 'II' to enable

the brake lights, wipers and direction indicators

to be operated, if necessary.

l Select neutral in gearbox and ensure HDC (hill

descent control) is deselected.

lSecure tow rope, chain or cable to towing eye.

lRelease the parking brake.

CAUTION: The brake servo and power assisted

steering system will not be functional without the

engine running. Greater pedal pressure will be

required to apply the brakes and the steering

system will require greater effort to turn the front

road wheels. The vehicle tow connection should

only be used under normal road conditions,

'snatch' recovery should be avoided.

Suspended tow by breakdown vehicle

Mark propeller shaft drive flanges and mating flanges

with identification lines to enable the propeller shaft

to be refitted in its original position.

Remove the propeller shaft fixings then remove the

shaft from the vehicle.

CAUTION: To prevent vehicle damage, rear

propeller shaft MUST BE removed.

Page 155 of 1007

MAINTENANCE

10-8 MAINTENANCE

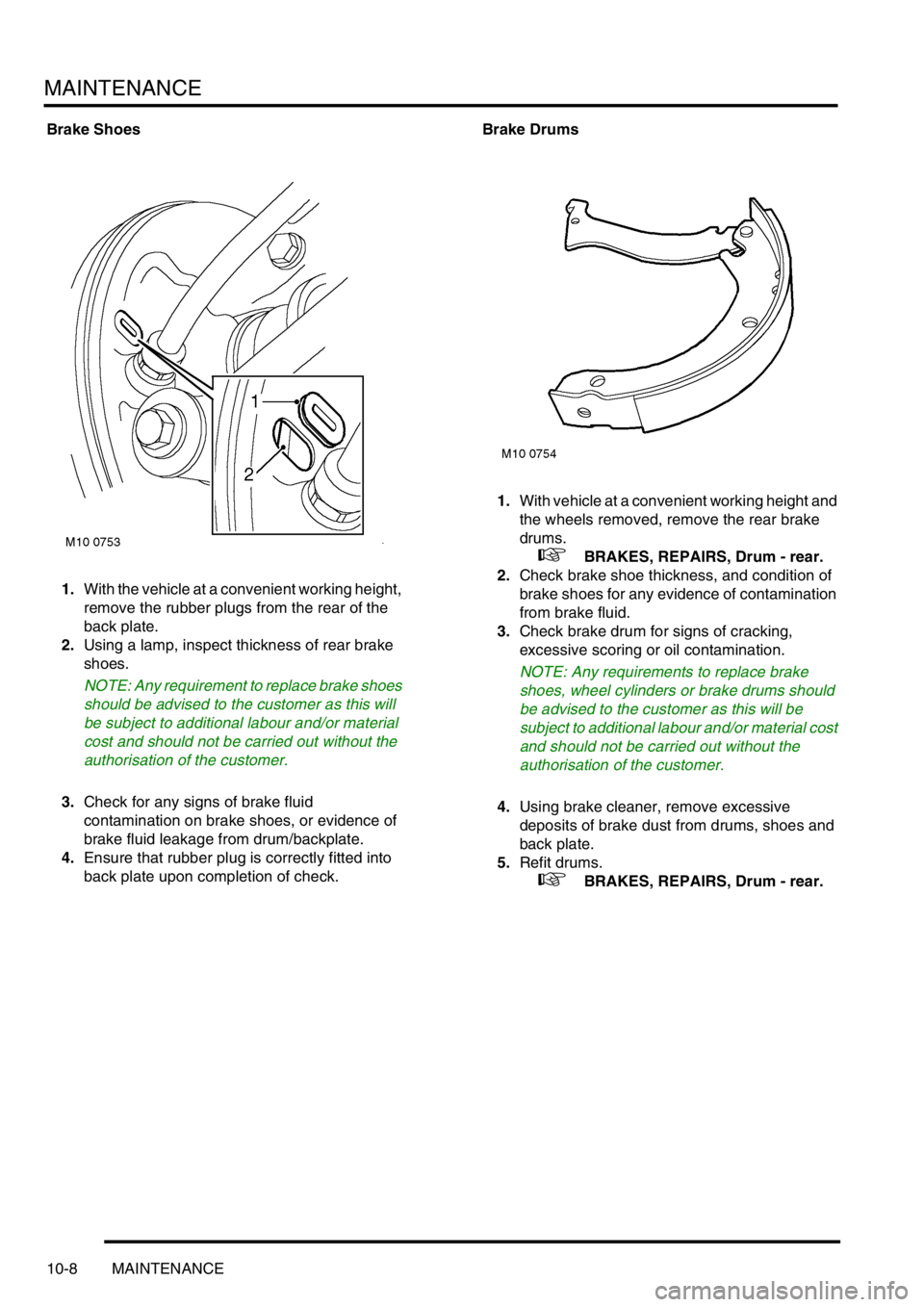

Brake Shoes

1.With the vehicle at a convenient working height,

remove the rubber plugs from the rear of the

back plate.

2.Using a lamp, inspect thickness of rear brake

shoes.

NOTE: Any requirement to replace brake shoes

should be advised to the customer as this will

be subject to additional labour and/or material

cost and should not be carried out without the

authorisation of the customer.

3.Check for any signs of brake fluid

contamination on brake shoes, or evidence of

brake fluid leakage from drum/backplate.

4.Ensure that rubber plug is correctly fitted into

back plate upon completion of check.Brake Drums

1.With vehicle at a convenient working height and

the wheels removed, remove the rear brake

drums.

+ BRAKES, REPAIRS, Drum - rear.

2.Check brake shoe thickness, and condition of

brake shoes for any evidence of contamination

from brake fluid.

3.Check brake drum for signs of cracking,

excessive scoring or oil contamination.

NOTE: Any requirements to replace brake

shoes, wheel cylinders or brake drums should

be advised to the customer as this will be

subject to additional labour and/or material cost

and should not be carried out without the

authorisation of the customer.

4.Using brake cleaner, remove excessive

deposits of brake dust from drums, shoes and

back plate.

5.Refit drums.

+ BRAKES, REPAIRS, Drum - rear.

Page 160 of 1007

MAINTENANCE

MAINTENANCE 10-13

Vent filter - turbocharger boost control

solenoid valve - Td4

Replace

1.Replace turbocharger solenoid valve vent filter.

+ FUEL DELIVERY SYSTEM - DIESEL,

REPAIRS, Vent filter - turbocharger boost

control solenoid valve - Td4.

Spark Plugs – K1.8

Check & Renew

1.Check spark plugs condition and gap. Renew if

necessary.

+ ENGINE MANAGEMENT SYSTEM -

MEMS, REPAIRS, Spark plugs.

Spark Plugs – KV6

Check & Renew

1.Check spark plugs condition and gap. Renew if

necessary.

+ ENGINE MANAGEMENT SYSTEM -

SIEMENS, REPAIRS, Spark plugs - up to

03MY.

Air Cleaner – Petrol Models

Replace

1.Replace air cleaner element.

+ FUEL DELIVERY SYSTEM -

PETROL, REPAIRS, Element - air cleaner -

KV6.

Clean

1.Clean the drain hole in filter casing.

Page 366 of 1007

COOLING SYSTEM - K SERIES KV6

ADJUSTMENTS 26-3-1

COOLING SYS TEM - K SER IES KV6 ADJUST ME NTS

Coolant - drain and refill

$% 26.10.01

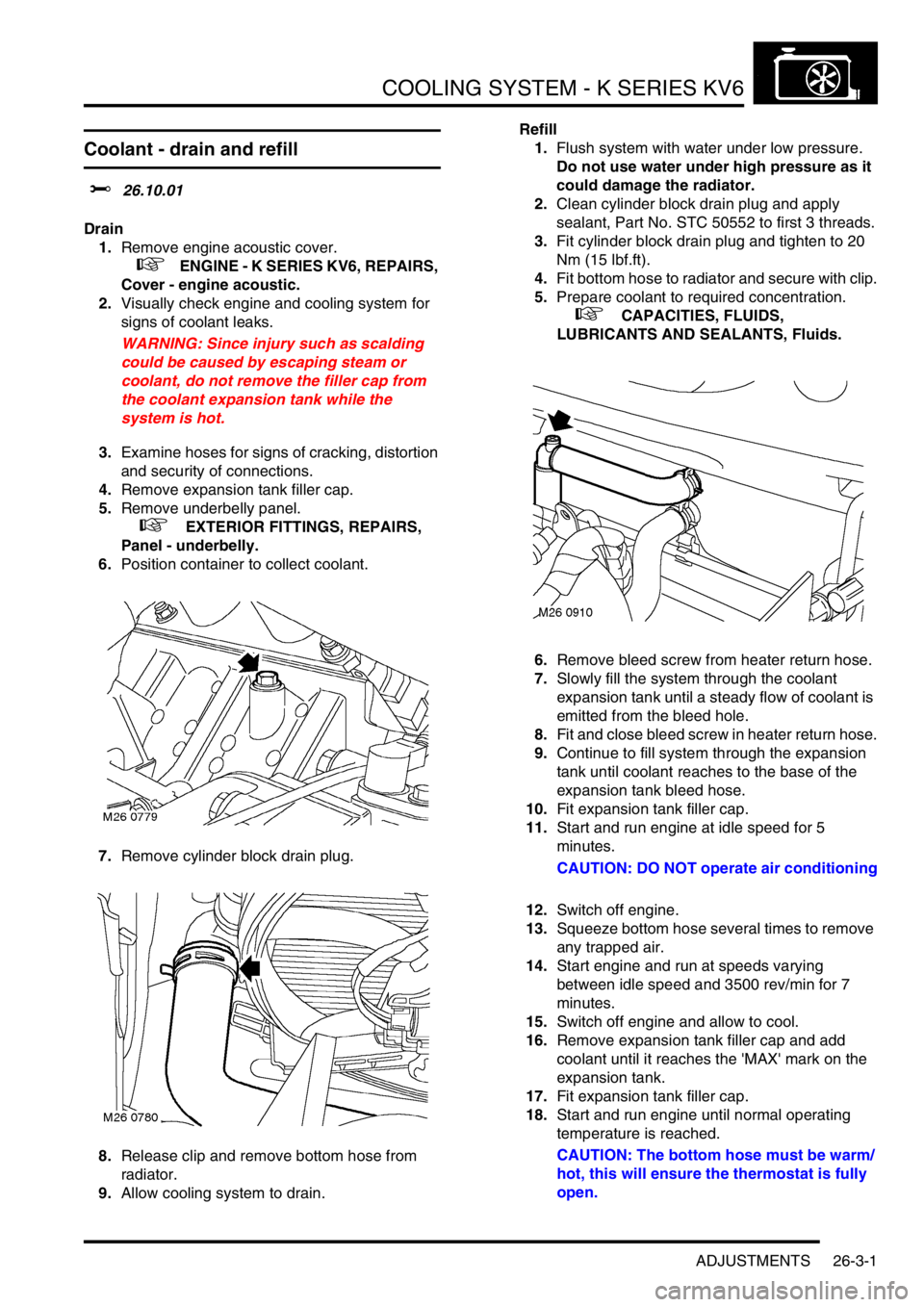

Drain

1.Remove engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

2.Visually check engine and cooling system for

signs of coolant leaks.

WARNING: Since injury such as scalding

could be caused by escaping steam or

coolant, do not remove the filler cap from

the coolant expansion tank while the

system is hot.

3.Examine hoses for signs of cracking, distortion

and security of connections.

4.Remove expansion tank filler cap.

5.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

6.Position container to collect coolant.

7.Remove cylinder block drain plug.

8.Release clip and remove bottom hose from

radiator.

9.Allow cooling system to drain.Refill

1.Flush system with water under low pressure.

Do not use water under high pressure as it

could damage the radiator.

2.Clean cylinder block drain plug and apply

sealant, Part No. STC 50552 to first 3 threads.

3.Fit cylinder block drain plug and tighten to 20

Nm (15 lbf.ft).

4.Fit bottom hose to radiator and secure with clip.

5.Prepare coolant to required concentration.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS, Fluids.

6.Remove bleed screw from heater return hose.

7.Slowly fill the system through the coolant

expansion tank until a steady flow of coolant is

emitted from the bleed hole.

8.Fit and close bleed screw in heater return hose.

9.Continue to fill system through the expansion

tank until coolant reaches to the base of the

expansion tank bleed hose.

10.Fit expansion tank filler cap.

11.Start and run engine at idle speed for 5

minutes.

CAUTION: DO NOT operate air conditioning

12.Switch off engine.

13.Squeeze bottom hose several times to remove

any trapped air.

14.Start engine and run at speeds varying

between idle speed and 3500 rev/min for 7

minutes.

15.Switch off engine and allow to cool.

16.Remove expansion tank filler cap and add

coolant until it reaches the 'MAX' mark on the

expansion tank.

17.Fit expansion tank filler cap.

18.Start and run engine until normal operating

temperature is reached.

CAUTION: The bottom hose must be warm/

hot, this will ensure the thermostat is fully

open.

Page 369 of 1007

COOLING SYSTEM - K SERIES KV6

26-3-4 REPAIRS

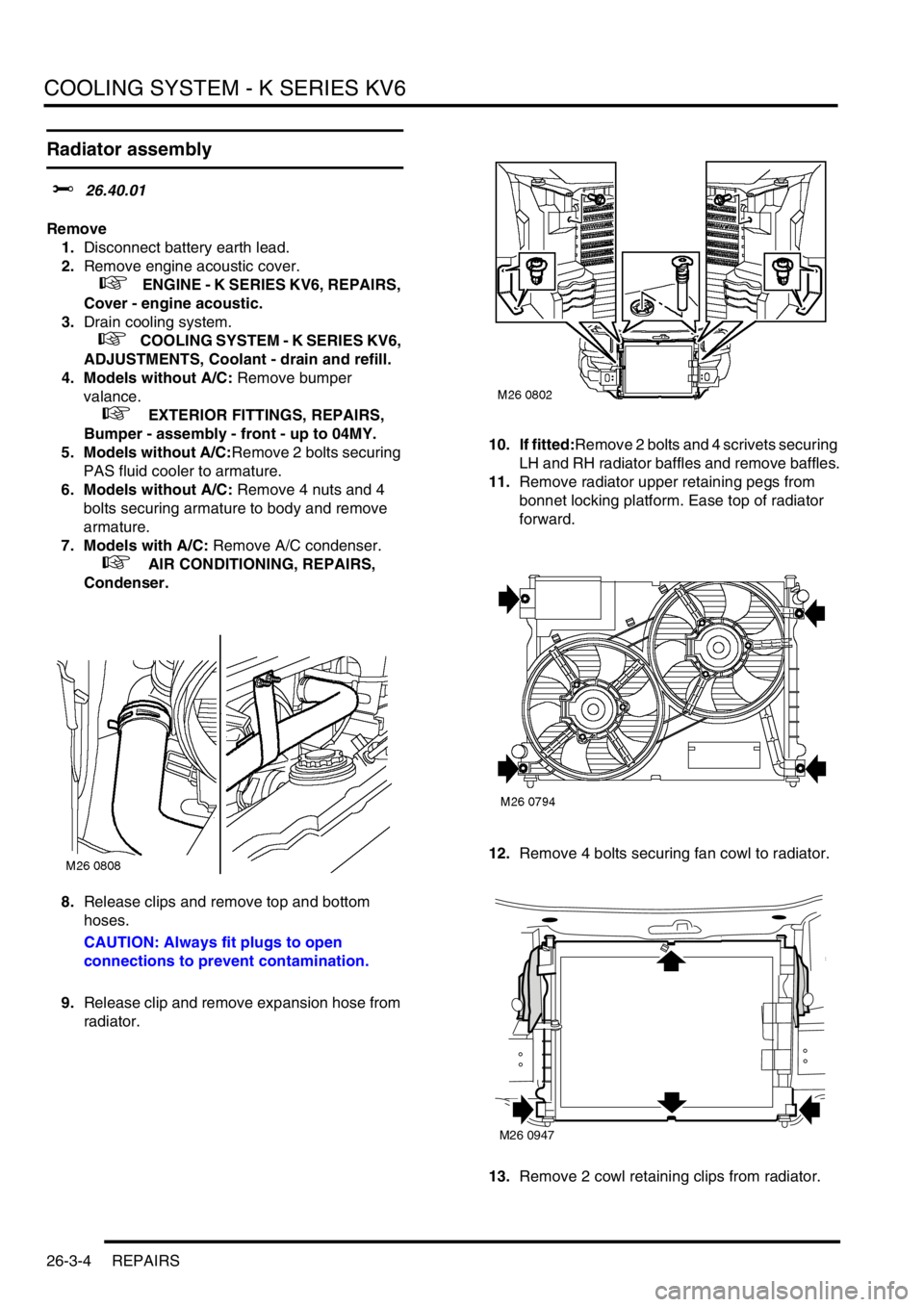

Radiator assembly

$% 26.40.01

Remove

1.Disconnect battery earth lead.

2.Remove engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

3.Drain cooling system.

+ COOLING SYSTEM - K SERIES KV6,

ADJUSTMENTS, Coolant - drain and refill.

4. Models without A/C: Remove bumper

valance.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper - assembly - front - up to 04MY.

5. Models without A/C:Remove 2 bolts securing

PAS fluid cooler to armature.

6. Models without A/C: Remove 4 nuts and 4

bolts securing armature to body and remove

armature.

7. Models with A/C: Remove A/C condenser.

+ AIR CONDITIONING, REPAIRS,

Condenser.

8.Release clips and remove top and bottom

hoses.

CAUTION: Always fit plugs to open

connections to prevent contamination.

9.Release clip and remove expansion hose from

radiator.10. If fitted:Remove 2 bolts and 4 scrivets securing

LH and RH radiator baffles and remove baffles.

11.Remove radiator upper retaining pegs from

bonnet locking platform. Ease top of radiator

forward.

12.Remove 4 bolts securing fan cowl to radiator.

13.Remove 2 cowl retaining clips from radiator.

M26 0947

Page 370 of 1007

COOLING SYSTEM - K SERIES KV6

REPAIRS 26-3-5

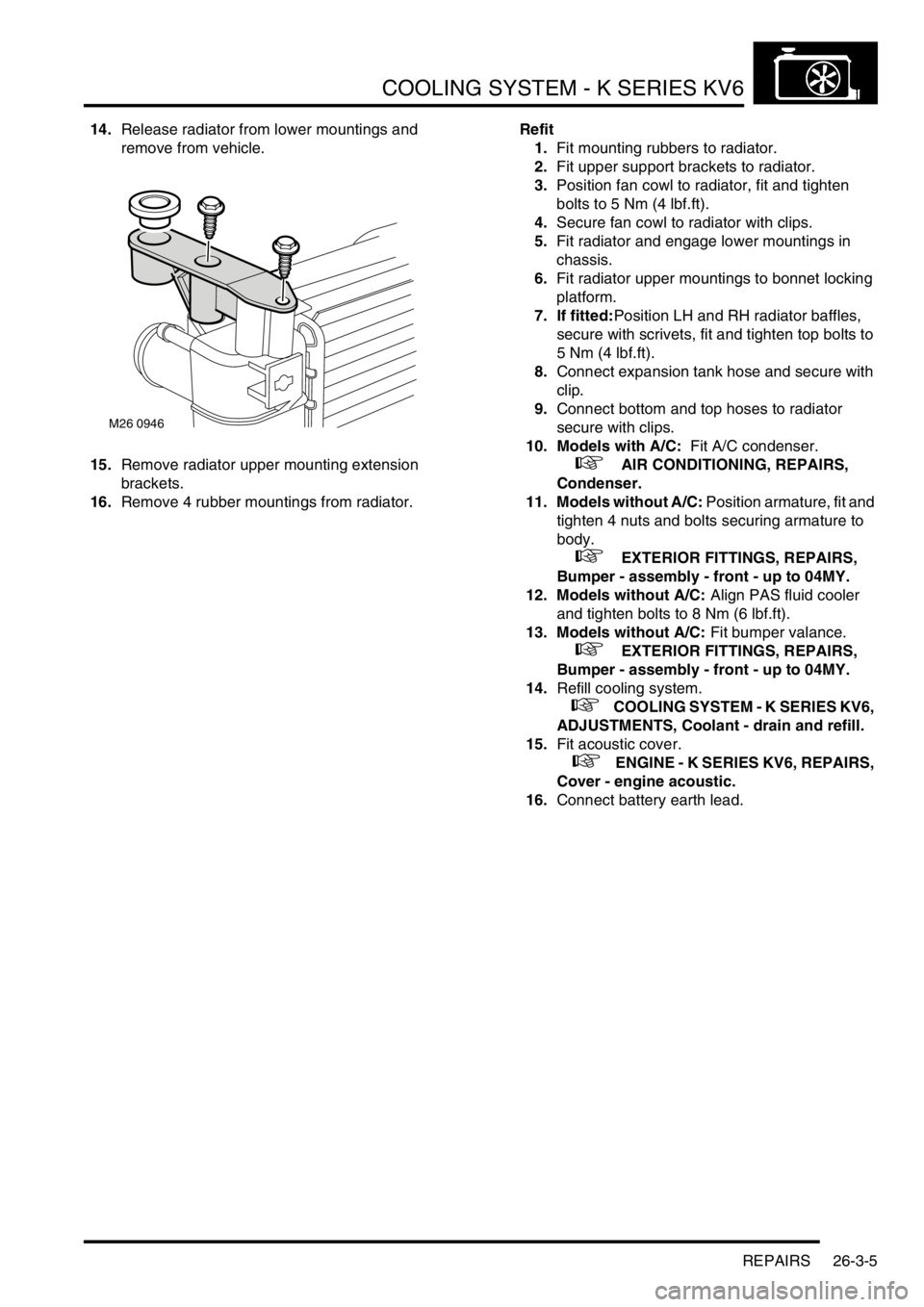

14.Release radiator from lower mountings and

remove from vehicle.

15.Remove radiator upper mounting extension

brackets.

16.Remove 4 rubber mountings from radiator.Refit

1.Fit mounting rubbers to radiator.

2.Fit upper support brackets to radiator.

3.Position fan cowl to radiator, fit and tighten

bolts to 5 Nm (4 lbf.ft).

4.Secure fan cowl to radiator with clips.

5.Fit radiator and engage lower mountings in

chassis.

6.Fit radiator upper mountings to bonnet locking

platform.

7. If fitted:Position LH and RH radiator baffles,

secure with scrivets, fit and tighten top bolts to

5 Nm (4 lbf.ft).

8.Connect expansion tank hose and secure with

clip.

9.Connect bottom and top hoses to radiator

secure with clips.

10. Models with A/C: Fit A/C condenser.

+ AIR CONDITIONING, REPAIRS,

Condenser.

11. Models without A/C: Position armature, fit and

tighten 4 nuts and bolts securing armature to

body.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper - assembly - front - up to 04MY.

12. Models without A/C: Align PAS fluid cooler

and tighten bolts to 8 Nm (6 lbf.ft).

13. Models without A/C: Fit bumper valance.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper - assembly - front - up to 04MY.

14.Refill cooling system.

+ COOLING SYSTEM - K SERIES KV6,

ADJUSTMENTS, Coolant - drain and refill.

15.Fit acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

16.Connect battery earth lead.

M26 0946

Page 492 of 1007

REAR AXLE & FINAL DRIVE

REPAIRS 51-7

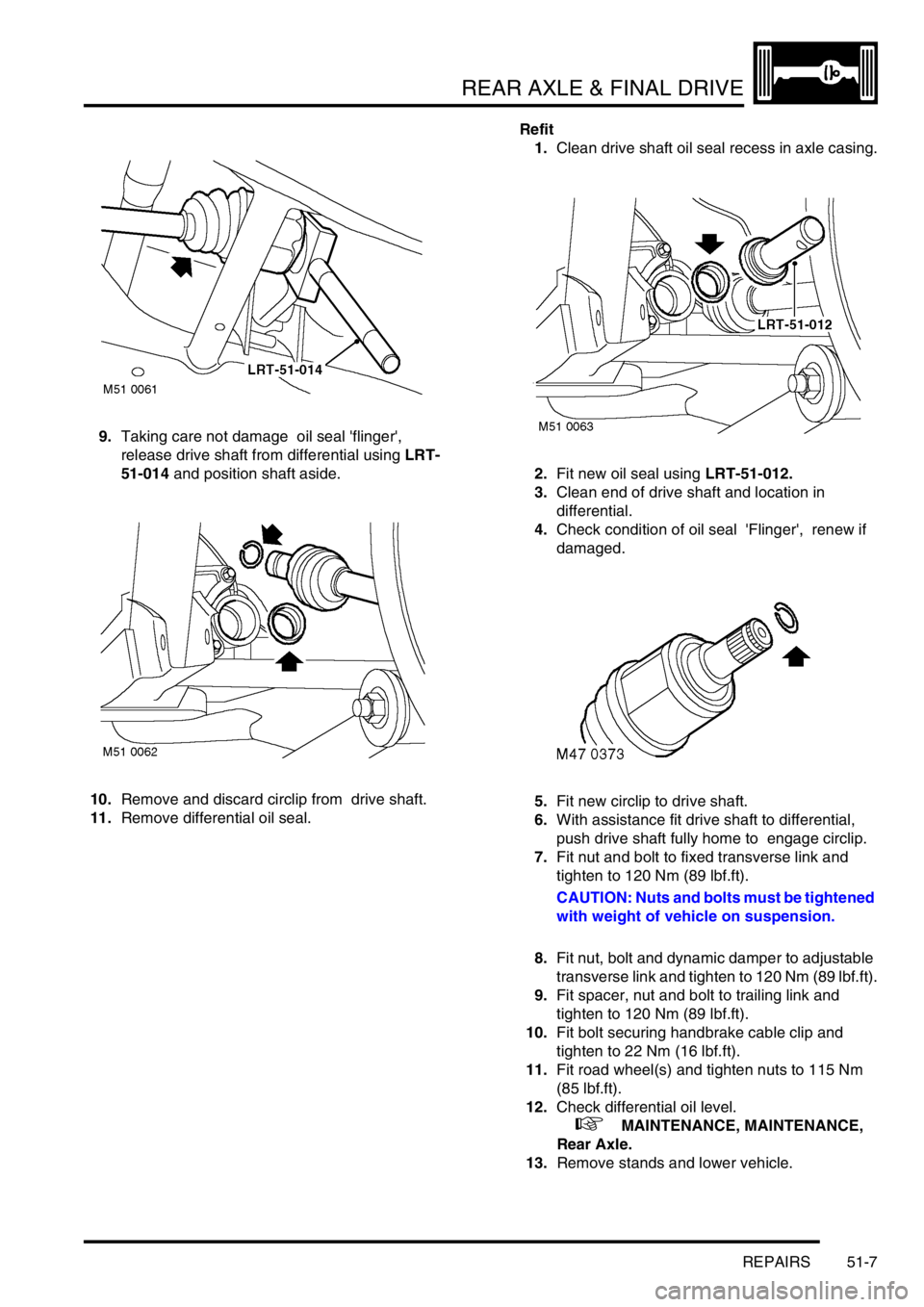

9.Taking care not damage oil seal 'flinger',

release drive shaft from differential using LRT-

51-014 and position shaft aside.

10.Remove and discard circlip from drive shaft.

11.Remove differential oil seal.Refit

1.Clean drive shaft oil seal recess in axle casing.

2.Fit new oil seal using LRT-51-012.

3.Clean end of drive shaft and location in

differential.

4.Check condition of oil seal 'Flinger', renew if

damaged.

5.Fit new circlip to drive shaft.

6.With assistance fit drive shaft to differential,

push drive shaft fully home to engage circlip.

7.Fit nut and bolt to fixed transverse link and

tighten to 120 Nm (89 lbf.ft).

CAUTION: Nuts and bolts must be tightened

with weight of vehicle on suspension.

8.Fit nut, bolt and dynamic damper to adjustable

transverse link and tighten to 120 Nm (89 lbf.ft).

9.Fit spacer, nut and bolt to trailing link and

tighten to 120 Nm (89 lbf.ft).

10.Fit bolt securing handbrake cable clip and

tighten to 22 Nm (16 lbf.ft).

11.Fit road wheel(s) and tighten nuts to 115 Nm

(85 lbf.ft).

12.Check differential oil level.

+ MAINTENANCE, MAINTENANCE,

Rear Axle.

13.Remove stands and lower vehicle.

Page 566 of 1007

BRAKES

REPAIRS 70-17

14.Check wheel cylinder pistons for freedom of

movement.

15.Check brake adjuster threads, nut and

handbrake linkage for wear. Renew if

necessary.

16.Check condition of return springs and renew if

necessary.

17.Ensure brake adjuster is fully off.

Refit

1.Position adjuster and expander to brake shoes

and fit return springs.

2.Smear brake shoe contact points with Molykote

111 grease.

3.Remove elastic band from wheel cylinder.

4.Manoeuvre brake shoes around rear hub and

locate to abutment and wheel cylinder.

5.Fit brake shoe retaining pins and secure with

clips.

6.Connect hand brake cable to brake shoe lever.

7.Fit brake drum.

+ BRAKES, REPAIRS, Drum - rear.

8.Apply brake pedal a min. of 30 times to ensure

full adjustment of rear brake shoes after

refitting.

9.Fit road wheel(s) and tighten nuts to 115 Nm

(85 lbf.ft).

10.Remove stands and lower vehicle.

Servo assembly - LHD

$% 70.50.01

Remove

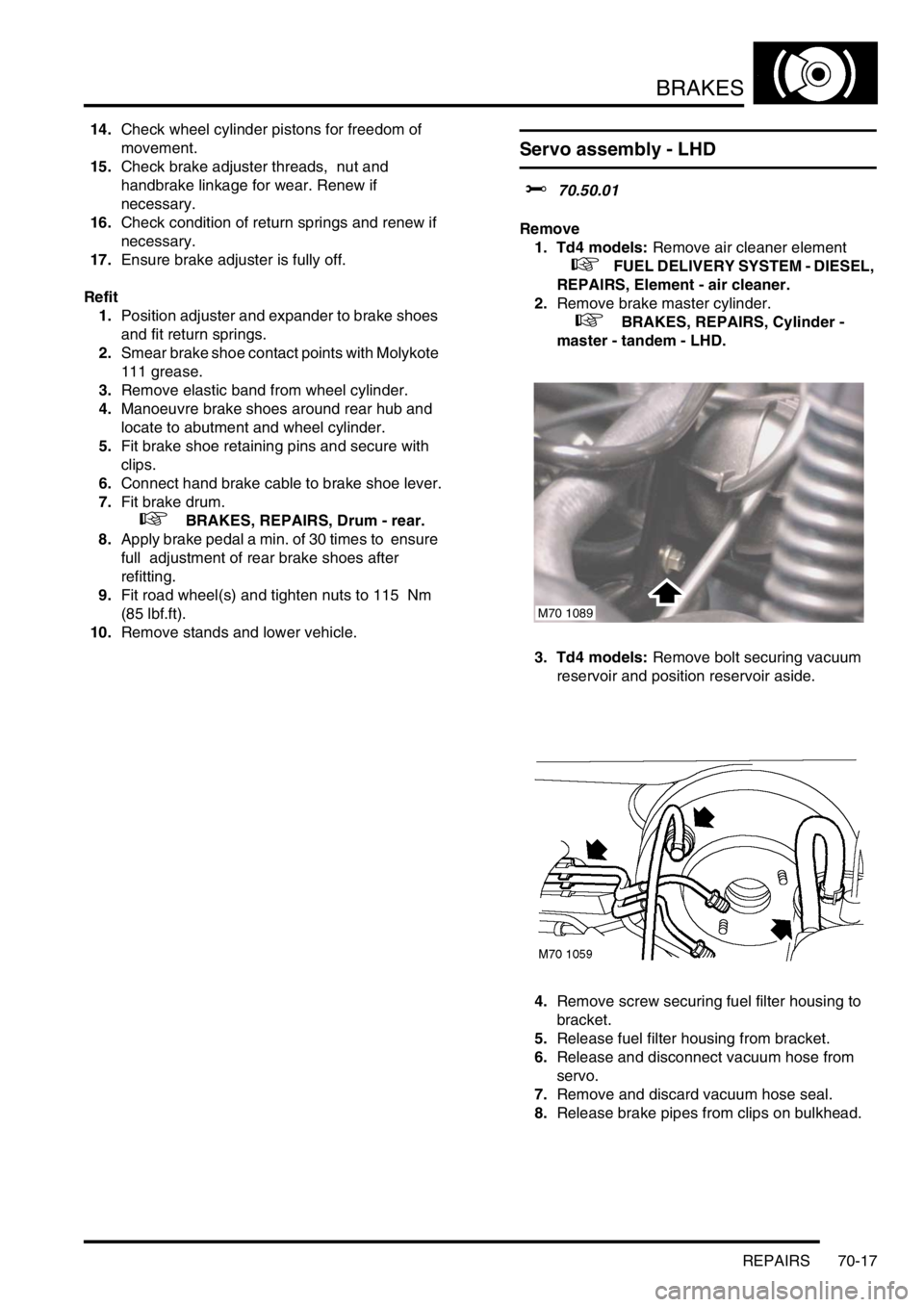

1. Td4 models: Remove air cleaner element

+ FUEL DELIVERY SYSTEM - DIESEL,

REPAIRS, Element - air cleaner.

2.Remove brake master cylinder.

+ BRAKES, REPAIRS, Cylinder -

master - tandem - LHD.

3. Td4 models: Remove bolt securing vacuum

reservoir and position reservoir aside.

4.Remove screw securing fuel filter housing to

bracket.

5.Release fuel filter housing from bracket.

6.Release and disconnect vacuum hose from

servo.

7.Remove and discard vacuum hose seal.

8.Release brake pipes from clips on bulkhead.

M70 1089

Page 590 of 1007

RESTRAINT SYSTEMS

REPAIRS 75-9

Pre-tensioner - seat belt - front -

deployment - off vehicle

$% 76.73.78

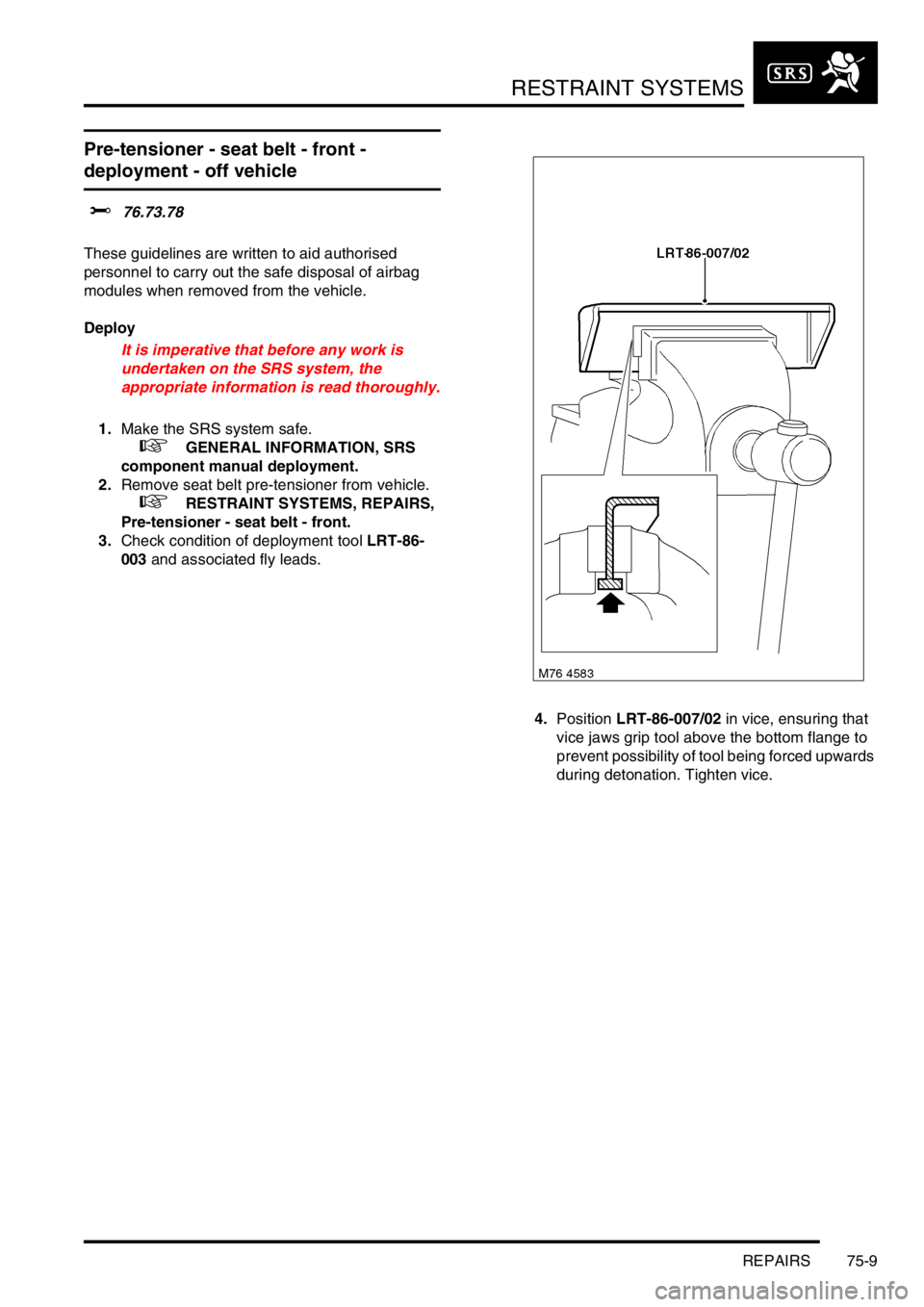

These guidelines are written to aid authorised

personnel to carry out the safe disposal of airbag

modules when removed from the vehicle.

Deploy

It is imperative that before any work is

undertaken on the SRS system, the

appropriate information is read thoroughly.

1.Make the SRS system safe.

+ GENERAL INFORMATION, SRS

component manual deployment.

2.Remove seat belt pre-tensioner from vehicle.

+ RESTRAINT SYSTEMS, REPAIRS,

Pre-tensioner - seat belt - front.

3.Check condition of deployment tool LRT-86-

003 and associated fly leads.

4.Position LRT-86-007/02 in vice, ensuring that

vice jaws grip tool above the bottom flange to

prevent possibility of tool being forced upwards

during detonation. Tighten vice.

Page 598 of 1007

RESTRAINT SYSTEMS

REPAIRS 75-17

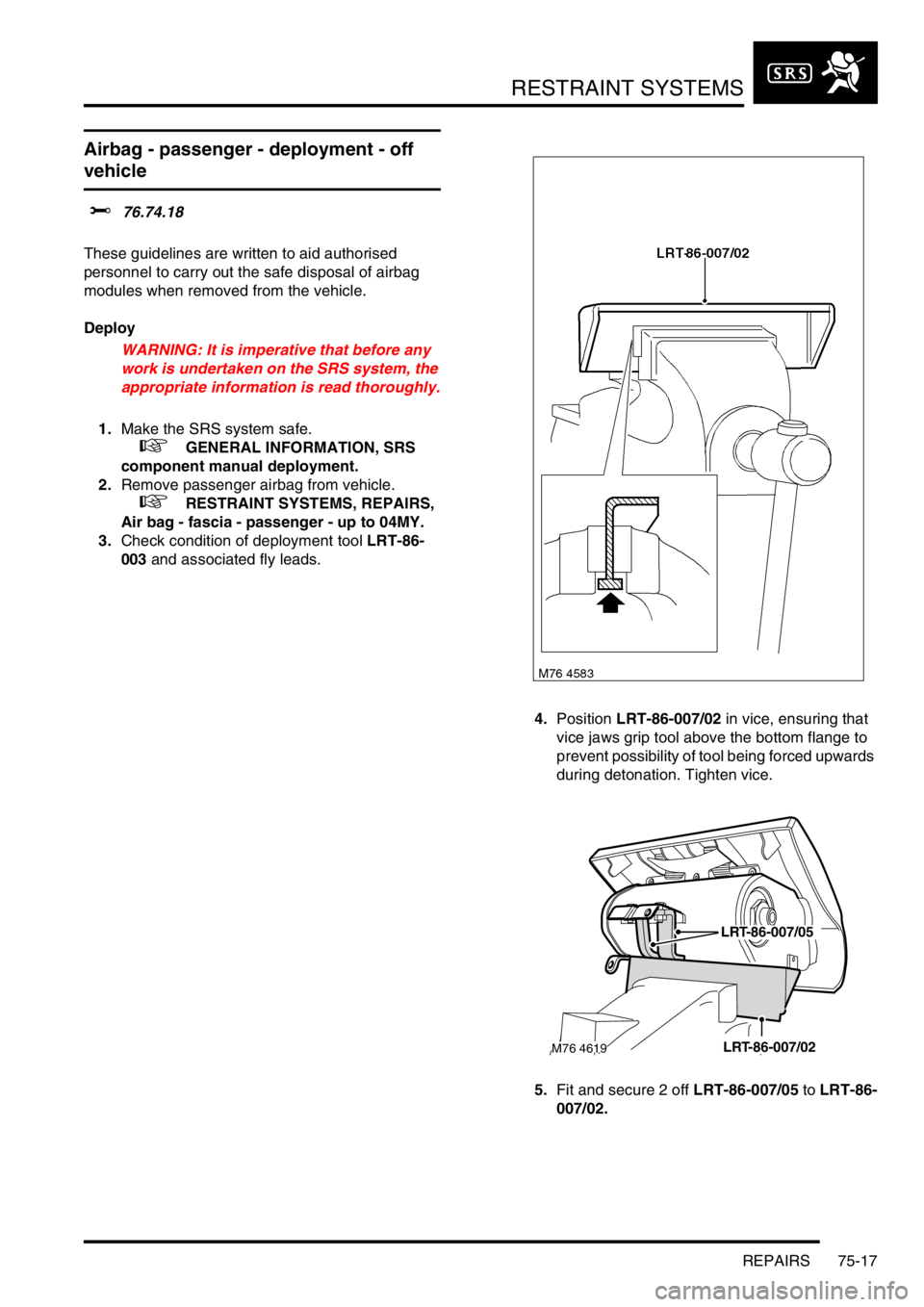

Airbag - passenger - deployment - off

vehicle

$% 76.74.18

These guidelines are written to aid authorised

personnel to carry out the safe disposal of airbag

modules when removed from the vehicle.

Deploy

WARNING: It is imperative that before any

work is undertaken on the SRS system, the

appropriate information is read thoroughly.

1.Make the SRS system safe.

+ GENERAL INFORMATION, SRS

component manual deployment.

2.Remove passenger airbag from vehicle.

+ RESTRAINT SYSTEMS, REPAIRS,

Air bag - fascia - passenger - up to 04MY.

3.Check condition of deployment tool LRT-86-

003 and associated fly leads.

4.Position LRT-86-007/02 in vice, ensuring that

vice jaws grip tool above the bottom flange to

prevent possibility of tool being forced upwards

during detonation. Tighten vice.

5.Fit and secure 2 off LRT-86-007/05 to LRT-86-

007/02.

M76 4619

LRT-86-007/05

LRT-86-007/02