sensor lexus LFA 2012 Technical Information / LEXUS 2012 LFA: INSIDE THE LFA

[x] Cancel search | Manufacturer: LEXUS, Model Year: 2012, Model line: LFA, Model: Lexus LFA 2012Pages: 128, PDF Size: 5.91 MB

Page 31 of 128

29

Operating the driving mode selector switch

■

■VDIM

The LFA employs VDIM (Vehicle Dynamics Integrated Management), a dynamic

control program that integrates braking and drive torque control to help ensure

overall vehicle stability and secure handling. VDIM also features vertical acceleration

and roll rate sensors, added exclusively for the LFA. The addition of these sensors

increases the precision and response of road camber estimation on banked roads,

such as “The Carousel” at the Nürburgring, to determine the vehicle’s performance

limits. This prevents excessive intervention on banked roads.

The LFA’s VDIM system allows for two individual control modes selected by the driver

using the driving mode selector switch.

When in SPORT mode, VDIM control is modified in order to enhance driving

pleasure and the driver’s confidence in the vehicle.

When not in SPORT mode, VDIM returns to NORMAL mode, designed to intervene

seamlessly as the vehicle reaches its performance limits, thereby realizing smoother

driving dynamics.

This helps ensure both overall vehicle stability and secure handling.

Page 34 of 128

32

When the driver depresses the accelerator pedal, a signal is sent to the ECU where

it is interpreted and used to control the throttle valve angle. This is all performed

electronically without a conventional cable linkage.

The throttle valves are opened and closed by a pair of electric motors, one for each

bank of cylinders. There are a total of 10 individual throttle valves, one for each

cylinder. This configuration minimizes the amount of air between each combustion

chamber and its corresponding independent throttle valve, promoting instantaneous

throttle action for outstanding engine response.

Furthermore, this drive-by-wire technology is able to tailor specific throttle valve

angle strategies to each available driving mode. Depending on which driving mode

is selected, depressing the accelerator pedal the same amount will result in a different

throttle valve angle. This variable control results in engine characteristics better suited

to the driver’s intentions and driving conditions.

■

■Accelerator pedal mechanism

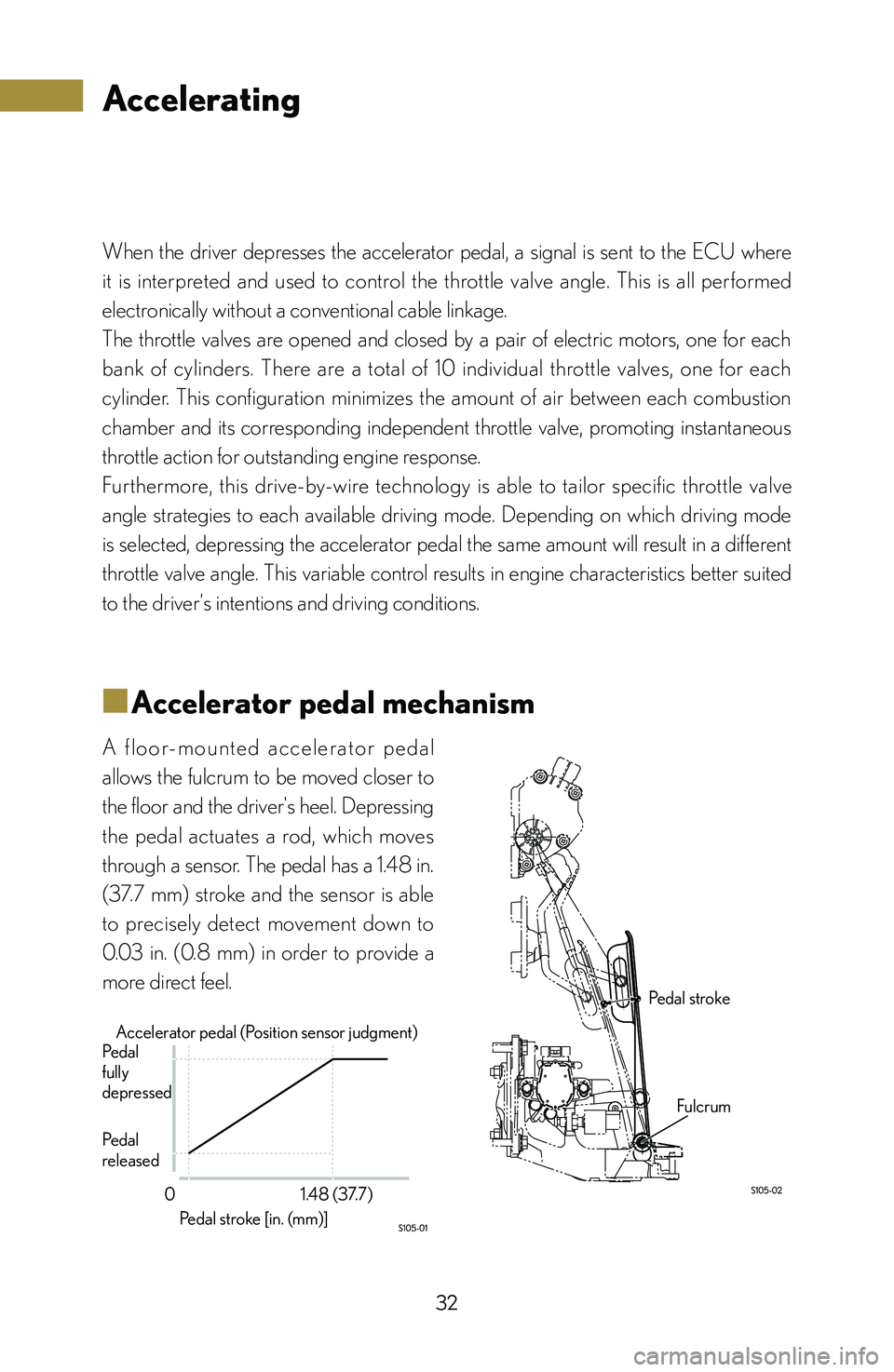

A f l o o r- m o u n t e d a c c e l e r a t o r p e d a l

allows the fulcrum to be moved closer to

the floor and the driver's heel. Depressing

the pedal actuates a rod, which moves

through a sensor. The pedal has a 1.48 in.

(37.7 mm) stroke and the sensor is able

to precisely detect movement down to

0.03 in. (0.8 mm) in order to provide a

more direct feel.

Pedal stroke

Fulcrum

Accelerator pedal (Position sensor judgment)

Pedal

released Pedal

fully

depressed 0 1.48 (37.7)

Pedal stroke [in. (mm)]

Accelerating

Page 52 of 128

50

Braking

The LFA is equipped with an ECB (Electronically Controlled Brake) system.

When the brake pedal is depressed, information on how much force is being used to

depress the pedal and the amount it is depressed is sent to the ECB computer. This

computer takes into account the vehicle’s overall condition using inputs from various

sensors and distributes the optimal amount of brake force to each individual wheel.

The ECB system uses an electric pump to generate hydraulic pressure, thereby

providing braking power without relying on engine vacuum. The use of this

technology ensures a consistent supply of effective braking power.

However, the detail behind the LFA brake system does not end with the ECB system.

Monoblock calipers and CCM (Carbon Ceramic Material) discs are just a few of the

other components that give the LFA its generous braking power. Furthermore, large

brake ducts have been proactively integrated in order to feed the brakes fresh, cold

air to keep them working at their optimum temperature for consistent performance.

Regarding the brake override system:

If the driver depresses the brake and accelerator pedals at the same time or if

the ECU judges that both acceleration and braking commands are being issued,

braking will be prioritized. The system will ignore the signal from the accelerator

pedal, close all throttle valves and provide the appropriate amount of braking force

demanded by the driver’s braking effort.

Page 62 of 128

60

■

■Engine coolant temperature gauge

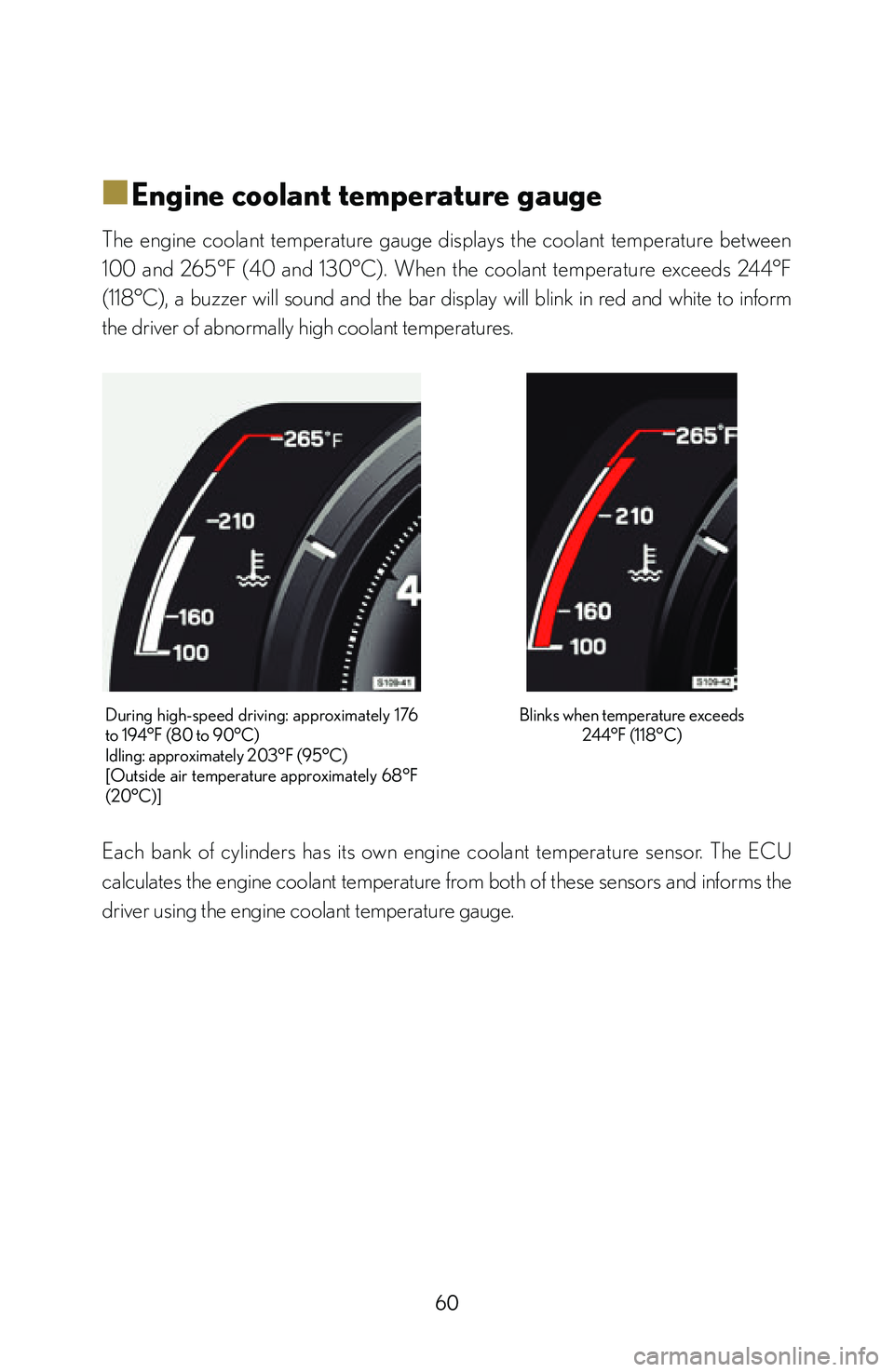

The engine coolant temperature gauge displays the coolant temperature between

100 and 265°F (40 and 130°C). When the coolant temperature exceeds 244°F

(118°C), a buzzer will sound and the bar display will blink in red and white to inform

the driver of abnormally high coolant temperatures.

During high-speed driving: approximately 176

to 194°F (80 to 90°C)

Idling: approximately 203°F (95°C)

[Outside air temperature approximately 68°F

(20°C)]Blinks when temperature exceeds

244°F (118°C)

Each bank of cylinders has its own engine coolant temperature sensor. The ECU

calculates the engine coolant temperature from both of these sensors and informs the

driver using the engine coolant temperature gauge.

Page 63 of 128

61

Checking the engine

■

■Engine oil temperature gauge

The engine oil temperature gauge displays the oil temperature from 100 to 320°F

(40 to 160°C). When the oil temperature exceeds 284°F (140°C), a buzzer will

sound and the bar display will blink in red and white to inform the driver that the

oil temperature is abnormally high and that the performance and lifespan of the

oil is severely compromised. Allowing the engine oil to cool and maintain a stable

temperature helps to stabilize its performance.

During high-speed driving: approximately 176

to 194°F (80 to 90°C)

[Outside air temperature approximately 68°F

(20°C)]Blinks when temperature exceeds

284°F (140°C)

An oil temperature sensor is installed near the oil filter to monitor the temperature

of the engine oil supplied by the oil pump. The ECU processes the engine oil

temperature from this sensor and informs the driver using the engine oil temperature

gauge.

Page 64 of 128

62

■

■Engine oil pressure gauge

The engine oil pressure gauge displays the engine oil pressure from 0 to 800

kPa. The rapid response of the TFT LCD panel allows for the fluctuations in engine

oil pressure that occur with engine speed to be displayed instantly. The engine oil

pressure is also affected by other factors such as engine oil type, temperature and

deterioration. If the engine oil pressure is too low, the master warning light comes on

and the “Engine oil pressure low” warning message is displayed. Checking the engine

oil pressure regularly aids understanding of the condition of the engine and engine oil.

During high-speed driving: approximately 400

to 800 kPa

(changes depending on driving conditions)

[Outside air temperature approximately 68°F

(20°C)]

When oil pressure is insufficient

An oil pressure sensor is installed near the oil filter.

The oil pressure measurements are processed by the ECU and displayed by the

engine oil pressure gauge.

Page 65 of 128

63

Checking the engine

■

■Fuel gauge

The fuel gauge displays the amount of fuel remaining on a scale of 0 to 1/1. The

saddle-shaped fuel tank consists of a main tank compartment and a sub-tank

compartment. When the fuel level drops to approximately 2.9 gal. (11 L, 2.4 Imp. gal.)

between both compartments, the bar display will blink in amber to inform the driver

that the remaining fuel level is low. In this state, the remaining amount of fuel is directed

into the main tank compartment in order to ensure a stable supply of fuel to the engine

even under high cornering G-loads.

S109-14Main tank

compartment Sub-tank compartment

Fuel

Remaining fuel directed to main tank

compartment

Blinks when remaining fuel drops to approx. 2.9 gal. (11 L, 2.4 Imp. gal.)

The main tank compar tment and sub-tank compar tment each have their own

individual sender gauges to monitor the fuel levels. The ECU calculates the total

amount of fuel remaining from both of these sensors and informs the driver using

the fuel gauge. The ECU digitally processes the fuel level data in order to display a

clear and accurate fuel level even when the fuel level fluctuates under high cornering

G-loads.

Page 70 of 128

68

■

■Oil level

An oil level sensor is installed in the oil tank to measure the amount of oil present. The

reading from this sensor is displayed to the driver. This allows the engine oil level to

be checked simply by operating the control pad, without needing to get out of the

vehicle.

■

■Measurement

1 Select “Status”2 Select “Oil Level”

3 Displays

measur

ement result

Measurement is possible when the following

conditions are met:

1. Engine oil temperature: Between 203 and

230 °F (95 and 110°C)

2. Engine speed: Between 900 and 1, 100 rpm

3. Vehicle status: Stationary and idling

4. Vehicle level: Allowable inclination of 4 degrees

or less.

Example of display when

conditions are not met

Page 104 of 128

102

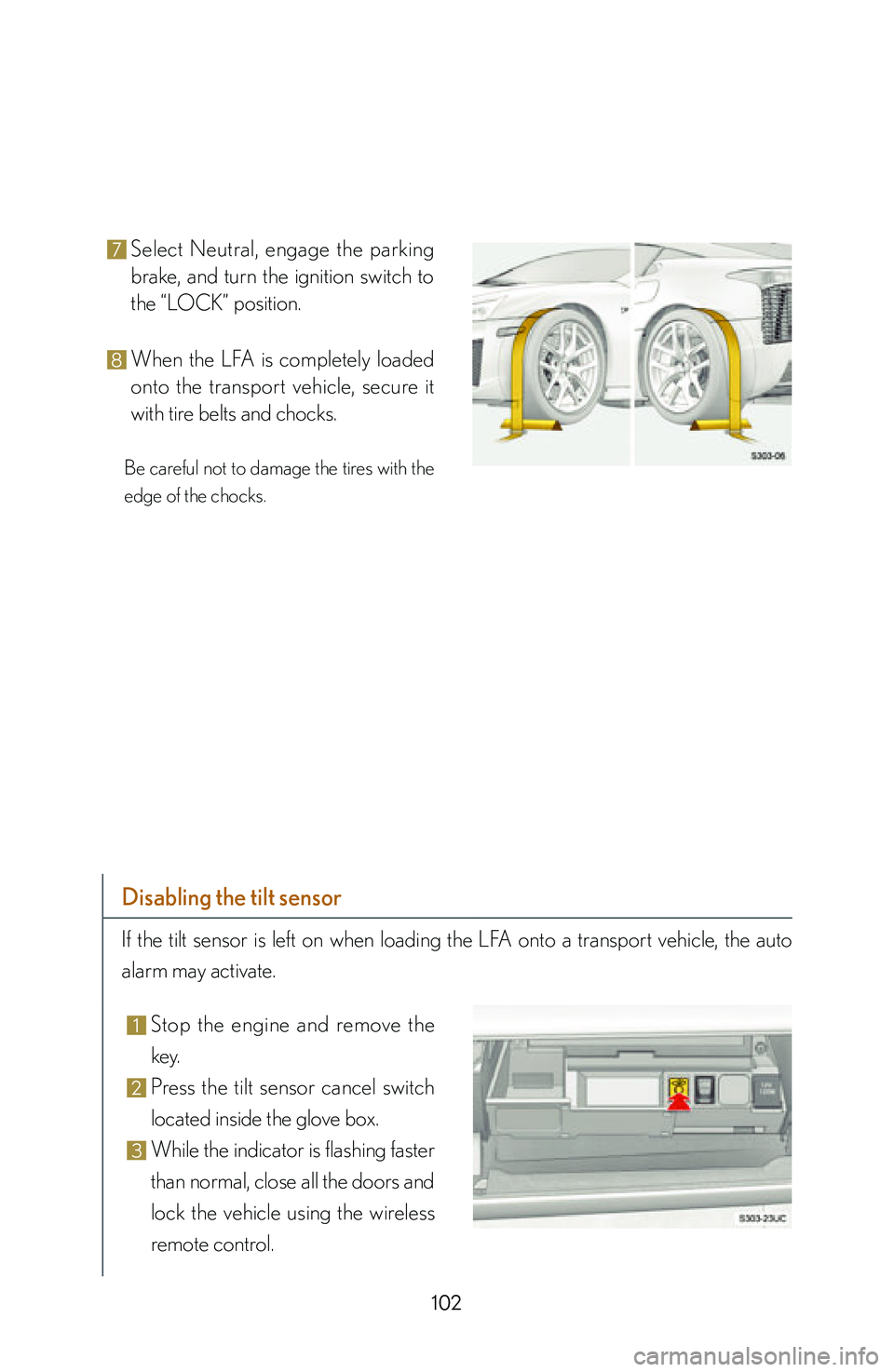

7 Select Neutral, engage the parking

brake, and turn the ignition switch to

the “LOCK” position.

8 When the LFA is completely loaded

onto the transport vehicle, secure it

with tire belts and chocks.

Be careful not to damage the tires with the

edge of the chocks.

Disabling the tilt sensor

If the tilt sensor is left on when loading the LFA onto a transport vehicle, the auto

alarm may activate.

1 Stop the engine and remove the

key.

2 Press the tilt sensor cancel switch

located inside the glove box.

3 While the indicator is flashing faster

than normal, close all the doors and

lock the vehicle using the wireless

remote control.

Page 117 of 128

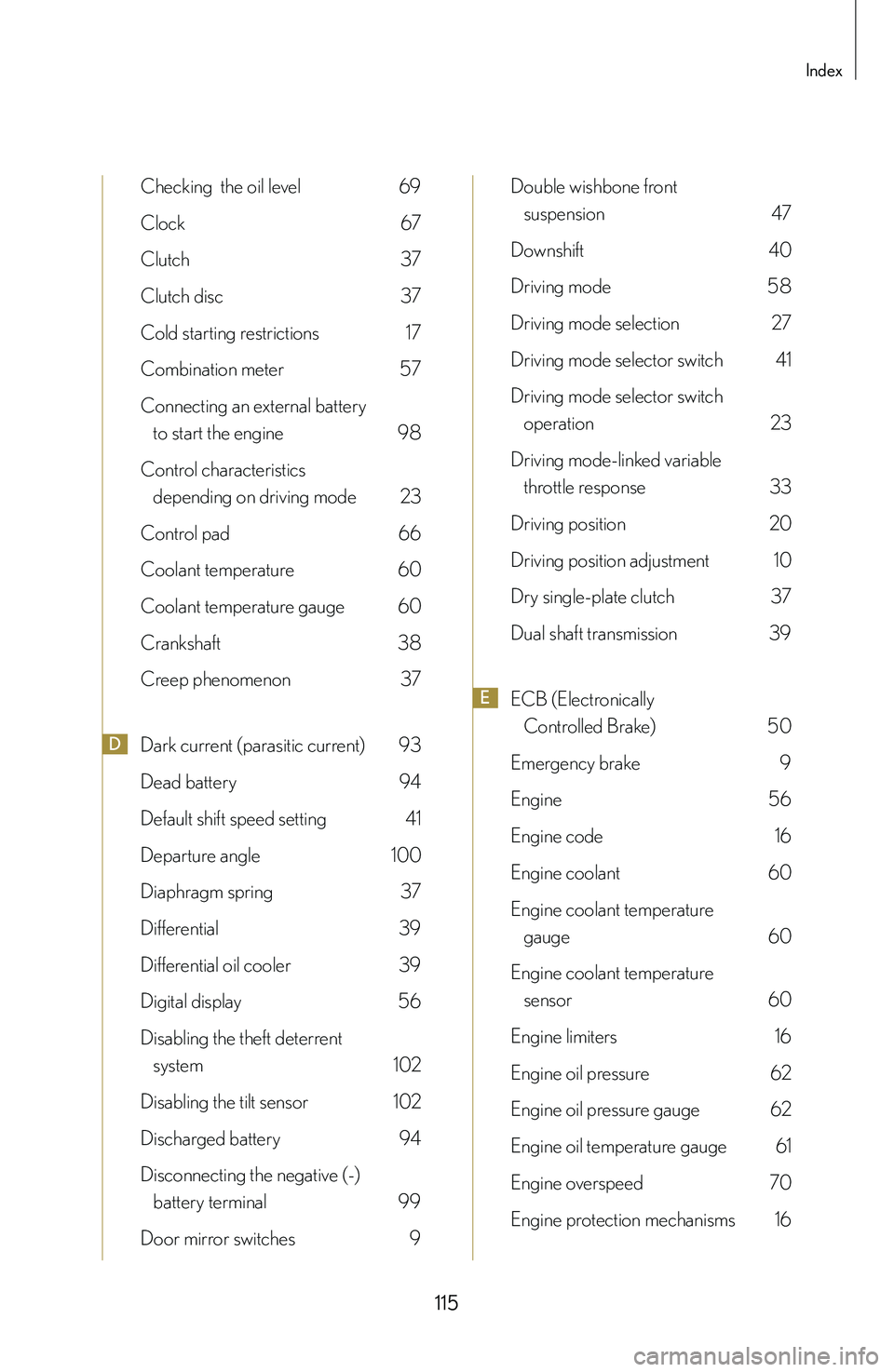

115

Index

Checking the oil level 69

Clock 67

Clutch 37

Clutch disc 37

Cold starting restrictions 17

Combination meter 57

Connecting an external battery

to start the engine 98

Control characteristics

depending on driving mode 23

Control pad 66

Coolant temperature 60

Coolant temperature gauge 60

Crankshaft 38

Creep phenomenon 37

DDark current (parasitic current) 93

Dead battery 94

Default shift speed setting 41

Departure angle 100

Diaphragm spring 37

Differential 39

Differential oil cooler 39

Digital display 56

Disabling the theft deterrent

system 102

Disabling the tilt sensor 102

Discharged battery 94

Disconnecting the negative (-)

battery terminal 99

Door mirror switches 9

Double wishbone front

suspension 47

Downshift 40

Driving mode 58

Driving mode selection 27

Driving mode selector switch 41

Driving mode selector switch

operation 23

Driving mode-linked variable

throttle response 33

Driving position 20

Driving position adjustment 10

Dry single-plate clutch 37

Dual shaft transmission 39

EECB (Electronically

Controlled Brake) 50

Emergency brake 9

Engine 56

Engine code 16

Engine coolant 60

Engine coolant temperature

gauge 60

Engine coolant temperature

sensor 60

Engine limiters 16

Engine oil pressure 62

Engine oil pressure gauge 62

Engine oil temperature gauge 61

Engine overspeed 70

Engine protection mechanisms 16