engine LEXUS SC400 1991 Service Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 1991, Model line: SC400, Model: LEXUS SC400 1991Pages: 4087, PDF Size: 75.75 MB

Page 2602 of 4087

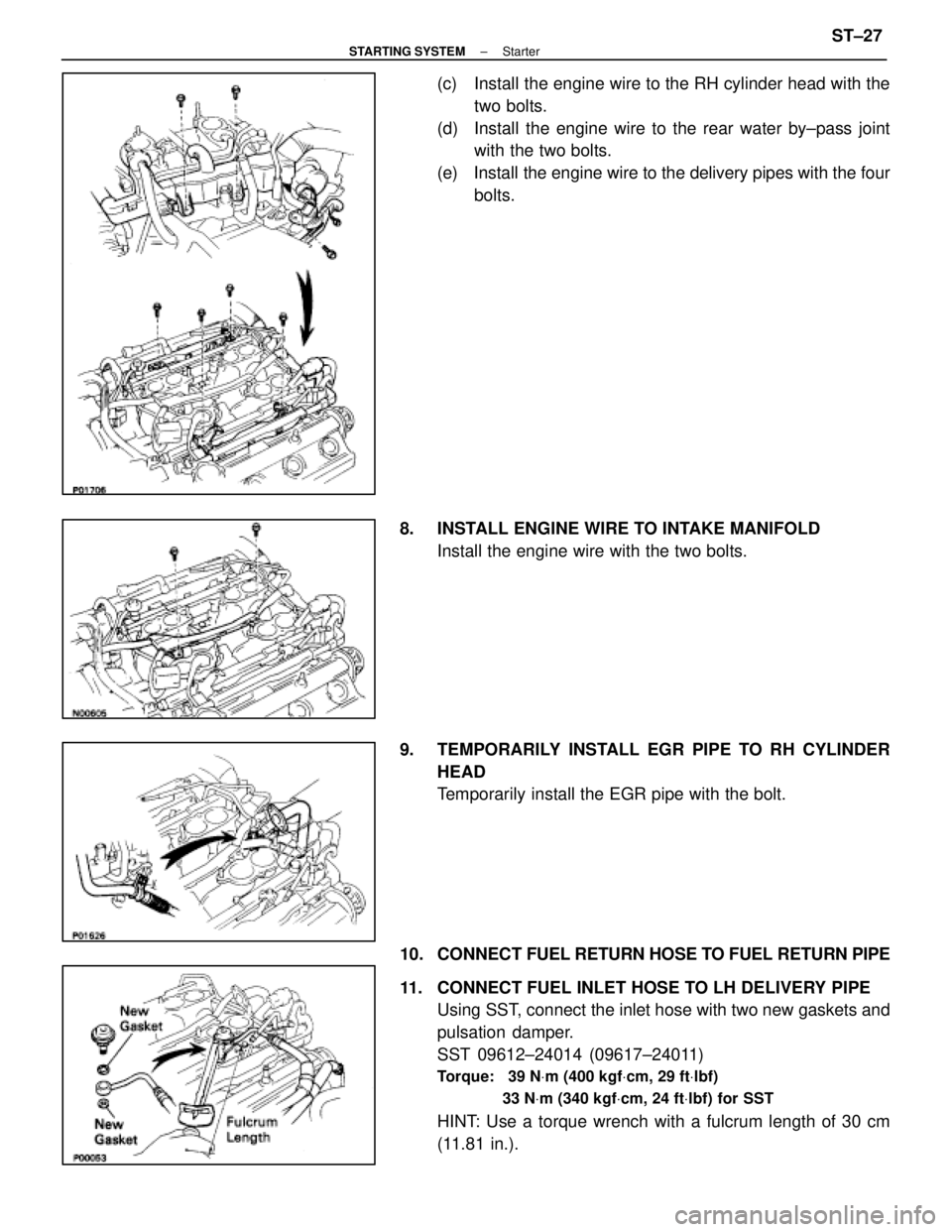

(c) Install the engine wire to the RH cylinder head with thetwo bolts.

(d) Install the engine wire to the rear water by±pass joint with the two bolts.

(e) Install the engine wire to the delivery pipes with the four bolts.

8. INSTALL ENGINE WIRE TO INTAKE MANIFOLD Install the engine wire with the two bolts.

9. TEMPORARILY INSTALL EGR PIPE TO RH CYLINDER HEAD

Temporarily install the EGR pipe with the bolt.

10. CONNECT FUEL RETURN HOSE TO FUEL RETURN PIPE

11. CONNECT FUEL INLET HOSE TO LH DELIVERY PIPE Using SST, connect the inlet hose with two new gaskets and

pulsation damper.

SST 09612±24014 (09617±24011)

Torque: 39 N Vm (400 kgf Vcm, 29 ft Vlbf)

33 N Vm (340 kgf Vcm, 24 ft Vlbf) for SST

HINT: Use a torque wrench with a fulcrum length of 30 cm

(11.81 in.).

±

STARTING SYSTEM StarterST±27

WhereEverybodyKnowsYourName

Page 2605 of 4087

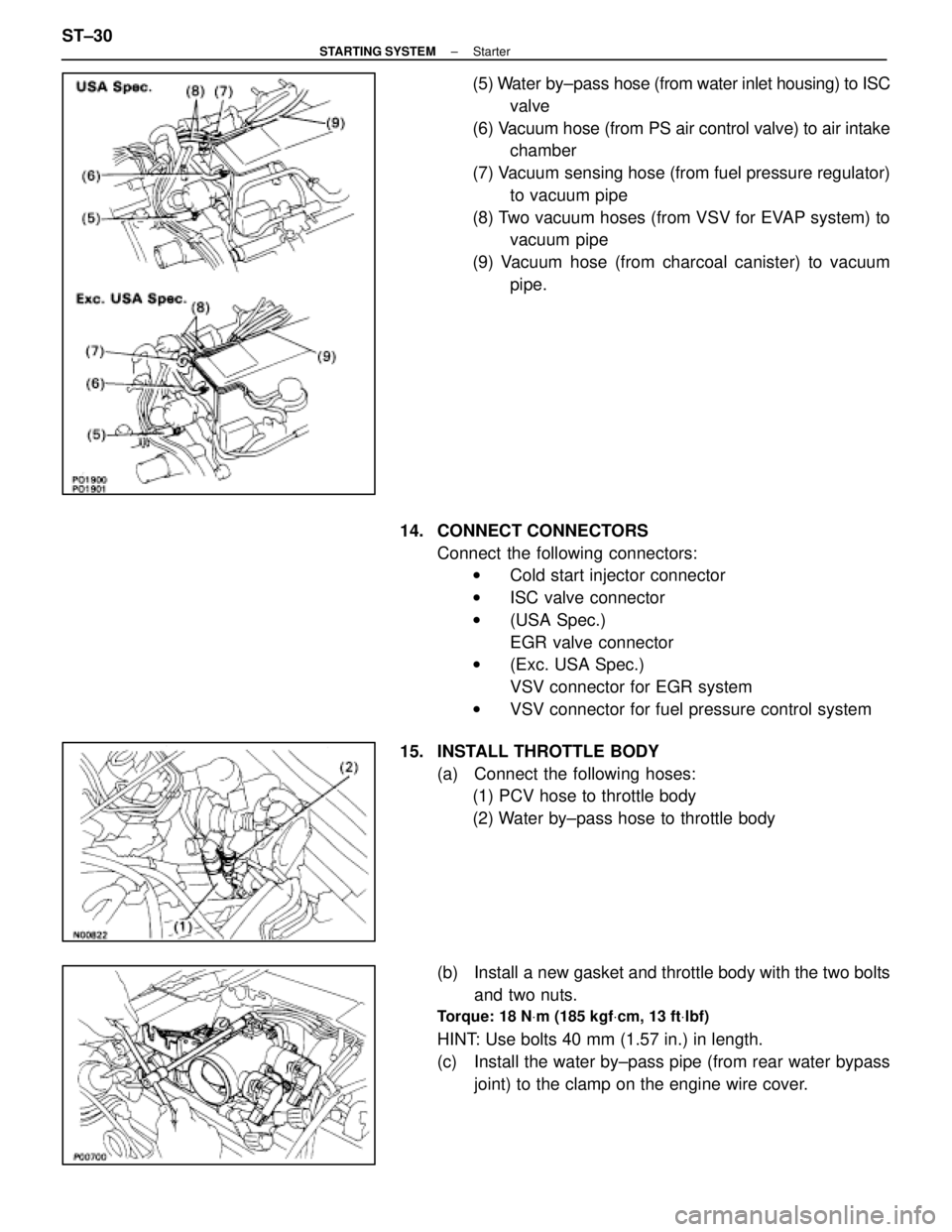

(5) Water by±pass hose (from water inlet housing) to ISC

valve

(6) Vacuum hose (from PS air control valve) to air intake chamber

(7) Vacuum sensing hose (from fuel pressure regulator) to vacuum pipe

(8) Two vacuum hoses (from VSV for EVAP system) to vacuum pipe

(9) Vacuum hose (from charcoal canister) to vacuum pipe.

14. CONNECT CONNECTORS Connect the following connectors:w Cold start injector connector

w ISC valve connector

w (USA Spec.)

EGR valve connector

w (Exc. USA Spec.)

VSV connector for EGR system

w VSV connector for fuel pressure control system

15. INSTALL THROTTLE BODY (a) Connect the following hoses:(1) PCV hose to throttle body

(2) Water by±pass hose to throttle body

(b) Install a new gasket and throttle body with the two bolts and two nuts.

Torque: 18 N Vm (185 kgf Vcm, 13 ft Vlbf)

HINT: Use bolts 40 mm (1.57 in.) in length.

(c) Install the water by±pass pipe (from rear water bypass

joint) to the clamp on the engine wire cover.

ST±30

±

STARTING SYSTEM Starter

WhereEverybodyKnowsYourName

Page 2607 of 4087

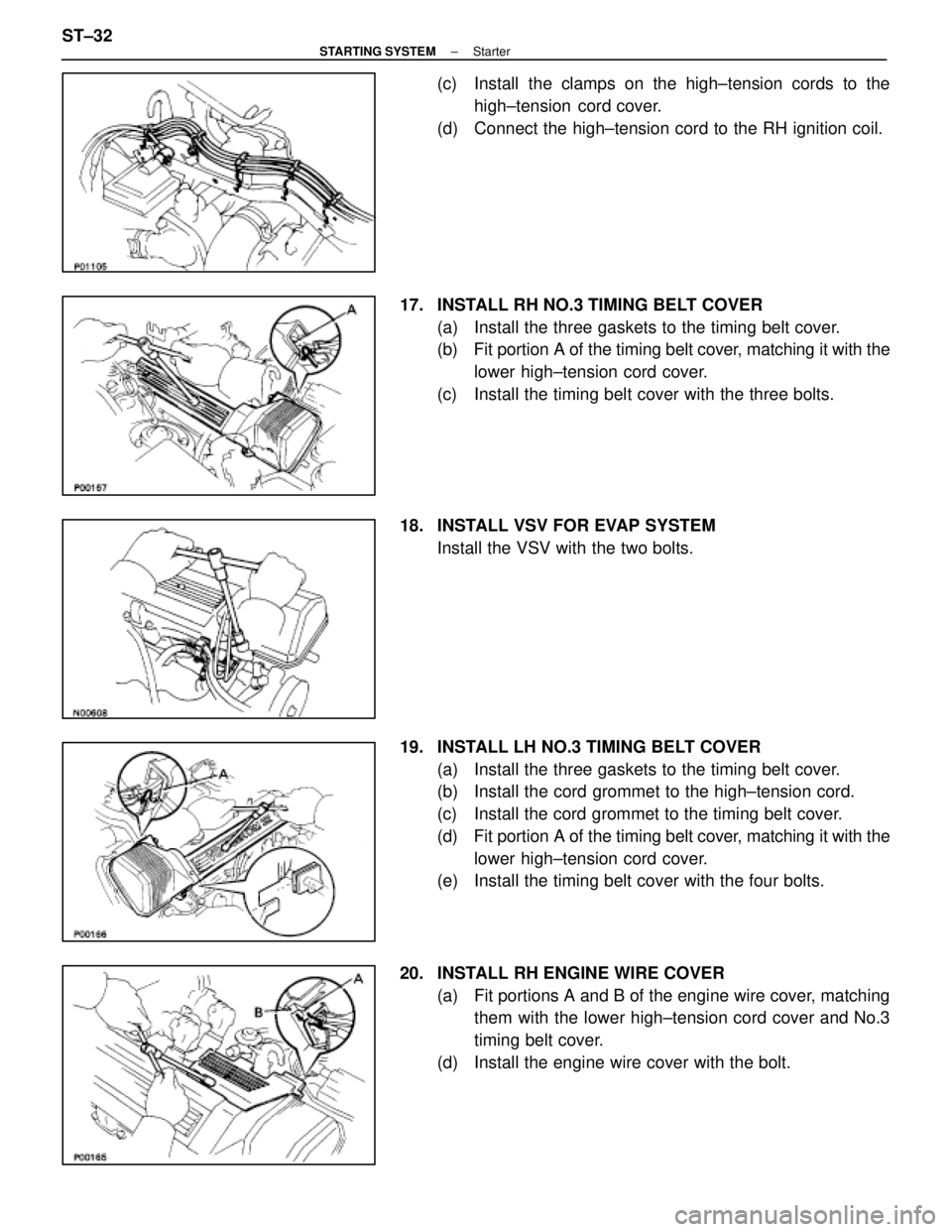

(c) Install the clamps on the high±tension cords to thehigh±tension cord cover.

(d) Connect the high±tension cord to the RH ignition coil.

17. INSTALL RH NO.3 TIMING BELT COVER (a) Install the three gaskets to the timing belt cover.

(b) Fit portion A of the timing belt cover, matching it with the

lower high±tension cord cover.

(c) Install the timing belt cover with the three bolts.

18. INSTALL VSV FOR EVAP SYSTEM Install the VSV with the two bolts.

19. INSTALL LH NO.3 TIMING BELT COVER (a) Install the three gaskets to the timing belt cover.

(b) Install the cord grommet to the high±tension cord.

(c) Install the cord grommet to the timing belt cover.

(d) Fit portion A of the timing belt cover, matching it with the

lower high±tension cord cover.

(e) Install the timing belt cover with the four bolts.

20. INSTALL RH ENGINE WIRE COVER (a) Fit portions A and B of the engine wire cover, matchingthem with the lower high±tension cord cover and No.3

timing belt cover.

(d) Install the engine wire cover with the bolt.

ST±32

±

STARTING SYSTEM Starter

WhereEverybodyKnowsYourName

Page 2608 of 4087

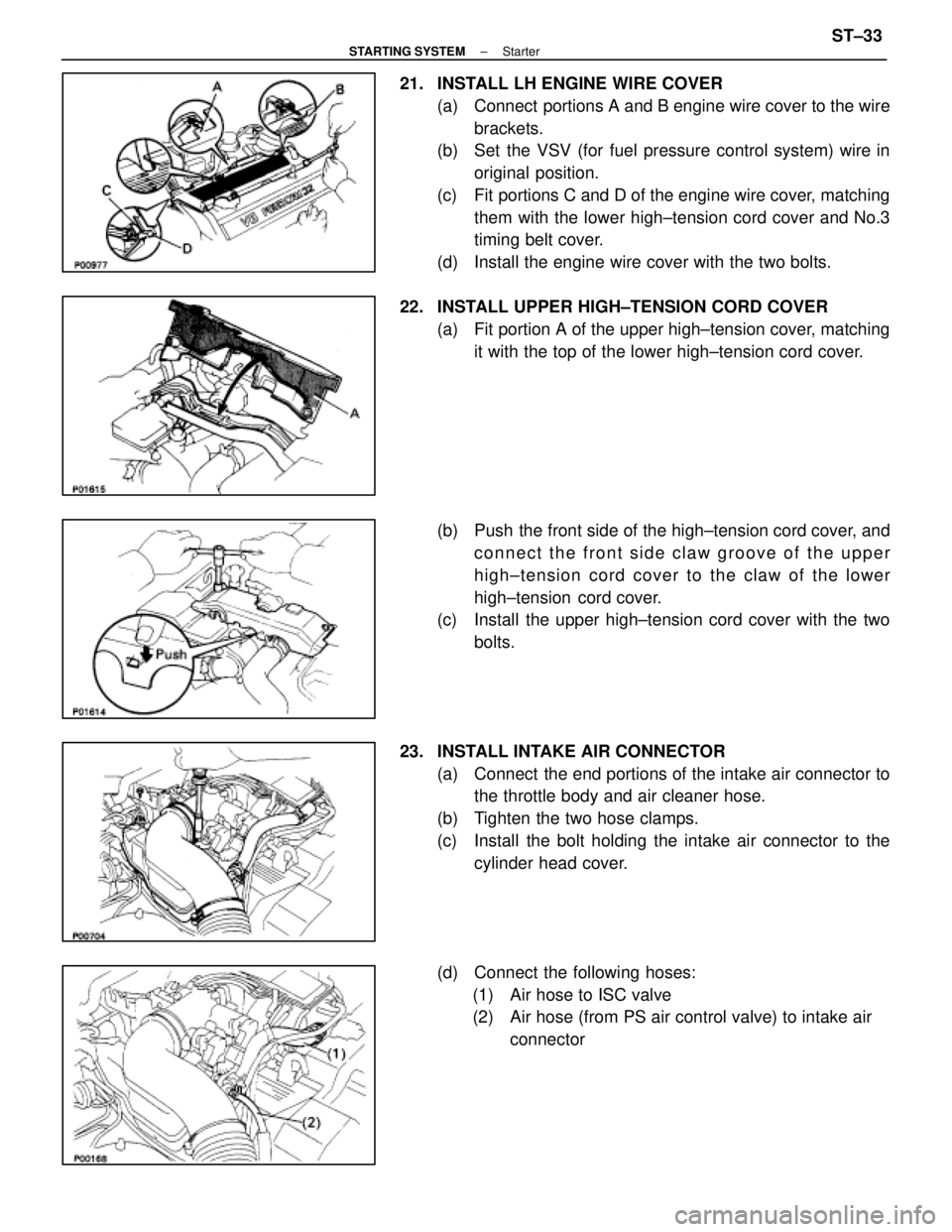

21. INSTALL LH ENGINE WIRE COVER(a) Connect portions A and B engine wire cover to the wirebrackets.

(b) Set the VSV (for fuel pressure control system) wire in

original position.

(c) Fit portions C and D of the engine wire cover, matching them with the lower high±tension cord cover and No.3

timing belt cover.

(d) Install the engine wire cover with the two bolts.

22. INSTALL UPPER HIGH±TENSION CORD COVER (a) Fit portion A of the upper high±tension cover, matchingit with the top of the lower high±tension cord cover.

(b) Push the front side of the high±tension cord cover, and connect the front side claw groove of the upper

high±tension cord cover to the claw of the lower

high±tension cord cover.

(c) Install the upper high±tension cord cover with the two

bolts.

23. INSTALL INTAKE AIR CONNECTOR (a) Connect the end portions of the intake air connector tothe throttle body and air cleaner hose.

(b) Tighten the two hose clamps.

(c) Install the bolt holding the intake air connector to the cylinder head cover.

(d) Connect the following hoses: (1) Air hose to ISC valve

(2) Air hose (from PS air control valve) to intake air connector

±

STARTING SYSTEM StarterST±33

WhereEverybodyKnowsYourName

Page 2609 of 4087

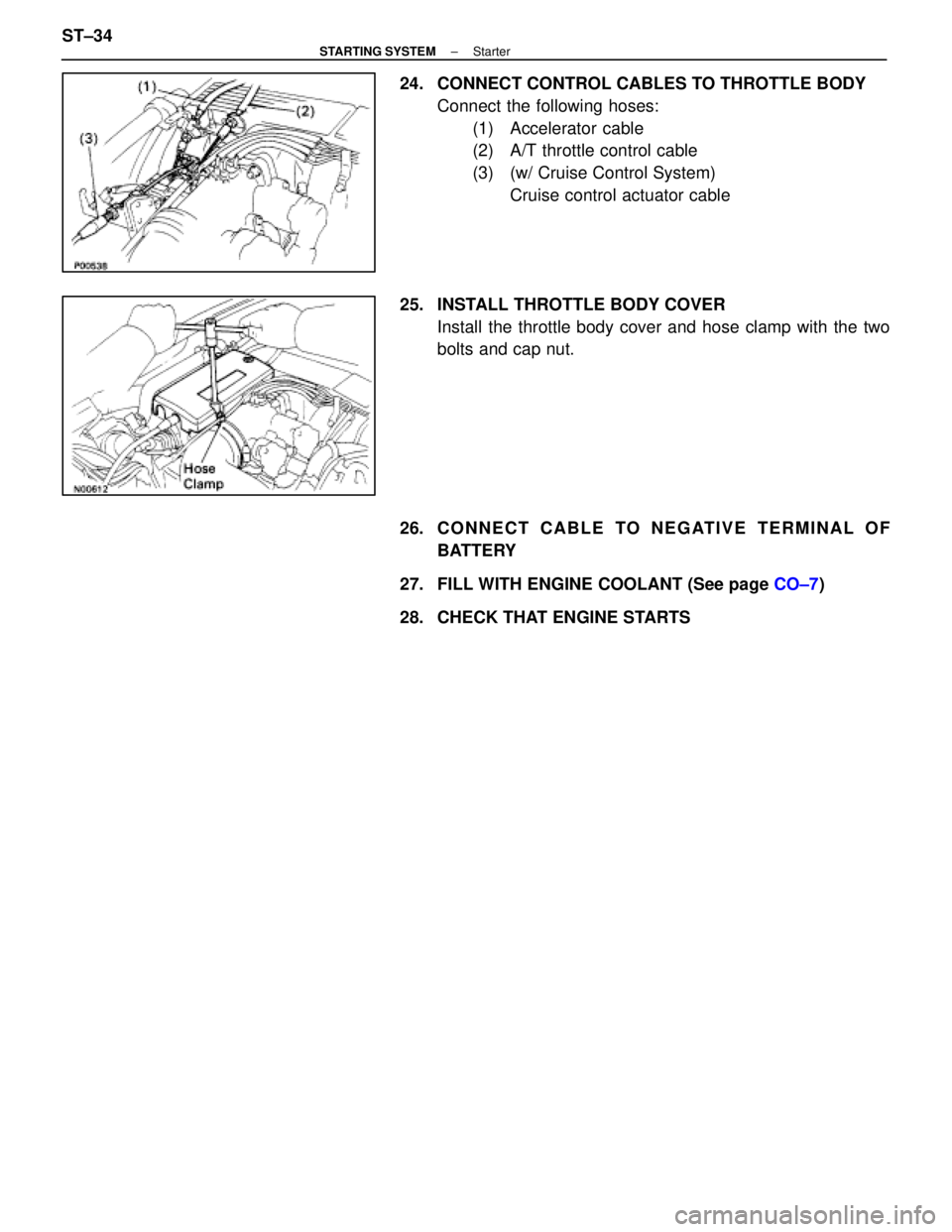

24. CONNECT CONTROL CABLES TO THROTTLE BODYConnect the following hoses:(1) Accelerator cable

(2) A/T throttle control cable

(3) (w/ Cruise Control System) Cruise control actuator cable

25. INSTALL THROTTLE BODY COVER Install the throttle body cover and hose clamp with the two

bolts and cap nut.

26. C O N N E C T C A B L E TO N E G AT I V E T E R M I N A L O F BATTERY

27. FILL WITH ENGINE COOLANT (See page CO±7)

28. CHECK THAT ENGINE STARTS

ST±34

±

STARTING SYSTEM Starter

WhereEverybodyKnowsYourName

Page 2610 of 4087

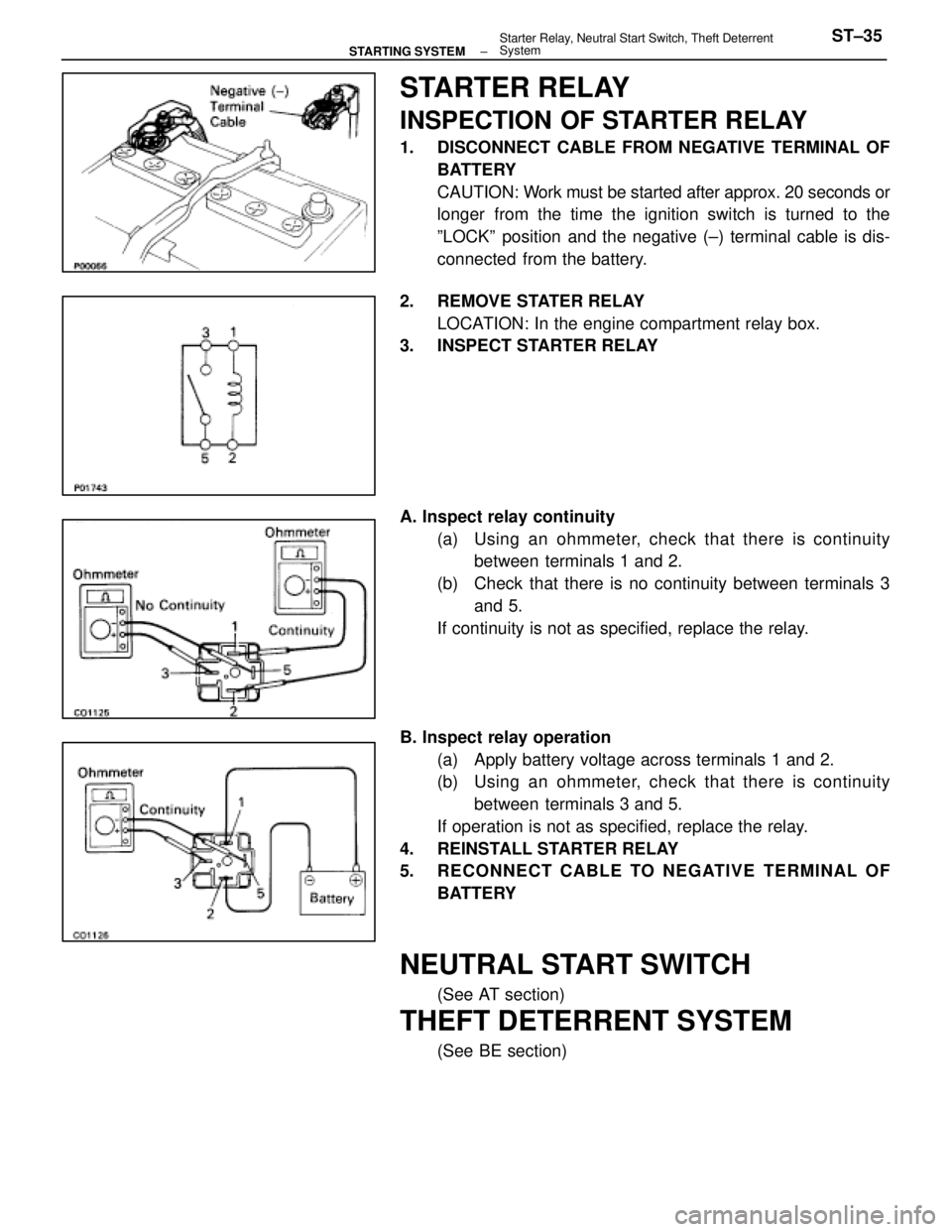

STARTER RELAY

INSPECTION OF STARTER RELAY

1. DISCONNECT CABLE FROM NEGATIVE TERMINAL OFBATTERY

CAUTION: Work must be started after approx. 20 seconds or

longer from the time the ignition switch is turned to the

ºLOCKº position and the negative (±) terminal cable is dis-

connected from the battery.

2. REMOVE STATER RELAY LOCATION: In the engine compartment relay box.

3. INSPECT STARTER RELAY

A. Inspect relay continuity

(a) Using an ohmmeter, check that there is continuitybetween terminals 1 and 2.

(b) Check that there is no continuity between terminals 3 and 5.

If continuity is not as specified, replace the relay.

B. Inspect relay operation (a) Apply battery voltage across terminals 1 and 2.

(b) Using an ohmmeter, check that there is continuitybetween terminals 3 and 5.

If operation is not as specified, replace the relay.

4. REINSTALL STARTER RELAY

5. RECONNECT CABLE TO NEGATIVE TERMINAL OF BATTERY

NEUTRAL START SWITCH

(See AT section)

THEFT DETERRENT SYSTEM

(See BE section)

±

STARTING SYSTEM Starter Relay, Neutral Start Switch, Theft Deterrent

SystemST±35

WhereEverybodyKnowsYourName

Page 2612 of 4087

ENGINE TROUBLESHOOTING

TR±1

WhereEverybodyKnowsYourName

Page 2613 of 4087

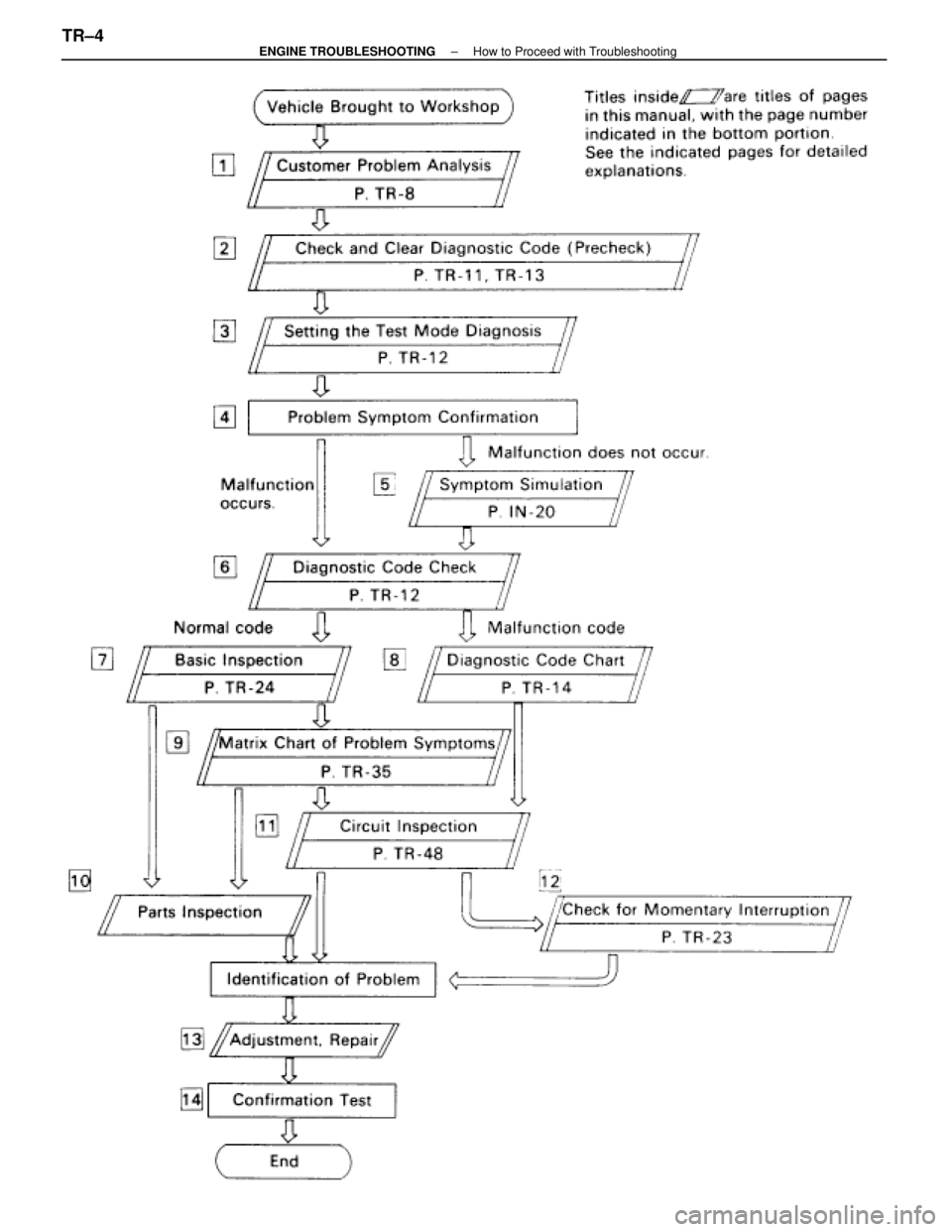

HOW TO PROCEED WITH TROUBLESHOOTING

The Engine Control System broadly consists of the sensors, ECU and actuator\

s. The ECU receives signals from

various sensors, judges the operating conditions and determines the opti\

mum injection duration, timing, ignition

timing and idle speed.

In general, the Engine Control System is considered to be a very intricate\

system to troubleshoot. But, the fact

is that if you proceed to inspect the circuit one by one following the p\

rocedures directed in this manual, trouble-

shooting of this system is not complex.

This section explains the most ideal method of troubleshooting and tells how\

to carry out the necessary repairs.

[1] CUSTOMER PROBLEM ANALYSISUsing the customer problem analysis check sheet for reference, ask the c\

ustomer in as much details as

possible about the problem.

[2] CHECK AND CLEAR DIAGNOSTIC CODE (PRECHECK) Before confirming the problem symptom, first check the diagnostic code and mak\

e a note of any malfunc-

tion code which is output, then clear the code.

HINT: Output of the malfunction code indicates that there is a malfunction in\

the circuit indicated. However,

it does not indicate whether the malfunction is still occurring or occur\

red in the past and returned to normal.

In order to determine this, the problem symptoms should be confirmed in 4 \

first and the diagnostic code

be rechecked in [6].

Accordingly, if troubleshooting is begun based on the malfunction code only in diag\

nostic code check in

[2] , it could result in a misdiagnosis, leading to troubleshooting of circuits which are normal \

and making

it more difficult to locate the cause of the problem.

[3] SETTING THE TEST MODE DIAGNOSIS, [4] PROBLEM SYMPTOM CONFIRMATION, [5] SYMPTOM SIMULATION

In order to find out the trouble more quickly, set the diagnosis check in test mode and with higher sensing

ability of the ECU, confirm the problem symptoms. If the trouble does not reappear, use the symptom simu-

lation method to make sure the trouble is reproduced.

[6] DIAGNOSTIC CODE CHECK IN TEST MODE Check the diagnostic code in test mode. If the malfunction code is output, pr\

oceed to ºstep [8] Diagnostic

Code Chartº. If the normal code is output, proceed to ºstep [7] Basic Inspectionº.

[7] BASIC INSPECTION Carry out basic inspection such as the spark check and fuel pressure che\

ck, etc.

[8] DIAGNOSTIC CODE CHART If the malfunction code is displayed, proceed to inspect the circuit ind\

icated by the chart for each code.

[9] MATRIX CHART OF PROBLEM SYMPTOMS If the normal code is displayed in the diagnosis in test mode, perform tro\

ubleshooting according to the in-

spection order in the Matrix Chart of Problem Symptoms.

[10] PARTS INSPECTION When the Matrix Chart of Problem Symptoms instructs to check the parts, proc\

eed to parts inspection sec-

tion included in this manual.

[11] CIRCUIT INSPECTION Determine if the malfunction is the sensor, actuator, wire harness, connector or the ECU.

TR±2

±

ENGINE TROUBLESHOOTING How to Proceed with Troubleshooting

WhereEverybodyKnowsYourName

Page 2614 of 4087

![LEXUS SC400 1991 Service Repair Manual

[12] CHECK FOR MOMENTARY INTERRUPTIONBy performing the check for momentary interruption, the place where moment\

ary interruptions or momen-

tary shorts are occurring due to poor contacts can be iso LEXUS SC400 1991 Service Repair Manual

[12] CHECK FOR MOMENTARY INTERRUPTIONBy performing the check for momentary interruption, the place where moment\

ary interruptions or momen-

tary shorts are occurring due to poor contacts can be iso](/img/36/57051/w960_57051-2613.png)

[12] CHECK FOR MOMENTARY INTERRUPTIONBy performing the check for momentary interruption, the place where moment\

ary interruptions or momen-

tary shorts are occurring due to poor contacts can be isolated.

[13] ADJUSTMENT, REPAIR After the cause of the problem is located, perform adjustment or repairs\

by following the inspection and

replacement procedures in this manual.

[14] CONFIRMATION TEST After completing adjustment or repairs, confirm not only that the malfunction\

is eliminated, but also conduct

a test drive, etc., to make sure the entire Engine Control System is oper\

ating normally.

±

ENGINE TROUBLESHOOTING How to Proceed with TroubleshootingTR±3

WhereEverybodyKnowsYourName

Page 2615 of 4087

TR±4±

ENGINE TROUBLESHOOTING How to Proceed with Troubleshooting

WhereEverybodyKnowsYourName