gas type LAND ROVER FREELANDER 2001 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 35 of 1007

GENERAL INFORMATION

03-4

Materials –

lkeep lids on containers of solvents;

lonly use the minimum quantity;

lconsider alternative materials;

lminimise over-spray when painting.

Gases –

luse the correct equipment for collecting

refrigerants;

ldon't burn rubbish on site.

Discharges to water

Most sites will have two systems for discharging

water: storm drains and foul drains. Storm drains

should only receive clean water, foul drains will take

dirty water.

The foul drain will accept many of the normal waste

waters such as washing water, detergents and

domestic type wastes, but oil, petrol, solvent, acids,

hydraulic oil, antifreeze and other such substances

should never be poured down the drain. If in any

doubt, speak to the local Water Company first.

Every precaution must be taken to prevent spillage of

oil, fuel, solvents etc. reaching the drains. All

handling of such materials must take place well away

from the drains and preferably in an area with a kerb

or wall around it, to prevent discharge into the drain.

If a spillage occurs, it should be soaked up

immediately. Having a spill kit available will make this

easier.

Additional precautions

Check whether the surface water drains are

connected to an oil/water separator, this could

reduce the pollution if an incident was to occur. Oil/

water separators require regular maintenance to

ensure effectiveness.

Checklist

Always adhere to the following:

Disposal –

lnever pour anything down a drain without first

checking that it is environmentally safe to do so,

and that it does not contravene any local

regulations or bye-laws;

lhave oil traps emptied regularly.

Spillage prevention –

lstore liquids in a walled area;

lmake sure the taps on liquid containers are

secure and cannot be accidentally turned on;

lprotect bulk storage tanks from vandalism by

locking the valves;

ltransfer liquids from one container to another in

an area away from open drains;

lensure lids are replaced securely on containers;

lhave spill kits available near to points of storage

and handling of liquids.Spill kits

Special materials are available to absorb a number of

different substances. They can be in granular form,

ready to use and bought in convenient containers for

storage. Disposal of used spill-absorbing material is

dealt with in the 'Waste Management' section.

Land contamination

Oils, fuels and solvents etc. can contaminate any soil

that they are allowed to contact. Such materials

should never be disposed of by pouring onto soil and

every precaution must be taken to prevent spillage

reaching soil. Waste materials stored on open

ground could also leak, or have polluting substances

washed off them that would contaminate the land.

Always store these materials in suitable skips or

other similarly robust containers.

Checklist

Always adhere to the following:

ldon't pour or spill anything onto the soil or bare

ground;

ldon't store waste materials on bare ground, see

'Spillage prevention' list.

Legal compliance

Some sites may have a discharge consent for

effluent discharge to the foul drain for a car wash etc.

It is important to know what materials are allowed in

the drain and to check the results of any monitoring

carried out by the Water Company.

Where paint spraying operations are carried out it

may be necessary to apply to the Local Authority for

an air emissions licence to operate the plant. If such

a licence is in operation, additional precautions will

be necessary to comply with the requirements, and

the results of any air quality monitoring must be

checked regularly.

Checklist

Always adhere to the following:

lknow what legal consents and licences apply to

the operations;

lcheck that the emissions and discharges

comply with legal requirements.

Page 41 of 1007

GENERAL INFORMATION

03-10

Joints and joint faces

General

Fit joints dry unless specified otherwise.

lAlways use the correct gaskets as specified.

lWhen joining compound is used, apply in a thin

uniform film to metal surfaces; take care to

prevent joining compound from entering

oilways, pipes or blind tapped holes.

lIf gaskets and/or joining compound is

recommended for use; remove all traces of old

joining material prior to reassembly. Do not use

a tool which will damage the joint faces and

smooth out any scratches or burrs using an oil

stone. Do not allow dirt or joining material to

enter any tapped holes or enclosed parts.

lPrior to reassembly, blow through any pipes,

channels or crevices with compressed air.

Locking devices

General

Always replace locking devices with one of the same

design.

Tab Washers

Always release locking tabs and fit new locking

washers, do not re-use locking tabs. Ensure the new

tab washer is the same design as that replaced.

Locking Nuts

Always use a backing spanner when loosening or

tightening locking nuts, brake and fuel pipe unions.

Roll Pins

Always fit new roll pins of an interference fit in the

hole.

Circlips

Always fit new circlips of the correct size for the

groove.

Locking wire

Always fit locking wire of the correct type. Arrange

wire so that its tension tends to tighten the bolt heads

or nuts to which it is fitted.

Keys and Keyways

Remove burrs from edges of keyways with a fine file

and clean thoroughly before attempting to refit key.

Clean and inspect key closely; keys are suitable for

refitting only if indistinguishable from new, as any

indentation may indicate the onset of wear.

Page 60 of 1007

GENERAL INFORMATION

03-29

Air conditioning system precautions

General

The air conditioning system contains fluids and

components which could be potentially hazardous to

the service engineer or the environment if not

serviced and handled correctly. The following

guidelines are intended to alert the service engineer

to potential sources of danger and emphasise the

importance of ensuring the integrity of the Air

Conditioning operating conditions and components

fitted to the vehicle.

Where necessary, additional specific precautions are

detailed in the relevant sections of this Manual which

should be referred to prior to commencing repair

operations.

The refrigerant used in the air conditioning system is

HFC-134a (Hydrofluorocarbon) R134a. Always

adhere to the following precautions:

WARNING: Servicing must only be carried out by

personnel familiar with both the vehicle system

and the charging and testing equipment. All

operations must be carried out in a well

ventilated area away from open flame and heat

sources.

WARNING: Do not allow a refrigerant container to

be heated by direct flame or to be placed near

any heating appliance. A refrigerant container

must not be heated above 50

°C.

Do not leave a container of refrigerant without its

cap fitted. Do not transport a container of

refrigerant that is unrestrained, especially in the

boot of a car.

WARNING: Do not smoke or weld in areas where

R134a is in use. Inhalation of concentrations of

vapour can cause dizziness, disorientation,

incoordination, narcosis, nausea or vomiting.

R134a is odourless and colourless. Do not

handle or discharge in an enclosed area, or any

area where the vapour and liquid can come in

contact with a naked flame or hot metal. R134a is

not flammable but can cause a highly toxic gas.

WARNING: Do not allow fluids other than R134a

or compressor lubricant to enter the air

conditioning system. Spontaneous combustion

may occur.WARNING: R134a is a hazardous liquid and when

handled incorrectly can cause serious injury.

Suitable protective clothing, consisting of face

protection, heat proof gloves, rubber boots and

rubber apron or waterproof overalls, must be

worn when carrying out operations on the air

conditioning system.

WARNING: Due to its low evaporating

temperature, R134a must be handled with care.

R134a splashed on any part of the body will

cause immediate freezing of that area. Also,

refrigerant cylinders and replenishment trolleys

when discharging will freeze skin to them if

contact is made.

WARNING: Under no circumstances should

refrigerant hoses be disconnected without first

discharging the system.

Do not disconnect any pipes in an air

conditioning refrigeration system unless trained

and instructed to do so. A refrigerant is used

which can cause blindness if allowed to contact

eyes.

WARNING: Refrigerant must always be recycled

before re-use to ensure that the purity of the

refrigerant is high enough for safe use in the air

conditioning system.

Recycling should always be carried out with

equipment which is design certified by

Underwriter Laboratory Inc. for compliance with

SAE J1991. Other equipment may not recycle

refrigerant to the required level of purity.

A R134a Refrigerant Recovery Recycling

Recharging Station must not be used with any

other type of refrigerant.

Refrigerant R134a from domestic and

commercial sources must not be used in motor

vehicle air conditioning systems.

Page 62 of 1007

GENERAL INFORMATION

03-31

When a major repair has been completed, a leak test

should be conducted; refer to the air conditioning

section of this manual for the correct procedure.

Refrigerant oil

Use an approved refrigerant lubricating oil:

ND Oil 8

CAUTION: Do not use any other type of

refrigerant oil.

CAUTION: Refrigerant oil easily absorbs water

and must not be stored for long periods. Do not

pour unused oil back into the container.

When renewing system components, add the

quantities of refrigerant oil recommended in the Air

Conditioning section of this manual.

Compressor

A new compressor is sealed and pressurised with

Nitrogen gas. When fitting a new compressor, slowly

release the sealing cap; gas pressure should be

heard to vent as the seal is broken.

CAUTION: A new compressor should always be

sealed and could be pressurised with nitrogen

gas. To avoid possible oil loss, release the

sealing cap(s) slowly. Do not remove the cap(s)

until immediately prior to connecting the air

conditioning pipes to the compressor.

Rapid refrigerant discharge

If the air conditioning system is involved in accident

damage and the system is punctured, the refrigerant

will discharge rapidly. The rapid discharge of

refrigerant will also result in the loss of most of the

oil from the system. The compressor must be

removed and all the remaining oil in the compressor

drained and refilled in accordance with the 'Air

Conditioning Compressor Replacement Procedure'.

Air conditioning compressor

replacement

A new compressor is supplied filled with a full charge

of (X cm3) of refrigerant oil.

A new compressor is supplied with an oil fill (X cm) of

120 cm

3.

A calculated quantity of oil must be drained from the

new compressor before fitting. To calculate the

quantity of oil to be drained:

1Remove the drain plug from the old

compressor.

2Invert the compressor and gravity drain the oil

into a calibrated measuring cylinder. Rotate the

compressor clutch to ensure the compressor is

completely drained.

3Note the quantity of oil drained (Y cm

3).

4Calculate the quantity of oil to be drained from

the new compressor using the following

formula:

X cm

3 – (Y cm3 + 20 cm3) = Q cm3

5Remove the drain plug from the new

compressor and drain Q cm3 of oil.

6Fit and tighten the compressor drain plug.

System components

When renewing system components, add the

following quantities of refrigerant oil:

lCondenser = 40 cm

3

lEvaporator = 30 cm 3

lReceiver drier = 15 cm 3

lPipe or hose = 5 cm 3

Page 67 of 1007

GENERAL DATA

04-4

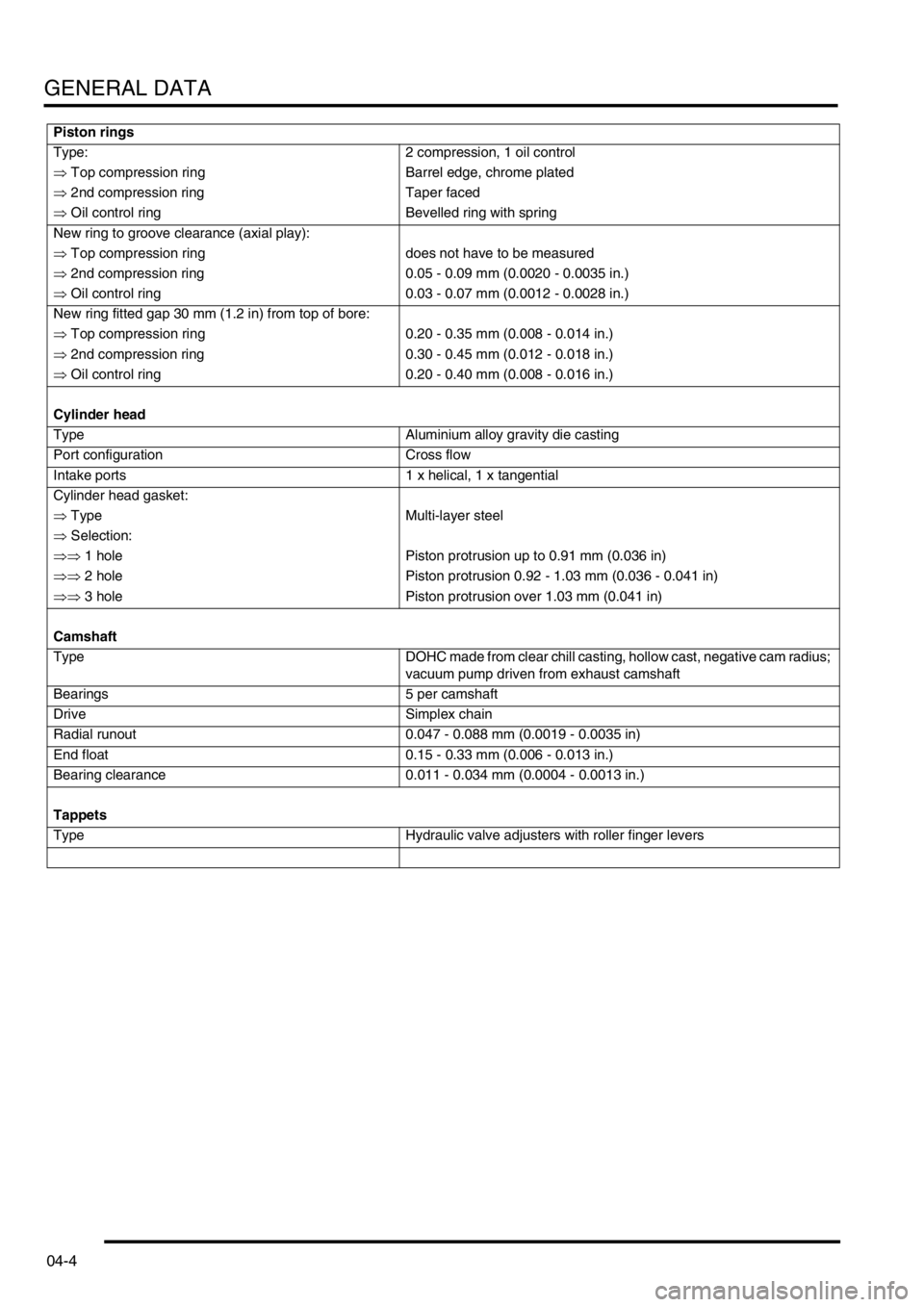

Piston rings

Type: 2 compression, 1 oil control

⇒ Top compression ring Barrel edge, chrome plated

⇒ 2nd compression ring Taper faced

⇒ Oil control ring Bevelled ring with spring

New ring to groove clearance (axial play):

⇒ Top compression ring does not have to be measured

⇒ 2nd compression ring 0.05 - 0.09 mm (0.0020 - 0.0035 in.)

⇒ Oil control ring 0.03 - 0.07 mm (0.0012 - 0.0028 in.)

New ring fitted gap 30 mm (1.2 in) from top of bore:

⇒ Top compression ring 0.20 - 0.35 mm (0.008 - 0.014 in.)

⇒ 2nd compression ring 0.30 - 0.45 mm (0.012 - 0.018 in.)

⇒ Oil control ring 0.20 - 0.40 mm (0.008 - 0.016 in.)

Cylinder head

Type Aluminium alloy gravity die casting

Port configuration Cross flow

Intake ports 1 x helical, 1 x tangential

Cylinder head gasket:

⇒ Type Multi-layer steel

⇒ Selection:

⇒⇒ 1 hole Piston protrusion up to 0.91 mm (0.036 in)

⇒⇒ 2 hole Piston protrusion 0.92 - 1.03 mm (0.036 - 0.041 in)

⇒⇒ 3 hole Piston protrusion over 1.03 mm (0.041 in)

Camshaft

Type DOHC made from clear chill casting, hollow cast, negative cam radius;

vacuum pump driven from exhaust camshaft

Bearings 5 per camshaft

Drive Simplex chain

Radial runout 0.047 - 0.088 mm (0.0019 - 0.0035 in)

End float 0.15 - 0.33 mm (0.006 - 0.013 in.)

Bearing clearance 0.011 - 0.034 mm (0.0004 - 0.0013 in.)

Tappets

Type Hydraulic valve adjusters with roller finger levers

Page 75 of 1007

GENERAL DATA

04-12

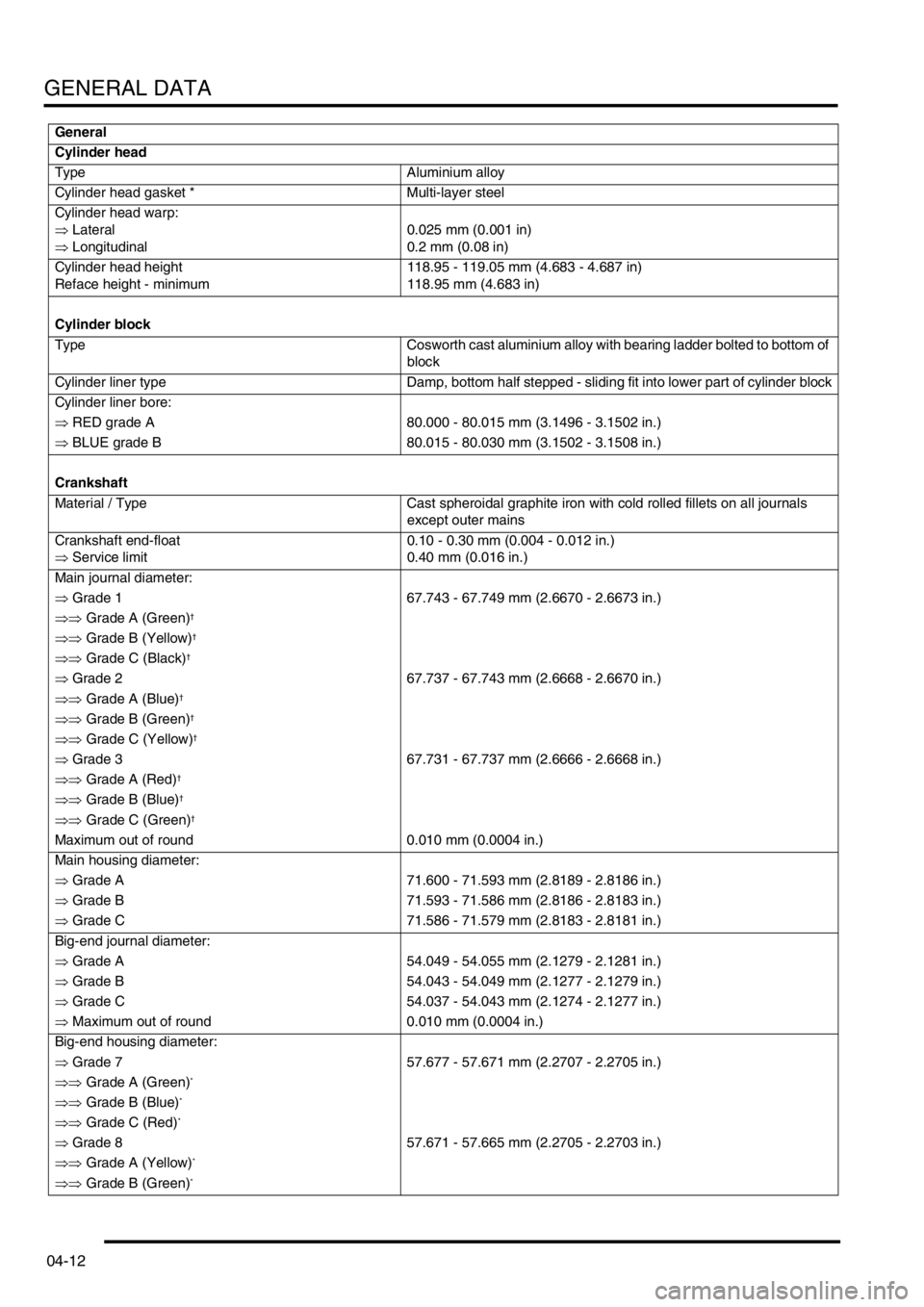

Cylinder head

Type Aluminium alloy

Cylinder head gasket * Multi-layer steel

Cylinder head warp:

⇒ Lateral

⇒ Longitudinal0.025 mm (0.001 in)

0.2 mm (0.08 in)

Cylinder head height

Reface height - minimum118.95 - 119.05 mm (4.683 - 4.687 in)

118.95 mm (4.683 in)

Cylinder block

Type Cosworth cast aluminium alloy with bearing ladder bolted to bottom of

block

Cylinder liner type Damp, bottom half stepped - sliding fit into lower part of cylinder block

Cylinder liner bore:

⇒ RED grade A 80.000 - 80.015 mm (3.1496 - 3.1502 in.)

⇒ BLUE grade B 80.015 - 80.030 mm (3.1502 - 3.1508 in.)

Crankshaft

Material / Type Cast spheroidal graphite iron with cold rolled fillets on all journals

except outer mains

Crankshaft end-float

⇒ Service limit0.10 - 0.30 mm (0.004 - 0.012 in.)

0.40 mm (0.016 in.)

Main journal diameter:

⇒ Grade 1 67.743 - 67.749 mm (2.6670 - 2.6673 in.)

⇒⇒ Grade A (Green)

†

⇒⇒ Grade B (Yellow)†

⇒⇒ Grade C (Black)†

⇒ Grade 2 67.737 - 67.743 mm (2.6668 - 2.6670 in.)

⇒⇒ Grade A (Blue)

†

⇒⇒ Grade B (Green)†

⇒⇒ Grade C (Yellow)†

⇒ Grade 3 67.731 - 67.737 mm (2.6666 - 2.6668 in.)

⇒⇒ Grade A (Red)

†

⇒⇒ Grade B (Blue)†

⇒⇒ Grade C (Green)†

Maximum out of round 0.010 mm (0.0004 in.)

Main housing diameter:

⇒ Grade A 71.600 - 71.593 mm (2.8189 - 2.8186 in.)

⇒ Grade B 71.593 - 71.586 mm (2.8186 - 2.8183 in.)

⇒ Grade C 71.586 - 71.579 mm (2.8183 - 2.8181 in.)

Big-end journal diameter:

⇒ Grade A 54.049 - 54.055 mm (2.1279 - 2.1281 in.)

⇒ Grade B 54.043 - 54.049 mm (2.1277 - 2.1279 in.)

⇒ Grade C 54.037 - 54.043 mm (2.1274 - 2.1277 in.)

⇒ Maximum out of round 0.010 mm (0.0004 in.)

Big-end housing diameter:

⇒ Grade 7 57.677 - 57.671 mm (2.2707 - 2.2705 in.)

⇒⇒ Grade A (Green)

*

⇒⇒ Grade B (Blue)*

⇒⇒ Grade C (Red)*

⇒ Grade 8 57.671 - 57.665 mm (2.2705 - 2.2703 in.)

⇒⇒ Grade A (Yellow)

*

⇒⇒ Grade B (Green)*

General

Page 78 of 1007

GENERAL DATA

04-15

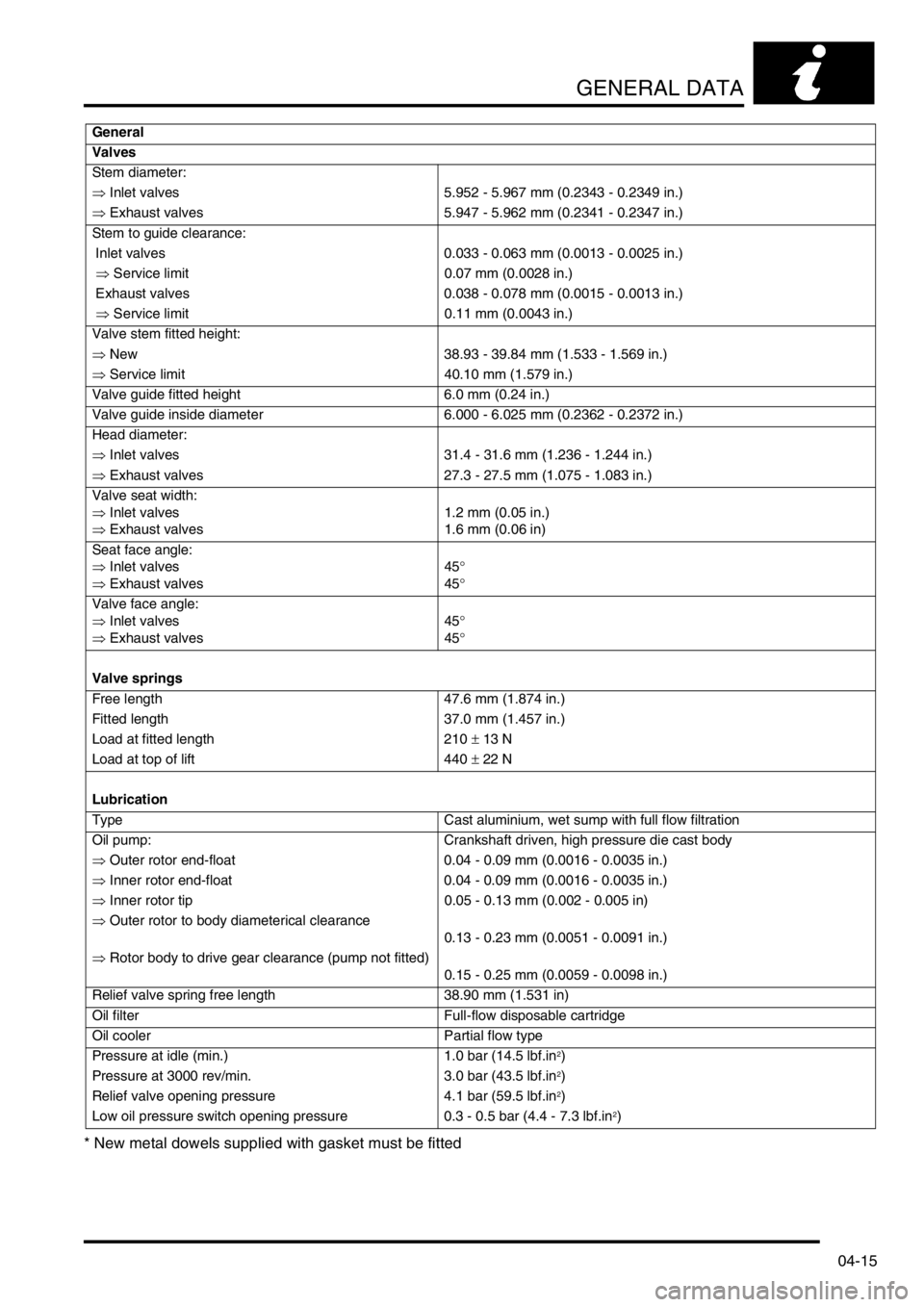

* New metal dowels supplied with gasket must be fitted

Valves

Stem diameter:

⇒ Inlet valves 5.952 - 5.967 mm (0.2343 - 0.2349 in.)

⇒ Exhaust valves 5.947 - 5.962 mm (0.2341 - 0.2347 in.)

Stem to guide clearance:

Inlet valves 0.033 - 0.063 mm (0.0013 - 0.0025 in.)

⇒ Service limit 0.07 mm (0.0028 in.)

Exhaust valves 0.038 - 0.078 mm (0.0015 - 0.0013 in.)

⇒ Service limit 0.11 mm (0.0043 in.)

Valve stem fitted height:

⇒ New 38.93 - 39.84 mm (1.533 - 1.569 in.)

⇒ Service limit 40.10 mm (1.579 in.)

Valve guide fitted height 6.0 mm (0.24 in.)

Valve guide inside diameter 6.000 - 6.025 mm (0.2362 - 0.2372 in.)

Head diameter:

⇒ Inlet valves 31.4 - 31.6 mm (1.236 - 1.244 in.)

⇒ Exhaust valves 27.3 - 27.5 mm (1.075 - 1.083 in.)

Valve seat width:

⇒ Inlet valves

⇒ Exhaust valves1.2 mm (0.05 in.)

1.6 mm (0.06 in)

Seat face angle:

⇒ Inlet valves

⇒ Exhaust valves45°

45°

Valve face angle:

⇒ Inlet valves

⇒ Exhaust valves45°

45°

Valve springs

Free length 47.6 mm (1.874 in.)

Fitted length 37.0 mm (1.457 in.)

Load at fitted length 210 ± 13 N

Load at top of lift 440 ± 22 N

Lubrication

Type Cast aluminium, wet sump with full flow filtration

Oil pump: Crankshaft driven, high pressure die cast body

⇒ Outer rotor end-float 0.04 - 0.09 mm (0.0016 - 0.0035 in.)

⇒ Inner rotor end-float 0.04 - 0.09 mm (0.0016 - 0.0035 in.)

⇒ Inner rotor tip 0.05 - 0.13 mm (0.002 - 0.005 in)

⇒ Outer rotor to body diameterical clearance

0.13 - 0.23 mm (0.0051 - 0.0091 in.)

⇒ Rotor body to drive gear clearance (pump not fitted)

0.15 - 0.25 mm (0.0059 - 0.0098 in.)

Relief valve spring free length 38.90 mm (1.531 in)

Oil filter Full-flow disposable cartridge

Oil cooler Partial flow type

Pressure at idle (min.) 1.0 bar (14.5 lbf.in

2)

Pressure at 3000 rev/min. 3.0 bar (43.5 lbf.in

2)

Relief valve opening pressure 4.1 bar (59.5 lbf.in

2)

Low oil pressure switch opening pressure 0.3 - 0.5 bar (4.4 - 7.3 lbf.in

2) General

Page 145 of 1007

CAPACITIES, FLUIDS, LUBRICANTS AND SEALANTS

09-2

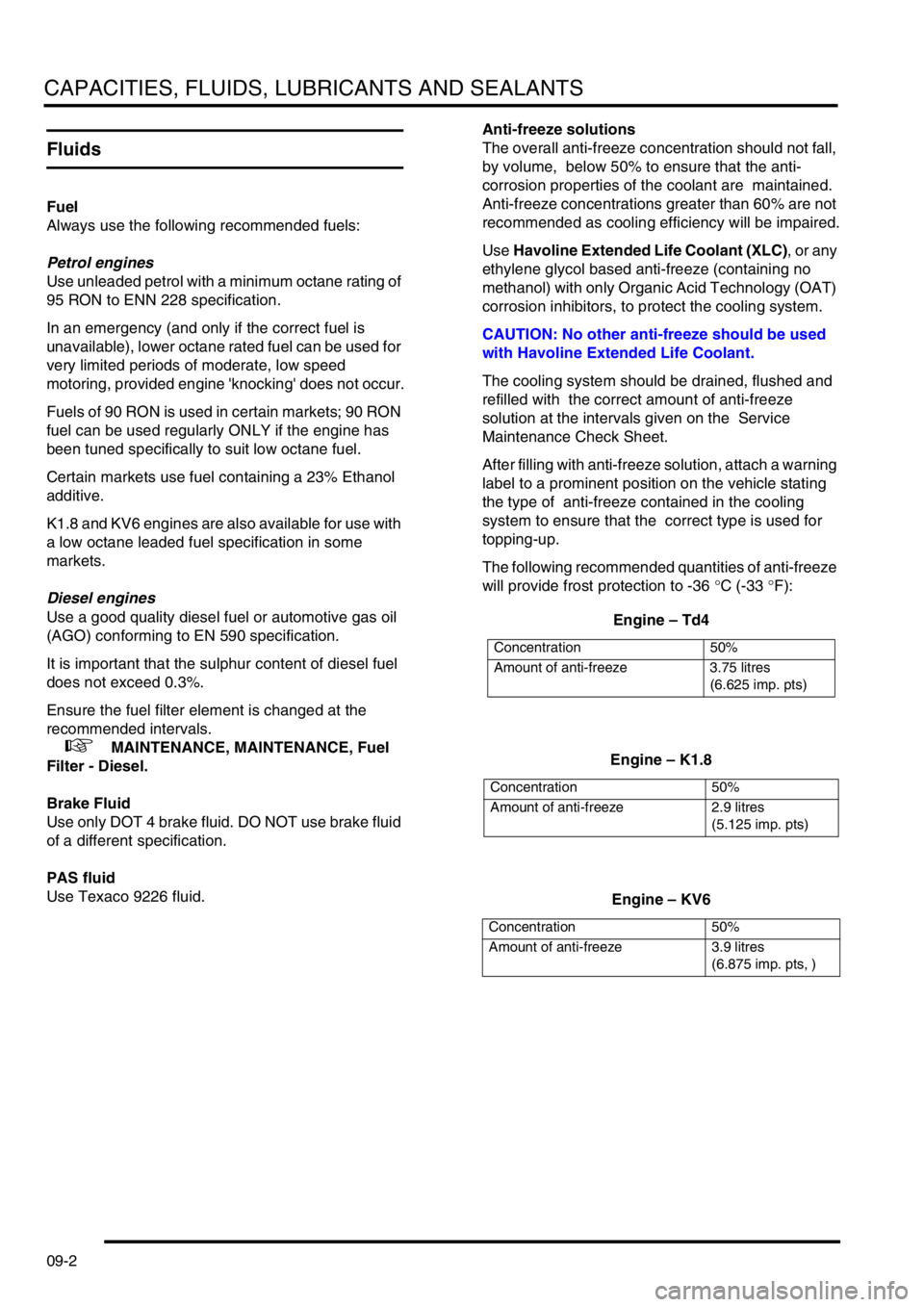

Fluids

Fuel

Always use the following recommended fuels:

Petrol engines

Use unleaded petrol with a minimum octane rating of

95 RON to ENN 228 specification.

In an emergency (and only if the correct fuel is

unavailable), lower octane rated fuel can be used for

very limited periods of moderate, low speed

motoring, provided engine 'knocking' does not occur.

Fuels of 90 RON is used in certain markets; 90 RON

fuel can be used regularly ONLY if the engine has

been tuned specifically to suit low octane fuel.

Certain markets use fuel containing a 23% Ethanol

additive.

K1.8 and KV6 engines are also available for use with

a low octane leaded fuel specification in some

markets.

Diesel engines

Use a good quality diesel fuel or automotive gas oil

(AGO) conforming to EN 590 specification.

It is important that the sulphur content of diesel fuel

does not exceed 0.3%.

Ensure the fuel filter element is changed at the

recommended intervals.

+ MAINTENANCE, MAINTENANCE, Fuel

Filter - Diesel.

Brake Fluid

Use only DOT 4 brake fluid. DO NOT use brake fluid

of a different specification.

PAS fluid

Use Texaco 9226 fluid.Anti-freeze solutions

The overall anti-freeze concentration should not fall,

by volume, below 50% to ensure that the anti-

corrosion properties of the coolant are maintained.

Anti-freeze concentrations greater than 60% are not

recommended as cooling efficiency will be impaired.

Use Havoline Extended Life Coolant (XLC), or any

ethylene glycol based anti-freeze (containing no

methanol) with only Organic Acid Technology (OAT)

corrosion inhibitors, to protect the cooling system.

CAUTION: No other anti-freeze should be used

with Havoline Extended Life Coolant.

The cooling system should be drained, flushed and

refilled with the correct amount of anti-freeze

solution at the intervals given on the Service

Maintenance Check Sheet.

After filling with anti-freeze solution, attach a warning

label to a prominent position on the vehicle stating

the type of anti-freeze contained in the cooling

system to ensure that the correct type is used for

topping-up.

The following recommended quantities of anti-freeze

will provide frost protection to -36 °C (-33 °F):

Engine – Td4

Engine – K1.8

Engine – KV6

Concentration 50%

Amount of anti-freeze 3.75 litres

(6.625 imp. pts)

Concentration 50%

Amount of anti-freeze 2.9 litres

(5.125 imp. pts)

Concentration 50%

Amount of anti-freeze 3.9 litres

(6.875 imp. pts, )

Page 771 of 1007

PANEL REPAIRS

77-2-16 WELDING PROCEDURES

General Welding Precautions

General

For ease of reference, the diagrams on the following pages show only the type of weld used in repair where it varies

from that used in production.

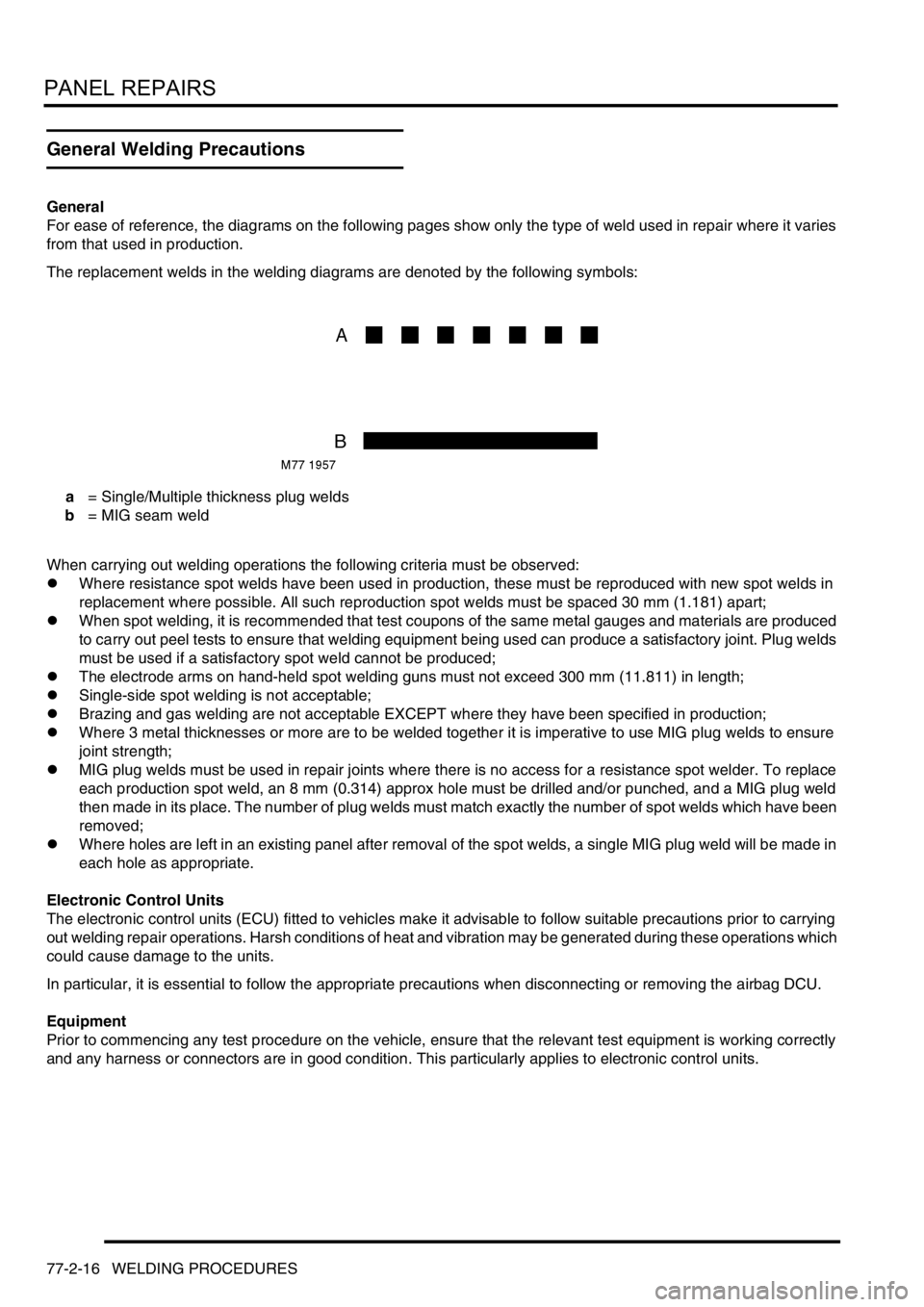

The replacement welds in the welding diagrams are denoted by the following symbols:

a = Single/Multiple thickness plug welds

b = MIG seam weld

When carrying out welding operations the following criteria must be observed:

lWhere resistance spot welds have been used in production, these must be reproduced with new spot welds in

replacement where possible. All such reproduction spot welds must be spaced 30 mm (1.181) apart;

lWhen spot welding, it is recommended that test coupons of the same metal gauges and materials are produced

to carry out peel tests to ensure that welding equipment being used can produce a satisfactory joint. Plug welds

must be used if a satisfactory spot weld cannot be produced;

lThe electrode arms on hand-held spot welding guns must not exceed 300 mm (11.811) in length;

lSingle-side spot welding is not acceptable;

lBrazing and gas welding are not acceptable EXCEPT where they have been specified in production;

lWhere 3 metal thicknesses or more are to be welded together it is imperative to use MIG plug welds to ensure

joint strength;

lMIG plug welds must be used in repair joints where there is no access for a resistance spot welder. To replace

each production spot weld, an 8 mm (0.314) approx hole must be drilled and/or punched, and a MIG plug weld

then made in its place. The number of plug welds must match exactly the number of spot welds which have been

removed;

lWhere holes are left in an existing panel after removal of the spot welds, a single MIG plug weld will be made in

each hole as appropriate.

Electronic Control Units

The electronic control units (ECU) fitted to vehicles make it advisable to follow suitable precautions prior to carrying

out welding repair operations. Harsh conditions of heat and vibration may be generated during these operations which

could cause damage to the units.

In particular, it is essential to follow the appropriate precautions when disconnecting or removing the airbag DCU.

Equipment

Prior to commencing any test procedure on the vehicle, ensure that the relevant test equipment is working correctly

and any harness or connectors are in good condition. This particularly applies to electronic control units.