check engine light LEXUS SC400 1991 Service User Guide

[x] Cancel search | Manufacturer: LEXUS, Model Year: 1991, Model line: SC400, Model: LEXUS SC400 1991Pages: 4087, PDF Size: 75.75 MB

Page 537 of 4087

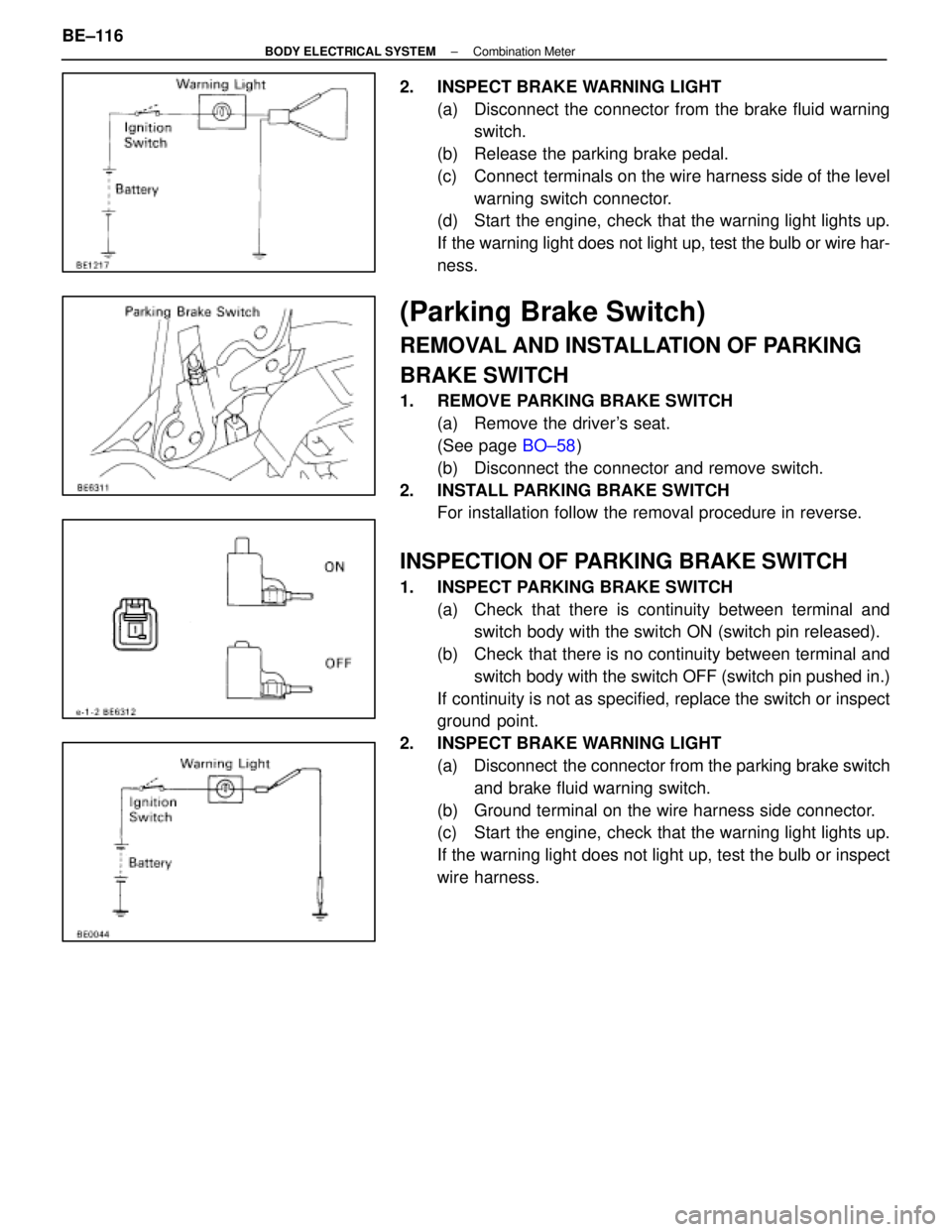

2. INSPECT BRAKE WARNING LIGHT(a) Disconnect the connector from the brake fluid warningswitch.

(b) Release the parking brake pedal.

(c) Connect terminals on the wire harness side of the level warning switch connector.

(d) Start the engine, check that the warning light lights up.

If the warning light does not light up, test the bulb or wire har-

ness.

(Parking Brake Switch)

REMOVAL AND INSTALLATION OF PARKING

BRAKE SWITCH

1. REMOVE PARKING BRAKE SWITCH

(a) Remove the driver's seat.

(See page BO±58)

(b) Disconnect the connector and remove switch.

2. INSTALL PARKING BRAKE SWITCH For installation follow the removal procedure in reverse.

INSPECTION OF PARKING BRAKE SWITCH

1. INSPECT PARKING BRAKE SWITCH

(a) Check that there is continuity between terminal andswitch body with the switch ON (switch pin released).

(b) Check that there is no continuity between terminal and switch body with the switch OFF (switch pin pushed in.)

If continuity is not as specified, replace the switch or inspect

ground point.

2. INSPECT BRAKE WARNING LIGHT (a) Disconnect the connector from the parking brake switchand brake fluid warning switch.

(b) Ground terminal on the wire harness side connector.

(c) Start the engine, check that the warning light lights up.

If the warning light does not light up, test the bulb or inspect

wire harness.

BE±116

±

BODY ELECTRICAL SYSTEM Combination Meter

WhereEverybodyKnowsYourName

Page 538 of 4087

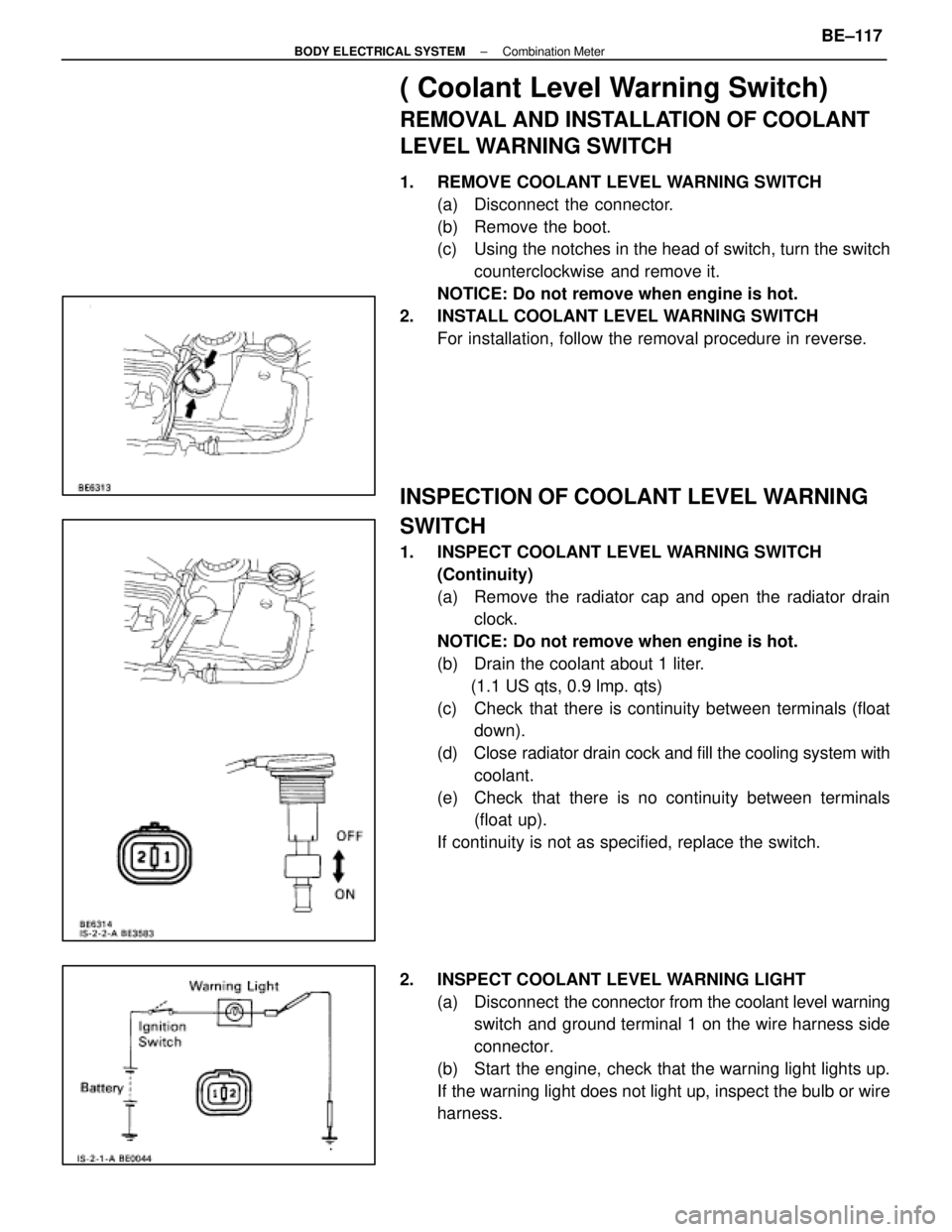

( Coolant Level Warning Switch)

REMOVAL AND INSTALLATION OF COOLANT

LEVEL WARNING SWITCH

1. REMOVE COOLANT LEVEL WARNING SWITCH(a) Disconnect the connector.

(b) Remove the boot.

(c) Using the notches in the head of switch, turn the switchcounterclockwise and remove it.

NOTICE: Do not remove when engine is hot.

2. INSTALL COOLANT LEVEL WARNING SWITCH For installation, follow the removal procedure in reverse.

INSPECTION OF COOLANT LEVEL WARNING

SWITCH

1. INSPECT COOLANT LEVEL WARNING SWITCH(Continuity)

(a) Remove the radiator cap and open the radiator drainclock.

NOTICE: Do not remove when engine is hot.

(b) Drain the coolant about 1 liter. (1.1 US qts, 0.9 lmp. qts)

(c) Check that there is continuity between terminals (float down).

(d) Close radiator drain cock and fill the cooling system with

coolant.

(e) Check that there is no continuity between terminals (float up).

If continuity is not as specified, replace the switch.

2. INSPECT COOLANT LEVEL WARNING LIGHT (a) Disconnect the connector from the coolant level warning

switch and ground terminal 1 on the wire harness side

connector.

(b) Start the engine, check that the warning light lights up.

If the warning light does not light up, inspect the bulb or wire

harness.

±

BODY ELECTRICAL SYSTEM Combination MeterBE±117

WhereEverybodyKnowsYourName

Page 816 of 4087

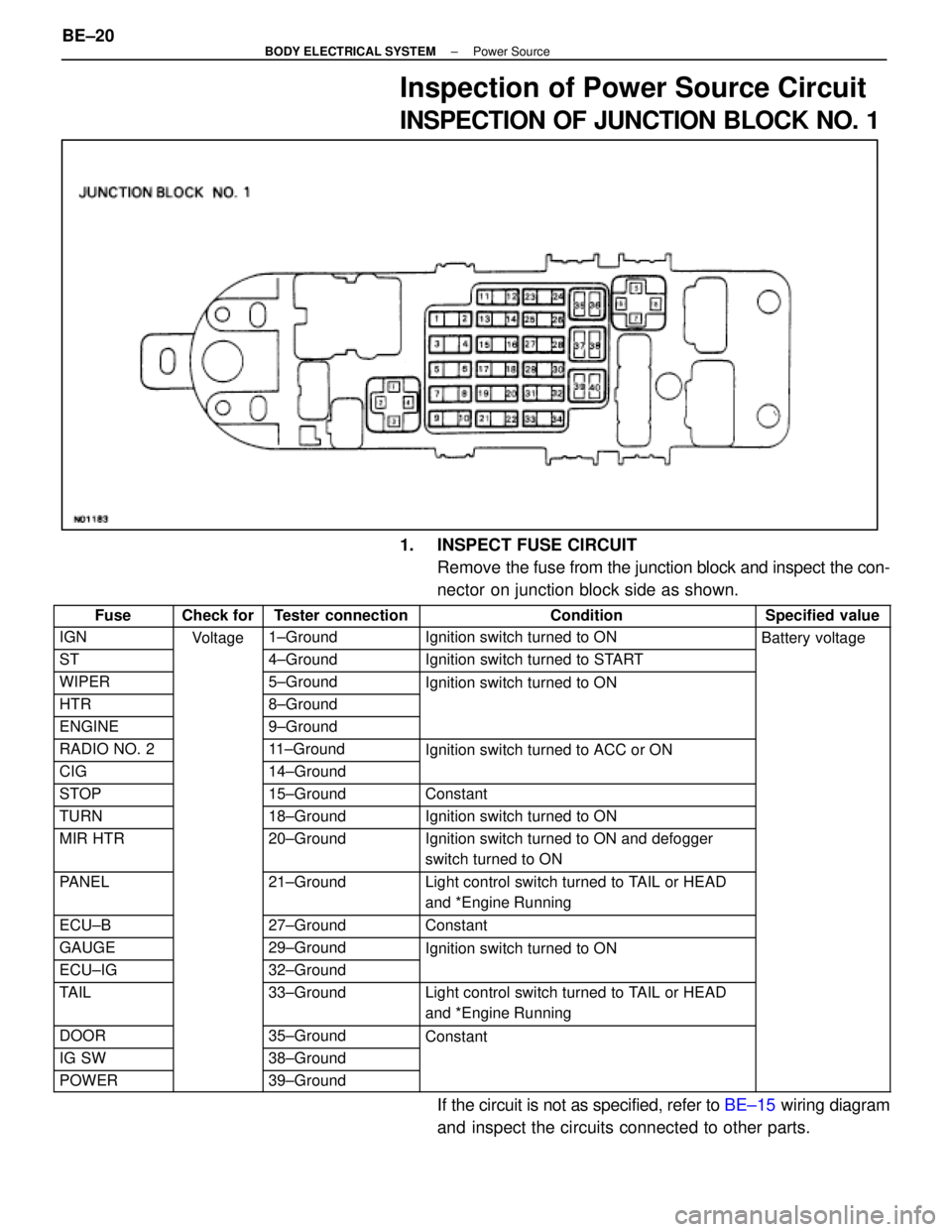

Inspection of Power Source Circuit

INSPECTION OF JUNCTION BLOCK NO. 1

1. INSPECT FUSE CIRCUITRemove the fuse from the junction block and inspect the con-

nector on junction block side as shown.

FuseCheck forTester connectionConditionSpecified value

IGNVoltage1±GroundIgnition switch turned to ONBattery voltage

ST

g

4±GroundIgnition switch turned to START

yg

WIPER5±GroundIgnition switch turned to ON

HTR8±Ground

g

ENGINE9±Ground

RADIO NO. 211±GroundIgnition switch turned to ACC or ON

CIG14±Ground

g

STOP15±GroundConstant

TURN18±GroundIgnition switch turned to ON

MIR HTR20±GroundIgnition switch turned to ON and defogger

switch turned to ON

PANEL21±GroundLight control switch turned to TAIL or HEAD

and *Engine Running

ECU±B27±GroundConstant

GAUGE29±GroundIgnition switch turned to ON

ECU±IG32±Ground

g

TAIL33±GroundLight control switch turned to TAIL or HEAD

and *Engine Running

DOOR35±GroundConstant

IG SW38±Ground

POWER39±Ground

If the circuit is not as specified, refer to BE±15 wiring diagram

and inspect the circuits connected to other parts.

BE±20

±

BODY ELECTRICAL SYSTEM Power Source

WhereEverybodyKnowsYourName

Page 818 of 4087

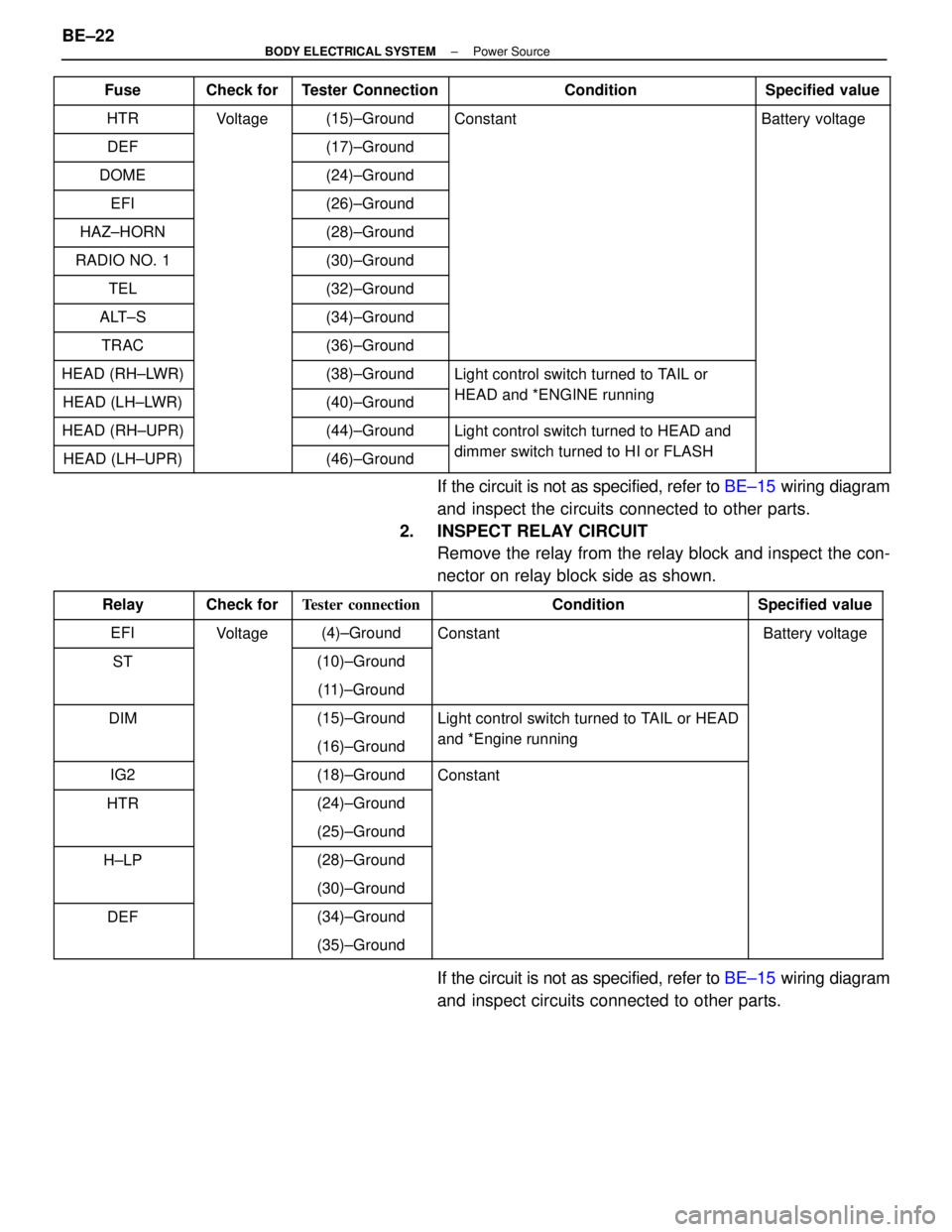

FuseCheck forTester ConnectionConditionSpecified value

HTRVoltage(15)±GroundConstantBattery voltage

DEF(17)±Ground

DOME(24)±Ground

EFI(26)±Ground

HAZ±HORN(28)±Ground

RADIO NO. 1(30)±Ground

TEL(32)±Ground

ALT±S(34)±Ground

TRAC(36)±Ground

HEAD (RH±LWR)(38)±GroundLight control switch turned to TAIL or

HEAD (LH±LWR)(40)±GroundHEAD and *ENGINE running

HEAD (RH±UPR)(44)±GroundLight control switch turned to HEAD and

HEAD (LH±UPR)(46)±Grounddimmer switch turned to HI or FLASH

If the circuit is not as specified, refer to BE±15 wiring diagram

and inspect the circuits connected to other parts.

2. INSPECT RELAY CIRCUIT Remove the relay from the relay block and inspect the con-

nector on relay block side as shown.

RelayCheck forTester connectionConditionSpecified value

EFIVoltage(4)±GroundConstantBattery voltage

ST(10)±Ground

(11)±Ground

DIM(15)±GroundLight control switch turned to TAIL or HEAD

(16)±Groundand *Engine running

IG2(18)±GroundConstant

HTR(24)±Ground

(25)±Ground

H±LP(28)±Ground

(30)±Ground

DEF(34)±Ground

(35)±Ground

If the circuit is not as specified, refer to BE±15 wiring diagram

and inspect circuits connected to other parts.

BE±22

±

BODY ELECTRICAL SYSTEM Power Source

WhereEverybodyKnowsYourName

Page 846 of 4087

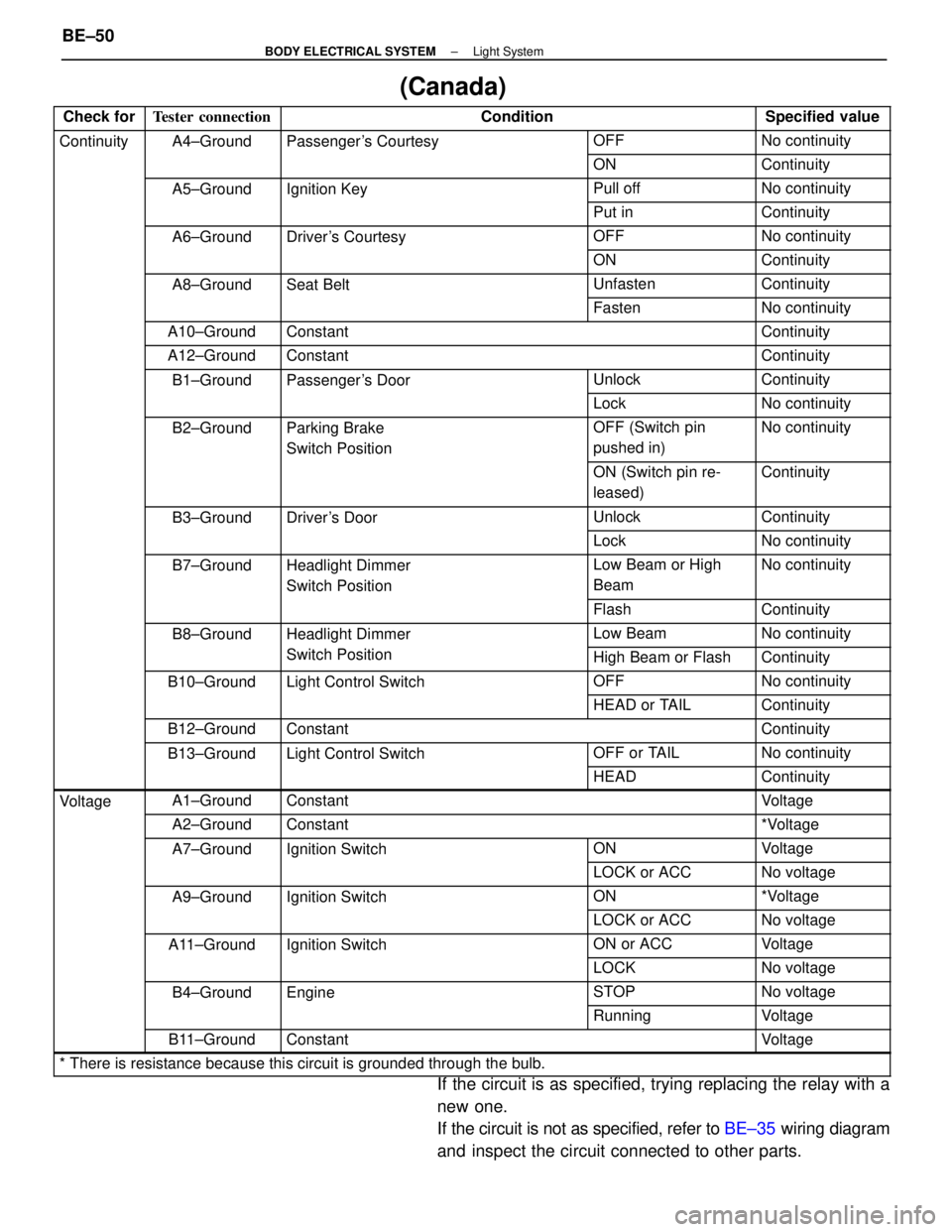

(Canada)

Check forTester connectionConditionSpecified value

ContinuityA4±GroundPassenger's CourtesyOFFNo continuityygy

ONContinuity

A5±GroundIgnition KeyPull offNo continuitygy

Put inContinuity

A6±GroundDriver's CourtesyOFFNo continuityy

ONContinuity

A8±GroundSeat BeltUnfastenContinuity

FastenNo continuity

A10±GroundConstantContinuity

A12±GroundConstantContinuity

B1±GroundPassenger's DoorUnlockContinuityg

LockNo continuity

B2±GroundParking Brake

Switch PositionOFF (Switch pin

pushed in)No continuity

ON (Switch pin re-

leased)Continuity

B3±GroundDriver's DoorUnlockContinuity

LockNo continuity

B7±GroundHeadlight Dimmer

Switch PositionLow Beam or High

BeamNo continuity

FlashContinuity

B8±GroundHeadlight DimmerLow BeamNo continuityg

Switch PositionHigh Beam or FlashContinuity

B10±GroundLight Control SwitchOFFNo continuityg

HEAD or TAILContinuity

B12±GroundConstantContinuity

B13±GroundLight Control SwitchOFF or TAILNo continuityg

HEADContinuity

VoltageA1±GroundConstantVoltageg

A2±GroundConstant*Voltage

A7±GroundIgnition SwitchONVoltageg

LOCK or ACCNo voltage

A9±GroundIgnition SwitchON*Voltageg

LOCK or ACCNo voltage

A11±GroundIgnition SwitchON or ACCVoltageg

LOCKNo voltage

B4±GroundEngineSTOPNo voltageg

RunningVoltage

B11±GroundConstantVoltage

* There is resistance because this circuit is grounded through the bulb.\

If the circuit is as specified, trying replacing the relay with a

new one.

If the circuit is not as specified, refer to BE±35 wiring diagram

and inspect the circuit connected to other parts.

BE±50

±

BODY ELECTRICAL SYSTEM Light System

WhereEverybodyKnowsYourName

Page 857 of 4087

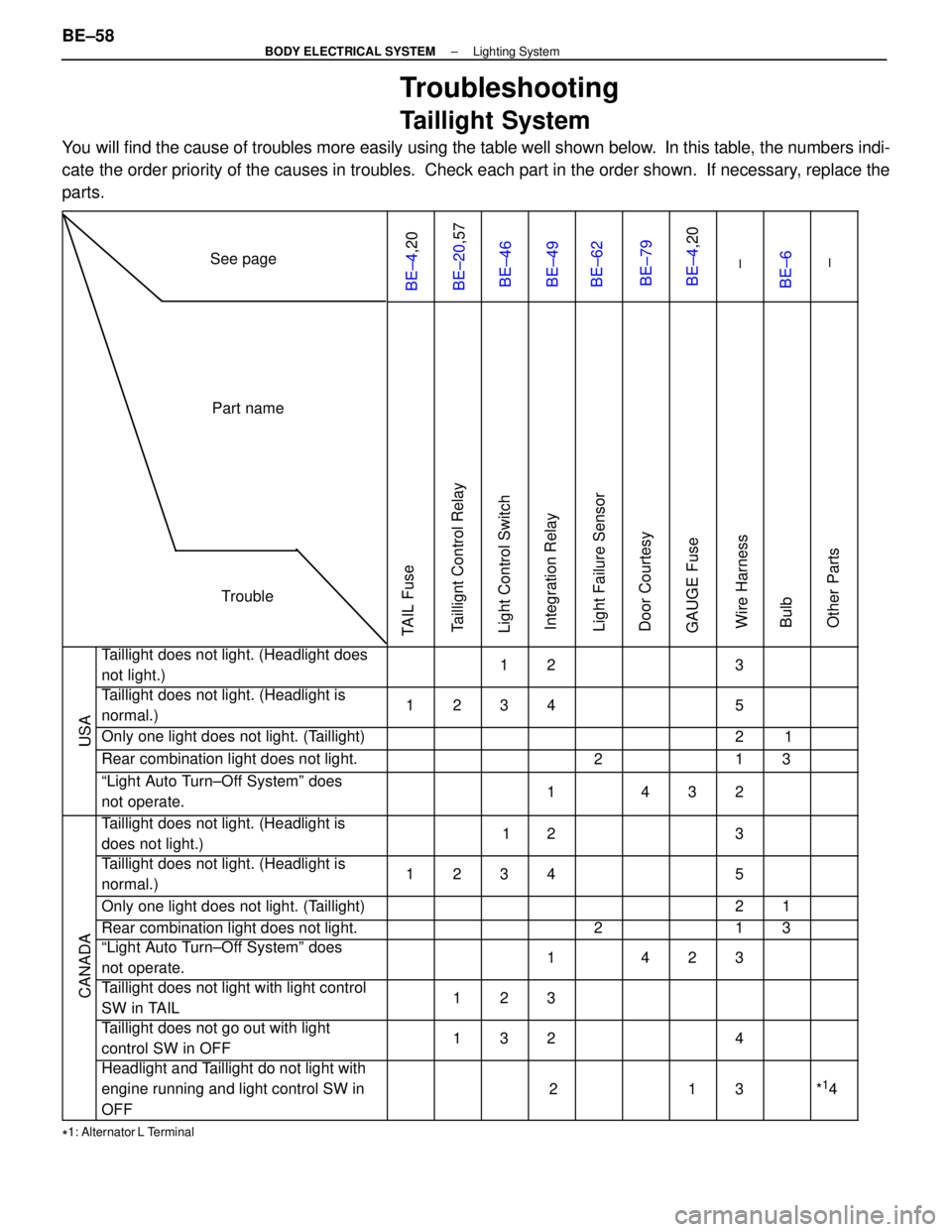

Troubleshooting

Taillight System

You will find the cause of troubles more easily using the table well shown \

below. In this table, the numbers indi-

cate the order priority of the causes in troubles. Check each part in the o\

rder shown. If necessary, replace the

parts.

See page

BE±4,20BE±20 ,57BE±46BE±49BE±62BE±79BE±4,20

±

BE±6

±

Trouble

Part name

TAIL FuseTaillignt Control RelayLight Control SwitchIntegration RelayLight Failure SensorDoor CourtesyGAUGE FuseWire HarnessBulbOther Parts

Taillight does not light. (Headlight does

not light.) 12 3

SA

Taillight does not light. (Headlight is

normal.)12345

US

A

Only one light does not light. (Taillight) 2 1 U

Rear combination light does not light. 213

ªLight Auto Turn±Off Systemº does

not operate. 1432

Taillight does not light. (Headlight is

does not light.) 123

Taillight does not light. (Headlight is

normal.)12345

Only one light does not light. (Taillight) 21

ARear combination light does not light. 213

ANADA

ªLight Auto Turn±Off Systemº does

not operate. 1423

CA

N

Taillight does not light with light control

SW in TAIL123

Taillight does not go out with light

control SW in OFF1324

Headlight and Taillight do not light with

engine running and light control SW in

OFF

213*14

*1:

Alternator

L

Terminal

BE±58±

BODY ELECTRICAL SYSTEM Lighting System

WhereEverybodyKnowsYourName

Page 907 of 4087

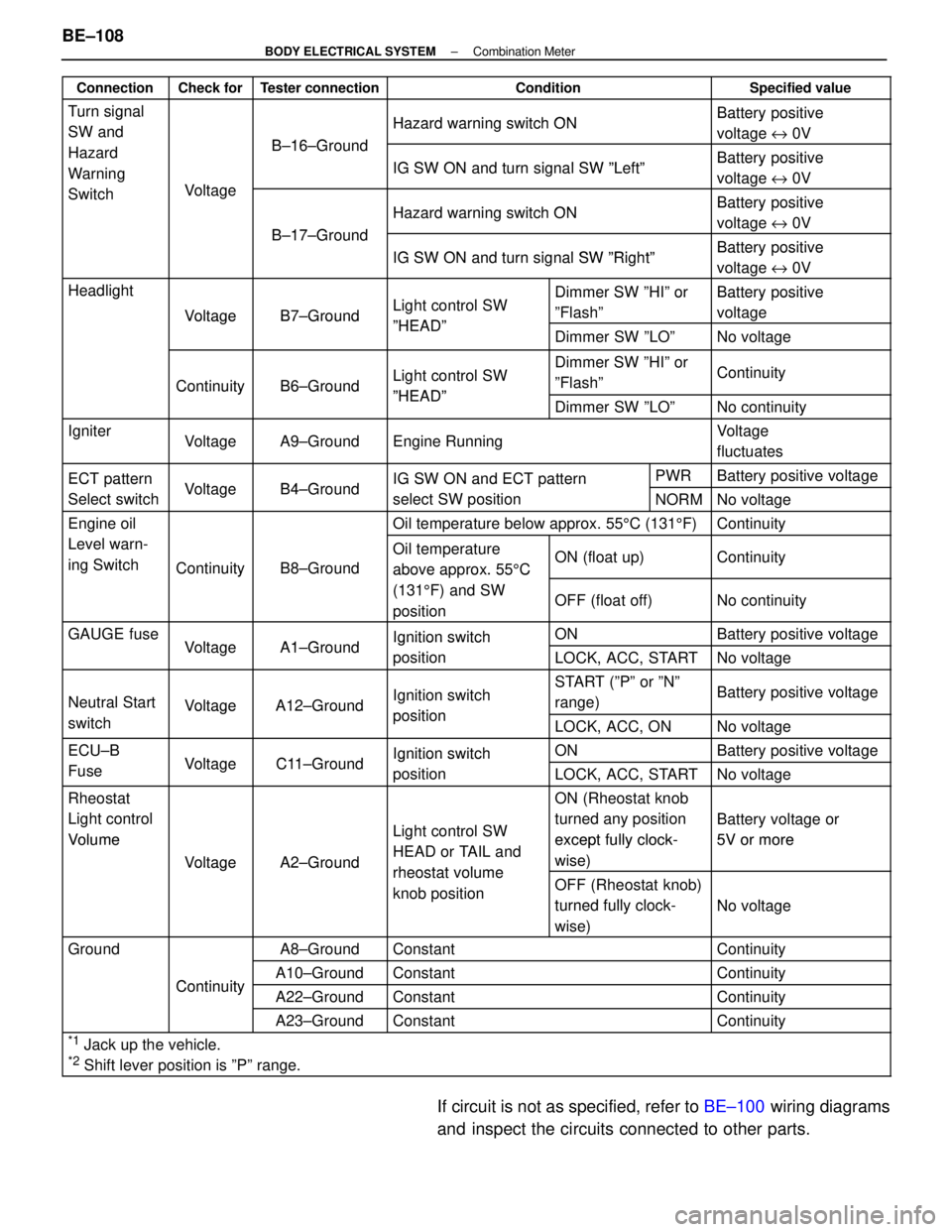

ConnectionCheck forTester connectionConditionSpecified value

Turn signalHazard warning switch ONBattery positiveTurn signal

SW andB 16 Ground

Hazard warning switch ONBattery ositive

voltage e 0V

HazardB±16±Ground

IG SW ON and turn signal SW ºLeftºBattery positive

Warning

Si hVoltage

IG SW ON and turn signal SW ºLeftºBattery ositive

voltage e 0V

SwitchVoltage

Hazard warning switch ONBattery positive

B 17 Ground

Hazard warning switch ONBattery ositive

voltage e 0VB±17±Ground

IG SW ON and turn signal SW ºRightºBattery positiveIG SW ON and turn signal SW ºRightºBattery ositive

voltage e 0V

HeadlightLi ht t l SWDimmer SW ºHIº orBattery positiveHeadlight

VoltageB7±GroundLight control SW

ºHEADº

Dimmer SW HI or

ºFlashº

Battery ositive

voltageVoltageB7±GroundºHEADºDimmer SW ºLOºNo voltage

ContinuityB6±GroundLight control SW

º

HEADº

Dimmer SW ºHIº or

ºFlashºContinuityContinuityB6 GroundºHEADºDimmer SW ºLOºNo continuity

IgniterVoltageA9±GroundEngine RunningVoltage

fluctuates

ECT patternVoltageB4 GroundIG SW ON and ECT patternPWRBattery positive voltageECT attern

Select switchVoltageB4±GroundIG SW ON and ECT attern

select SW positionNORMNo voltage

Engine oilOil temperature below approx. 55 5C (131 5F)Continuityg

Level warn-

ing Switch

ContinuityB8±Ground

Oil temperature

above approx. 55 5CON (float up)ContinuitygContinuityB8 Groundabove a rox. 55 C

(131 5F) and SW

positionOFF (float off)No continuity

GAUGE fuseVoltageA1 GroundIgnition switchONBattery positive voltageVoltageA1±GroundIgnition switch

positionLOCK, ACC, STARTNo voltage

Neutral StartVoltageA12±GroundIgnition switch

position

START (ºPº or ºNº

range)Battery positive voltage

switch

VoltageA12 GroundpositionLOCK, ACC, ONNo voltage

ECU±BVoltageC11 GroundIgnition switchONBattery positive voltage

FuseVoltageC11±GroundIgnition switch

positionLOCK, ACC, STARTNo voltage

Rheostat

Li ht t l

ON (Rheostat knob

t d itiBtt ltLight control

VolumeLight control SWturned any position

except fully clock-

Battery voltage or

5V or moreVolume

VoltageA2±Ground

g

HEAD or TAIL and

rheostat volume

except fully clock-

wise)5V or more

VoltageA2 Groundrheostat volume

knob positionOFF (Rheostat knob)

turned fully clockNo voltageknob ositionturned fully clock-

wise)No voltage

GroundA8±GroundConstantContinuity

ContinuityA10±GroundConstantContinuityContinuityA22±GroundConstantContinuity

A23±GroundConstantContinuity

*1 Jack up the vehicle.*2 Shift lever position is ºPº range.

If circuit is not as specified, refer to BE±100 wiring diagrams

and inspect the circuits connected to other parts.

BE±108

±

BODY ELECTRICAL SYSTEM Combination Meter

WhereEverybodyKnowsYourName

Page 984 of 4087

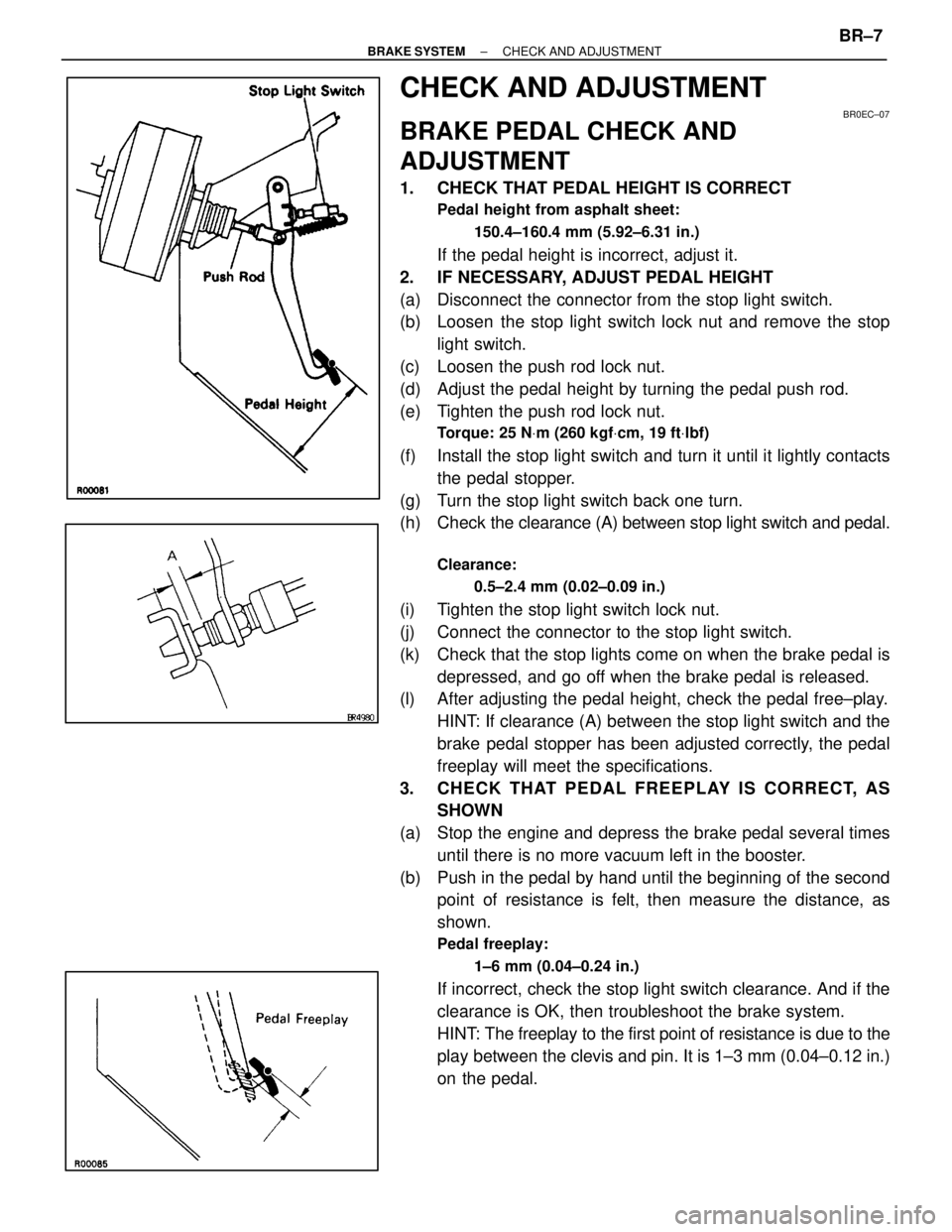

CHECK AND ADJUSTMENT

BR0EC±07

BRAKE PEDAL CHECK AND

ADJUSTMENT

1. CHECK THAT PEDAL HEIGHT IS CORRECT

Pedal height from asphalt sheet:150.4±160.4 mm (5.92±6.31 in.)

If the pedal height is incorrect, adjust it.

2. IF NECESSARY, ADJUST PEDAL HEIGHT

(a) Disconnect the connector from the stop light switch.

(b) Loosen the stop light switch lock nut and remove the stop light switch.

(c) Loosen the push rod lock nut.

(d) Adjust the pedal height by turning the pedal push rod.

(e) Tighten the push rod lock nut.

Torque: 25 N Vm (260 kgf Vcm, 19 ft Vlbf)

(f) Install the stop light switch and turn it until it lightly contacts

the pedal stopper.

(g) Turn the stop light switch back one turn.

(h) Check the clearance (A) between stop light switch and pedal.

Clearance:

0.5±2.4 mm (0.02±0.09 in.)

(i) Tighten the stop light switch lock nut.

(j) Connect the connector to the stop light switch.

(k) Check that the stop lights come on when the brake pedal isdepressed, and go off when the brake pedal is released.

(l) After adjusting the pedal height, check the pedal free±play.

HINT: If clearance (A) between the stop light switch and the

brake pedal stopper has been adjusted correctly, the pedal

freeplay will meet the specifications.

3. CHECK THAT PEDAL FREEPLAY IS CORRECT, AS SHOWN

(a) Stop the engine and depress the brake pedal several times until there is no more vacuum left in the booster.

(b) Push in the pedal by hand until the beginning of the second point of resistance is felt, then measure the distance, as

shown.

Pedal freeplay:

1±6 mm (0.04±0.24 in.)

If incorrect, check the stop light switch clearance. And if the

clearance is OK, then troubleshoot the brake system.

HINT: The freeplay to the first point of resistance is due to the

play between the clevis and pin. It is 1±3 mm (0.04±0.12 in.)

on the pedal.

±

BRAKE SYSTEM CHECK AND ADJUSTMENTBR±7

WhereEverybodyKnowsYourName

Page 985 of 4087

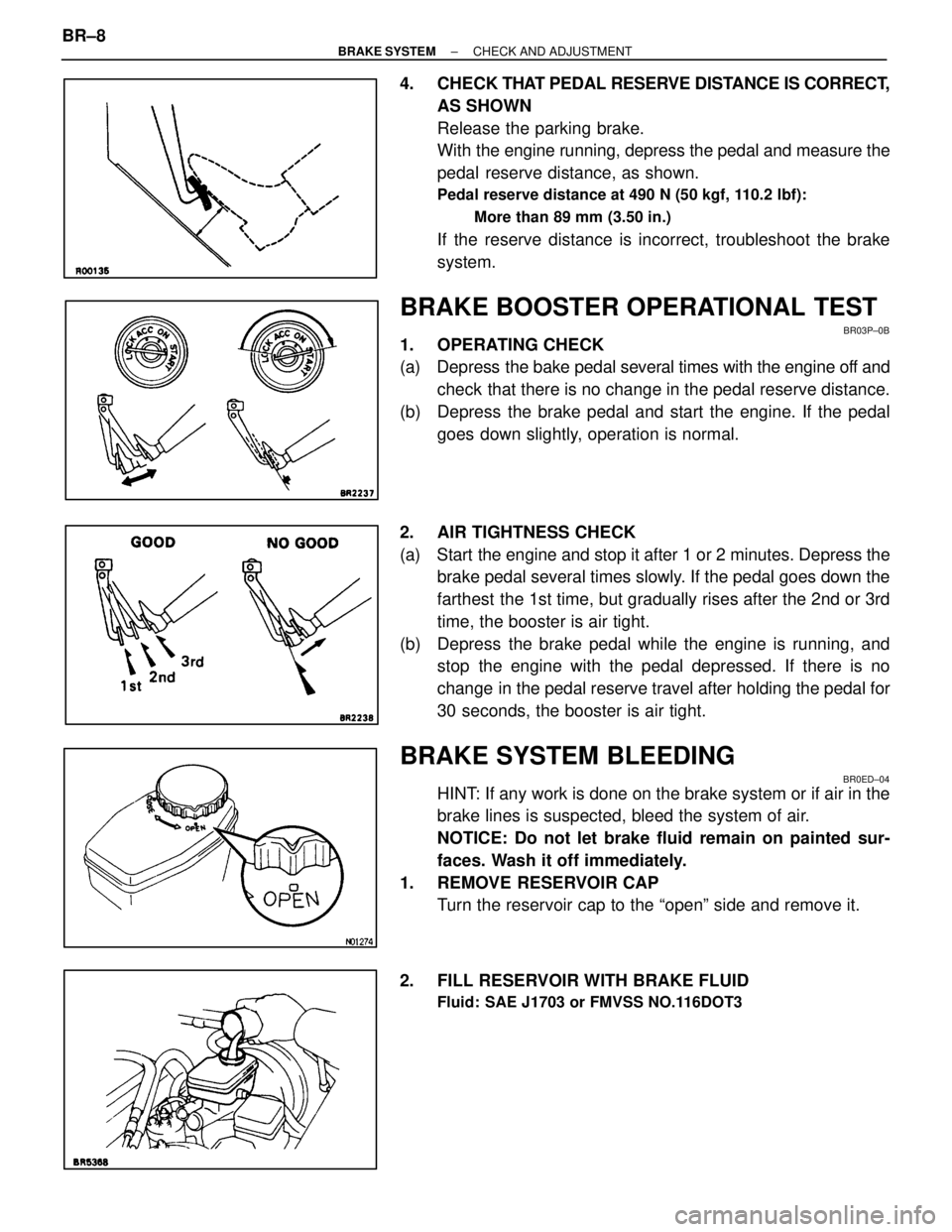

4. CHECK THAT PEDAL RESERVE DISTANCE IS CORRECT,

AS SHOWN

Release the parking brake.

With the engine running, depress the pedal and measure the

pedal reserve distance, as shown.

Pedal reserve distance at 490 N (50 kgf, 110.2 lbf):

More than 89 mm (3.50 in.)

If the reserve distance is incorrect, troubleshoot the brake

system.

BRAKE BOOSTER OPERATIONAL TEST

BR03P±0B

1. OPERATING CHECK

(a) Depress the bake pedal several times with the engine off and

check that there is no change in the pedal reserve distance.

(b) Depress the brake pedal and start the engine. If the pedal goes down slightly, operation is normal.

2. AIR TIGHTNESS CHECK

(a) Start the engine and stop it after 1 or 2 minutes. Depress the brake pedal several times slowly. If the pedal goes down the

farthest the 1st time, but gradually rises after the 2nd or 3rd

time, the booster is air tight.

(b) Depress the brake pedal while the engine is running, and stop the engine with the pedal depressed. If there is no

change in the pedal reserve travel after holding the pedal for

30 seconds, the booster is air tight.

BRAKE SYSTEM BLEEDING

BR0ED±04

HINT: If any work is done on the brake system or if air in the

brake lines is suspected, bleed the system of air.

NOTICE: Do not let brake fluid remain on painted sur-

faces. Wash it off immediately.

1. REMOVE RESERVOIR CAP Turn the reservoir cap to the ªopenº side and remove it.

2. FILL RESERVOIR WITH BRAKE FLUID

Fluid: SAE J1703 or FMVSS NO.116DOT3

BR±8±

BRAKE SYSTEM CHECK AND ADJUSTMENT

WhereEverybodyKnowsYourName

Page 1049 of 4087

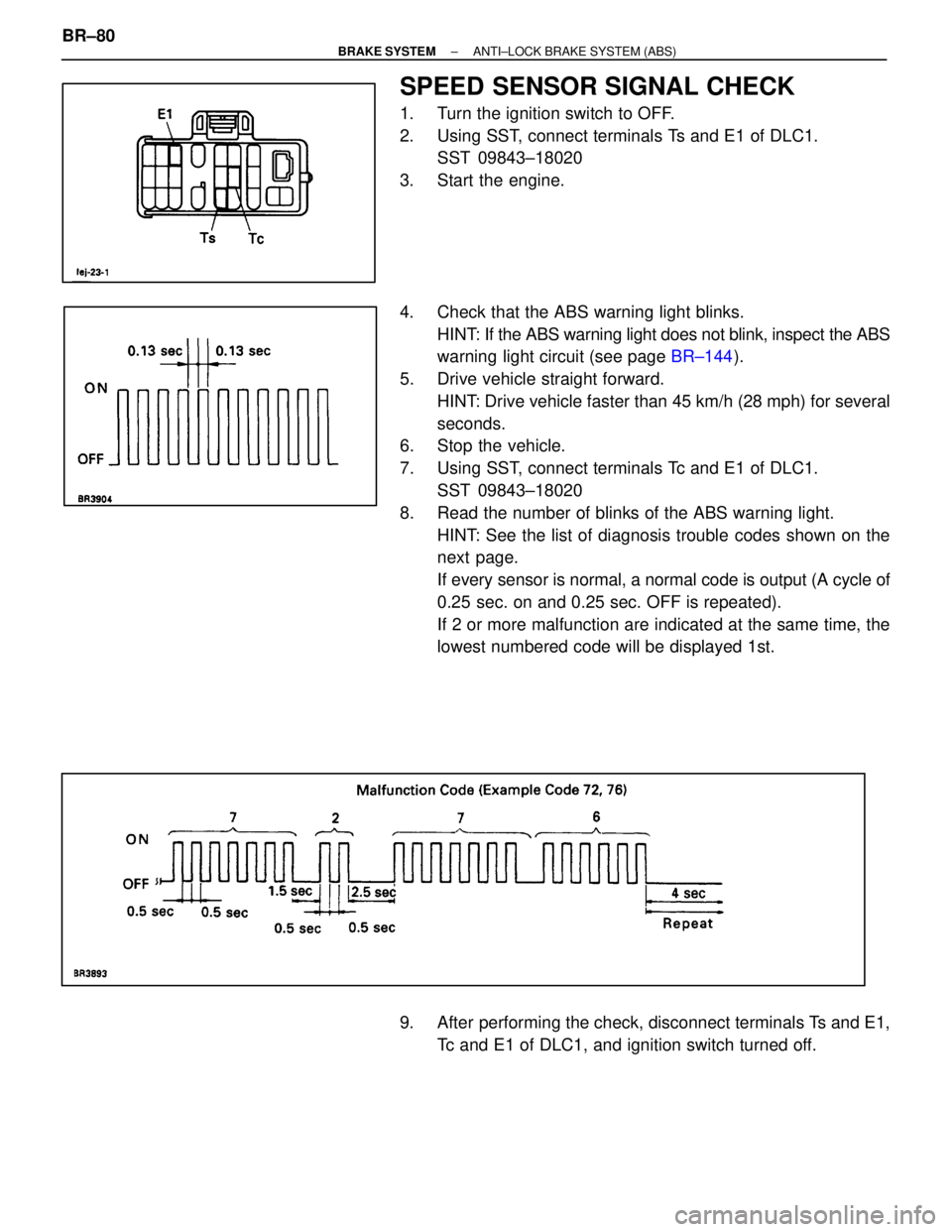

SPEED SENSOR SIGNAL CHECK

1. Turn the ignition switch to OFF.

2. Using SST, connect terminals Ts and E1 of DLC1.SST 09843±18020

3. Start the engine.

4. Check that the ABS warning light blinks. HINT: If the ABS warning light does not blink, inspect the ABS

warning light circuit (see page BR±144).

5. Drive vehicle straight forward. HINT: Drive vehicle faster than 45 km/h (28 mph) for several

seconds.

6. Stop the vehicle.

7. Using SST, connect terminals Tc and E1 of DLC1.

SST 09843±18020

8. Read the number of blinks of the ABS warning light. HINT: See the list of diagnosis trouble codes shown on the

next page.

If every sensor is normal, a normal code is output (A cycle of

0.25 sec. on and 0.25 sec. OFF is repeated).

If 2 or more malfunction are indicated at the same time, the

lowest numbered code will be displayed 1st.

9. After performing the check, disconnect terminals Ts and E1,Tc and E1 of DLC1, and ignition switch turned off.

BR±80

±

BRAKE SYSTEM ANTI±LOCK BRAKE SYSTEM (ABS)

WhereEverybodyKnowsYourName