sensor LEXUS SC300 1991 Service Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 1991, Model line: SC300, Model: LEXUS SC300 1991Pages: 4087, PDF Size: 75.75 MB

Page 1523 of 4087

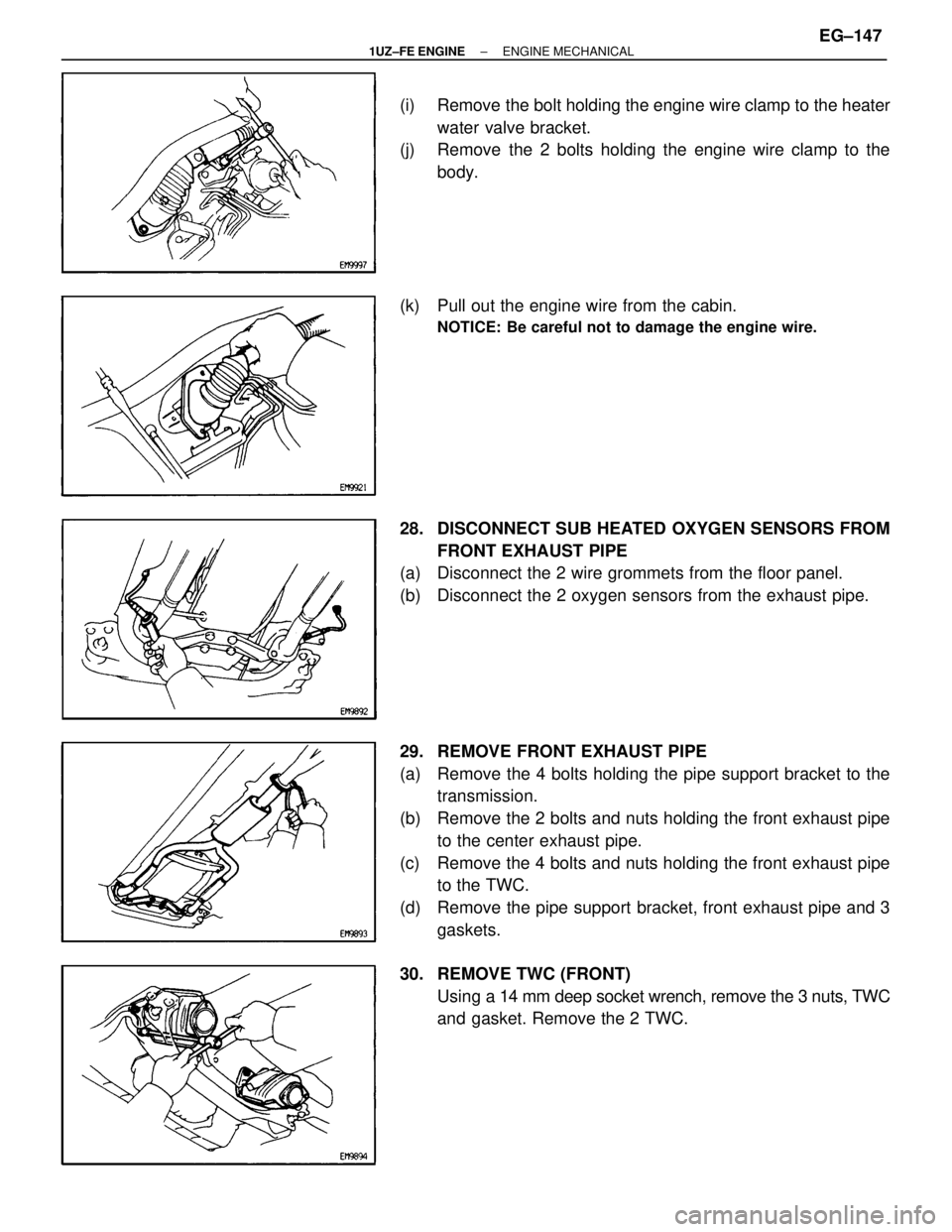

(i) Remove the bolt holding the engine wire clamp to the heaterwater valve bracket.

(j) Remove the 2 bolts holding the engine wire clamp to the

body.

(k) Pull out the engine wire from the cabin.

NOTICE: Be careful not to damage the engine wire.

28. DISCONNECT SUB HEATED OXYGEN SENSORS FROM FRONT EXHAUST PIPE

(a) Disconnect the 2 wire grommets from the floor panel.

(b) Disconnect the 2 oxygen sensors from the exhaust pipe.

29. REMOVE FRONT EXHAUST PIPE

(a) Remove the 4 bolts holding the pipe support bracket to the transmission.

(b) Remove the 2 bolts and nuts holding the front exhaust pipe to the center exhaust pipe.

(c) Remove the 4 bolts and nuts holding the front exhaust pipe to the TWC.

(d) Remove the pipe support bracket, front exhaust pipe and 3 gaskets.

30. REMOVE TWC (FRONT) Using a 14 mm deep socket wrench, remove the 3 nuts, TWC

and gasket. Remove the 2 TWC.

±

1UZ±FE ENGINE ENGINE MECHANICALEG±147

WhereEverybodyKnowsYourName

Page 1527 of 4087

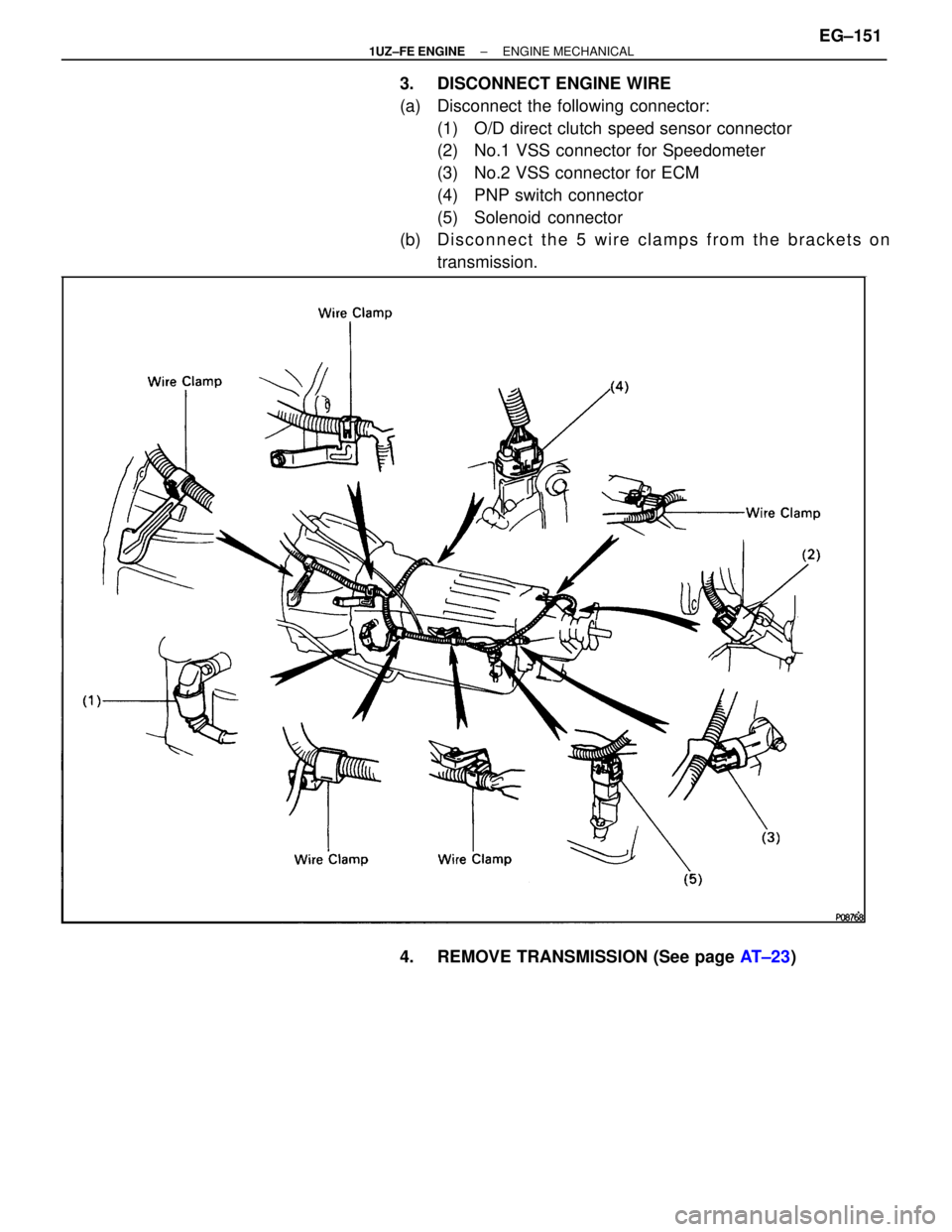

3. DISCONNECT ENGINE WIRE

(a) Disconnect the following connector:(1) O/D direct clutch speed sensor connector

(2) No.1 VSS connector for Speedometer

(3) No.2 VSS connector for ECM

(4) PNP switch connector

(5) Solenoid connector

(b) D i s c onnect the 5 wire clamps from the brackets on

transmission.

4. REMOVE TRANSMISSION (See page AT±23)

±

1UZ±FE ENGINE ENGINE MECHANICALEG±151

WhereEverybodyKnowsYourName

Page 1530 of 4087

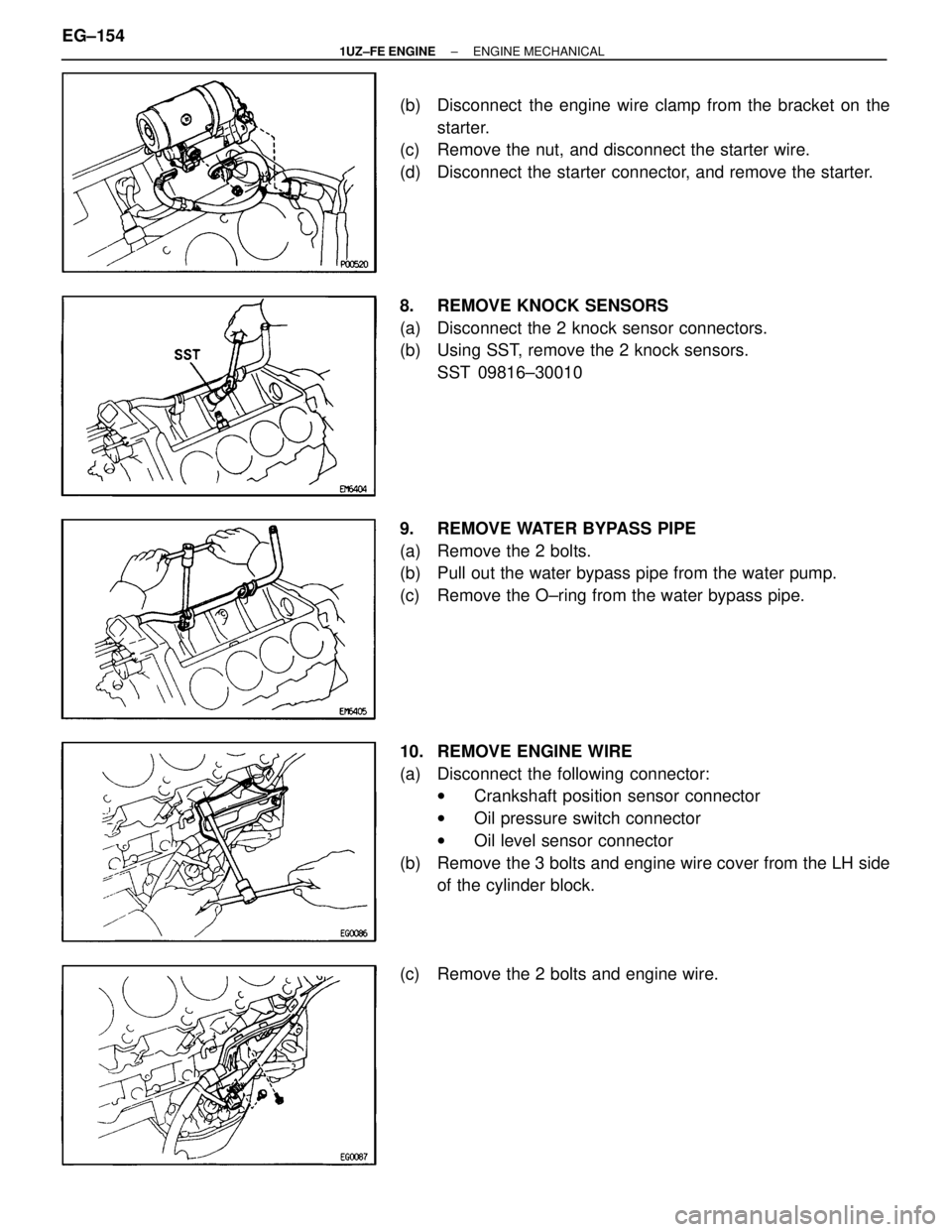

(b) Disconnect the engine wire clamp from the bracket on thestarter.

(c) Remove the nut, and disconnect the starter wire.

(d) Disconnect the starter connector, and remove the starter.

8. REMOVE KNOCK SENSORS

(a) Disconnect the 2 knock sensor connectors.

(b) Using SST, remove the 2 knock sensors.

SST 09816±30010

9. REMOVE WATER BYPASS PIPE

(a) Remove the 2 bolts.

(b) Pull out the water bypass pipe from the water pump.

(c) Remove the O±ring from the water bypass pipe.

10. REMOVE ENGINE WIRE

(a) Disconnect the following connector: wCrankshaft position sensor connector

w Oil pressure switch connector

w Oil level sensor connector

(b) Remove the 3 bolts and engine wire cover from the LH side of the cylinder block.

(c) Remove the 2 bolts and engine wire.

EG±154

±

1UZ±FE ENGINE ENGINE MECHANICAL

WhereEverybodyKnowsYourName

Page 1564 of 4087

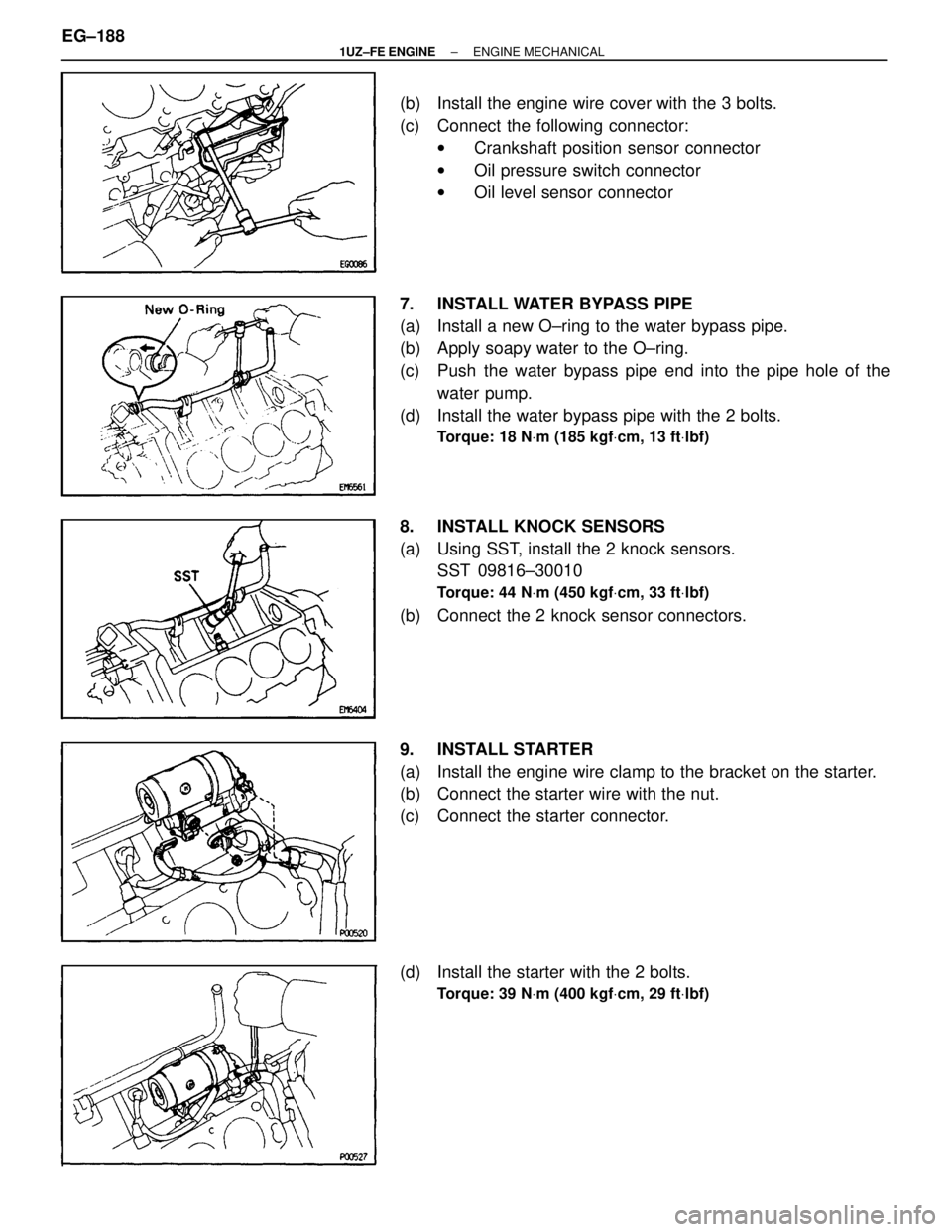

(b) Install the engine wire cover with the 3 bolts.

(c) Connect the following connector:wCrankshaft position sensor connector

w Oil pressure switch connector

w Oil level sensor connector

7. INSTALL WATER BYPASS PIPE

(a) Install a new O±ring to the water bypass pipe.

(b) Apply soapy water to the O±ring.

(c) Push the water bypass pipe end into the pipe hole of the water pump.

(d) Install the water bypass pipe with the 2 bolts.

Torque: 18 N Vm (185 kgf Vcm, 13 ft Vlbf)

8. INSTALL KNOCK SENSORS

(a) Using SST, install the 2 knock sensors.

SST 09816±30010

Torque: 44 N Vm (450 kgf Vcm, 33 ft Vlbf)

(b) Connect the 2 knock sensor connectors.

9. INSTALL STARTER

(a) Install the engine wire clamp to the bracket on the starter.

(b) Connect the starter wire with the nut.

(c) Connect the starter connector.

(d) Install the starter with the 2 bolts.

Torque: 39 N Vm (400 kgf Vcm, 29 ft Vlbf)

EG±188±

1UZ±FE ENGINE ENGINE MECHANICAL

WhereEverybodyKnowsYourName

Page 1566 of 4087

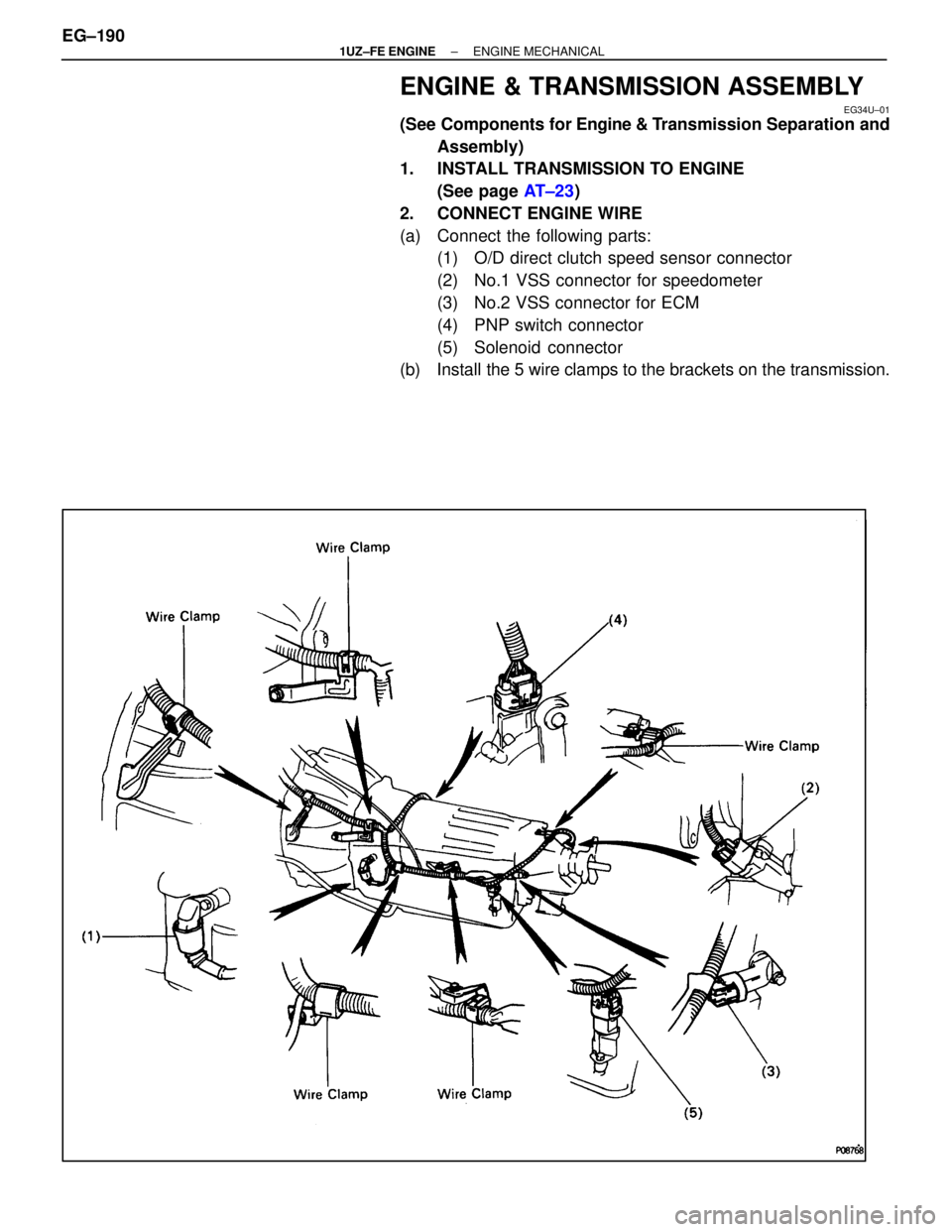

ENGINE & TRANSMISSION ASSEMBLY

EG34U±01

(See Components for Engine & Transmission Separation and

Assembly)

1. INSTALL TRANSMISSION TO ENGINE

(See page AT±23)

2. CONNECT ENGINE WIRE

(a) Connect the following parts: (1) O/D direct clutch speed sensor connector

(2) No.1 VSS connector for speedometer

(3) No.2 VSS connector for ECM

(4) PNP switch connector

(5) Solenoid connector

(b) Install the 5 wire clamps to the brackets on the transmission.

EG±190

±

1UZ±FE ENGINE ENGINE MECHANICAL

WhereEverybodyKnowsYourName

Page 1570 of 4087

7. INSTALL TAILPIPE

(a) Install the hook of the tailpipe to the ring on the tailpipebracket.

(b) Install a new gasket and tailpipe to the center exhaust pipe with 2 bolts. Install the 2 tailpipes.

Torque: 19 N Vm (195 kgf Vcm, 14 ft Vlbf)

8. INSTALL TWC (FRONT)

Using a 14 mm deep socket wrench, install a new gasket and

the TWC with 3 new nuts. Install the 2 TWC.

Torque: 62 N Vm (630 kgf Vcm, 46 ft Vlbf)

9. INSTALL FRONT EXHAUST PIPE

(a) Temporarily install the pipe support bracket with the 4 bolts.

(b) Temporarily install 3 new gaskets and the exhaust pipe with

the 6 bolts and nuts.

(c) Tighten the 4 bolts and nuts holding the TWC to the front exhaust pipe.

Torque: 43 N Vm (440 kgf Vcm, 32 ft Vlbf)

(d) Tighten the 2 bolts and nuts holding the front exhaust pipe to

the center exhaust pipe.

Torque: 43 N Vm (440 kgf Vcm, 32 ft Vlbf)

(e) Tighten the 4 bolts holding the pipe support bracket to the

transmission.

Torque: 43 N Vm (440 kgf Vcm, 32 ft Vlbf)

10. INSTALL SUB HEATED OXYGEN SENSORS

Install the 2 oxygen sensors to the front exhaust pipe.

Torque: 44 N Vm (450 kgf Vcm, 33 ft Vlbf)

HINT:

w Before installing the oxygen sensor, twist the sensor

wire counterclockwise 3 1/2 turns.

w After installing the oxygen sensor, check that the sensor

wire is not twisted. If it is twisted, remove the oxygen

sensor and reinstall it.

EG±194

±

1UZ±FE ENGINE ENGINE MECHANICAL

WhereEverybodyKnowsYourName

Page 1577 of 4087

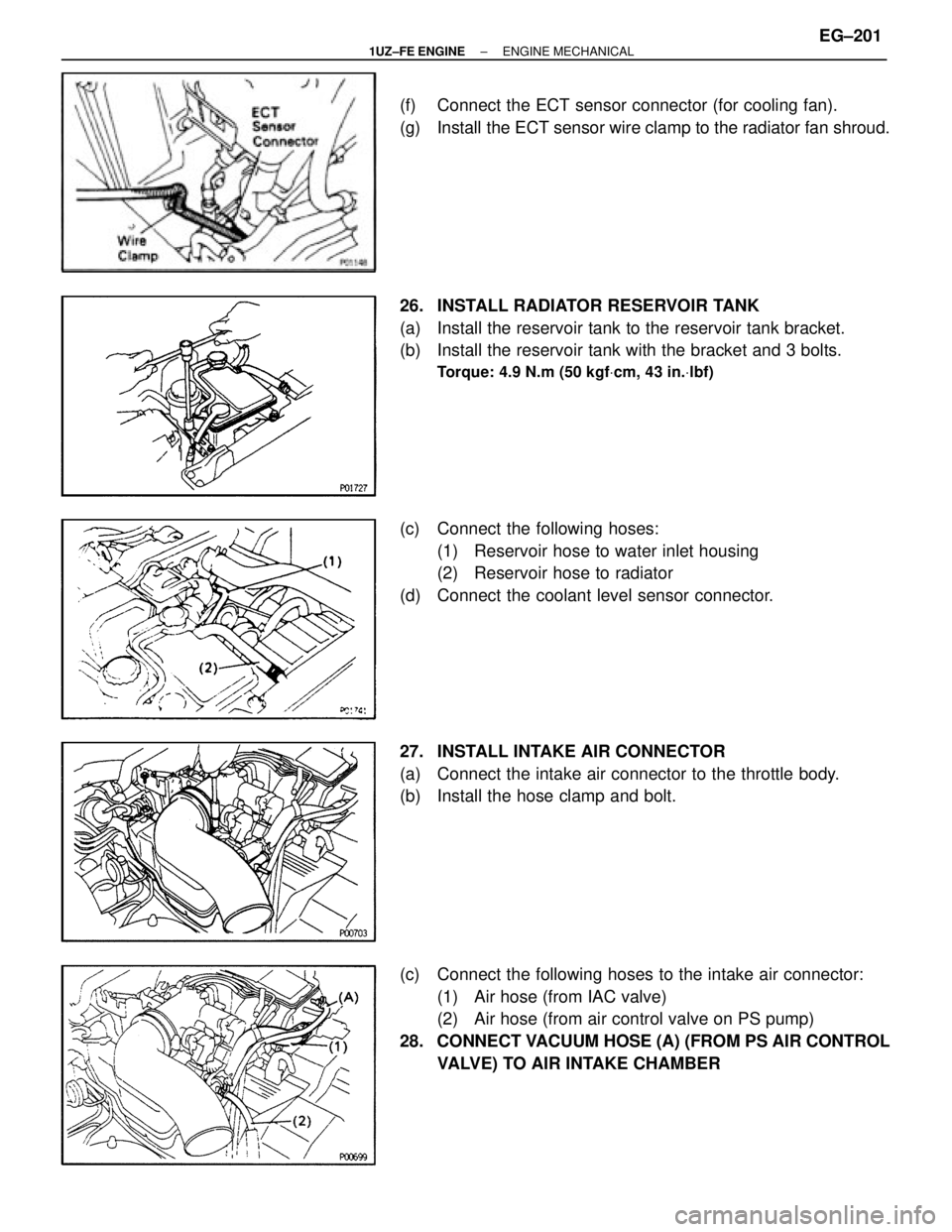

(f) Connect the ECT sensor connector (for cooling fan).

(g) Install the ECT sensor wire clamp to the radiator fan shroud.

26. INSTALL RADIATOR RESERVOIR TANK

(a) Install the reservoir tank to the reservoir tank bracket.

(b) Install the reservoir tank with the bracket and 3 bolts.

Torque: 4.9 N.m (50 kgfVcm, 43 in. Vlbf)

(c) Connect the following hoses:

(1) Reservoir hose to water inlet housing

(2) Reservoir hose to radiator

(d) Connect the coolant level sensor connector.

27. INSTALL INTAKE AIR CONNECTOR

(a) Connect the intake air connector to the throttle body.

(b) Install the hose clamp and bolt.

(c) Connect the following hoses to the intake air connector: (1) Air hose (from IAC valve)

(2) Air hose (from air control valve on PS pump)

28. CONNECT VACUUM HOSE (A) (FROM PS AIR CONTROL VALVE) TO AIR INTAKE CHAMBER

±

1UZ±FE ENGINE ENGINE MECHANICALEG±201

WhereEverybodyKnowsYourName

Page 1585 of 4087

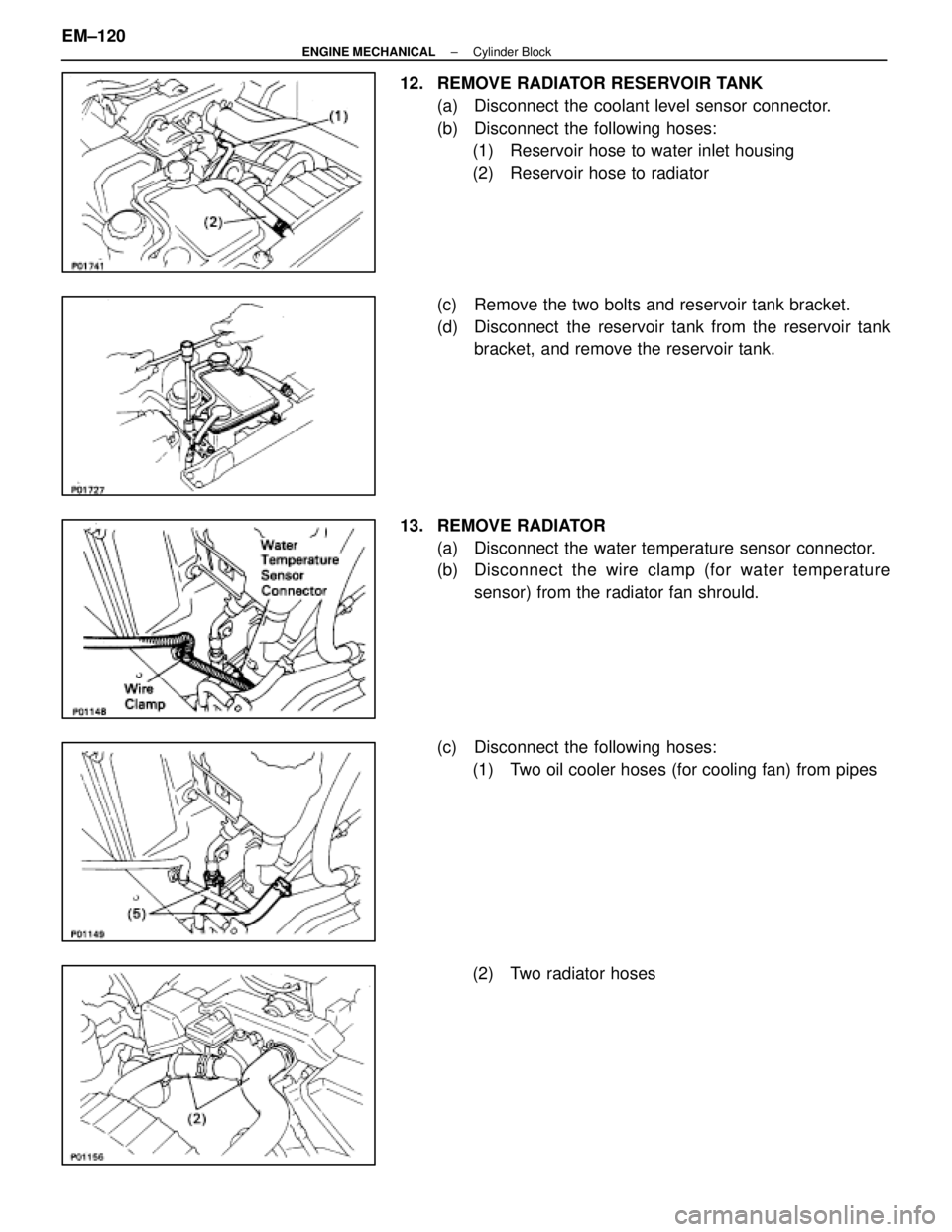

12. REMOVE RADIATOR RESERVOIR TANK(a) Disconnect the coolant level sensor connector.

(b) Disconnect the following hoses:(1) Reservoir hose to water inlet housing

(2) Reservoir hose to radiator

(c) Remove the two bolts and reservoir tank bracket.

(d) Disconnect the reservoir tank from the reservoir tank bracket, and remove the reservoir tank.

13. REMOVE RADIATOR (a) Disconnect the water temperature sensor connector.

(b) Disc onnect the wire clamp (for water temperature

sensor) from the radiator fan shrould.

(c) Disconnect the following hoses: (1) Two oil cooler hoses (for cooling fan) from pipes

(2) Two radiator hoses

EM±120

±

ENGINE MECHANICAL Cylinder Block

WhereEverybodyKnowsYourName

Page 1591 of 4087

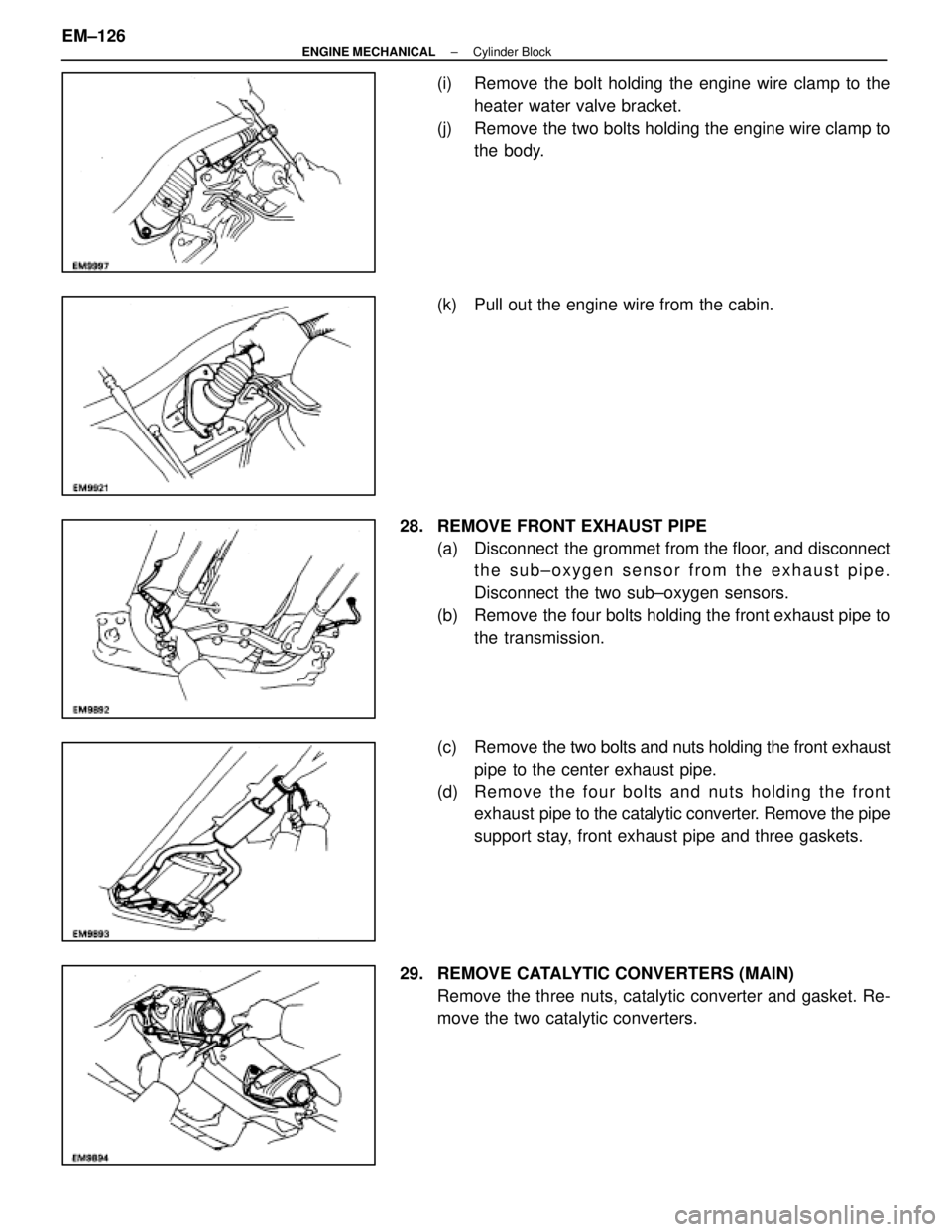

(i) Remove the bolt holding the engine wire clamp to theheater water valve bracket.

(j) Remove the two bolts holding the engine wire clamp to the body.

(k) Pull out the engine wire from the cabin.

28. REMOVE FRONT EXHAUST PIPE (a) Disconnect the grommet from the floor, and disconnectthe sub±oxygen sensor from the exhaust pipe.

Disconnect the two sub±oxygen sensors.

(b) Remove the four bolts holding the front exhaust pipe to the transmission.

(c) Remove the two bolts and nuts holding the front exhaust

pipe to the center exhaust pipe.

(d) Re mo ve th e fo u r bo lts an d nu ts ho ld in g th e fro n t

exhaust pipe to the catalytic converter. Remove the pipe

support stay, front exhaust pipe and three gaskets.

29. REMOVE CATALYTIC CONVERTERS (MAIN) Remove the three nuts, catalytic converter and gasket. Re-

move the two catalytic converters.

EM±126

±

ENGINE MECHANICAL Cylinder Block

WhereEverybodyKnowsYourName

Page 1595 of 4087

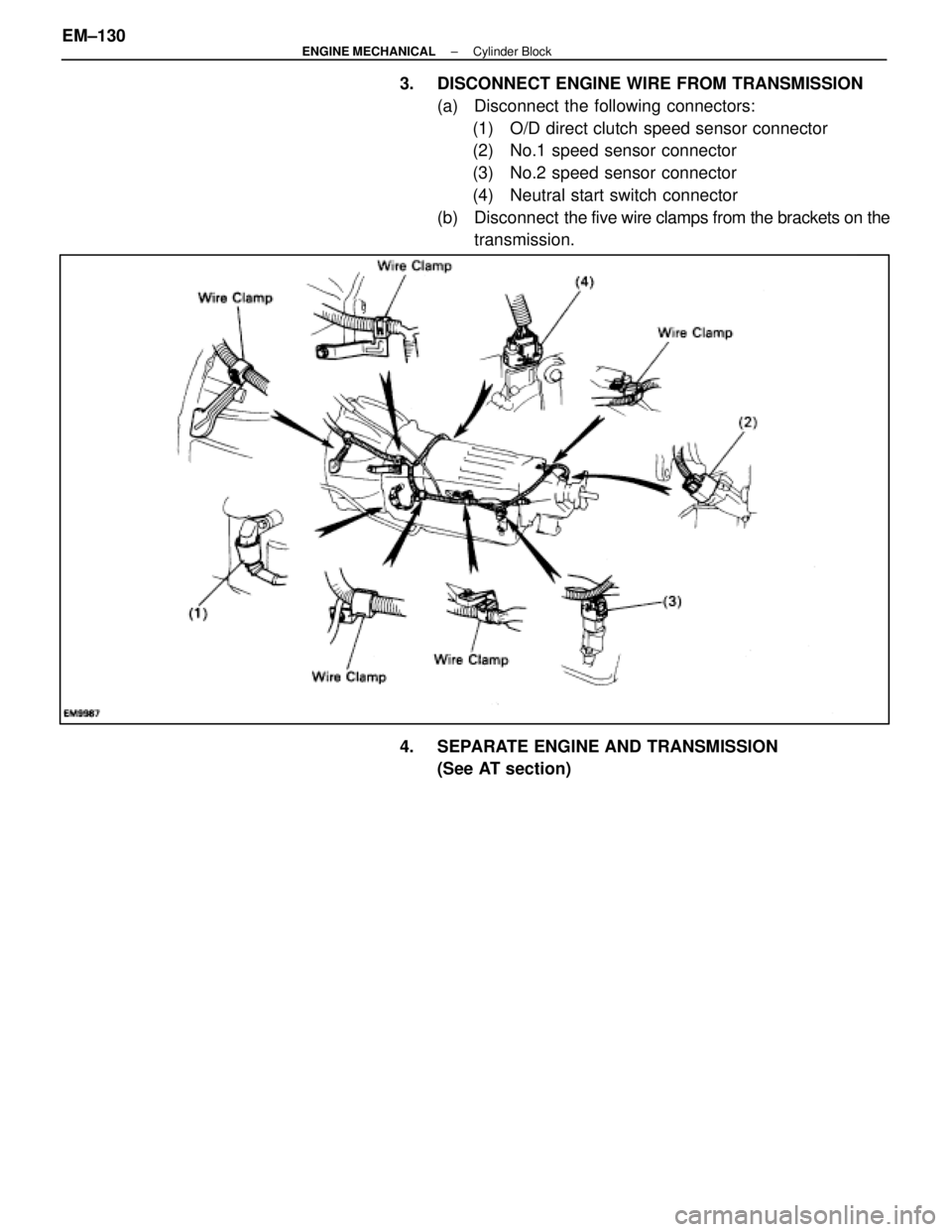

3. DISCONNECT ENGINE WIRE FROM TRANSMISSION(a) Disconnect the following connectors:(1) O/D direct clutch speed sensor connector

(2) No.1 speed sensor connector

(3) No.2 speed sensor connector

(4) Neutral start switch connector

(b) Disconnect the five wire clamps from the brackets on the

transmission.

4. SEPARATE ENGINE AND TRANSMISSION (See AT section)

EM±130

±

ENGINE MECHANICAL Cylinder Block

WhereEverybodyKnowsYourName