ignition LEXUS SC300 1991 Service Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 1991, Model line: SC300, Model: LEXUS SC300 1991Pages: 4087, PDF Size: 75.75 MB

Page 2396 of 4087

PRECAUTIONS

1. Before working on the fuel system, disconnect the cablefrom negative (±) terminal of the battery.

HINT: Any diagnostic code retained by the computer will be

erased when the battery terminal is removed. Therefore, if

necessary, read the diagnosis before removing the battery

terminal.

CAUTION: Work must be started after approx. 20 se-

conds or longer from the time the ignition switch is

turned to the ºLOCKº position and negative (±) terminal

cable is disconnected from the battery.

2. Do not smoke or work on open flame when working on the fuel system.

3. Keep gasoline away from rubber or leather parts.

INSPECTION PRECAUTIONS

MAINTENANCE PRECAUTIONS

1. CHECK CORRECT ENGINE TUNE±UP (See page EM±8)

2. PRECAUTIONS WHEN CONNECTING GAUGE (a) Use the battery as the power source for the timing light,tachometer, etc.

(b) Connect the test probe of a tachometer to the terminal IG of the check connector.

3. IN EVENT OF ENGINE MISFIRE, FOLLOWING PRECAUTIONS SHOULD BE TAKEN

(a) Check proper connection of battery terminals, etc.

(b) Handle high±tension cords carefully.

(c) After repair work, check that the ignition coil terminalsand all other ignition system lines are reconnected

securely.

(d) When cleaning the engine compartment, be especially careful to protect the electrical system from water.

4. PRECAUTIONS WHEN HANDLING OXYGEN SENSOR (a) Do not allow oxygen sensor to drop or hit against anobject.

(b) Do not allow the sensor to come into contact with water.

FI±12

± Precautions, Inspection PrecautionsEFI SYSTEM

WhereEverybodyKnowsYourName

Page 2397 of 4087

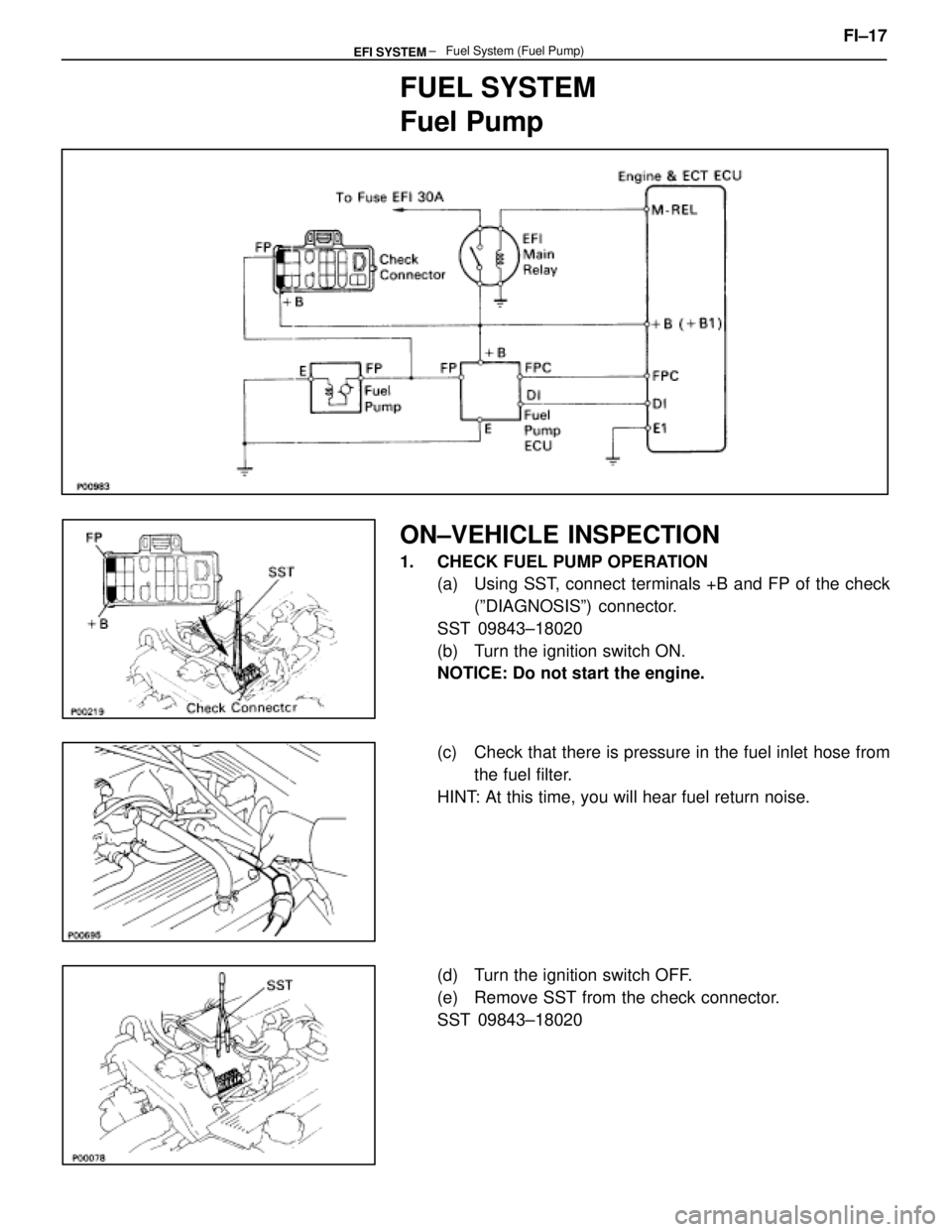

FUEL SYSTEM

Fuel Pump

ON±VEHICLE INSPECTION

1. CHECK FUEL PUMP OPERATION(a) Using SST, connect terminals +B and FP of the check

(ºDIAGNOSISº) connector.

SST 09843±18020

(b) Turn the ignition switch ON.

NOTICE: Do not start the engine.

(c) Check that there is pressure in the fuel inlet hose from the fuel filter.

HINT: At this time, you will hear fuel return noise.

(d) Turn the ignition switch OFF.

(e) Remove SST from the check connector.

SST 09843±18020 FI±17

± Fuel System (Fuel Pump)EFI SYSTEM

WhereEverybodyKnowsYourName

Page 2398 of 4087

If there is no pressure, check the following parts:w Fuses

w EFI main relay

w Fuel pump ECU

w Fuel pump

w Engine & ECT ECU

w Wiring connections

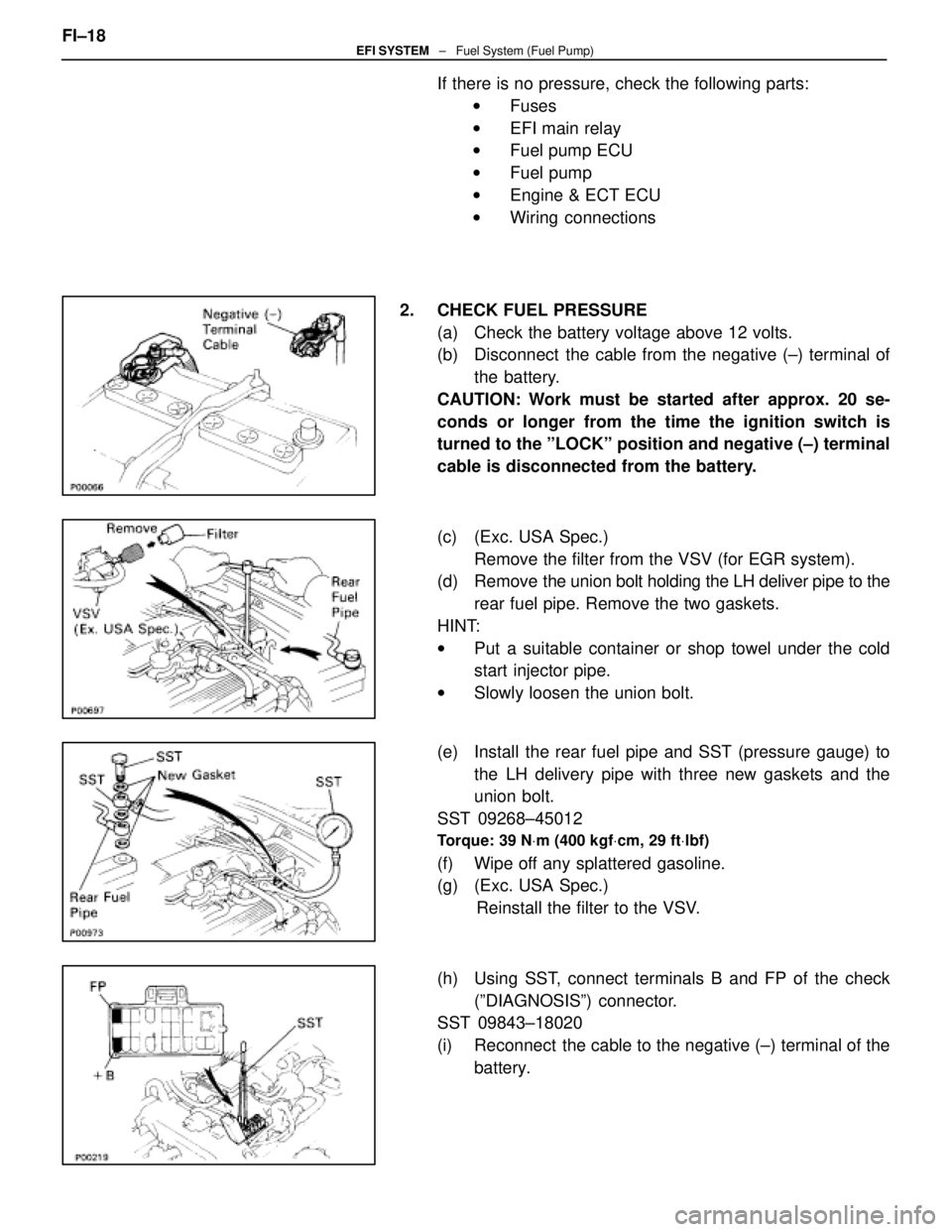

2. CHECK FUEL PRESSURE (a) Check the battery voltage above 12 volts.

(b) Disconnect the cable from the negative (±) terminal ofthe battery.

CAUTION: Work must be started after approx. 20 se-

conds or longer from the time the ignition switch is

turned to the ºLOCKº position and negative (±) terminal

cable is disconnected from the battery.

(c) (Exc. USA Spec.) Remove the filter from the VSV (for EGR system).

(d) Remove the union bolt holding the LH deliver pipe to the

rear fuel pipe. Remove the two gaskets.

HINT:

w Put a suitable container or shop towel under the cold

start injector pipe.

w Slowly loosen the union bolt.

(e) Install the rear fuel pipe and SST (pressure gauge) to the LH delivery pipe with three new gaskets and the

union bolt.

SST 09268±45012

Torque: 39 N Vm (400 kgf Vcm, 29 ft Vlbf)

(f) Wipe off any splattered gasoline.

(g) (Exc. USA Spec.)

Reinstall the filter to the VSV.

(h) Using SST, connect terminals B and FP of the check (ºDIAGNOSISº) connector.

SST 09843±18020

(i) Reconnect the cable to the negative (±) terminal of the

battery.

FI±18

EFI SYSTEM

± Fuel System (Fuel Pump)

WhereEverybodyKnowsYourName

Page 2399 of 4087

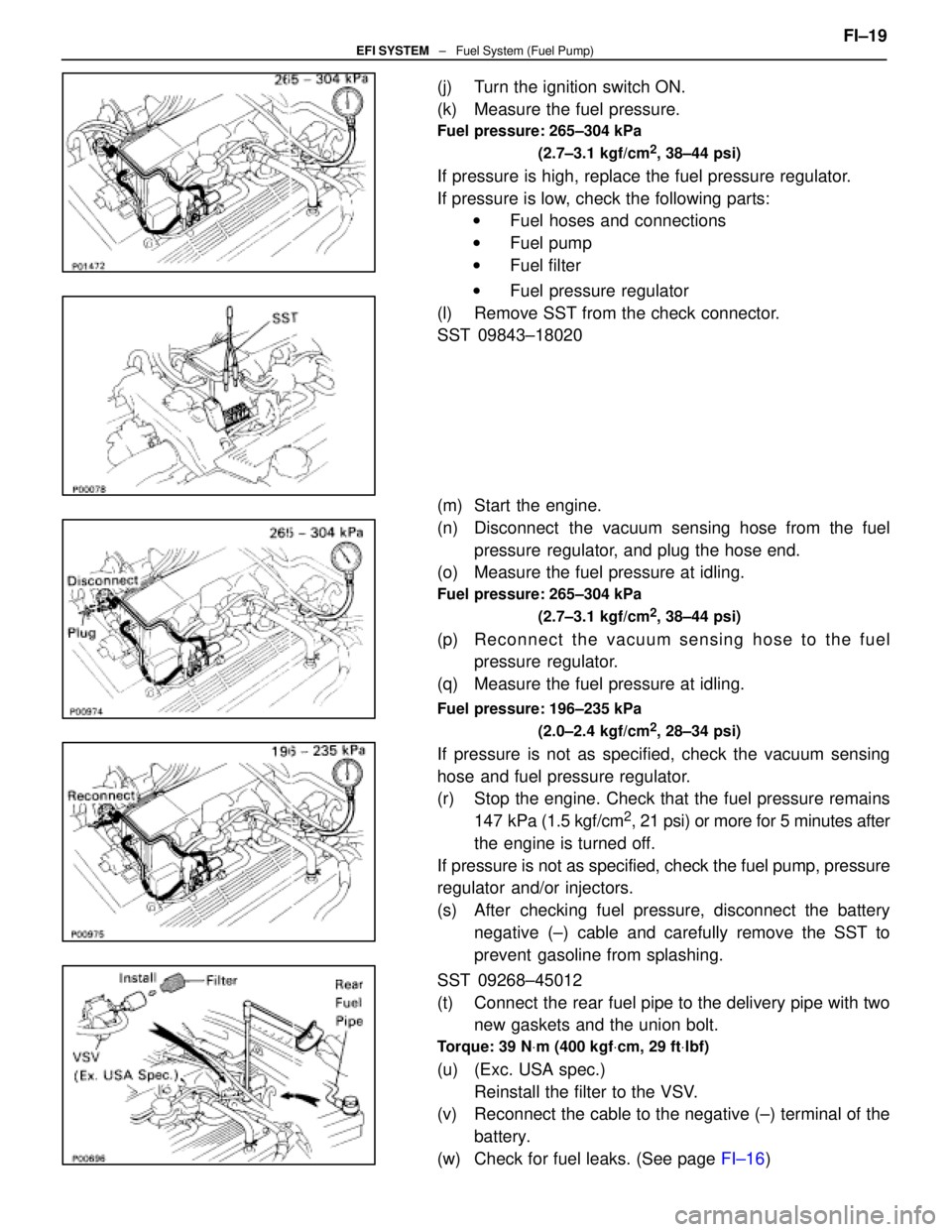

(j) Turn the ignition switch ON.

(k) Measure the fuel pressure.

Fuel pressure: 265±304 kPa(2.7±3.1 kgf/cm

2, 38±44 psi)

If pressure is high, replace the fuel pressure regulator.

If pressure is low, check the following parts:w Fuel hoses and connections

w Fuel pump

w Fuel filter

w Fuel pressure regulator

(l) Remove SST from the check connector.

SST 09843±18020

(m) Start the engine.

(n) Disconnect the vacuum sensing hose from the fuel pressure regulator, and plug the hose end.

(o) Measure the fuel pressure at idling.

Fuel pressure: 265±304 kPa

(2.7±3.1 kgf/cm

2, 38±44 psi)

(p) Re connect the vacuum sensing hose to the fuel

pressure regulator.

(q) Measure the fuel pressure at idling.

Fuel pressure: 196±235 kPa

(2.0±2.4 kgf/cm

2, 28±34 psi)

If pressure is not as specified, check the vacuum sensing

hose and fuel pressure regulator.

(r) Stop the engine. Check that the fuel pressure remains147 kPa (1.5 kgf/cm

2, 21 psi) or more for 5 minutes after

the engine is turned off.

If pressure is not as specified, check the fuel pump, pressure

regulator and/or injectors.

(s) After checking fuel pressure, disconnect the battery negative (±) cable and carefully remove the SST to

prevent gasoline from splashing.

SST 09268±45012

(t) Connect the rear fuel pipe to the delivery pipe with two new gaskets and the union bolt.

Torque: 39 N Vm (400 kgf Vcm, 29 ft Vlbf)

(u) (Exc. USA spec.)

Reinstall the filter to the VSV.

(v) Reconnect the cable to the negative (±) terminal of the

battery.

(w) Check for fuel leaks. (See page FI±16) FI±19

EFI SYSTEM

± Fuel System (Fuel Pump)

WhereEverybodyKnowsYourName

Page 2401 of 4087

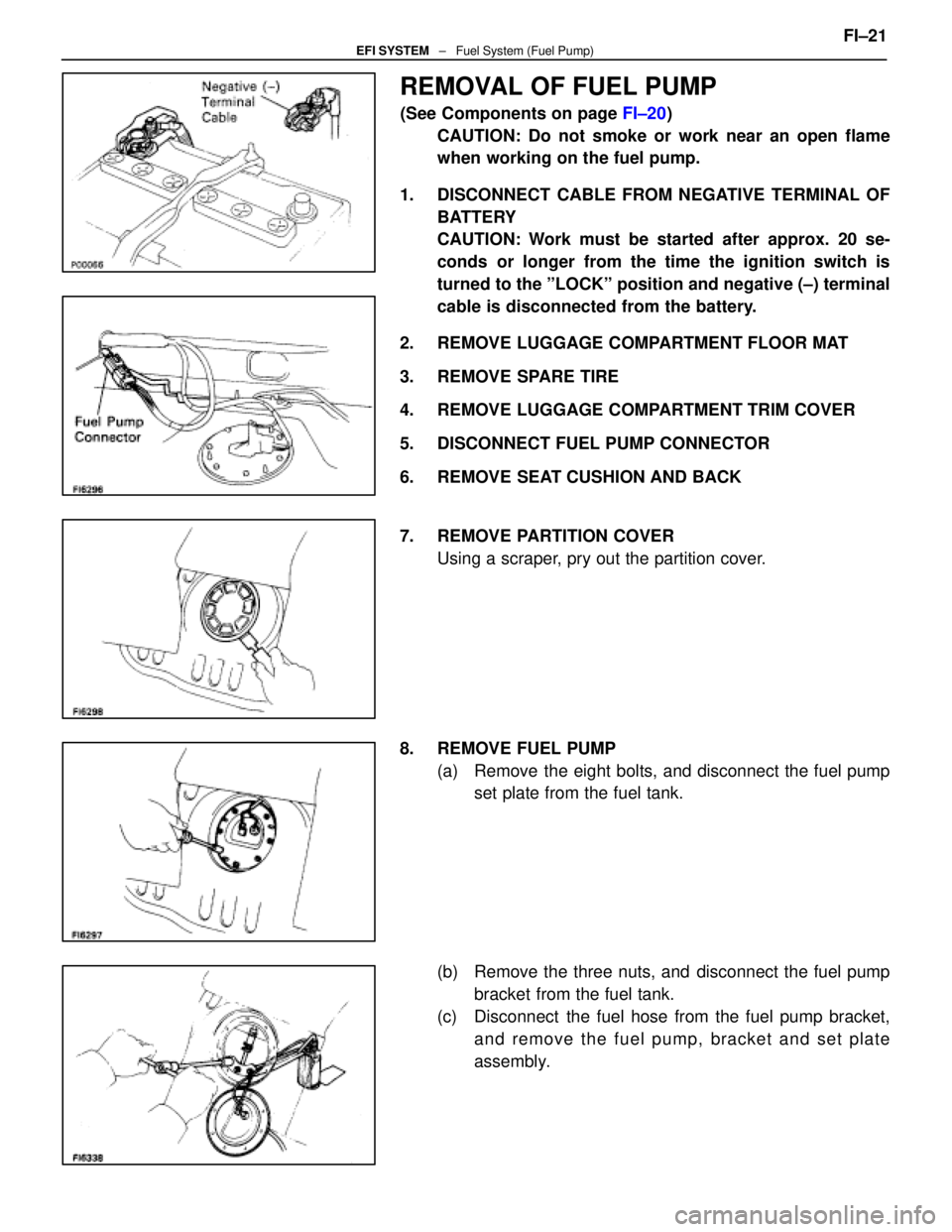

REMOVAL OF FUEL PUMP

(See Components on page FI±20)

CAUTION: Do not smoke or work near an open flame

when working on the fuel pump.

1. DISCONNECT CABLE FROM NEGATIVE TERMINAL OF BATTERY

CAUTION: Work must be started after approx. 20 se-

conds or longer from the time the ignition switch is

turned to the ºLOCKº position and negative (±) terminal

cable is disconnected from the battery.

2. REMOVE LUGGAGE COMPARTMENT FLOOR MAT

3. REMOVE SPARE TIRE

4. REMOVE LUGGAGE COMPARTMENT TRIM COVER

5. DISCONNECT FUEL PUMP CONNECTOR

6. REMOVE SEAT CUSHION AND BACK

7. REMOVE PARTITION COVER Using a scraper, pry out the partition cover.

8. REMOVE FUEL PUMP (a) Remove the eight bolts, and disconnect the fuel pumpset plate from the fuel tank.

(b) Remove the three nuts, and disconnect the fuel pump bracket from the fuel tank.

(c) Disconnect the fuel hose from the fuel pump bracket, and remove the fuel pump, bracket and set plate

assembly. FI±21

EFI SYSTEM

± Fuel System (Fuel Pump)

WhereEverybodyKnowsYourName

Page 2407 of 4087

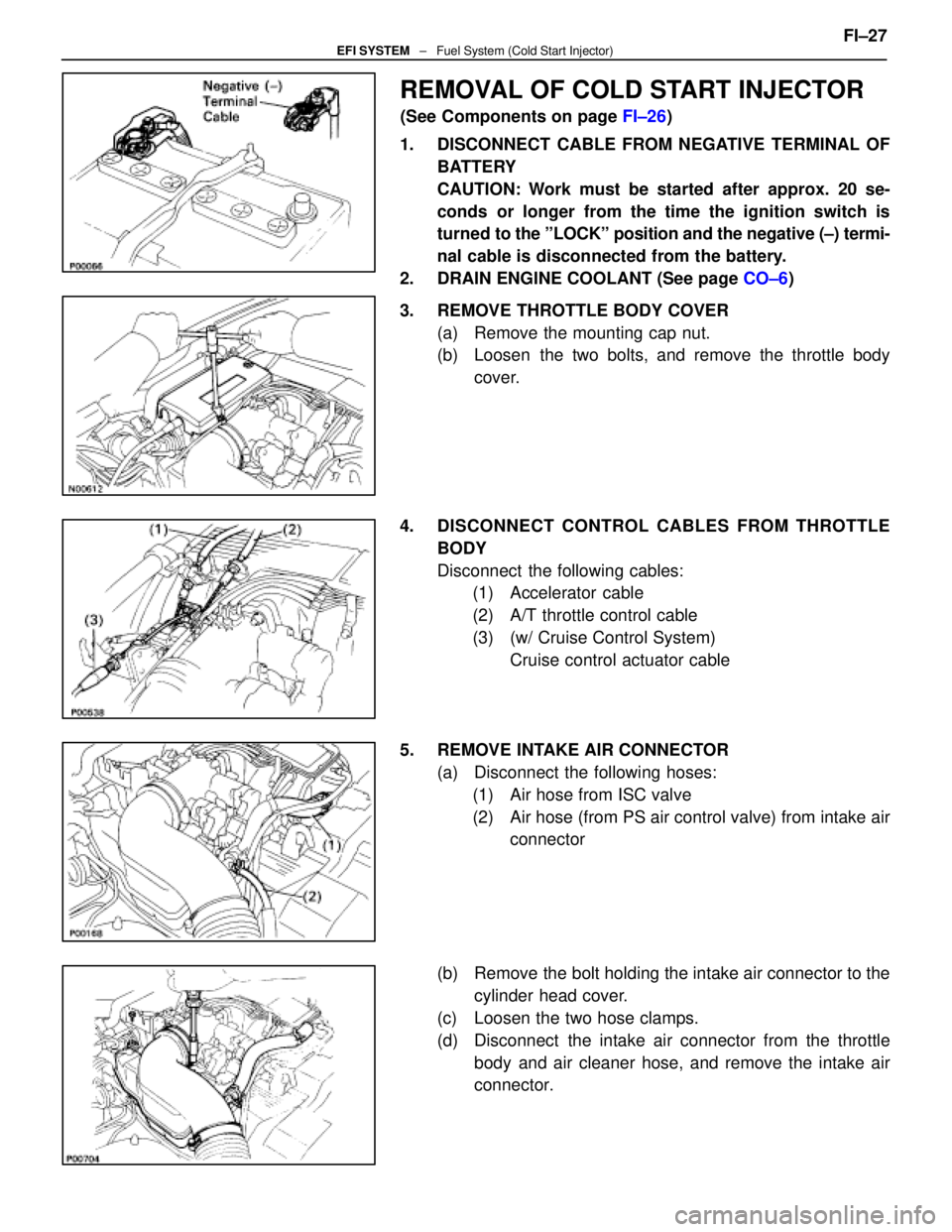

REMOVAL OF COLD START INJECTOR

(See Components on page FI±26)

1. DISCONNECT CABLE FROM NEGATIVE TERMINAL OF BATTERY

CAUTION: Work must be started after approx. 20 se-

conds or longer from the time the ignition switch is

turned to the ºLOCKº position and the negative (±) termi-

nal cable is disconnected from the battery.

2. DRAIN ENGINE COOLANT (See page CO±6)

3. REMOVE THROTTLE BODY COVER (a) Remove the mounting cap nut.

(b) Loosen the two bolts, and remove the throttle bodycover.

4. DISCONNECT CONTROL CABLES FROM THROTTLE BODY

Disconnect the following cables:(1) Accelerator cable

(2) A/T throttle control cable

(3) (w/ Cruise Control System)

Cruise control actuator cable

5. REMOVE INTAKE AIR CONNECTOR (a) Disconnect the following hoses:(1) Air hose from ISC valve

(2) Air hose (from PS air control valve) from intake air connector

(b) Remove the bolt holding the intake air connector to the cylinder head cover.

(c) Loosen the two hose clamps.

(d) Disconnect the intake air connector from the throttle body and air cleaner hose, and remove the intake air

connector. FI±27

EFI SYSTEM

± Fuel System (Cold Start Injector)

WhereEverybodyKnowsYourName

Page 2409 of 4087

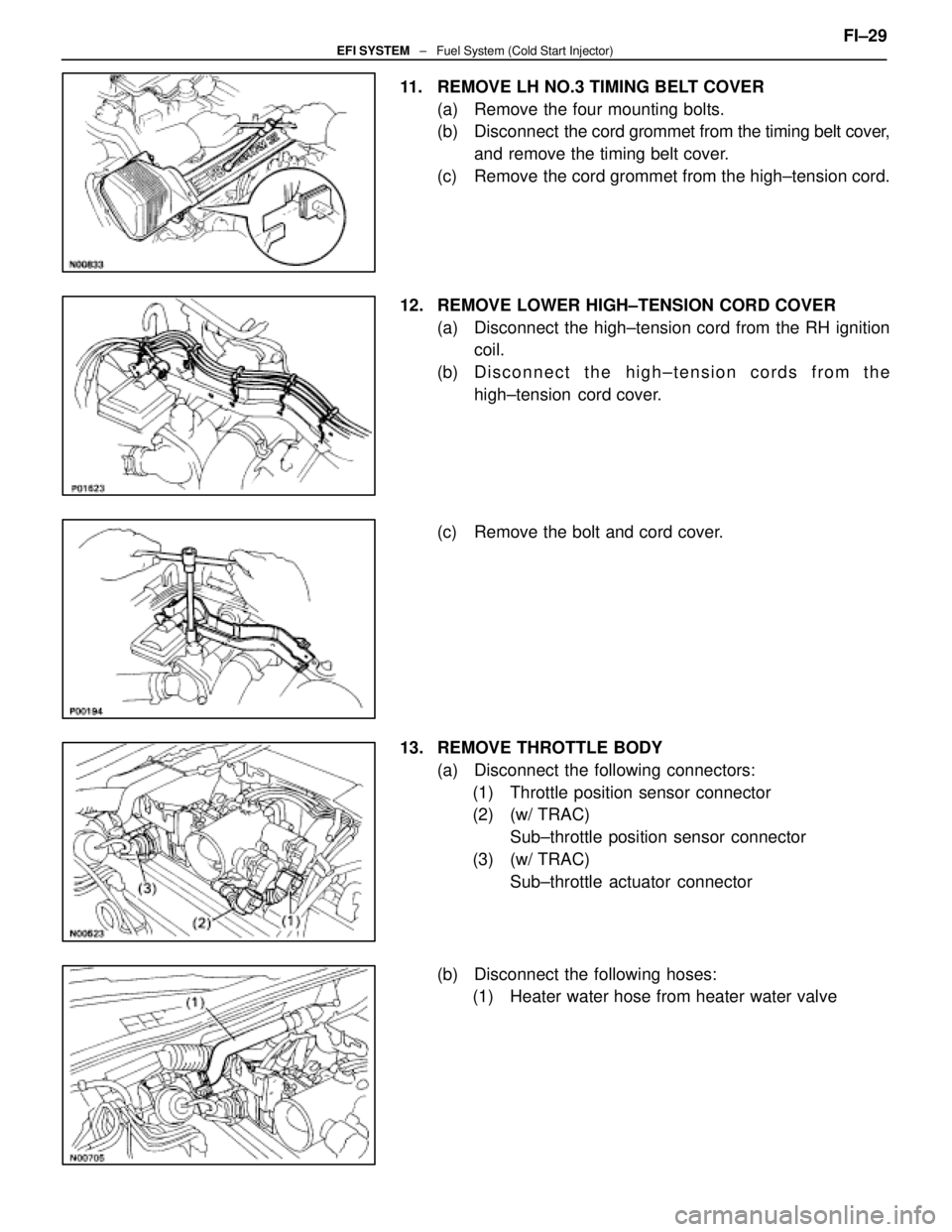

11. REMOVE LH NO.3 TIMING BELT COVER(a) Remove the four mounting bolts.

(b) Disconnect the cord grommet from the timing belt cover,

and remove the timing belt cover.

(c) Remove the cord grommet from the high±tension cord.

12. REMOVE LOWER HIGH±TENSION CORD COVER (a) Disconnect the high±tension cord from the RH ignitioncoil.

(b) D i s c onnect the high±tension cords from the

high±tension cord cover.

(c) Remove the bolt and cord cover.

13. REMOVE THROTTLE BODY (a) Disconnect the following connectors:(1) Throttle position sensor connector

(2) (w/ TRAC) Sub±throttle position sensor connector

(3) (w/ TRAC) Sub±throttle actuator connector

(b) Disconnect the following hoses: (1) Heater water hose from heater water valve FI±29

EFI SYSTEM

± Fuel System (Cold Start Injector)

WhereEverybodyKnowsYourName

Page 2414 of 4087

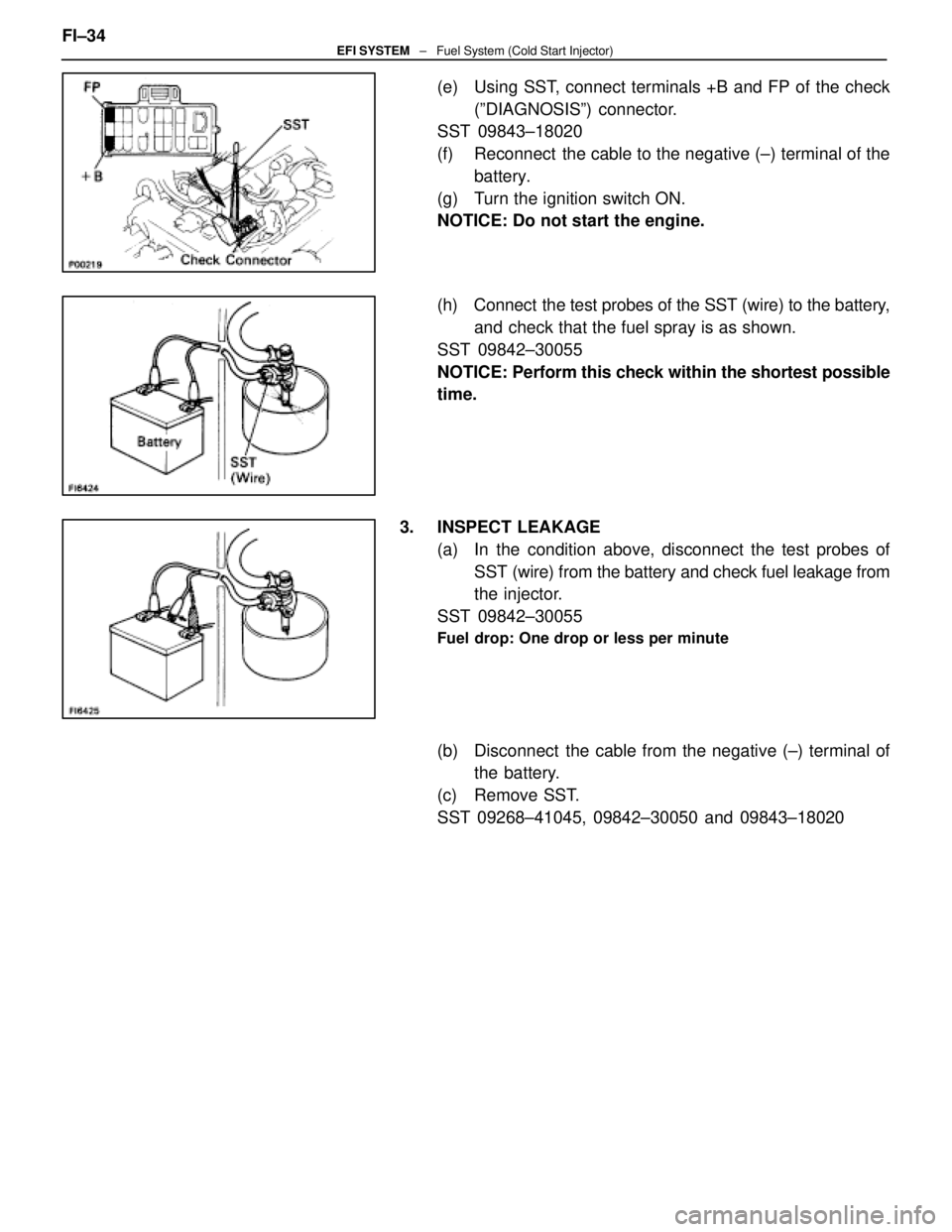

(e) Using SST, connect terminals +B and FP of the check(ºDIAGNOSISº) connector.

SST 09843±18020

(f) Reconnect the cable to the negative (±) terminal of the

battery.

(g) Turn the ignition switch ON.

NOTICE: Do not start the engine.

(h) Connect the test probes of the SST (wire) to the battery, and check that the fuel spray is as shown.

SST 09842±30055

NOTICE: Perform this check within the shortest possible

time.

3. INSPECT LEAKAGE (a) In the condition above, disconnect the test probes ofSST (wire) from the battery and check fuel leakage from

the injector.

SST 09842±30055

Fuel drop: One drop or less per minute

(b) Disconnect the cable from the negative (±) terminal of the battery.

(c) Remove SST.

SST 09268±41045, 09842±30050 and 09843±18020

FI±34

EFI SYSTEM

± Fuel System (Cold Start Injector)

WhereEverybodyKnowsYourName

Page 2419 of 4087

(4) Heater water hose to heater water valve

(e) Connect the following connectors: (1) Throttle position sensor connector

(2) (w/ TRAC)

Sub±throttle position sensor connector

(3) (w/ TRAC) Sub±throttle actuator connector

5. INSTALL LOWER HIGH±TENSION CORD COVER (a) Connect the end portions of the high±tension cord to the

cord clamps

(b) Install the high±tension cord cover with the bolt.

(c) Install the clamps on the high±tension cords to the

high±tension cord cover.

(d) Connect the high±tension cord to the RH ignition coil.

7. INSTALL RH NO.3 TIMING BELT COVER (a) Install the three gaskets to the timing belt cover.

(b) Fit portion A of the timing belt cover, matching it with the

lower high±tension cord cover.

(c) Install the timing belt cover with the three bolts. FI±39

EFI SYSTEM

± Fuel System (Cold Start Injector)

WhereEverybodyKnowsYourName

Page 2423 of 4087

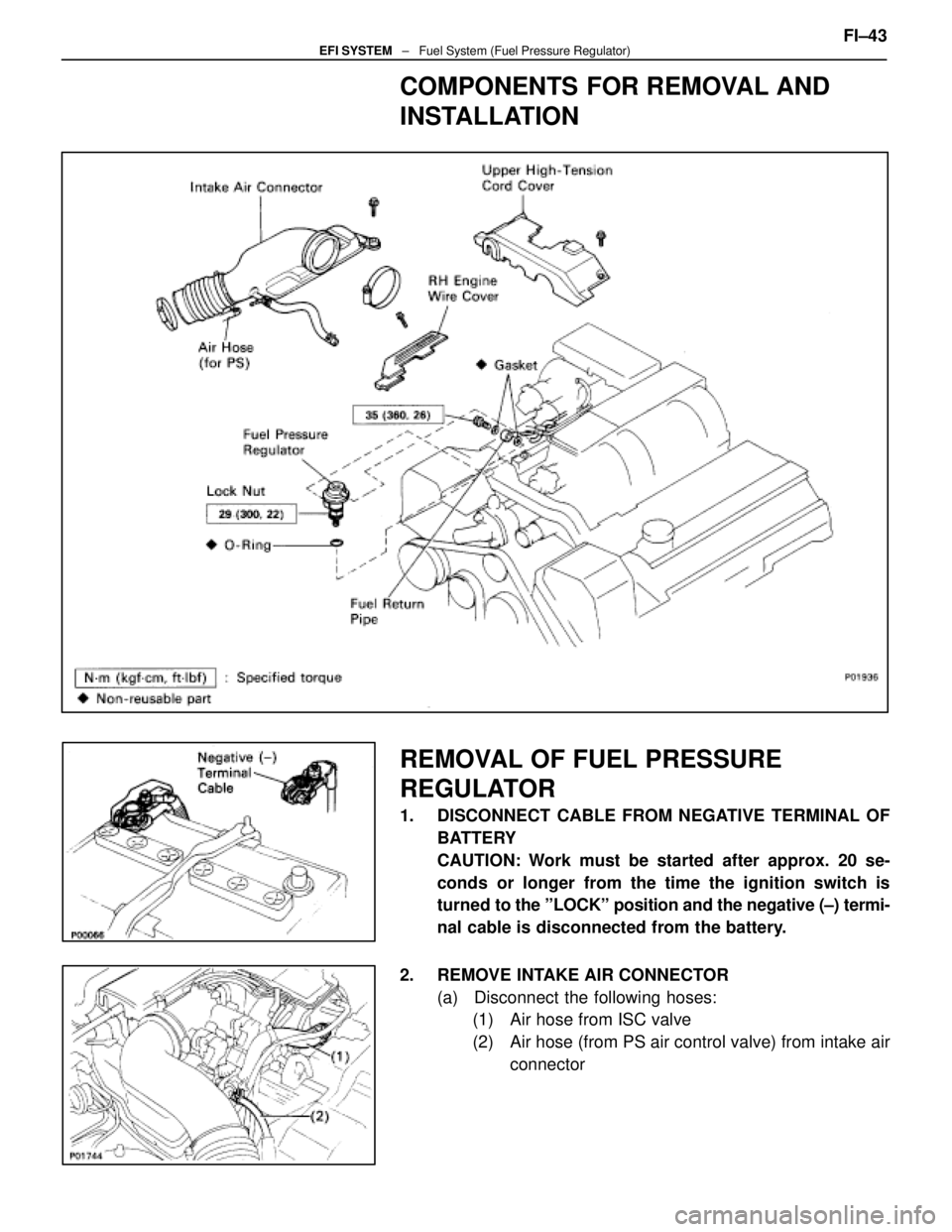

COMPONENTS FOR REMOVAL AND

INSTALLATION

REMOVAL OF FUEL PRESSURE

REGULATOR

1. DISCONNECT CABLE FROM NEGATIVE TERMINAL OFBATTERY

CAUTION: Work must be started after approx. 20 se-

conds or longer from the time the ignition switch is

turned to the ºLOCKº position and the negative (±) termi-

nal cable is disconnected from the battery.

2. REMOVE INTAKE AIR CONNECTOR (a) Disconnect the following hoses:(1) Air hose from ISC valve

(2) Air hose (from PS air control valve) from intake air

connector FI±43

EFI SYSTEM

± Fuel System (Fuel Pressure Regulator)

WhereEverybodyKnowsYourName