boot LEXUS SC400 1991 Service User Guide

[x] Cancel search | Manufacturer: LEXUS, Model Year: 1991, Model line: SC400, Model: LEXUS SC400 1991Pages: 4087, PDF Size: 75.75 MB

Page 1011 of 4087

(c) Repeat (b) until the disc has been installed on the 3remaining hub positions.

(d) If the minimum runout recorded in (b) and (c) is less than 0.05

mm (0.0020 in.), install the disc in that position.

(e) If the minimum runout recorded in (b) and (c) is greater than 0.05 mm (0.0020 in.), replace the disc and repeat step 3.

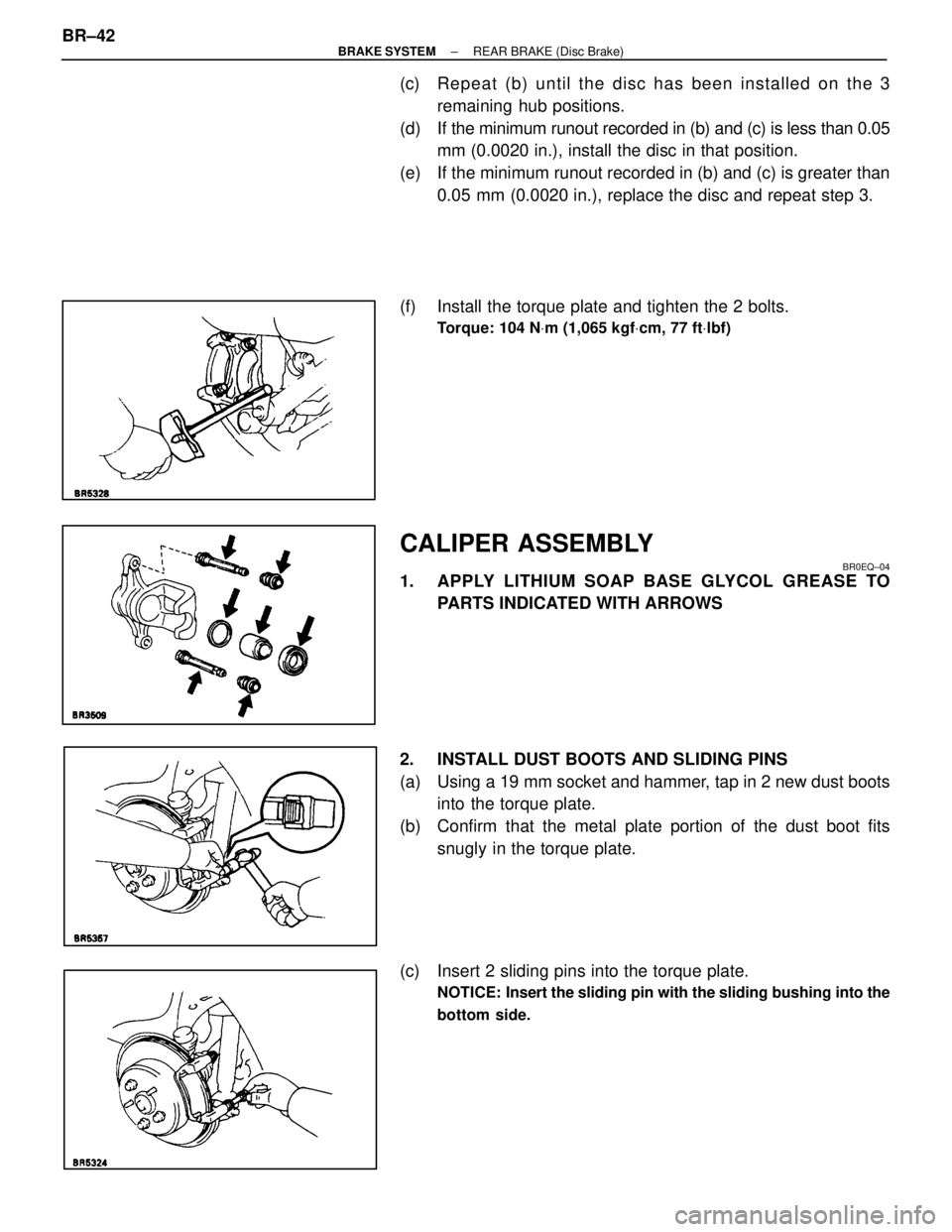

(f) Install the torque plate and tighten the 2 bolts.

Torque: 104 N Vm (1,065 kgf Vcm, 77 ft Vlbf)

CALIPER ASSEMBLY

BR0EQ±04

1. APPLY LITHIUM SOAP BASE GLYCOL GREASE TO

PARTS INDICATED WITH ARROWS

2. INSTALL DUST BOOTS AND SLIDING PINS

(a) Using a 19 mm socket and hammer, tap in 2 new dust boots into the torque plate.

(b) Confirm that the metal plate portion of the dust boot fits snugly in the torque plate.

(c) Insert 2 sliding pins into the torque plate.

NOTICE: Insert the sliding pin with the sliding bushing into the

bottom side.

BR±42±

BRAKE SYSTEM REAR BRAKE (Disc Brake)

WhereEverybodyKnowsYourName

Page 1012 of 4087

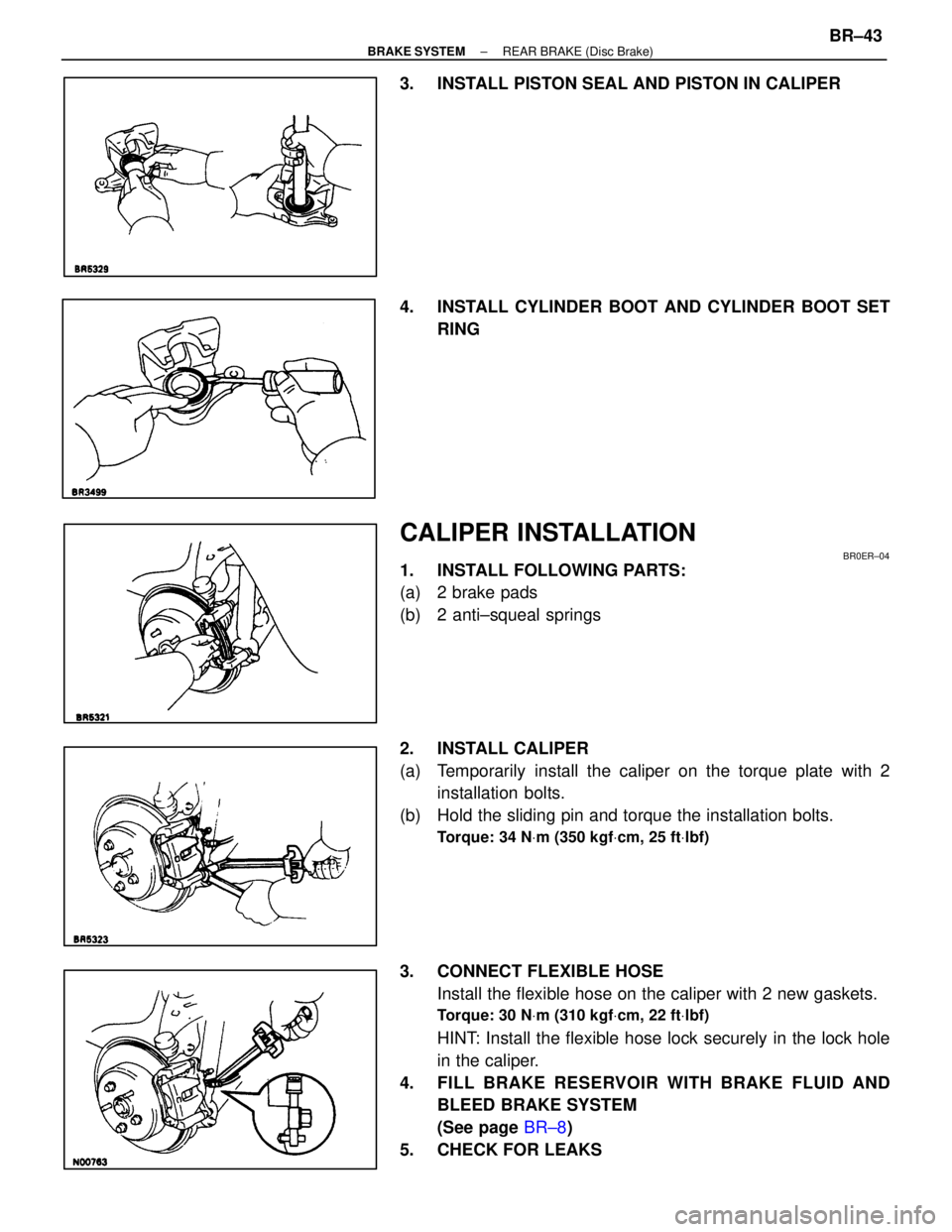

3. INSTALL PISTON SEAL AND PISTON IN CALIPER

4. INSTALL CYLINDER BOOT AND CYLINDER BOOT SETRING

CALIPER INSTALLATION

BR0ER±04

1. INSTALL FOLLOWING PARTS:

(a) 2 brake pads

(b) 2 anti±squeal springs

2. INSTALL CALIPER

(a) Temporarily install the caliper on the torque plate with 2installation bolts.

(b) Hold the sliding pin and torque the installation bolts.

Torque: 34 N Vm (350 kgf Vcm, 25 ft Vlbf)

3. CONNECT FLEXIBLE HOSE

Install the flexible hose on the caliper with 2 new gaskets.

Torque: 30 N Vm (310 kgf Vcm, 22 ft Vlbf)

HINT: Install the flexible hose lock securely in the lock hole

in the caliper.

4. FILL BRAKE R ESERVOIR WITH BRAKE FLUID AND

BLEED BRAKE SYSTEM

(See page BR±8)

5. CHECK FOR LEAKS

±

BRAKE SYSTEM REAR BRAKE (Disc Brake)BR±43

WhereEverybodyKnowsYourName

Page 1415 of 4087

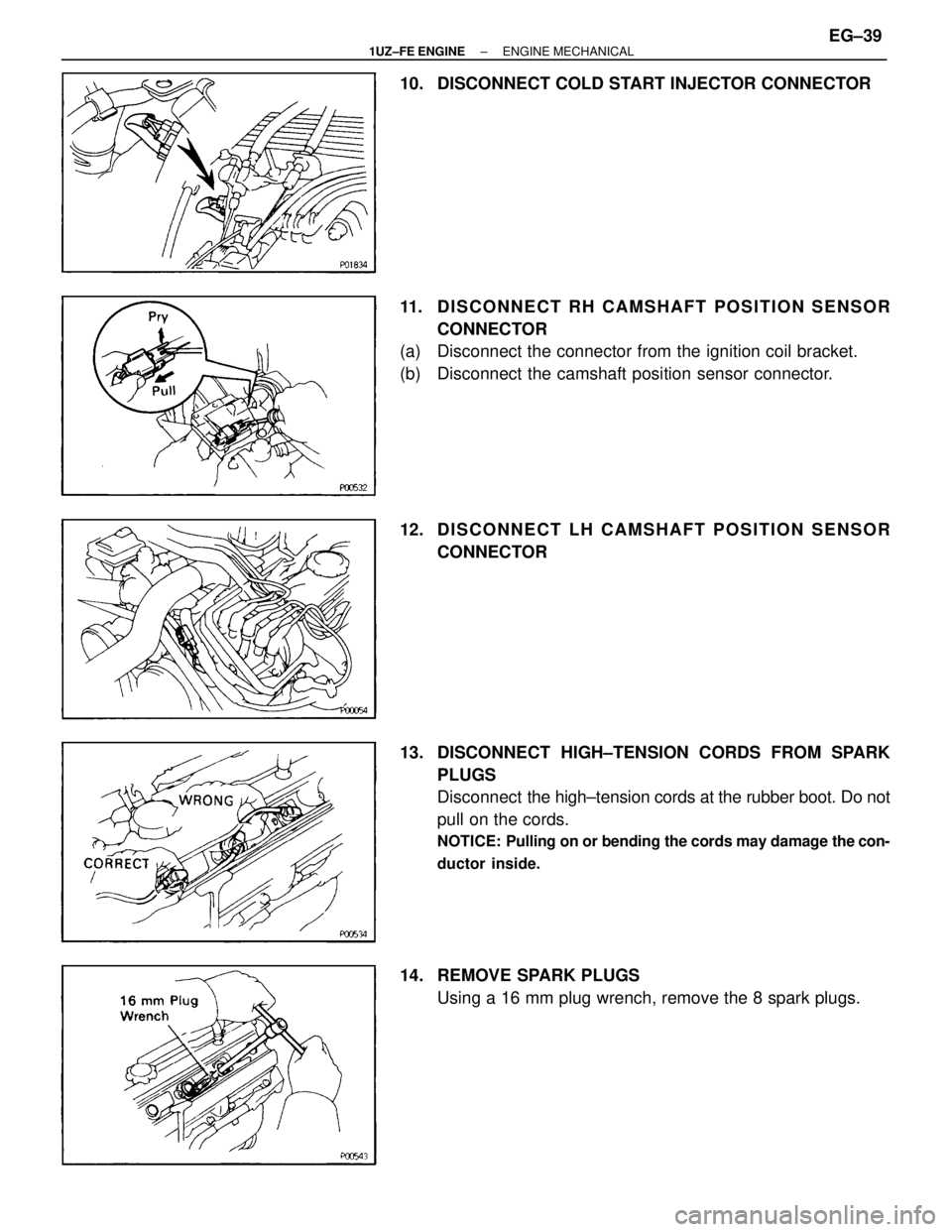

10. DISCONNECT COLD START INJECTOR CONNECTOR

11. DISCONNECT RH CAMSHAFT POSITION SENSORCONNECTOR

(a) Disconnect the connector from the ignition coil bracket.

(b) Disconnect the camshaft position sensor connector.

12. D I S C O N N E C T L H C A M S H A F T P O S I T I O N S E N S O R

CONNECTOR

13. DISCONNECT HIGH±TENSION CORDS FROM SPARK PLUGS

Disconnect the high±tension cords at the rubber boot. Do not

pull on the cords.

NOTICE: Pulling on or bending the cords may damage the con-

ductor inside.

14. REMOVE SPARK PLUGS Using a 16 mm plug wrench, remove the 8 spark plugs.

±

1UZ±FE ENGINE ENGINE MECHANICALEG±39

WhereEverybodyKnowsYourName

Page 1430 of 4087

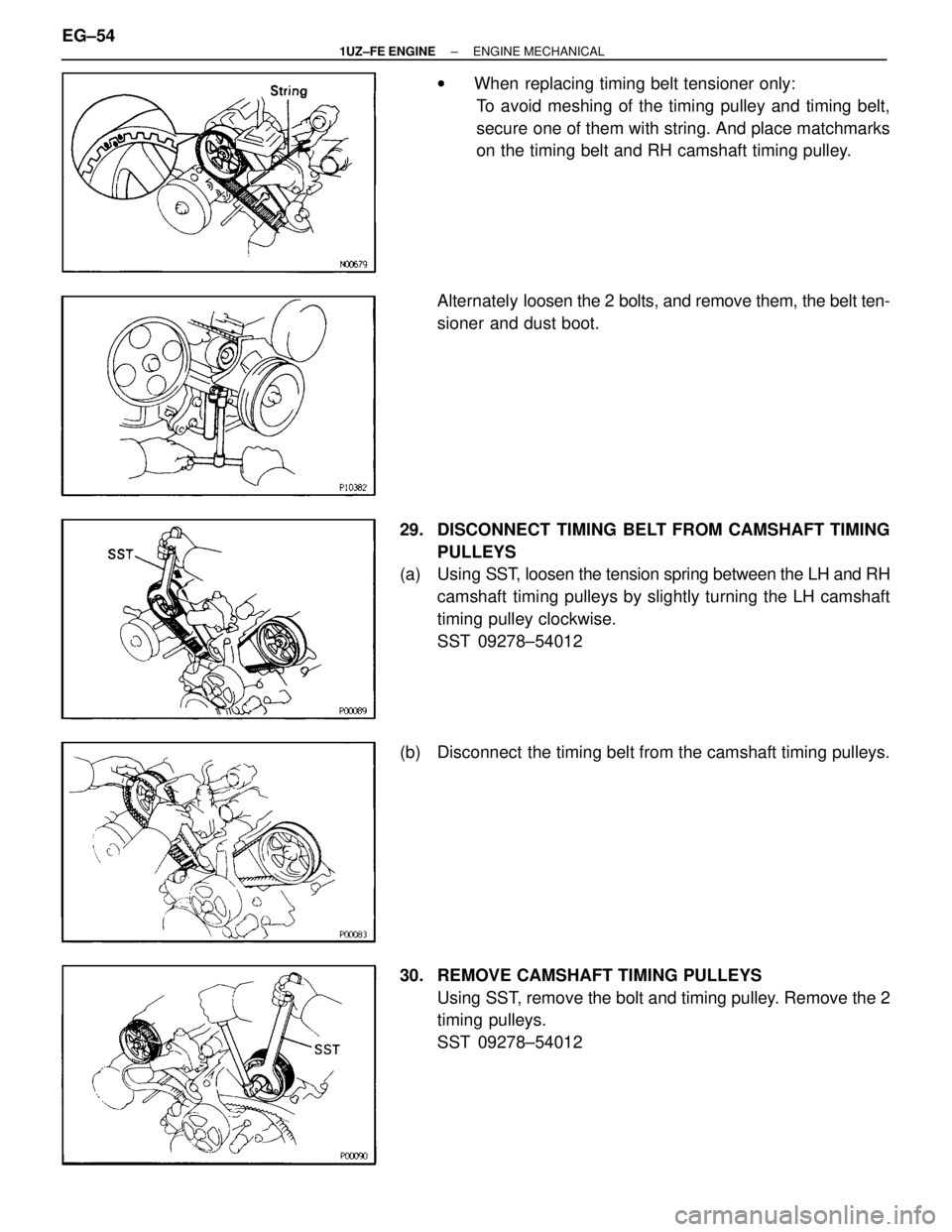

wWhen replacing timing belt tensioner only:

To avoid meshing of the timing pulley and timing belt,

secure one of them with string. And place matchmarks

on the timing belt and RH camshaft timing pulley.

Alternately loosen the 2 bolts, and remove them, the belt ten-

sioner and dust boot.

29. DISCONNECT TIMING BELT FROM CAMSHAFT TIMING PULLEYS

(a) Using SST, loosen the tension spring between the LH and RH

camshaft timing pulleys by slightly turning the LH camshaft

timing pulley clockwise.

SST 09278±54012

(b) Disconnect the timing belt from the camshaft timing pulleys.

30. REMOVE CAMSHAFT TIMING PULLEYS Using SST, remove the bolt and timing pulley. Remove the 2

timing pulleys.

SST 09278±54012

EG±54

±

1UZ±FE ENGINE ENGINE MECHANICAL

WhereEverybodyKnowsYourName

Page 1439 of 4087

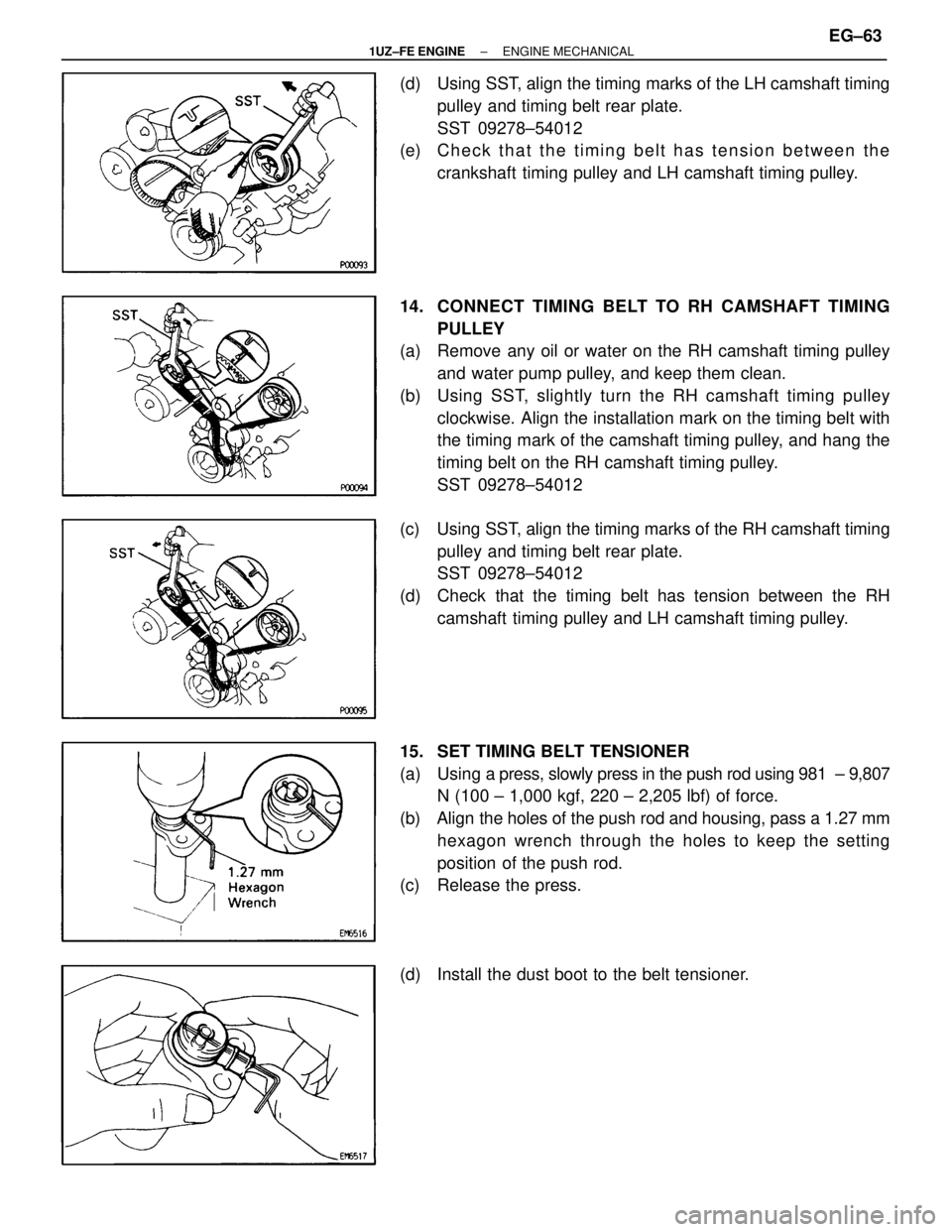

(d) Using SST, align the timing marks of the LH camshaft timingpulley and timing belt rear plate.

SST 09278±54012

(e) C h e c k t h a t t h e t i m i n g b e l t h a s t e n s i o n b e t w e e n t h e

crankshaft timing pulley and LH camshaft timing pulley.

14. CONNECT TIMING BELT TO RH CAMSHAFT TIMING PULLEY

(a) Remove any oil or water on the RH camshaft timing pulley

and water pump pulley, and keep them clean.

(b) Using SST, slightly turn the RH camshaft timing pulley clockwise. Align the installation mark on the timing belt with

the timing mark of the camshaft timing pulley, and hang the

timing belt on the RH camshaft timing pulley.

SST 09278±54012

(c) Using SST, align the timing marks of the RH camshaft timing pulley and timing belt rear plate.

SST 09278±54012

(d) Check that the timing belt has tension between the RH camshaft timing pulley and LH camshaft timing pulley.

15. SET TIMING BELT TENSIONER

(a) Using a press, slowly press in the push rod using 981 ± 9,807

N (100 ± 1,000 kgf, 220 ± 2,205 lbf) of force.

(b) Align the holes of the push rod and housing, pass a 1.27 mm hexagon wrench through the holes to keep the setting

position of the push rod.

(c) Release the press.

(d) Install the dust boot to the belt tensioner.

±

1UZ±FE ENGINE ENGINE MECHANICALEG±63

WhereEverybodyKnowsYourName

Page 1658 of 4087

6. REMOVE THROTTLE BODY WITH INTAKE AIRCONNECTOR

(a) Disconnect the following hoses and connectors:(1) PCV hose

(2) Three vacuum hoses

(3) VSV (for EGR) connector

(4) Throttle position sensor connector

(5) IAC valve connector

(6) (w/ TRAC)

Sub±throttle position sensor connector

(7) (w/ TRAC) Sub±throttle actuator connector

(8) (USA spec. only)

EGR gas temperature sensor connector

(b) Remove the four bolts and two nuts holding the intake air connector to the intake chamber.

(c) Remove the VSV nut.

(d) Disc onnect the two water by±pass hoses from the

throttle body. Plug the hose ends.

(e) Remove the throttle body with the intake air connector and gasket.

7. REMOVE NO. 3 TIMING BELT COVER AND CYLINDER

HEAD REAR COVER

(a) Remove the oil filler cap.

(b) Using a 5 mm hexagon wrench, remove the ten bolts,No. 3 timing belt cover and cylinder head rear cover.

8. DISCONNECT HIGH±TENSION CORDS FROM SPARK PLUGS

(a) Remove the bolt holding the cord clamp from thecylinder head.

(b) Disconnect the two high±tension cord clamps from the No. 3 cylinder head cover.

(c) Disconnect the high±tension cords at the rubber boot. Do not pull on the cords.

NOTICE: Pulling on or bending the cords may damage

the conductor inside.

±

ENGINE MECHANICAL Engine Tune±UpEM±11

WhereEverybodyKnowsYourName

Page 1692 of 4087

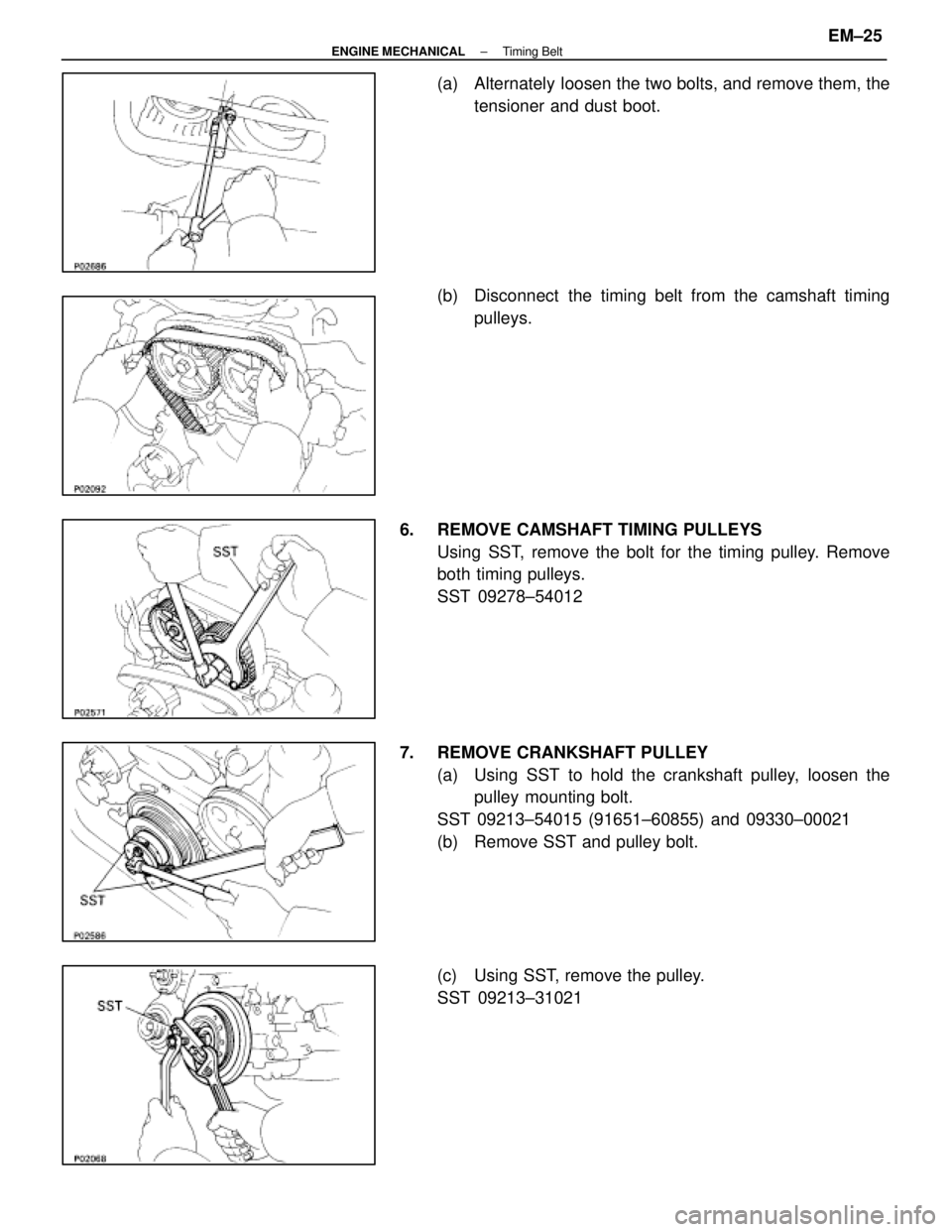

(a) Alternately loosen the two bolts, and remove them, thetensioner and dust boot.

(b) Disconnect the timing belt from the camshaft timing pulleys.

6. REMOVE CAMSHAFT TIMING PULLEYS Using SST, remove the bolt for the timing pulley. Remove

both timing pulleys.

SST 09278±54012

7. REMOVE CRANKSHAFT PULLEY (a) Using SST to hold the crankshaft pulley, loosen thepulley mounting bolt.

SST 09213±54015 (91651±60855) and 09330±00021

(b) Remove SST and pulley bolt.

(c) Using SST, remove the pulley.

SST 09213±31021

±

ENGINE MECHANICAL Timing BeltEM±25

WhereEverybodyKnowsYourName

Page 1698 of 4087

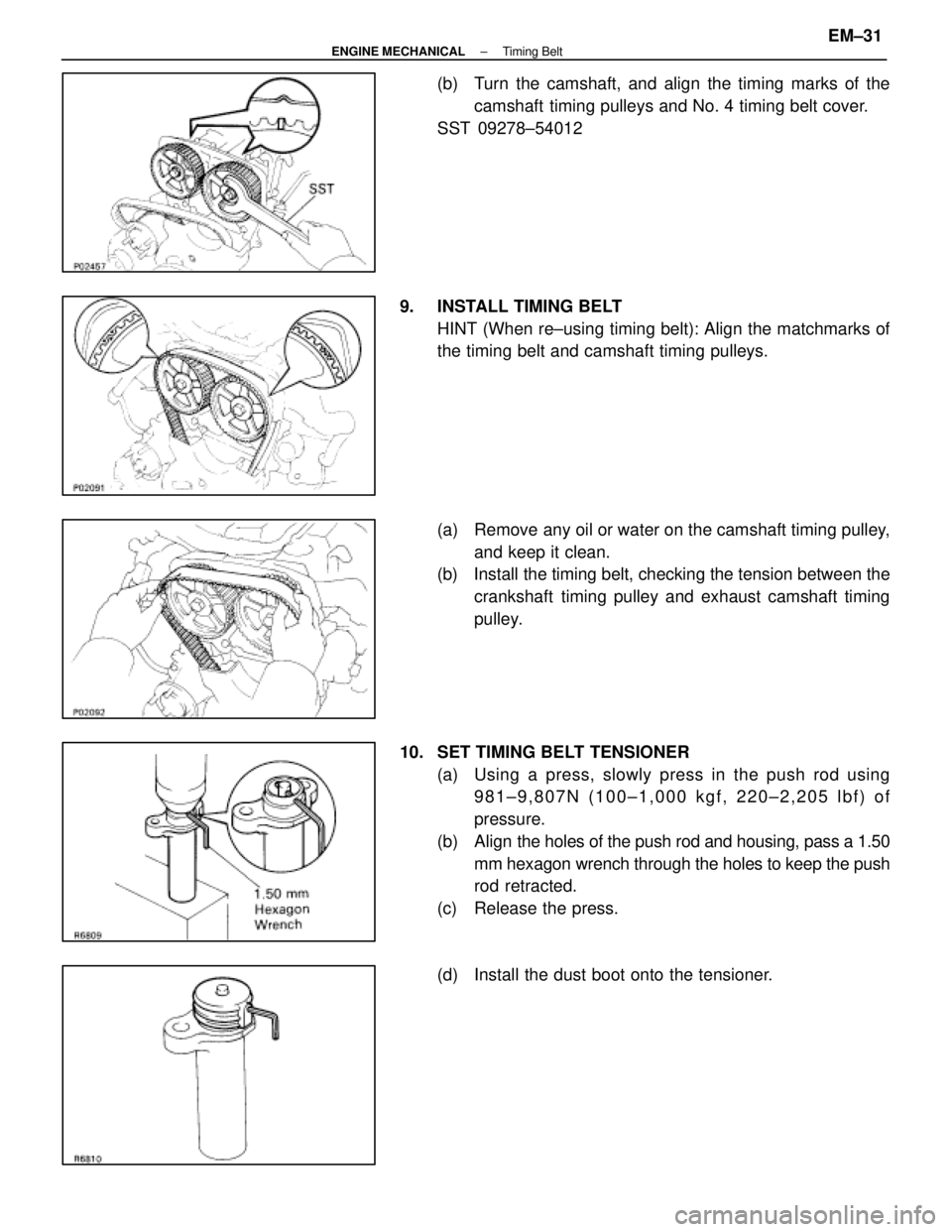

(b) Turn the camshaft, and align the timing marks of thecamshaft timing pulleys and No. 4 timing belt cover.

SST 09278±54012

9. INSTALL TIMING BELT HINT (When re±using timing belt): Align the matchmarks of

the timing belt and camshaft timing pulleys.

(a) Remove any oil or water on the camshaft timing pulley,and keep it clean.

(b) Install the timing belt, checking the tension between the

crankshaft timing pulley and exhaust camshaft timing

pulley.

10. SET TIMING BELT TENSIONER (a) Using a press, slowly press in the push rod using981±9,807N (100±1,000 kgf, 220±2,205 lbf) of

pressure.

(b) Align the holes of the push rod and housing, pass a 1.50

mm hexagon wrench through the holes to keep the push

rod retracted.

(c) Release the press.

(d) Install the dust boot onto the tensioner.

±

ENGINE MECHANICAL Timing BeltEM±31

WhereEverybodyKnowsYourName

Page 1703 of 4087

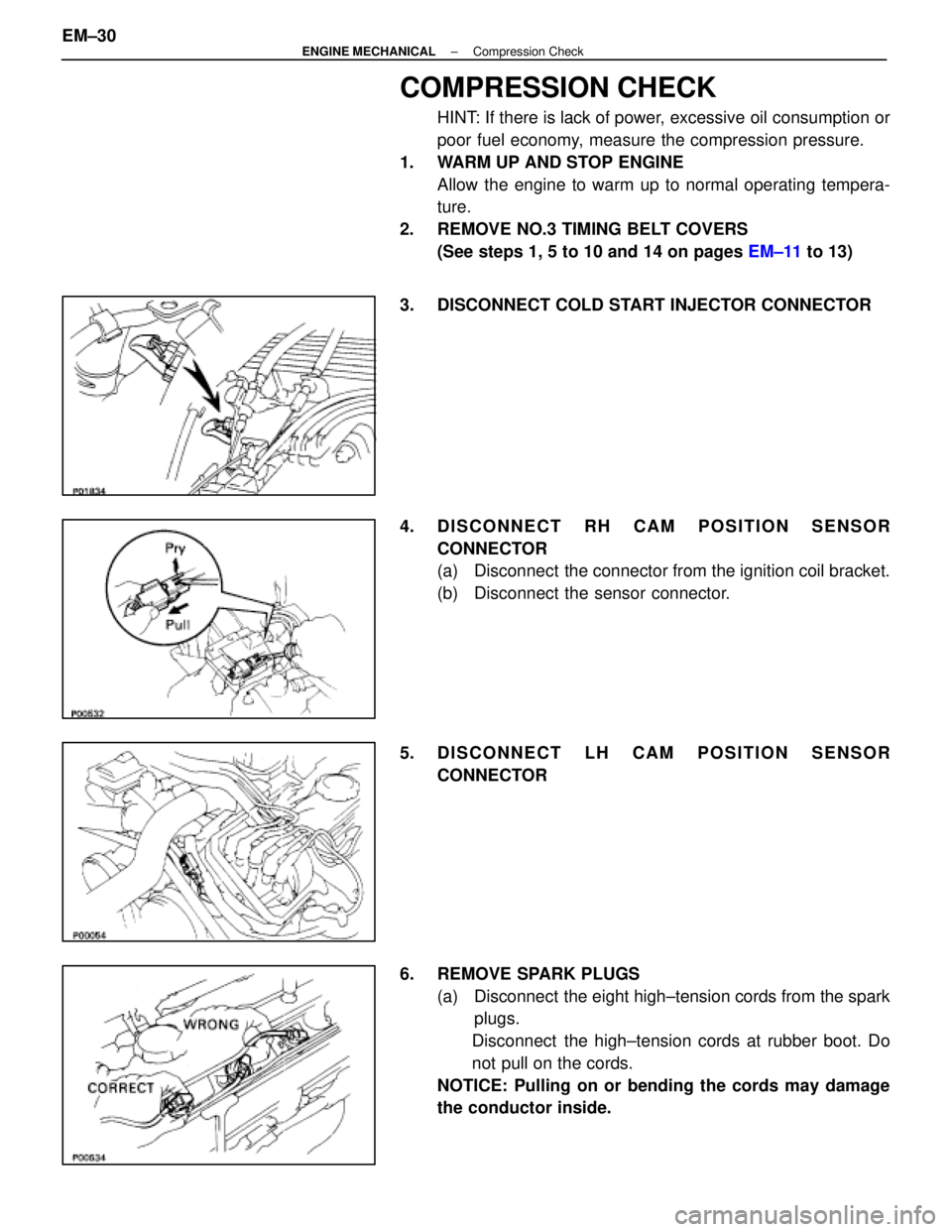

COMPRESSION CHECK

HINT: If there is lack of power, excessive oil consumption or

poor fuel economy, measure the compression pressure.

1. WARM UP AND STOP ENGINE Allow the engine to warm up to normal operating tempera-

ture.

2. REMOVE NO.3 TIMING BELT COVERS (See steps 1, 5 to 10 and 14 on pages EM±11 to 13)

3. DISCONNECT COLD START INJECTOR CONNECTOR

4. DISCONNECT RH CAM POSITION SENSOR CONNECTOR

(a) Disconnect the connector from the ignition coil bracket.

(b) Disconnect the sensor connector.

5. DISCONNECT LH CAM POSITION SENSOR CONNECTOR

6. REMOVE SPARK PLUGS (a) Disconnect the eight high±tension cords from the sparkplugs.

Disconnect the high±tension cords at rubber boot. Do

not pull on the cords.

NOTICE: Pulling on or bending the cords may damage

the conductor inside.

EM±30

±

ENGINE MECHANICAL Compression Check

WhereEverybodyKnowsYourName

Page 1714 of 4087

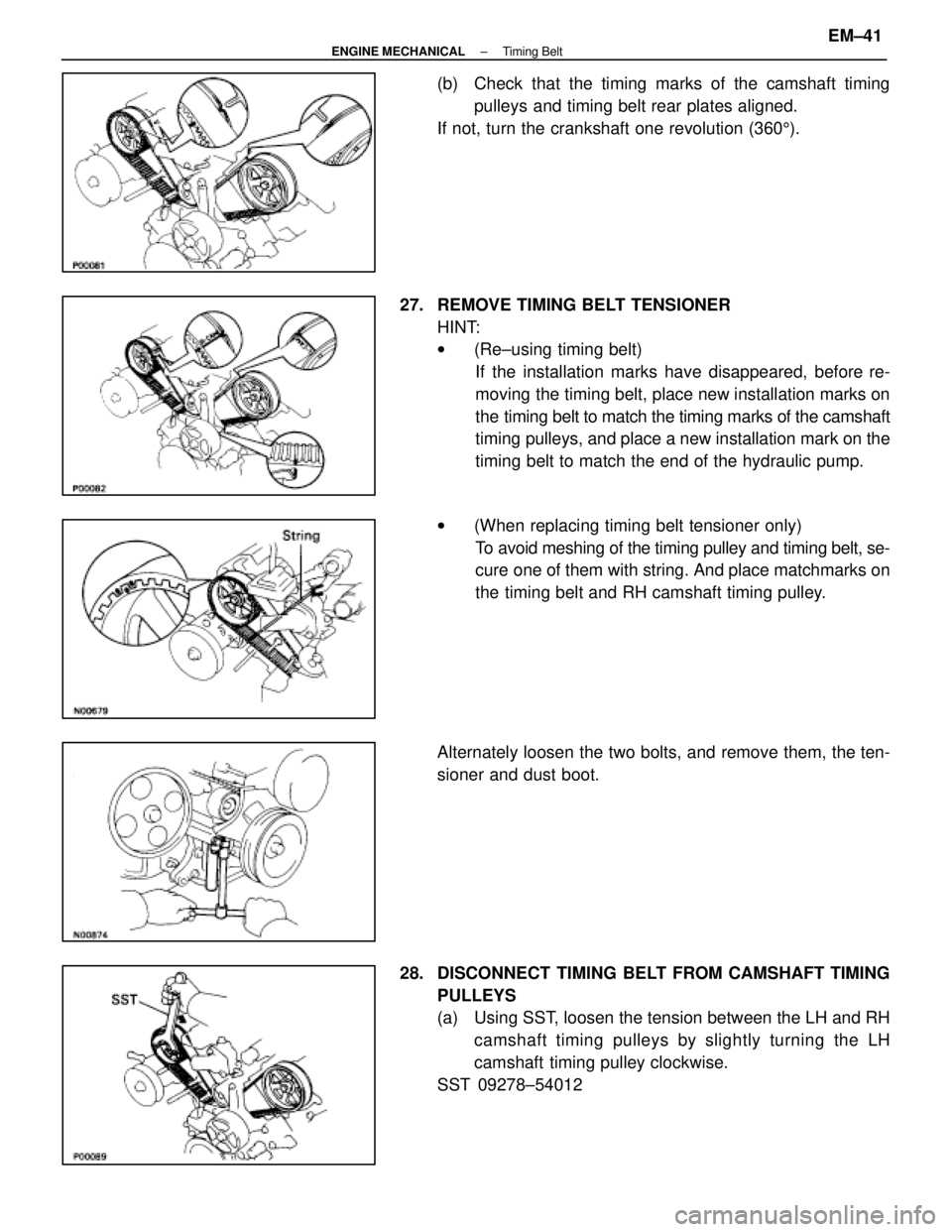

(b) Check that the timing marks of the camshaft timingpulleys and timing belt rear plates aligned.

If not, turn the crankshaft one revolution (360 5).

27. REMOVE TIMING BELT TENSIONER HINT:

w(Re±using timing belt)

If the installation marks have disappeared, before re-

moving the timing belt, place new installation marks on

the timing belt to match the timing marks of the camshaft

timing pulleys, and place a new installation mark on the

timing belt to match the end of the hydraulic pump.

w (When replacing timing belt tensioner only)

To avoid meshing of the timing pulley and timing belt, se-

cure one of them with string. And place matchmarks on

the timing belt and RH camshaft timing pulley.

Alternately loosen the two bolts, and remove them, the ten-

sioner and dust boot.

28. DISCONNECT TIMING BELT FROM CAMSHAFT TIMING PULLEYS

(a) Using SST, loosen the tension between the LH and RHcamshaft timing pulleys by slightly turning the LH

camshaft timing pulley clockwise.

SST 09278±54012

±

ENGINE MECHANICAL Timing BeltEM±41

WhereEverybodyKnowsYourName