splash LEXUS SC300 1991 Service User Guide

[x] Cancel search | Manufacturer: LEXUS, Model Year: 1991, Model line: SC300, Model: LEXUS SC300 1991Pages: 4087, PDF Size: 75.75 MB

Page 2068 of 4087

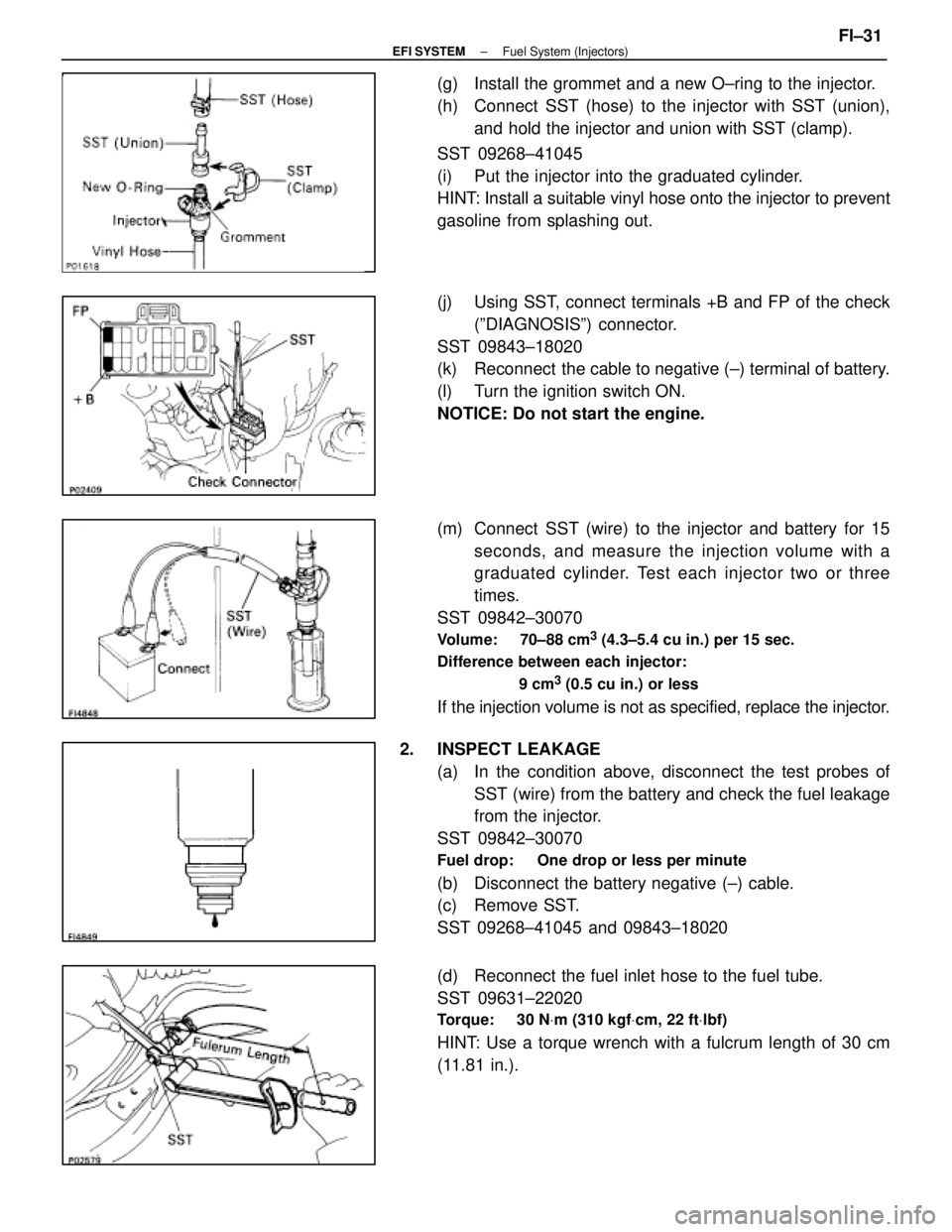

(g) Install the grommet and a new O±ring to the injector.

(h) Connect SST (hose) to the injector with SST (union),and hold the injector and union with SST (clamp).

SST 09268±41045

(i) Put the injector into the graduated cylinder.

HINT: Install a suitable vinyl hose onto the injector to prevent

gasoline from splashing out.

(j) Using SST, connect terminals +B and FP of the check (ºDIAGNOSISº) connector.

SST 09843±18020

(k) Reconnect the cable to negative (±) terminal of battery.

(l) Turn the ignition switch ON.

NOTICE: Do not start the engine.

(m) Connect SST (wire) to the injector and battery for 15 seconds, and measure the injection volume with a

graduated cylinder. Test each injector two or three

times.

SST 09842±30070

Volume: 70±88 cm3 (4.3±5.4 cu in.) per 15 sec.

Difference between each injector:

9 cm

3 (0.5 cu in.) or less

If the injection volume is not as specified, replace the injector.

2. INSPECT LEAKAGE (a) In the condition above, disconnect the test probes ofSST (wire) from the battery and check the fuel leakage

from the injector.

SST 09842±30070

Fuel drop: One drop or less per minute

(b) Disconnect the battery negative (±) cable.

(c) Remove SST.

SST 09268±41045 and 09843±18020

(d) Reconnect the fuel inlet hose to the fuel tube.

SST 09631±22020

Torque: 30 N Vm (310 kgf Vcm, 22 ft Vlbf)

HINT: Use a torque wrench with a fulcrum length of 30 cm

(11.81 in.).

±

EFI SYSTEM Fuel System (Injectors)FI±31

WhereEverybodyKnowsYourName

Page 2399 of 4087

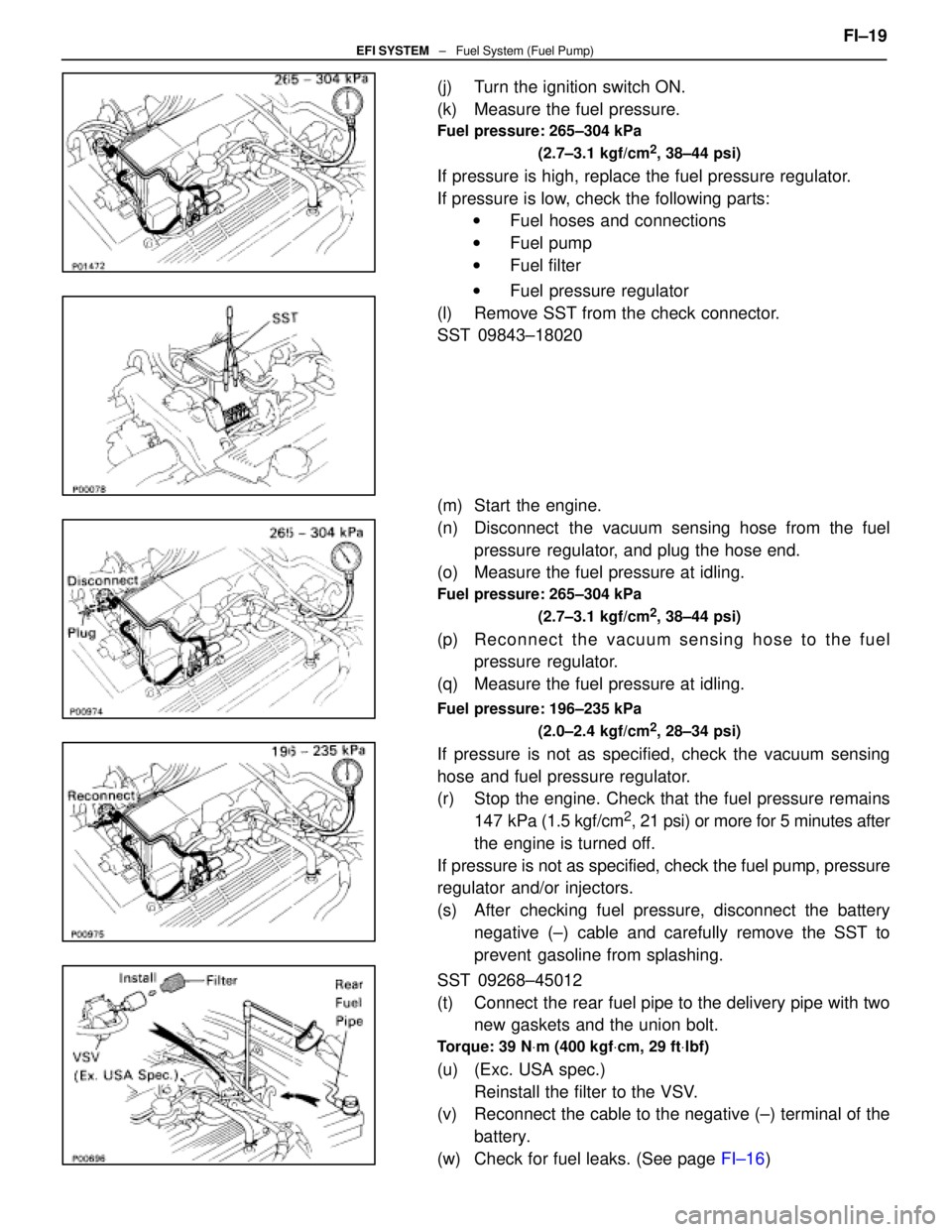

(j) Turn the ignition switch ON.

(k) Measure the fuel pressure.

Fuel pressure: 265±304 kPa(2.7±3.1 kgf/cm

2, 38±44 psi)

If pressure is high, replace the fuel pressure regulator.

If pressure is low, check the following parts:w Fuel hoses and connections

w Fuel pump

w Fuel filter

w Fuel pressure regulator

(l) Remove SST from the check connector.

SST 09843±18020

(m) Start the engine.

(n) Disconnect the vacuum sensing hose from the fuel pressure regulator, and plug the hose end.

(o) Measure the fuel pressure at idling.

Fuel pressure: 265±304 kPa

(2.7±3.1 kgf/cm

2, 38±44 psi)

(p) Re connect the vacuum sensing hose to the fuel

pressure regulator.

(q) Measure the fuel pressure at idling.

Fuel pressure: 196±235 kPa

(2.0±2.4 kgf/cm

2, 28±34 psi)

If pressure is not as specified, check the vacuum sensing

hose and fuel pressure regulator.

(r) Stop the engine. Check that the fuel pressure remains147 kPa (1.5 kgf/cm

2, 21 psi) or more for 5 minutes after

the engine is turned off.

If pressure is not as specified, check the fuel pump, pressure

regulator and/or injectors.

(s) After checking fuel pressure, disconnect the battery negative (±) cable and carefully remove the SST to

prevent gasoline from splashing.

SST 09268±45012

(t) Connect the rear fuel pipe to the delivery pipe with two new gaskets and the union bolt.

Torque: 39 N Vm (400 kgf Vcm, 29 ft Vlbf)

(u) (Exc. USA spec.)

Reinstall the filter to the VSV.

(v) Reconnect the cable to the negative (±) terminal of the

battery.

(w) Check for fuel leaks. (See page FI±16) FI±19

EFI SYSTEM

± Fuel System (Fuel Pump)

WhereEverybodyKnowsYourName

Page 2433 of 4087

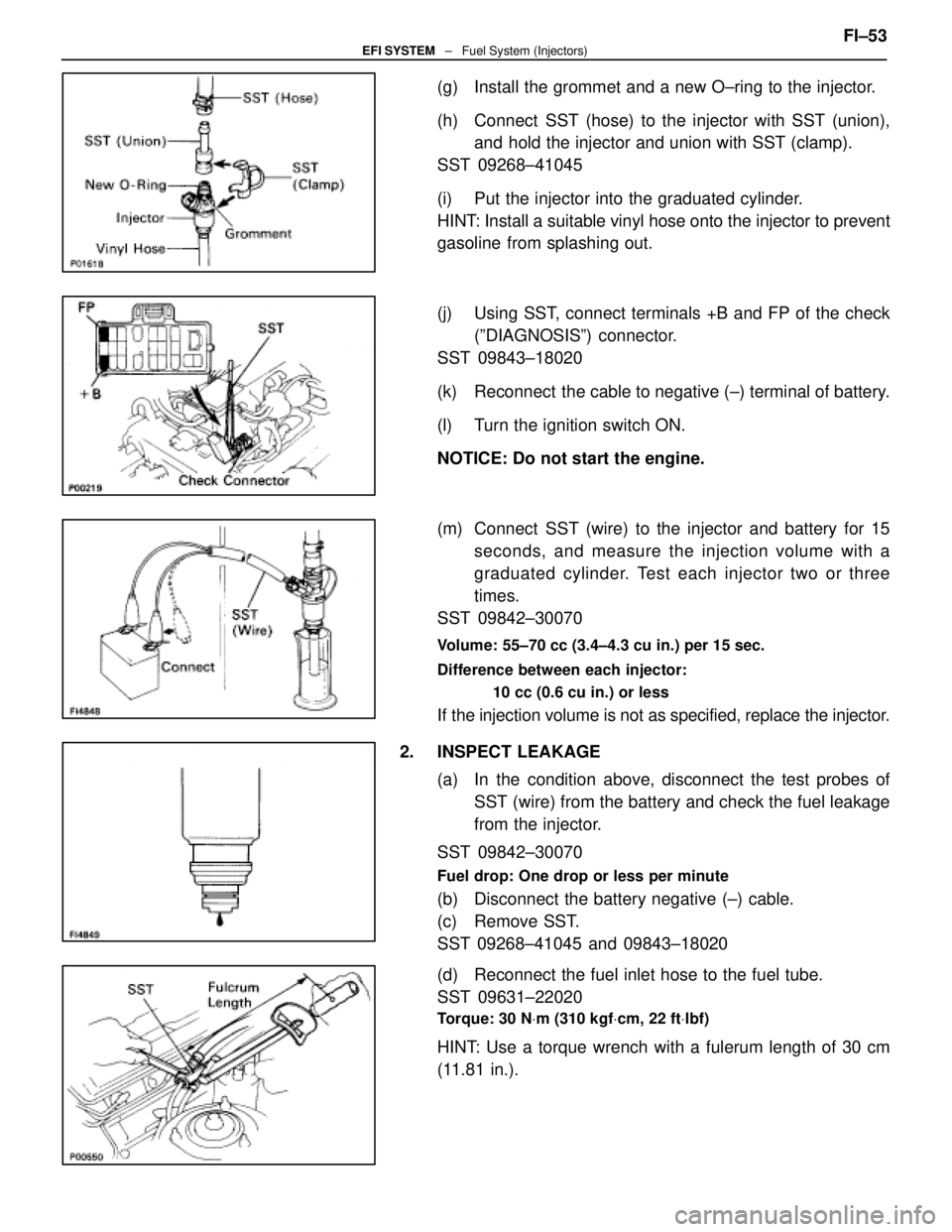

(g) Install the grommet and a new O±ring to the injector.

(h) Connect SST (hose) to the injector with SST (union),and hold the injector and union with SST (clamp).

SST 09268±41045

(i) Put the injector into the graduated cylinder.

HINT: Install a suitable vinyl hose onto the injector to prevent

gasoline from splashing out.

(j) Using SST, connect terminals +B and FP of the check (ºDIAGNOSISº) connector.

SST 09843±18020

(k) Reconnect the cable to negative (±) terminal of battery.

(l) Turn the ignition switch ON.

NOTICE: Do not start the engine.

(m) Connect SST (wire) to the injector and battery for 15 seconds, and measure the injection volume with a

graduated cylinder. Test each injector two or three

times.

SST 09842±30070

Volume: 55±70 cc (3.4±4.3 cu in.) per 15 sec.

Difference between each injector:

10 cc (0.6 cu in.) or less

If the injection volume is not as specified, replace the injector.

2. INSPECT LEAKAGE (a) In the condition above, disconnect the test probes ofSST (wire) from the battery and check the fuel leakage

from the injector.

SST 09842±30070

Fuel drop: One drop or less per minute

(b) Disconnect the battery negative (±) cable.

(c) Remove SST.

SST 09268±41045 and 09843±18020

(d) Reconnect the fuel inlet hose to the fuel tube.

SST 09631±22020

Torque: 30 N Vm (310 kgf Vcm, 22 ft Vlbf)

HINT: Use a torque wrench with a fulerum length of 30 cm

(11.81 in.). FI±53

EFI SYSTEM

± Fuel System (Injectors)

WhereEverybodyKnowsYourName

Page 3297 of 4087

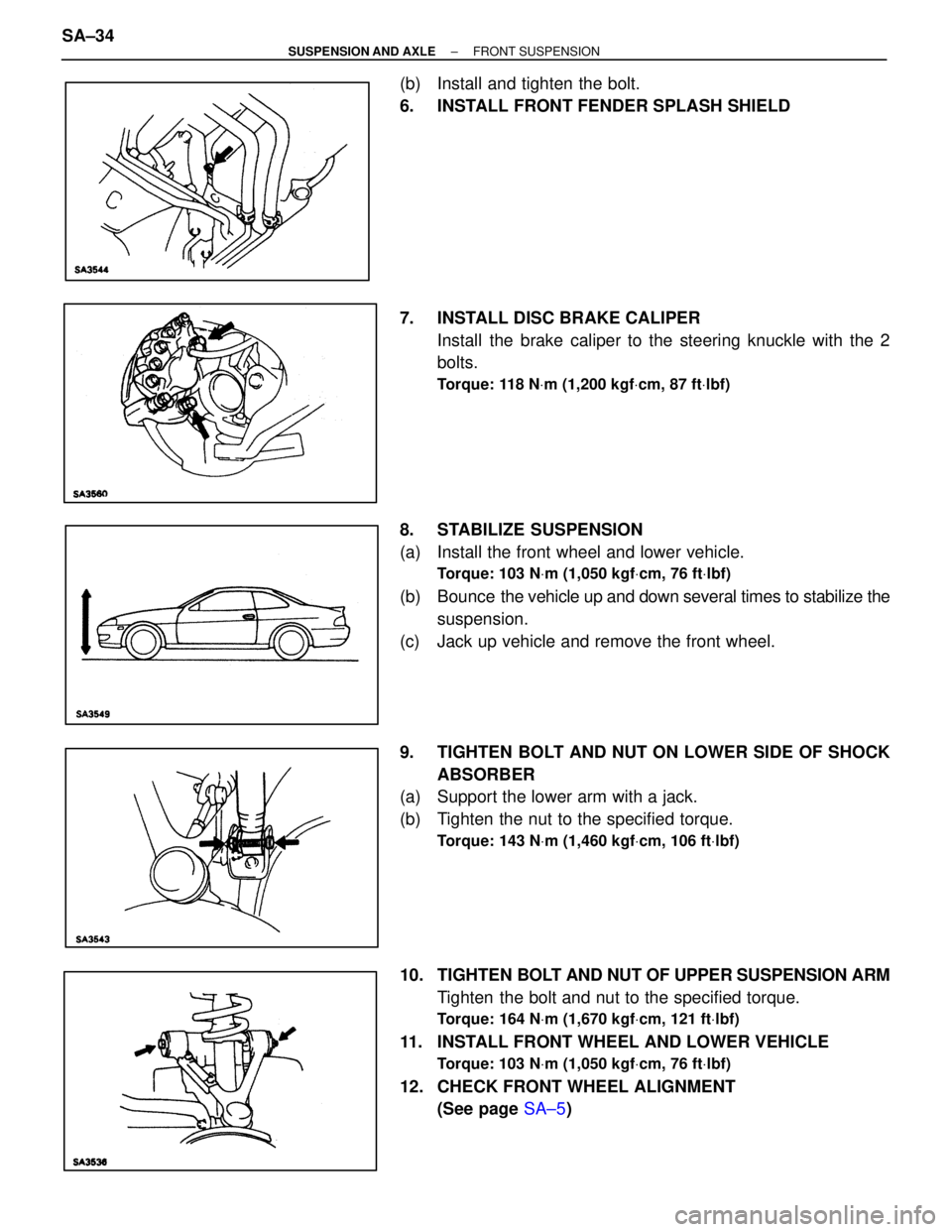

(b) Install and tighten the bolt.

6. INSTALL FRONT FENDER SPLASH SHIELD

7. INSTALL DISC BRAKE CALIPERInstall the brake caliper to the steering knuckle with the 2

bolts.

Torque: 118 N Vm (1,200 kgf Vcm, 87 ft Vlbf)

8. STABILIZE SUSPENSION

(a) Install the front wheel and lower vehicle.

Torque: 103 N Vm (1,050 kgf Vcm, 76 ft Vlbf)

(b) Bounce the vehicle up and down several times to stabilize the

suspension.

(c) Jack up vehicle and remove the front wheel.

9. TIGHTEN BOLT AND NUT ON LOWER SIDE OF SHOCK ABSORBER

(a) Support the lower arm with a jack.

(b) Tighten the nut to the specified torque.

Torque: 143 N Vm (1,460 kgf Vcm, 106 ft Vlbf)

10. TIGHTEN BOLT AND NUT OF UPPER SUSPENSION ARM

Tighten the bolt and nut to the specified torque.

Torque: 164 N Vm (1,670 kgf Vcm, 121 ft Vlbf)

11. INSTALL FRONT WHEEL AND LOWER VEHICLE

Torque: 103 N Vm (1,050 kgf Vcm, 76 ft Vlbf)

12. CHECK FRONT WHEEL ALIGNMENT

(See page SA±5)

SA±34

±

SUSPENSION AND AXLE FRONT SUSPENSION

WhereEverybodyKnowsYourName

Page 3299 of 4087

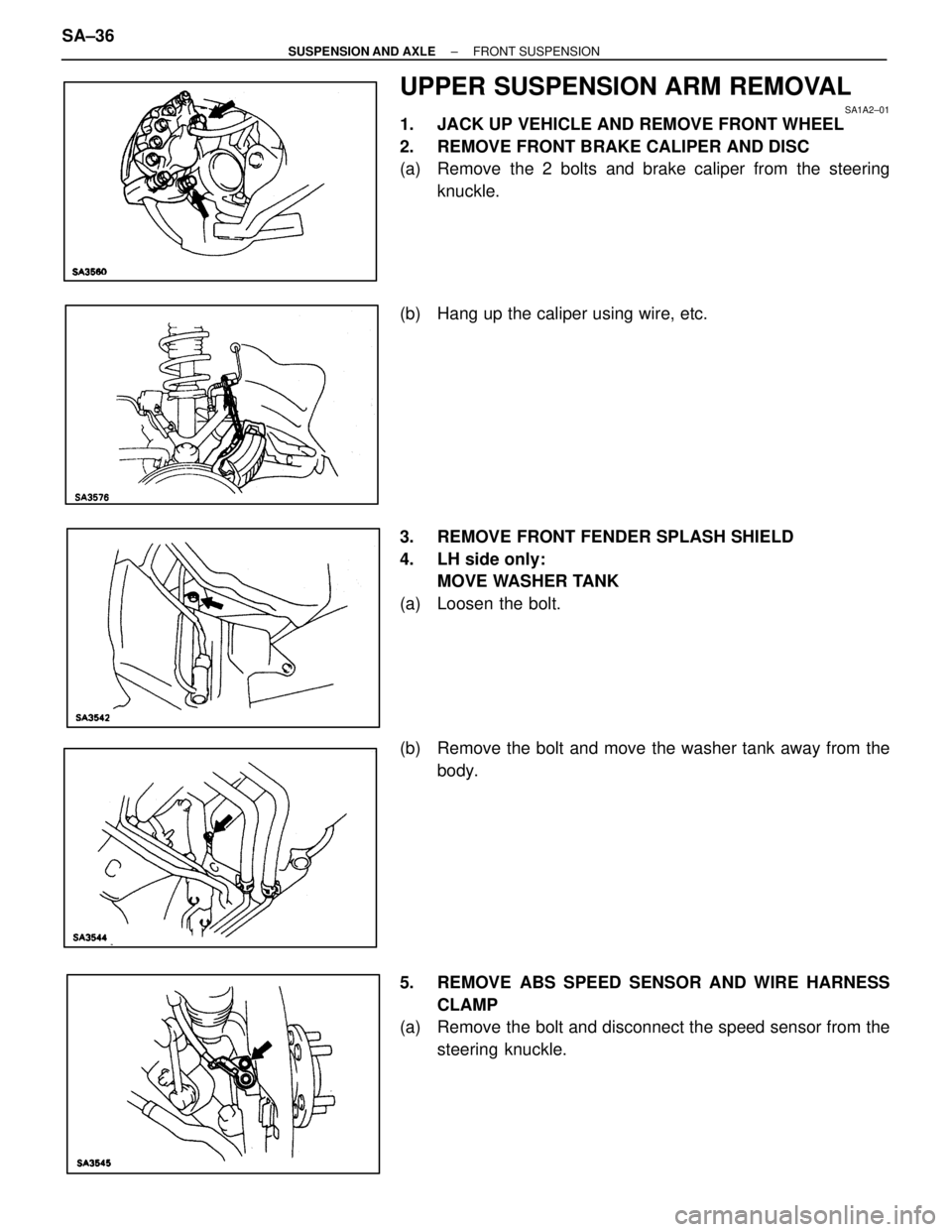

UPPER SUSPENSION ARM REMOVAL

SA1A2±01

1. JACK UP VEHICLE AND REMOVE FRONT WHEEL

2. REMOVE FRONT BRAKE CALIPER AND DISC

(a) Remove the 2 bolts and brake caliper from the steeringknuckle.

(b) Hang up the caliper using wire, etc.

3. REMOVE FRONT FENDER SPLASH SHIELD

4. LH side only: MOVE WASHER TANK

(a) Loosen the bolt.

(b) Remove the bolt and move the washer tank away from the body.

5. REMOVE ABS SPEED SENSOR AND WIRE HARNESS CLAMP

(a) Remove the bolt and disconnect the speed sensor from the

steering knuckle.

SA±36

±

SUSPENSION AND AXLE FRONT SUSPENSION

WhereEverybodyKnowsYourName

Page 3302 of 4087

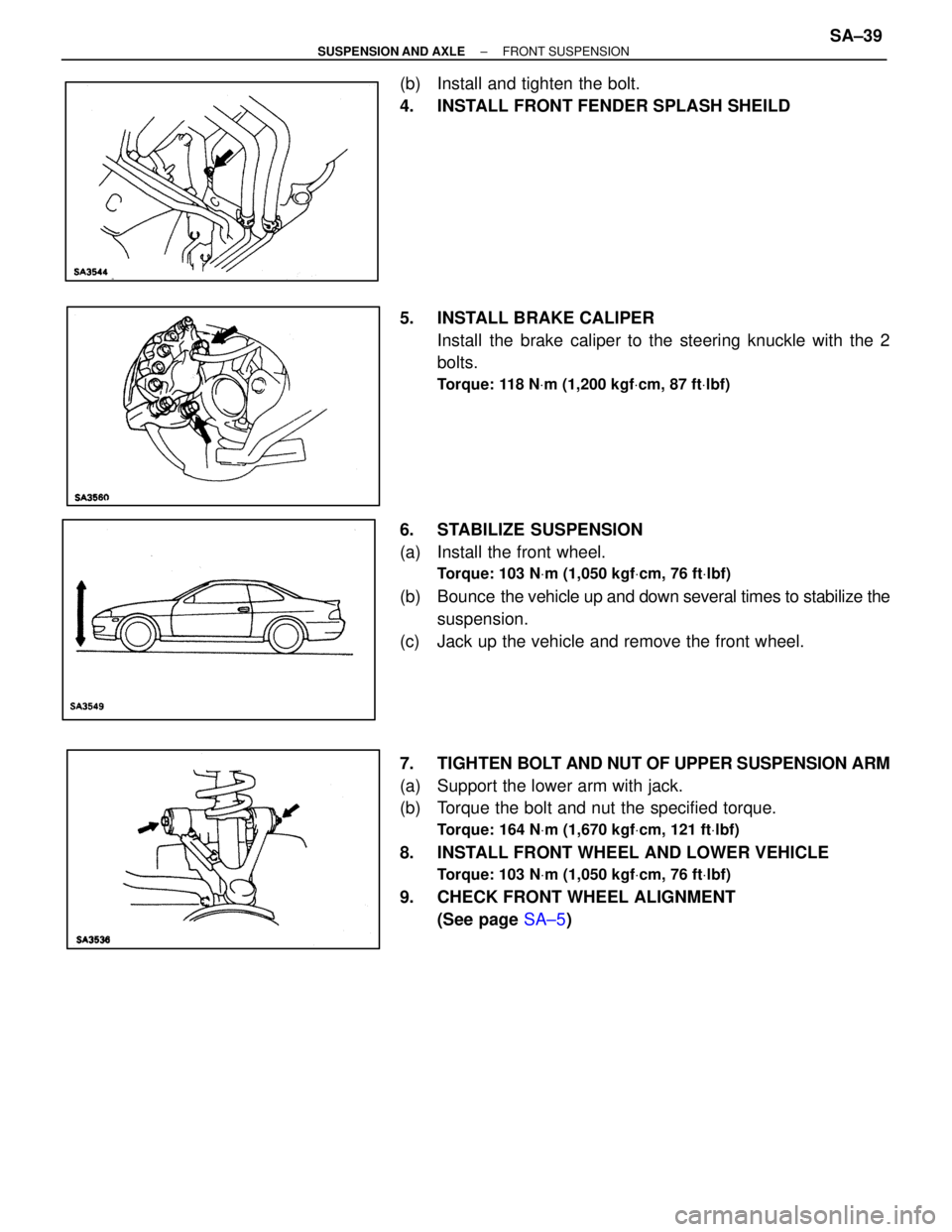

(b) Install and tighten the bolt.

4. INSTALL FRONT FENDER SPLASH SHEILD

5. INSTALL BRAKE CALIPERInstall the brake caliper to the steering knuckle with the 2

bolts.

Torque: 118 N Vm (1,200 kgf Vcm, 87 ft Vlbf)

6. STABILIZE SUSPENSION

(a) Install the front wheel.

Torque: 103 N Vm (1,050 kgf Vcm, 76 ft Vlbf)

(b) Bounce the vehicle up and down several times to stabilize the

suspension.

(c) Jack up the vehicle and remove the front wheel.

7. TIGHTEN BOLT AND NUT OF UPPER SUSPENSION ARM

(a) Support the lower arm with jack.

(b) Torque the bolt and nut the specified torque.

Torque: 164 N Vm (1,670 kgf Vcm, 121 ft Vlbf)

8. INSTALL FRONT WHEEL AND LOWER VEHICLE

Torque: 103 N Vm (1,050 kgf Vcm, 76 ft Vlbf)

9. CHECK FRONT WHEEL ALIGNMENT

(See page SA±5)

±

SUSPENSION AND AXLE FRONT SUSPENSIONSA±39

WhereEverybodyKnowsYourName