LEXUS SC300 1991 Service Service Manual

Manufacturer: LEXUS, Model Year: 1991, Model line: SC300, Model: LEXUS SC300 1991Pages: 4087, PDF Size: 75.75 MB

Page 41 of 4087

R±12 AIR CONDITIONER SYSTEM RETROFIT ± AC001±98 April 3, 1998

Page 4 of 4

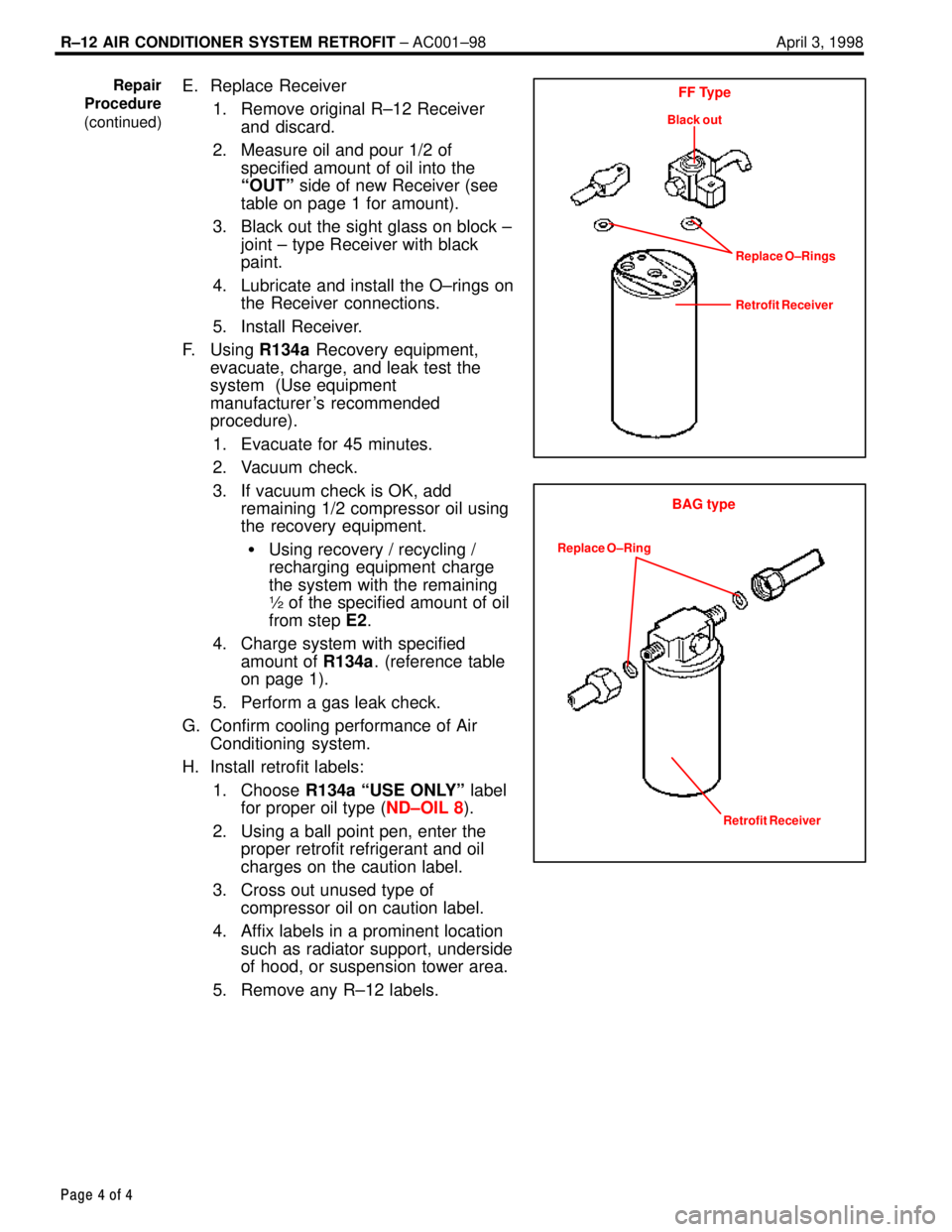

E. Replace Receiver

1. Remove original R±12 Receiverand discard.

2. Measure oil and pour 1/2 of specified amount of oil into the

ªOUTº side of new Receiver (see

table on page 1 for amount).

3. Black out the sight glass on block ± joint ± type Receiver with black

paint.

4. Lubricate and install the O±rings on the Receiver connections.

5. Install Receiver.

F. Using R134a Recovery equipment,

evacuate, charge, and leak test the

system (Use equipment

manufacturer 's recommended

procedure).

1. Evacuate for 45 minutes.

2. Vacuum check.

3. If vacuum check is OK, add remaining 1/2 compressor oil using

the recovery equipment.

� Using recovery / recycling /

recharging equipment charge

the system with the remaining

½ of the specified amount of oil

from step E2.

4. Charge system with specified amount of R134a. (reference table

on page 1).

5. Perform a gas leak check.

G. Confirm cooling performance of Air Conditioning system.

H. Install retrofit labels:

1. Choose R134a ªUSE ONLYº label

for proper oil type ( ND±OIL 8).

2. Using a ball point pen, enter the proper retrofit refrigerant and oil

charges on the caution label.

3. Cross out unused type of compressor oil on caution label.

4. Affix labels in a prominent location such as radiator support, underside

of hood, or suspension tower area.

5. Remove any R±12 labels.Repair

Procedure

(continued)FF Type

Black out

Replace O±Rings

Retrofit Receiver

BAG type

Replace O±Ring

Retrofit Receiver

WhereEverybodyKnowsYourName

Page 42 of 4087

AIR CONDITIONING

SYSTEM

±

AIR CONDITIONING SYSTEMAC±1

WhereEverybodyKnowsYourName

Page 43 of 4087

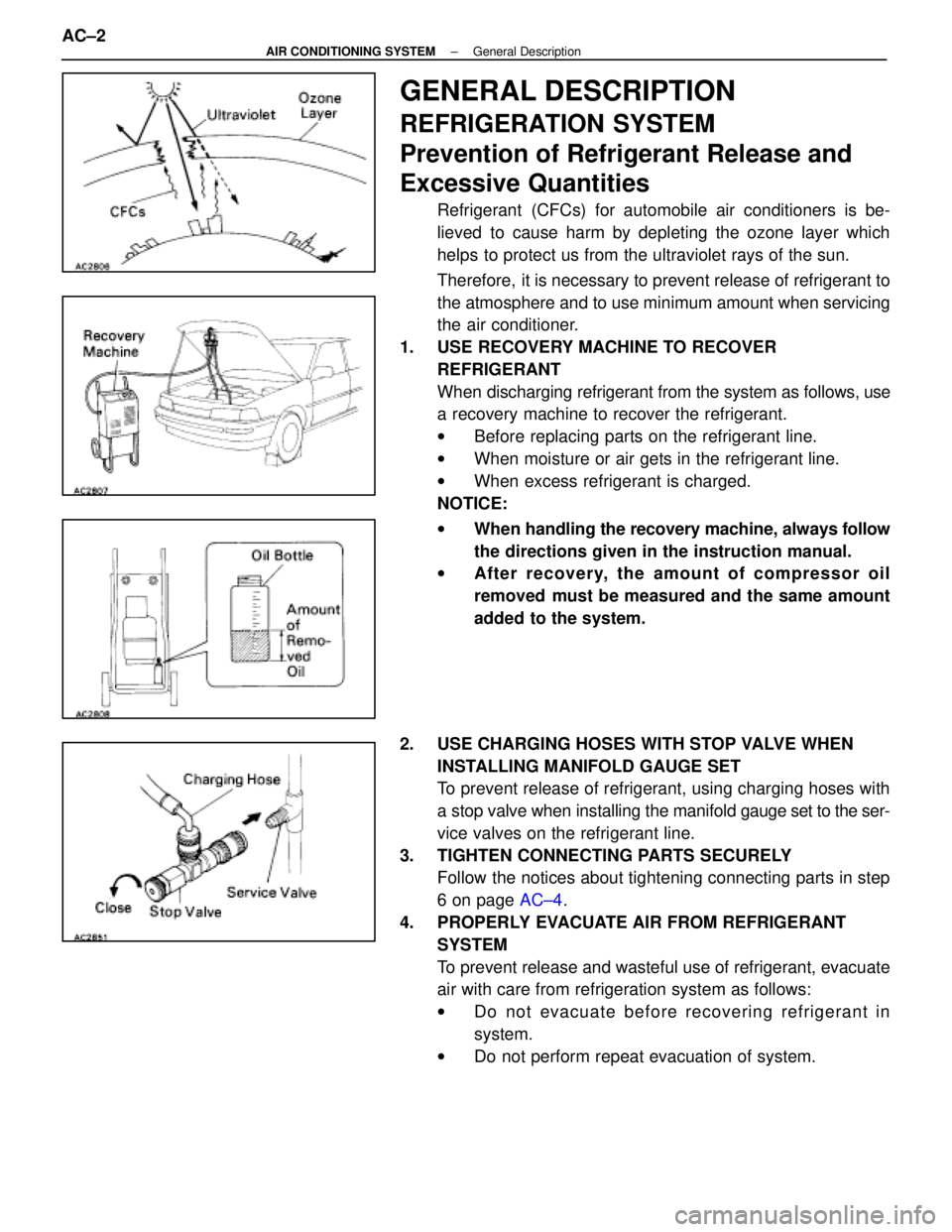

GENERAL DESCRIPTION

REFRIGERATION SYSTEM

Prevention of Refrigerant Release and

Excessive Quantities

Refrigerant (CFCs) for automobile air conditioners is be-

lieved to cause harm by depleting the ozone layer which

helps to protect us from the ultraviolet rays of the sun.

Therefore, it is necessary to prevent release of refrigerant to

the atmosphere and to use minimum amount when servicing

the air conditioner.

1. USE RECOVERY MACHINE TO RECOVER REFRIGERANT

When discharging refrigerant from the system as follows, use

a recovery machine to recover the refrigerant.

wBefore replacing parts on the refrigerant line.

w When moisture or air gets in the refrigerant line.

w When excess refrigerant is charged.

NOTICE:

w When handling the recovery machine, always follow

the directions given in the instruction manual.

w After recovery, the amount of compr essor oil

removed must be measured and the same amount

added to the system.

2. USE CHARGING HOSES WITH STOP VALVE WHEN INSTALLING MANIFOLD GAUGE SET

To prevent release of refrigerant, using charging hoses with

a stop valve when installing the manifold gauge set to the ser-

vice valves on the refrigerant line.

3. TIGHTEN CONNECTING PARTS SECURELY Follow the notices about tightening connecting parts in step

6 on page AC±4.

4. PROPERLY EVACUATE AIR FROM REFRIGERANT SYSTEM

To prevent release and wasteful use of refrigerant, evacuate

air with care from refrigeration system as follows:

wDo not evacuate before recovering refrigerant in

system.

w Do not perform repeat evacuation of system.

AC±2

±

AIR CONDITIONING SYSTEM General Description

WhereEverybodyKnowsYourName

Page 44 of 4087

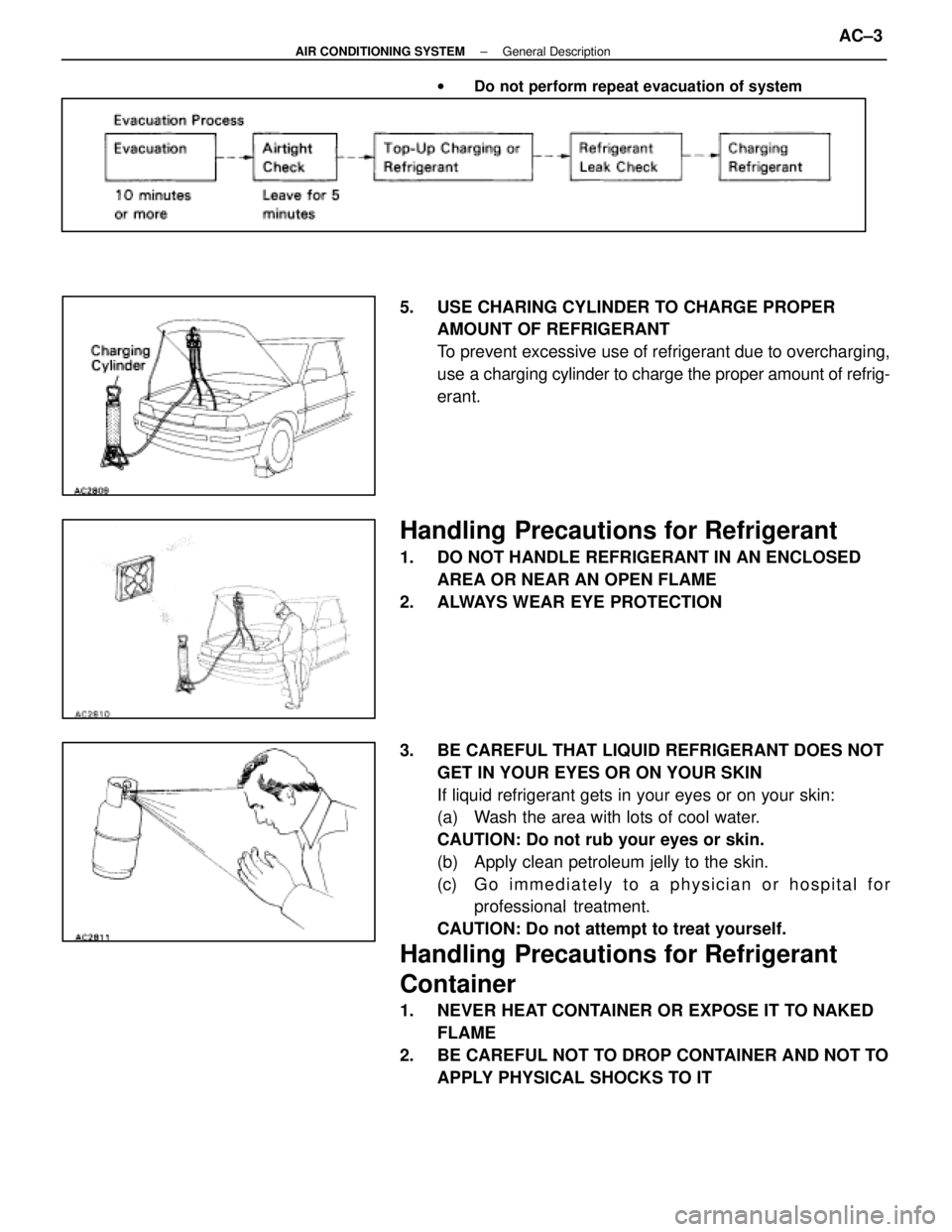

wDo not perform repeat evacuation of system

5. USE CHARING CYLINDER TO CHARGE PROPER

AMOUNT OF REFRIGERANT

To prevent excessive use of refrigerant due to overcharging,

use a charging cylinder to charge the proper amount of refrig-

erant.

Handling Precautions for Refrigerant

1. DO NOT HANDLE REFRIGERANT IN AN ENCLOSED

AREA OR NEAR AN OPEN FLAME

2. ALWAYS WEAR EYE PROTECTION

3. BE CAREFUL THAT LIQUID REFRIGERANT DOES NOT GET IN YOUR EYES OR ON YOUR SKIN

If liquid refrigerant gets in your eyes or on your skin:

(a) Wash the area with lots of cool water.

CAUTION: Do not rub your eyes or skin.

(b) Apply clean petroleum jelly to the skin.

(c) G o i m m e d i a t e l y t o a p h y s i c i a n o r h o s p i t a l f o rprofessional treatment.

CAUTION: Do not attempt to treat yourself.

Handling Precautions for Refrigerant

Container

1. NEVER HEAT CONTAINER OR EXPOSE IT TO NAKED FLAME

2. BE CAREFUL NOT TO DROP CONTAINER AND NOT TO APPLY PHYSICAL SHOCKS TO IT

±

AIR CONDITIONING SYSTEM General DescriptionAC±3

WhereEverybodyKnowsYourName

Page 45 of 4087

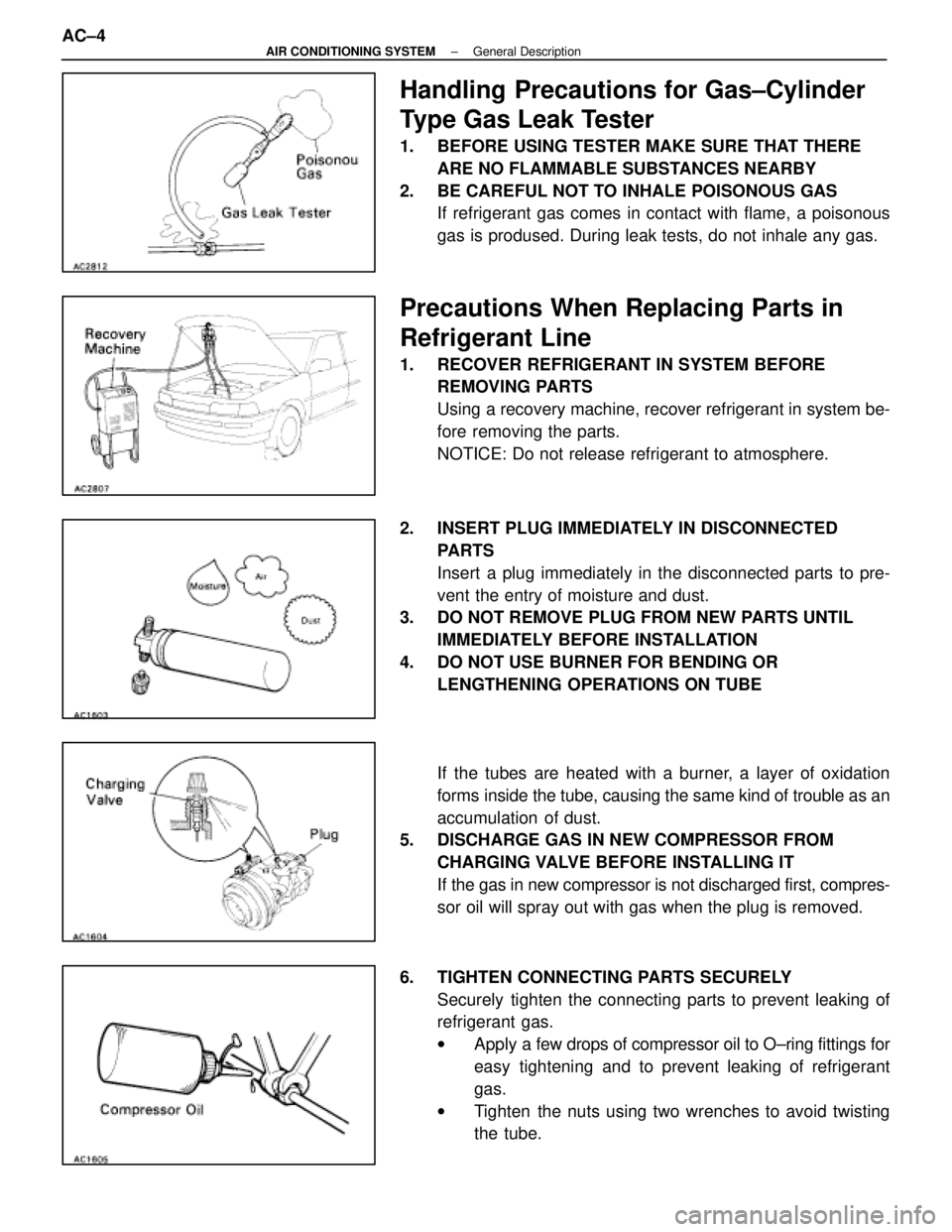

Handling Precautions for Gas±Cylinder

Type Gas Leak Tester

1. BEFORE USING TESTER MAKE SURE THAT THEREARE NO FLAMMABLE SUBSTANCES NEARBY

2. BE CAREFUL NOT TO INHALE POISONOUS GAS If refrigerant gas comes in contact with flame, a poisonous

gas is prodused. During leak tests, do not inhale any gas.

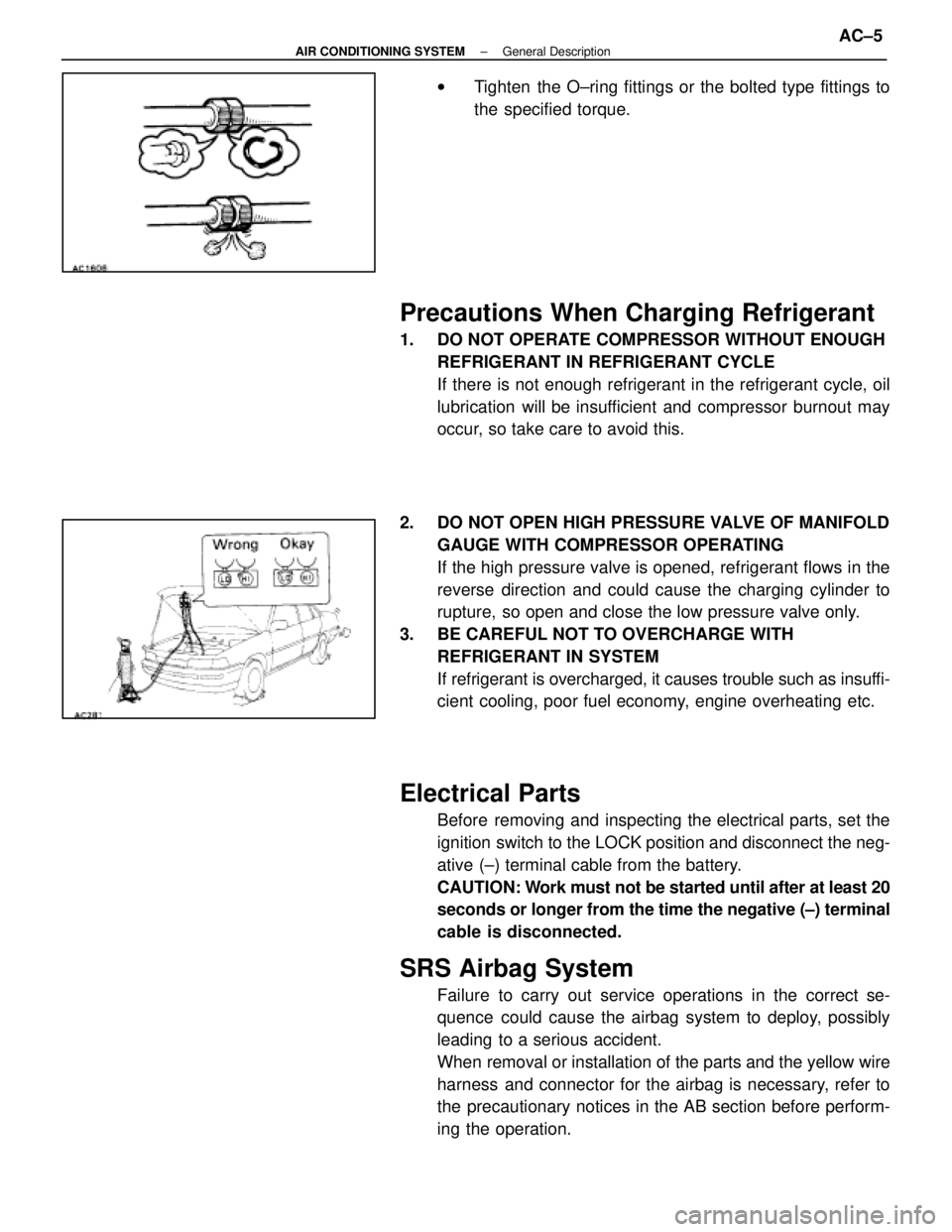

Precautions When Replacing Parts in

Refrigerant Line

1. RECOVER REFRIGERANT IN SYSTEM BEFOREREMOVING PARTS

Using a recovery machine, recover refrigerant in system be-

fore removing the parts.

NOTICE: Do not release refrigerant to atmosphere.

2. INSERT PLUG IMMEDIATELY IN DISCONNECTED PARTS

Insert a plug immediately in the disconnected parts to pre-

vent the entry of moisture and dust.

3. DO NOT REMOVE PLUG FROM NEW PARTS UNTIL

IMMEDIATELY BEFORE INSTALLATION

4. DO NOT USE BURNER FOR BENDING OR LENGTHENING OPERATIONS ON TUBE

If the tubes are heated with a burner, a layer of oxidation

forms inside the tube, causing the same kind of trouble as an

accumulation of dust.

5. DISCHARGE GAS IN NEW COMPRESSOR FROM

CHARGING VALVE BEFORE INSTALLING IT

If the gas in new compressor is not discharged first, compres-

sor oil will spray out with gas when the plug is removed.

6. TIGHTEN CONNECTING PARTS SECURELY Securely tighten the connecting parts to prevent leaking of

refrigerant gas.

wApply a few drops of compressor oil to O±ring fittings for

easy tightening and to prevent leaking of refrigerant

gas.

w Tighten the nuts using two wrenches to avoid twisting

the tube.

AC±4

±

AIR CONDITIONING SYSTEM General Description

WhereEverybodyKnowsYourName

Page 46 of 4087

wTighten the O±ring fittings or the bolted type fittings to

the specified torque.

Precautions When Charging Refrigerant

1. DO NOT OPERATE COMPRESSOR WITHOUT ENOUGH

REFRIGERANT IN REFRIGERANT CYCLE

If there is not enough refrigerant in the refrigerant cycle, oil

lubrication will be insufficient and compressor burnout may

occur, so take care to avoid this.

2. DO NOT OPEN HIGH PRESSURE VALVE OF MANIFOLD GAUGE WITH COMPRESSOR OPERATING

If the high pressure valve is opened, refrigerant flows in the

reverse direction and could cause the charging cylinder to

rupture, so open and close the low pressure valve only.

3. BE CAREFUL NOT TO OVERCHARGE WITH REFRIGERANT IN SYSTEM

If refrigerant is overcharged, it causes trouble such as insuffi-

cient cooling, poor fuel economy, engine overheating etc.

Electrical Parts

Before removing and inspecting the electrical parts, set the

ignition switch to the LOCK position and disconnect the neg-

ative (±) terminal cable from the battery.

CAUTION: Work must not be started until after at least 20

seconds or longer from the time the negative (±) terminal

cable is disconnected.

SRS Airbag System

Failure to carry out service operations in the correct se-

quence could cause the airbag system to deploy, possibly

leading to a serious accident.

When removal or installation of the parts and the yellow wire

harness and connector for the airbag is necessary, refer to

the precautionary notices in the AB section before perform-

ing the operation.

±

AIR CONDITIONING SYSTEM General DescriptionAC±5

WhereEverybodyKnowsYourName

Page 47 of 4087

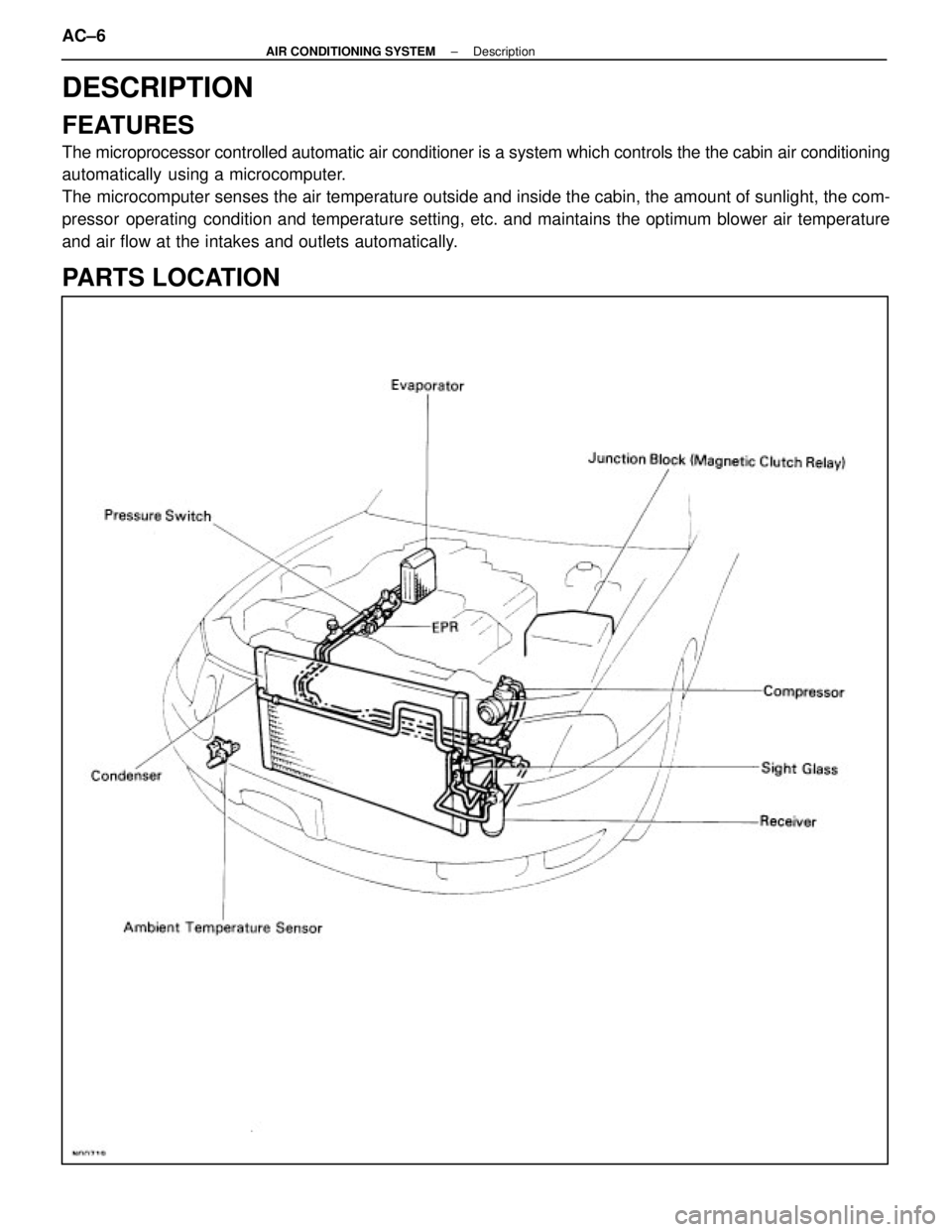

DESCRIPTION

FEATURES

The microprocessor controlled automatic air conditioner is a system whic\

h controls the the cabin air conditioning

automatically using a microcomputer.

The microcomputer senses the air temperature outside and inside the cabin, \

the amount of sunlight, the com-

pressor operating condition and temperature setting, etc. and maintains the optimum blower\

air temperature

and air flow at the intakes and outlets automatically.

PARTS LOCATION

AC±6±

AIR CONDITIONING SYSTEM Description

WhereEverybodyKnowsYourName

Page 48 of 4087

PARTS LOCATION (Cont'd)

±

AIR CONDITIONING SYSTEM DescriptionAC±7

WhereEverybodyKnowsYourName

Page 49 of 4087

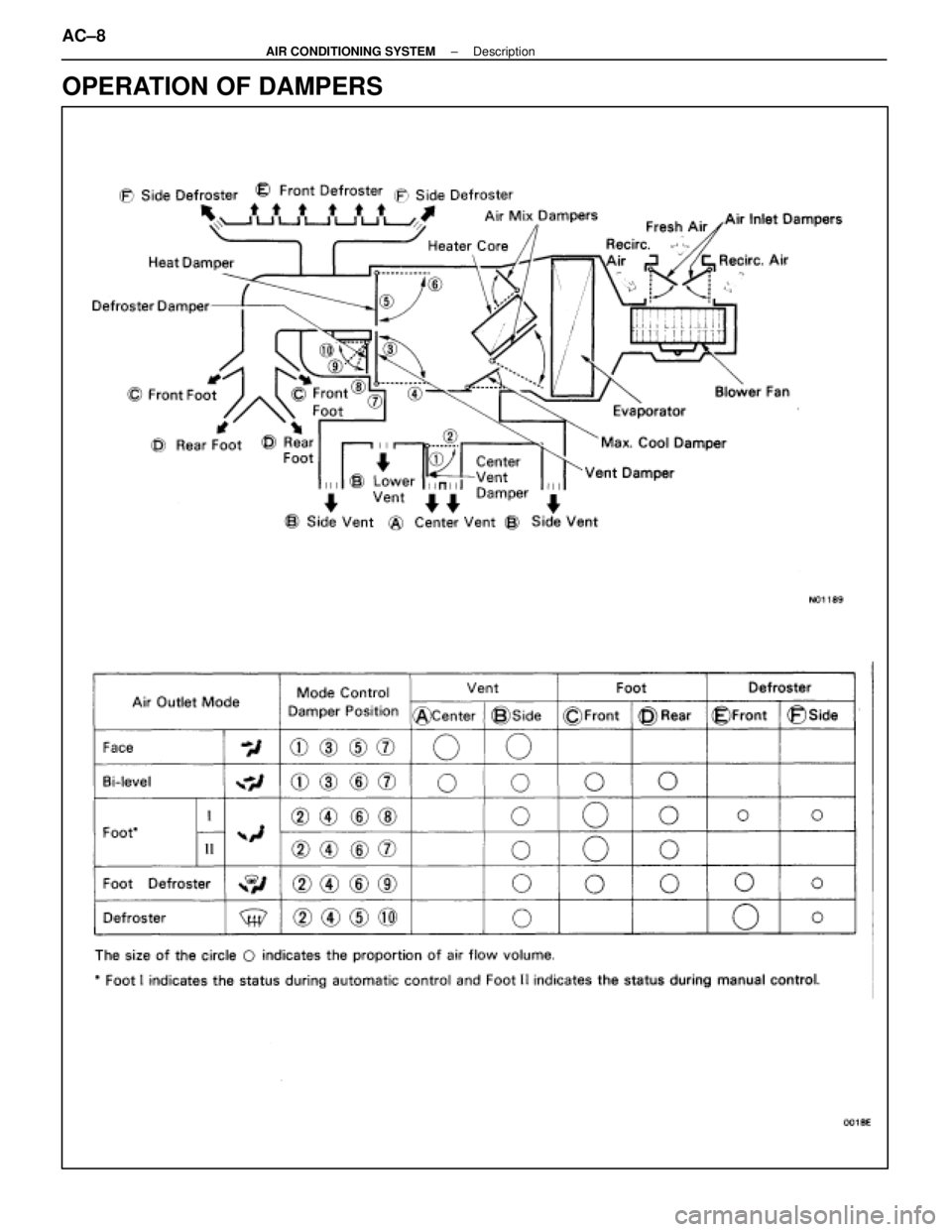

OPERATION OF DAMPERS

AC±8±

AIR CONDITIONING SYSTEM Description

WhereEverybodyKnowsYourName

Page 50 of 4087

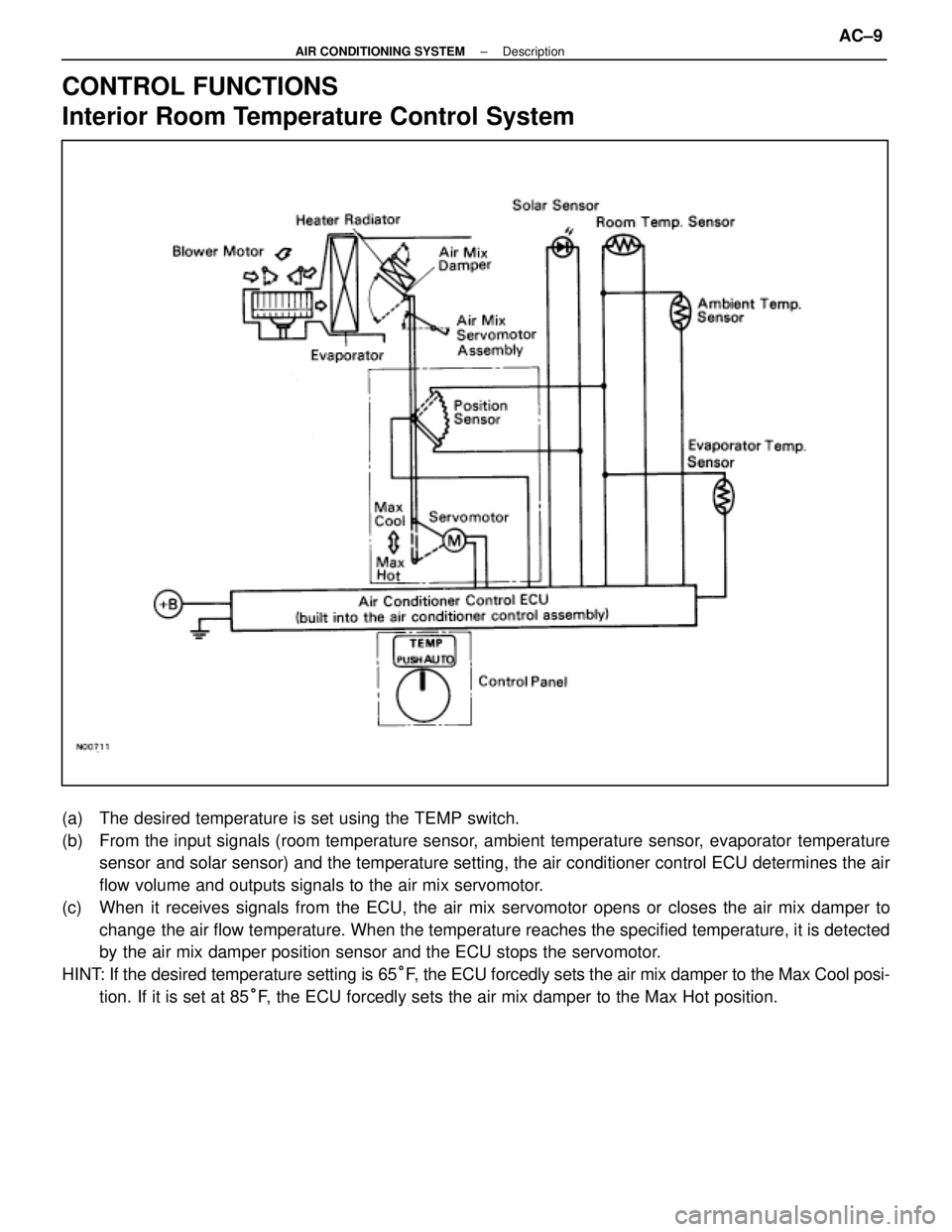

CONTROL FUNCTIONS

Interior Room Temperature Control System

(a) The desired temperature is set using the TEMP switch.

(b) From the input signals (room temperature sensor, ambient temperature sensor, evaporator temperaturesensor and solar sensor) and the temperature setting, the air conditioner con\

trol ECU determines the air

flow volume and outputs signals to the air mix servomotor.

(c) When it receives signals from the ECU, the air mix servomotor opens or close\

s the air mix damper to change the air flow temperature. When the temperature reaches the specified te\

mperature, it is detected

by the air mix damper position sensor and the ECU stops the servomotor.

HINT: If the desired temperature setting is 65 °F, the ECU forcedly sets the air mix damper to the Max Cool posi-

tion. If it is set at 85 °F, the ECU forcedly sets the air mix damper to the Max Hot position.

±

AIR CONDITIONING SYSTEM DescriptionAC±9

WhereEverybodyKnowsYourName