belt LAND ROVER FREELANDER 2001 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 132 of 1007

TORQUE WRENCH SETTINGS

06-29

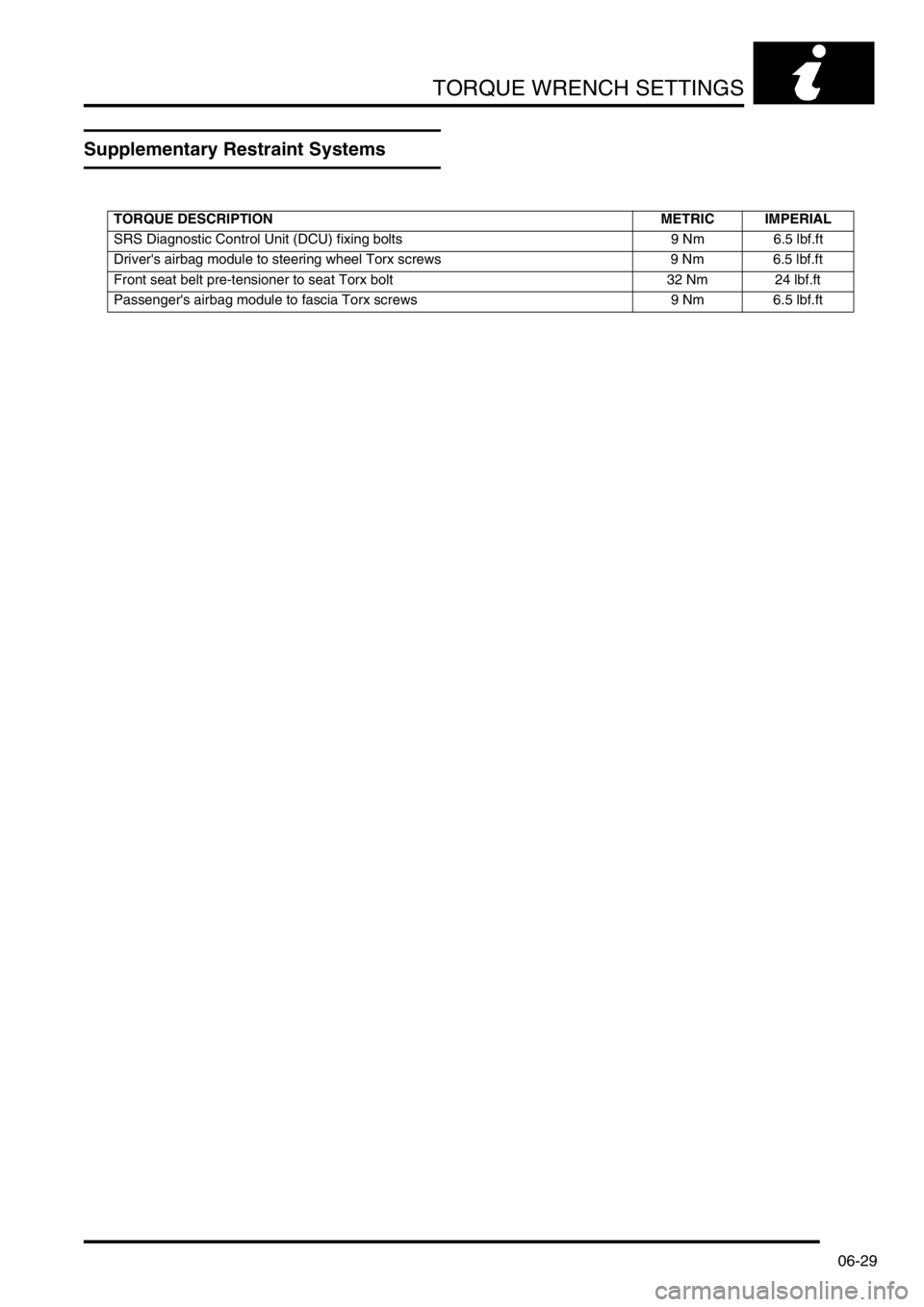

Supplementary Restraint Systems

TORQUE DESCRIPTION METRIC IMPERIAL

SRS Diagnostic Control Unit (DCU) fixing bolts 9 Nm 6.5 lbf.ft

Driver's airbag module to steering wheel Torx screws 9 Nm 6.5 lbf.ft

Front seat belt pre-tensioner to seat Torx bolt 32 Nm 24 lbf.ft

Passenger's airbag module to fascia Torx screws 9 Nm 6.5 lbf.ft

Page 134 of 1007

TORQUE WRENCH SETTINGS

06-31

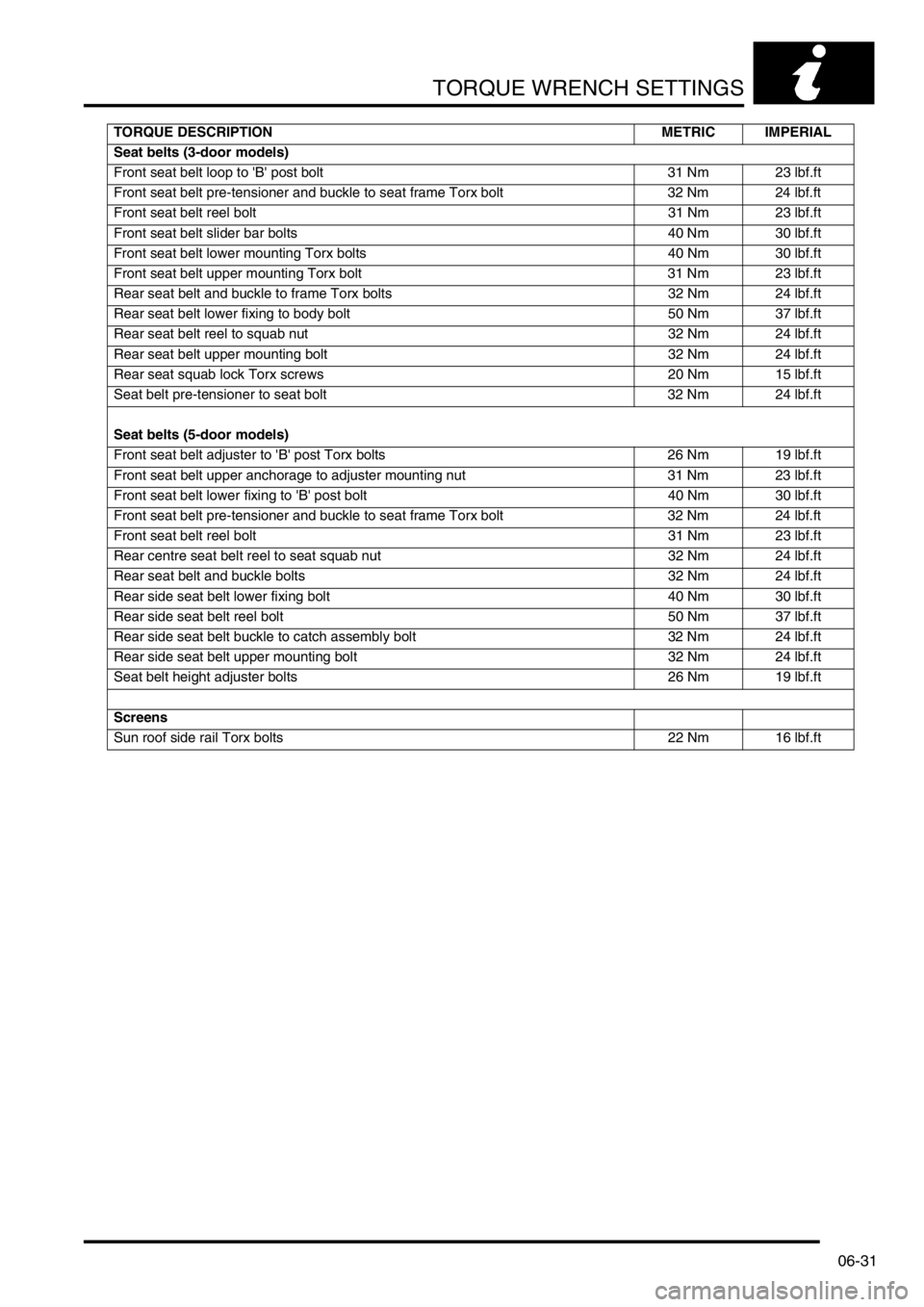

Seat belts (3-door models)

Front seat belt loop to 'B' post bolt 31 Nm 23 lbf.ft

Front seat belt pre-tensioner and buckle to seat frame Torx bolt 32 Nm 24 lbf.ft

Front seat belt reel bolt 31 Nm 23 lbf.ft

Front seat belt slider bar bolts 40 Nm 30 lbf.ft

Front seat belt lower mounting Torx bolts 40 Nm 30 lbf.ft

Front seat belt upper mounting Torx bolt 31 Nm 23 lbf.ft

Rear seat belt and buckle to frame Torx bolts 32 Nm 24 lbf.ft

Rear seat belt lower fixing to body bolt 50 Nm 37 lbf.ft

Rear seat belt reel to squab nut 32 Nm 24 lbf.ft

Rear seat belt upper mounting bolt 32 Nm 24 lbf.ft

Rear seat squab lock Torx screws 20 Nm 15 lbf.ft

Seat belt pre-tensioner to seat bolt 32 Nm 24 lbf.ft

Seat belts (5-door models)

Front seat belt adjuster to 'B' post Torx bolts 26 Nm 19 lbf.ft

Front seat belt upper anchorage to adjuster mounting nut 31 Nm 23 lbf.ft

Front seat belt lower fixing to 'B' post bolt 40 Nm 30 lbf.ft

Front seat belt pre-tensioner and buckle to seat frame Torx bolt 32 Nm 24 lbf.ft

Front seat belt reel bolt 31 Nm 23 lbf.ft

Rear centre seat belt reel to seat squab nut 32 Nm 24 lbf.ft

Rear seat belt and buckle bolts 32 Nm 24 lbf.ft

Rear side seat belt lower fixing bolt 40 Nm 30 lbf.ft

Rear side seat belt reel bolt 50 Nm 37 lbf.ft

Rear side seat belt buckle to catch assembly bolt 32 Nm 24 lbf.ft

Rear side seat belt upper mounting bolt 32 Nm 24 lbf.ft

Seat belt height adjuster bolts 26 Nm 19 lbf.ft

Screens

Sun roof side rail Torx bolts 22 Nm 16 lbf.ft TORQUE DESCRIPTION METRIC IMPERIAL

Page 136 of 1007

TORQUE WRENCH SETTINGS

06-33

Air Conditioning

TORQUE DESCRIPTION METRIC IMPERIAL

A/C compressor to mounting bracket bolts (Td4 & K1.8) 25 Nm 18 lbf.ft

A/C compressor mounting bracket to cylinder block bolts (Td4 & K1.8) 45 Nm 33 lbf.ft

A/C compressor mounting bracket to cylinder block bolts (KV6) 45 Nm 33 lbf.ft

A/C compressor support bracket to sump bolt (Td4) 10 Nm 7.5 lbf.ft

A/C compressor drive belt tensioner clamp bolt (Td4) 24 Nm 18 lbf.ft

A/C compressor drive belt tensioner pivot bolt (Td4) 24 Nm 18 lbf.ft

A/C compressor upper and lower securing bolts (KV6) 25 Nm 18 lbf.ft

A/C pipe rail to condenser bolt (KV6) 8 Nm 6 lbf.ft

A/C pipe rail to condenser bolt (KV6) 8 Nm 6 lbf.ft

Condenser bracket to radiator bolts 8 Nm 6 lbf.ft

Receiver drier to condenser bolts 12 Nm 9 lbf.ft

Refrigerant pressure sensor 10 Nm 7.5 lbf.ft

TXV to bulkhead Allen screws 25 Nm 18 lbf.ft

Page 138 of 1007

TORQUE WRENCH SETTINGS

06-35

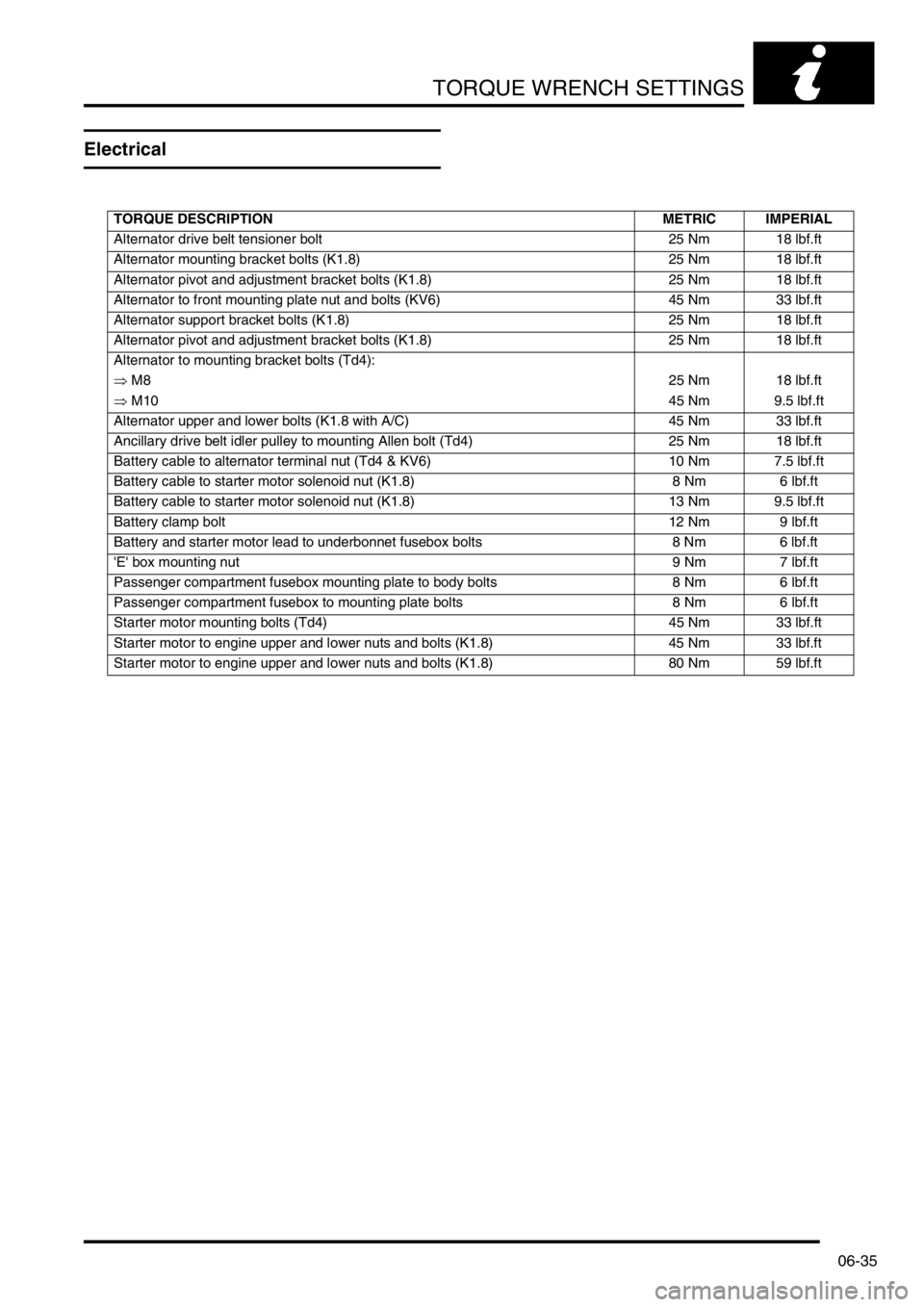

Electrical

TORQUE DESCRIPTION METRIC IMPERIAL

Alternator drive belt tensioner bolt 25 Nm 18 lbf.ft

Alternator mounting bracket bolts (K1.8) 25 Nm 18 lbf.ft

Alternator pivot and adjustment bracket bolts (K1.8) 25 Nm 18 lbf.ft

Alternator to front mounting plate nut and bolts (KV6) 45 Nm 33 lbf.ft

Alternator support bracket bolts (K1.8) 25 Nm 18 lbf.ft

Alternator pivot and adjustment bracket bolts (K1.8) 25 Nm 18 lbf.ft

Alternator to mounting bracket bolts (Td4):

⇒ M825 Nm 18 lbf.ft

⇒ M1045 Nm 9.5 lbf.ft

Alternator upper and lower bolts (K1.8 with A/C) 45 Nm 33 lbf.ft

Ancillary drive belt idler pulley to mounting Allen bolt (Td4) 25 Nm 18 lbf.ft

Battery cable to alternator terminal nut (Td4 & KV6) 10 Nm 7.5 lbf.ft

Battery cable to starter motor solenoid nut (K1.8) 8 Nm 6 lbf.ft

Battery cable to starter motor solenoid nut (K1.8) 13 Nm 9.5 lbf.ft

Battery clamp bolt 12 Nm 9 lbf.ft

Battery and starter motor lead to underbonnet fusebox bolts 8 Nm 6 lbf.ft

'E' box mounting nut 9 Nm 7 lbf.ft

Passenger compartment fusebox mounting plate to body bolts 8 Nm 6 lbf.ft

Passenger compartment fusebox to mounting plate bolts 8 Nm 6 lbf.ft

Starter motor mounting bolts (Td4) 45 Nm 33 lbf.ft

Starter motor to engine upper and lower nuts and bolts (K1.8) 45 Nm 33 lbf.ft

Starter motor to engine upper and lower nuts and bolts (K1.8) 80 Nm 59 lbf.ft

Page 143 of 1007

LIFTING AND TOWING

08-4

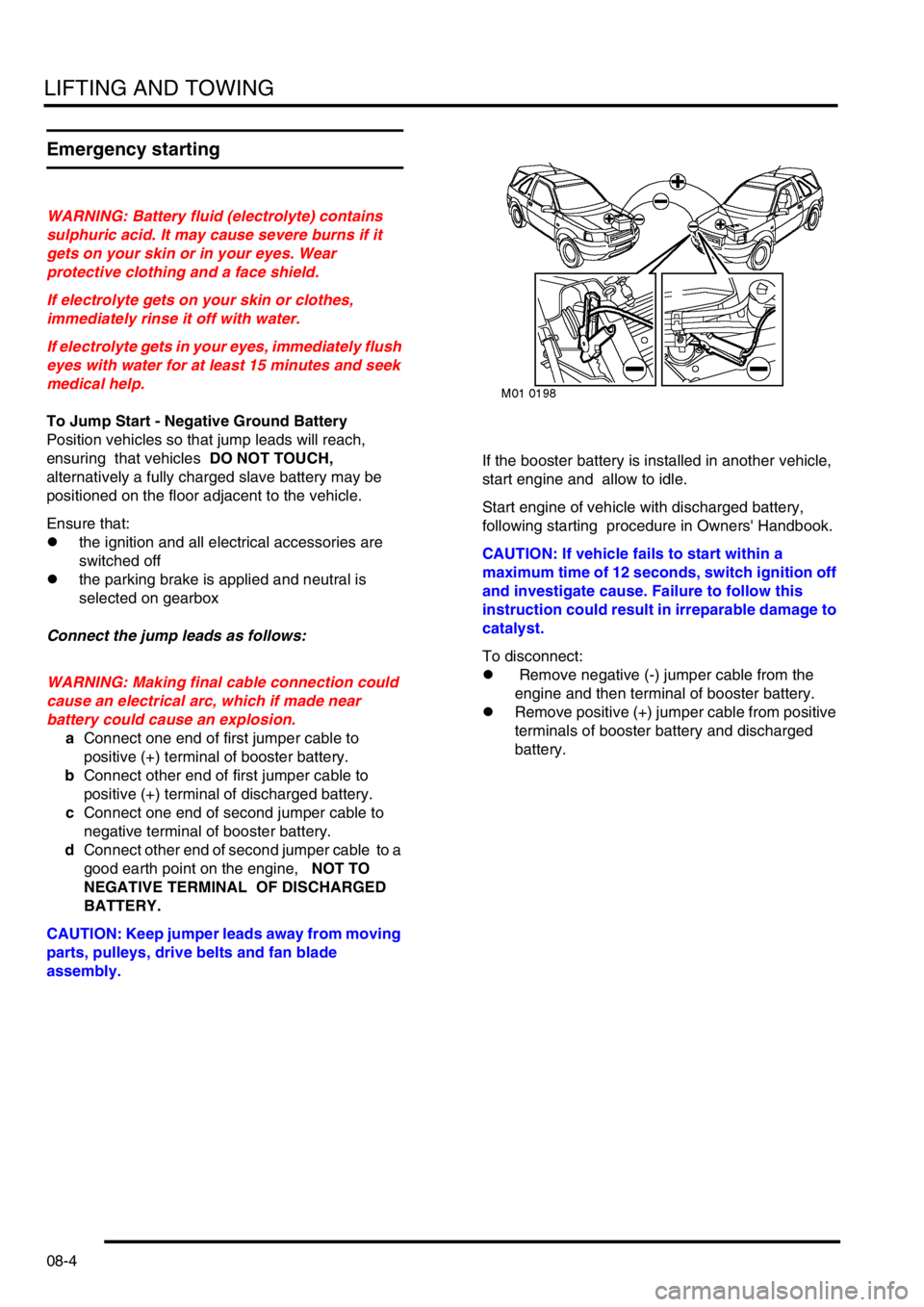

Emergency starting

WARNING: Battery fluid (electrolyte) contains

sulphuric acid. It may cause severe burns if it

gets on your skin or in your eyes. Wear

protective clothing and a face shield.

If electrolyte gets on your skin or clothes,

immediately rinse it off with water.

If electrolyte gets in your eyes, immediately flush

eyes with water for at least 15 minutes and seek

medical help.

To Jump Start - Negative Ground Battery

Position vehicles so that jump leads will reach,

ensuring that vehicles DO NOT TOUCH,

alternatively a fully charged slave battery may be

positioned on the floor adjacent to the vehicle.

Ensure that:

lthe ignition and all electrical accessories are

switched off

lthe parking brake is applied and neutral is

selected on gearbox

Connect the jump leads as follows:

WARNING: Making final cable connection could

cause an electrical arc, which if made near

battery could cause an explosion.

aConnect one end of first jumper cable to

positive (+) terminal of booster battery.

bConnect other end of first jumper cable to

positive (+) terminal of discharged battery.

cConnect one end of second jumper cable to

negative terminal of booster battery.

dConnect other end of second jumper cable to a

good earth point on the engine, NOT TO

NEGATIVE TERMINAL OF DISCHARGED

BATTERY.

CAUTION: Keep jumper leads away from moving

parts, pulleys, drive belts and fan blade

assembly.If the booster battery is installed in another vehicle,

start engine and allow to idle.

Start engine of vehicle with discharged battery,

following starting procedure in Owners' Handbook.

CAUTION: If vehicle fails to start within a

maximum time of 12 seconds, switch ignition off

and investigate cause. Failure to follow this

instruction could result in irreparable damage to

catalyst.

To disconnect:

l Remove negative (-) jumper cable from the

engine and then terminal of booster battery.

lRemove positive (+) jumper cable from positive

terminals of booster battery and discharged

battery.

Page 147 of 1007

CAPACITIES, FLUIDS, LUBRICANTS AND SEALANTS

09-4

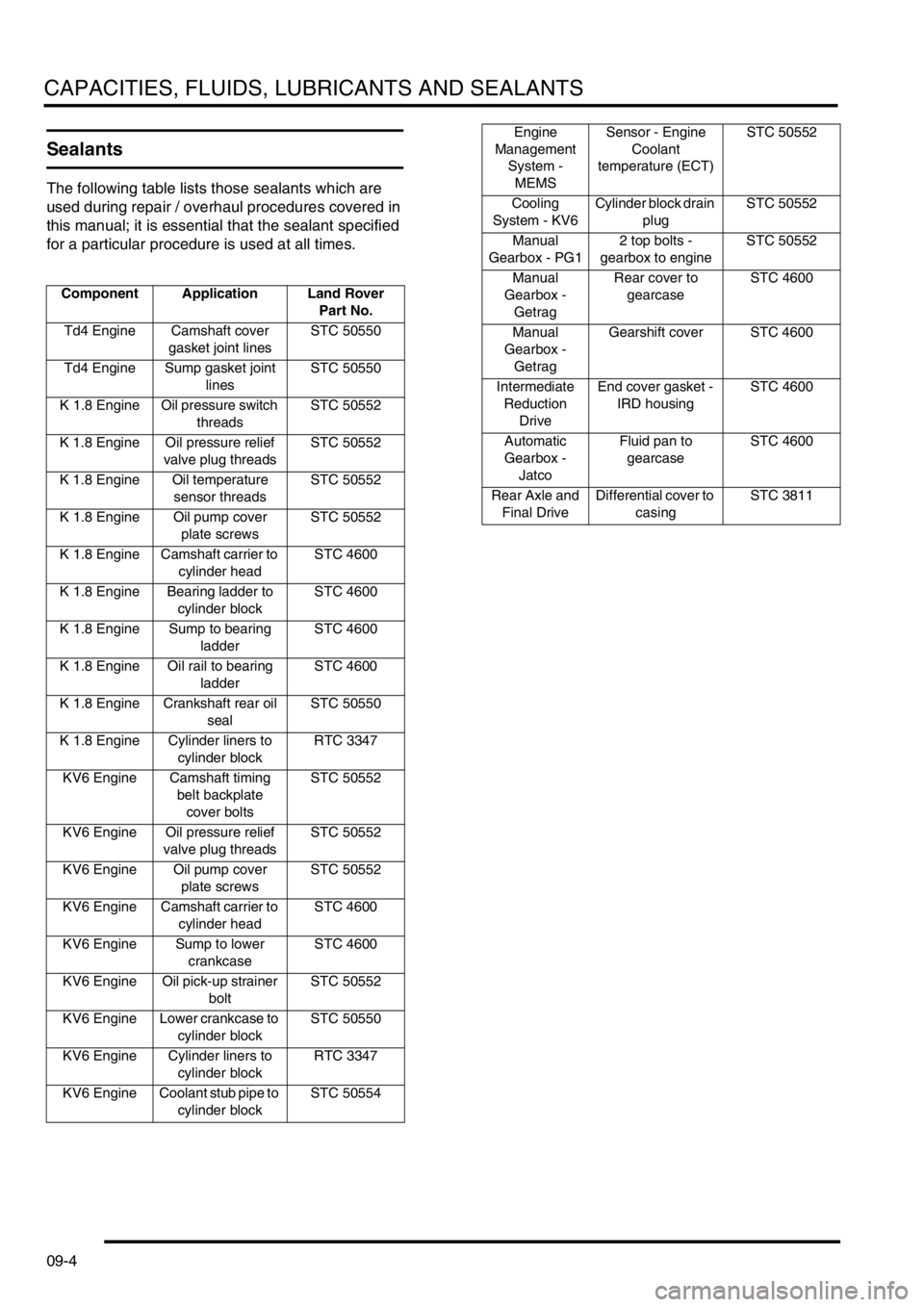

Sealants

The following table lists those sealants which are

used during repair / overhaul procedures covered in

this manual; it is essential that the sealant specified

for a particular procedure is used at all times.

Component Application Land Rover

Part No.

Td4 Engine Camshaft cover

gasket joint linesSTC 50550

Td4 Engine Sump gasket joint

linesSTC 50550

K 1.8 Engine Oil pressure switch

threadsSTC 50552

K 1.8 Engine Oil pressure relief

valve plug threadsSTC 50552

K 1.8 Engine Oil temperature

sensor threadsSTC 50552

K 1.8 Engine Oil pump cover

plate screwsSTC 50552

K 1.8 Engine Camshaft carrier to

cylinder headSTC 4600

K 1.8 Engine Bearing ladder to

cylinder blockSTC 4600

K 1.8 Engine Sump to bearing

ladderSTC 4600

K 1.8 Engine Oil rail to bearing

ladderSTC 4600

K 1.8 Engine Crankshaft rear oil

seal STC 50550

K 1.8 Engine Cylinder liners to

cylinder blockRTC 3347

KV6 Engine Camshaft timing

belt backplate

cover boltsSTC 50552

KV6 Engine Oil pressure relief

valve plug threadsSTC 50552

KV6 Engine Oil pump cover

plate screwsSTC 50552

KV6 Engine Camshaft carrier to

cylinder headSTC 4600

KV6 Engine Sump to lower

crankcaseSTC 4600

KV6 Engine Oil pick-up strainer

boltSTC 50552

KV6 Engine Lower crankcase to

cylinder blockSTC 50550

KV6 Engine Cylinder liners to

cylinder blockRTC 3347

KV6 Engine Coolant stub pipe to

cylinder blockSTC 50554

Engine

Management

System -

MEMSSensor - Engine

Coolant

temperature (ECT)STC 50552

Cooling

System - KV6Cylinder block drain

plugSTC 50552

Manual

Gearbox - PG12 top bolts -

gearbox to engineSTC 50552

Manual

Gearbox -

GetragRear cover to

gearcaseSTC 4600

Manual

Gearbox -

GetragGearshift cover STC 4600

Intermediate

Reduction

DriveEnd cover gasket -

IRD housingSTC 4600

Automatic

Gearbox -

JatcoFluid pan to

gearcaseSTC 4600

Rear Axle and

Final DriveDifferential cover to

casingSTC 3811

Page 151 of 1007

MAINTENANCE

10-4 MAINTENANCE

Seats and Seat Belts

Check

1.Check seat frames are secured to floor and

show no signs of movement.

2.Check operation of seat slide and tilt

mechanisms, ensuring there is no excessive

play between seat cushion and seat back.

3.Check tightness of accessible seat fixings.

4.Fully extract seat belt and allow it to return

under its own recoil mechanism.

5.Check entire length of seat belt webbing for

signs of fraying or damage. Repeat for all belts.

6.Check security of seat belt upper mountings.

7.Check for correct operation of seat belt height

adjusters.

8.Check security of seat belt buckle mountings.

9.Connect each belt to the correct buckle, check

seat belt buckle and tongue are secure.

Release seat belt buckle and check for correct

operation.

10.Check tightness of accessible seat belt

mountings.

Lamps, Horns and Warning Indicators

Check

1.Switch on side, head and tail lights and check

operation.

2.Check headlamp dim/dip operation.

3.Check headlamp levelling operation.

4.Check turn signals and hazard warning lights

operation.

5.Press brake pedal and check operation of

brake lights.

6.Check all exterior lamp lenses for clarity and

condition. Pay particular attention to head lamp

lenses for signs of stone chips or damage.

7.Check horn for loud clear sound.

8.Check operation of all instrument pack warning

and indicator lights.

9.Check for correct operation of interior courtesy

lights.

10.Switch on headlamps (with ignition switch at 'O'

position) and check light reminder warning

operates when door is opened.

Page 161 of 1007

MAINTENANCE

10-14 MAINTENANCE

Ancillary Drive Belt – Td4

Check

1.Check ancillary drive belts for tension, signs of

fraying, damage and for any oil contamination.

Replace

1.Replace ancillary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Ancillary drive belt - Td4.

Ancillary Drive Belt – K1.8

Check

1.Check ancillary drive belts for tension, signs of

fraying, damage and for any oil contamination.

Replace

1.Replace ancillary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Ancillary drive belt - K1.8 without

A/C.

+ CHARGING AND STARTING,

REPAIRS, Ancillary drive belt - K1.8 with A/

C.

Page 162 of 1007

MAINTENANCE

MAINTENANCE 10-15

Ancillary Drive Belt – KV6

Check

1.Check ancillary drive belts for tension, signs of

fraying, damage and for any oil contamination.

Replace

1.Replace ancillary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Ancillary drive belt - KV6.

Camshaft Timing Belt – K1.8

Check

1.Check camshaft drive belt and renew if

necessary.

+ ENGINE - K SERIES 1.8, REPAIRS,

Camshaft timing belt.

Page 163 of 1007

MAINTENANCE

10-16 MAINTENANCE

Camshaft Timing Belt – KV6

Check

1.Check camshaft drive belt and renew if

necessary.

+ ENGINE - K SERIES KV6, REPAIRS,

Camshaft timing belt.

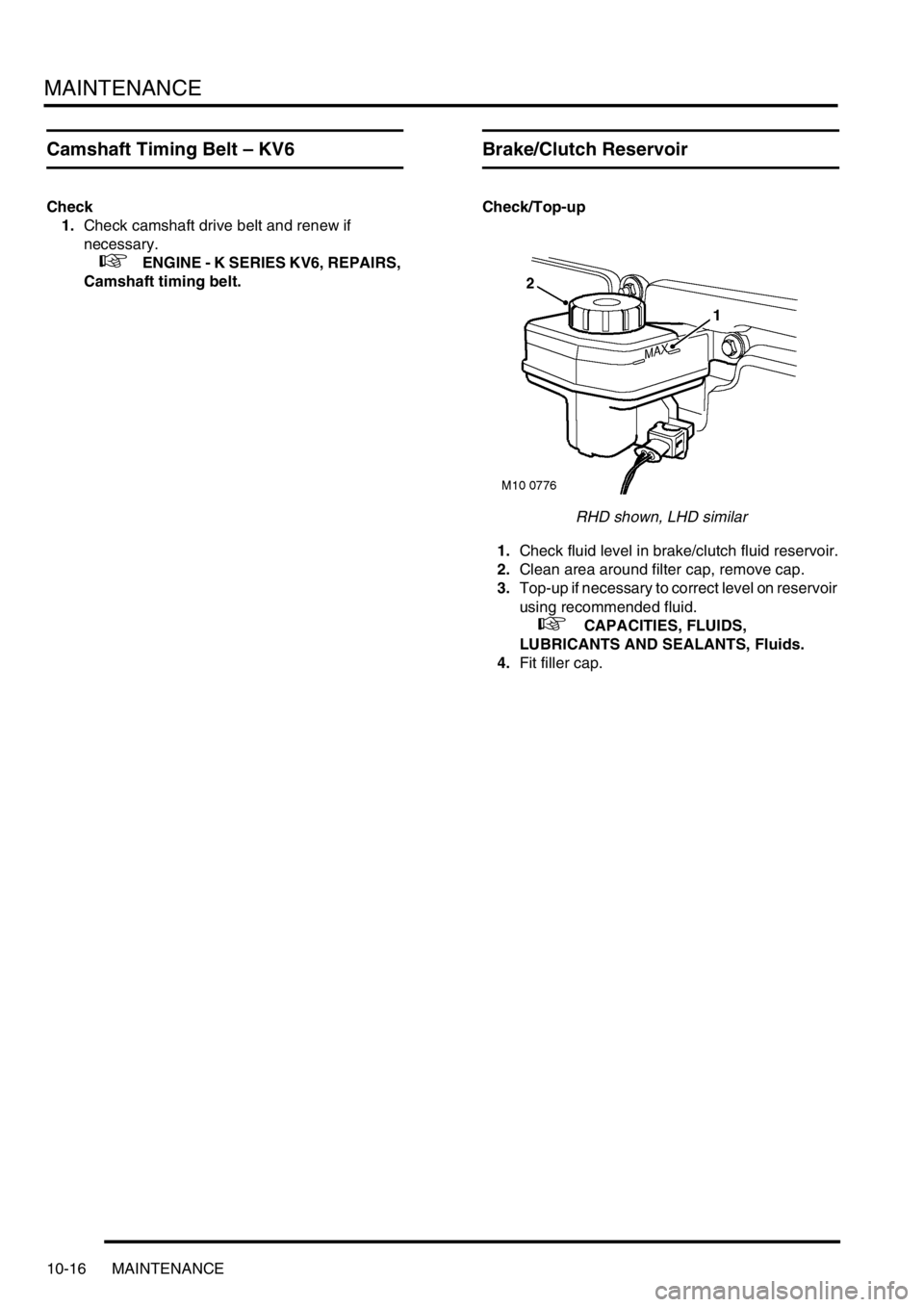

Brake/Clutch Reservoir

Check/Top-up

RHD shown, LHD similar

1.Check fluid level in brake/clutch fluid reservoir.

2.Clean area around filter cap, remove cap.

3.Top-up if necessary to correct level on reservoir

using recommended fluid.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS, Fluids.

4.Fit filler cap.