LEXUS SC400 1991 Service Repair Manual

Manufacturer: LEXUS, Model Year: 1991,

Model line: SC400,

Model: LEXUS SC400 1991

Pages: 4087, PDF Size: 75.75 MB

LEXUS SC400 1991 Service Repair Manual

SC400 1991

LEXUS

LEXUS

https://www.carmanualsonline.info/img/36/57051/w960_57051-0.png

LEXUS SC400 1991 Service Repair Manual

Trending: engine oil capacity, check transmission fluid, refrigerant type, wiring, headlights, tires, drain bolt

Page 3611 of 4087

OKNG

OKNG

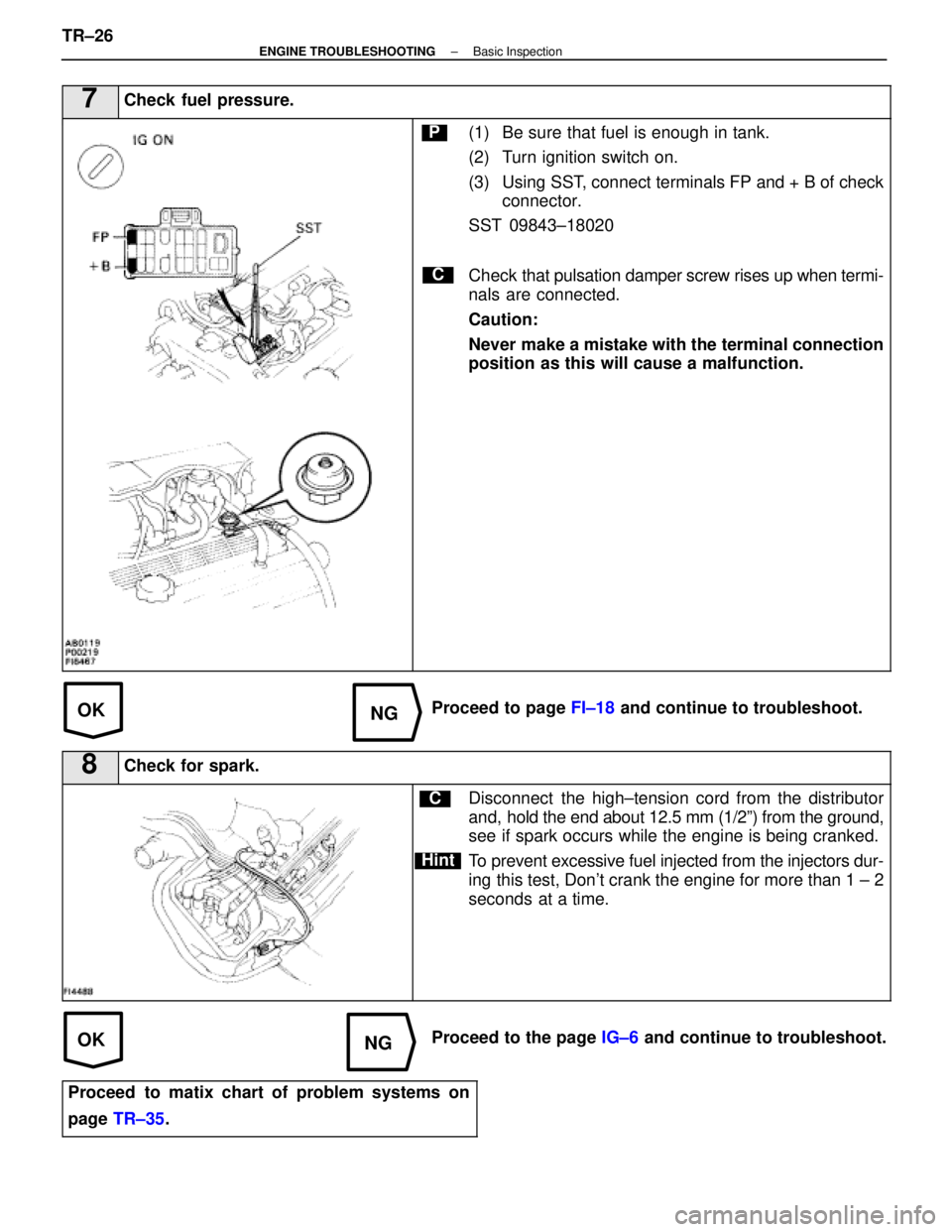

7Check fuel pressure.

C

P(1) Be sure that fuel is enough in tank.

(2) Turn ignition switch on.

(3) Using SST, connect terminals FP and + B of checkconnector.

SST 09843±18020

Check that pulsation damper screw rises up when termi-

nals are connected.

Caution:

Never make a mistake with the terminal connection

position as this will cause a malfunction.

Proceed to page FI±18 and continue to troubleshoot.

8Check for spark.

C

Hint

Disconnect the high±tension cord from the distributor

and, hold the end about 12.5 mm (1/2º) from the ground,

see if spark occurs while the engine is being cranked.

To prevent excessive fuel injected from the injectors dur-

ing this test, Don't crank the engine for more than 1 ± 2

seconds at a time.

Proceed to the page IG±6 and continue to troubleshoot.

Proceed to matix chart of problem systems on

page TR±35 .

TR±26±

ENGINE TROUBLESHOOTING Basic Inspection

WhereEverybodyKnowsYourName

Page 3612 of 4087

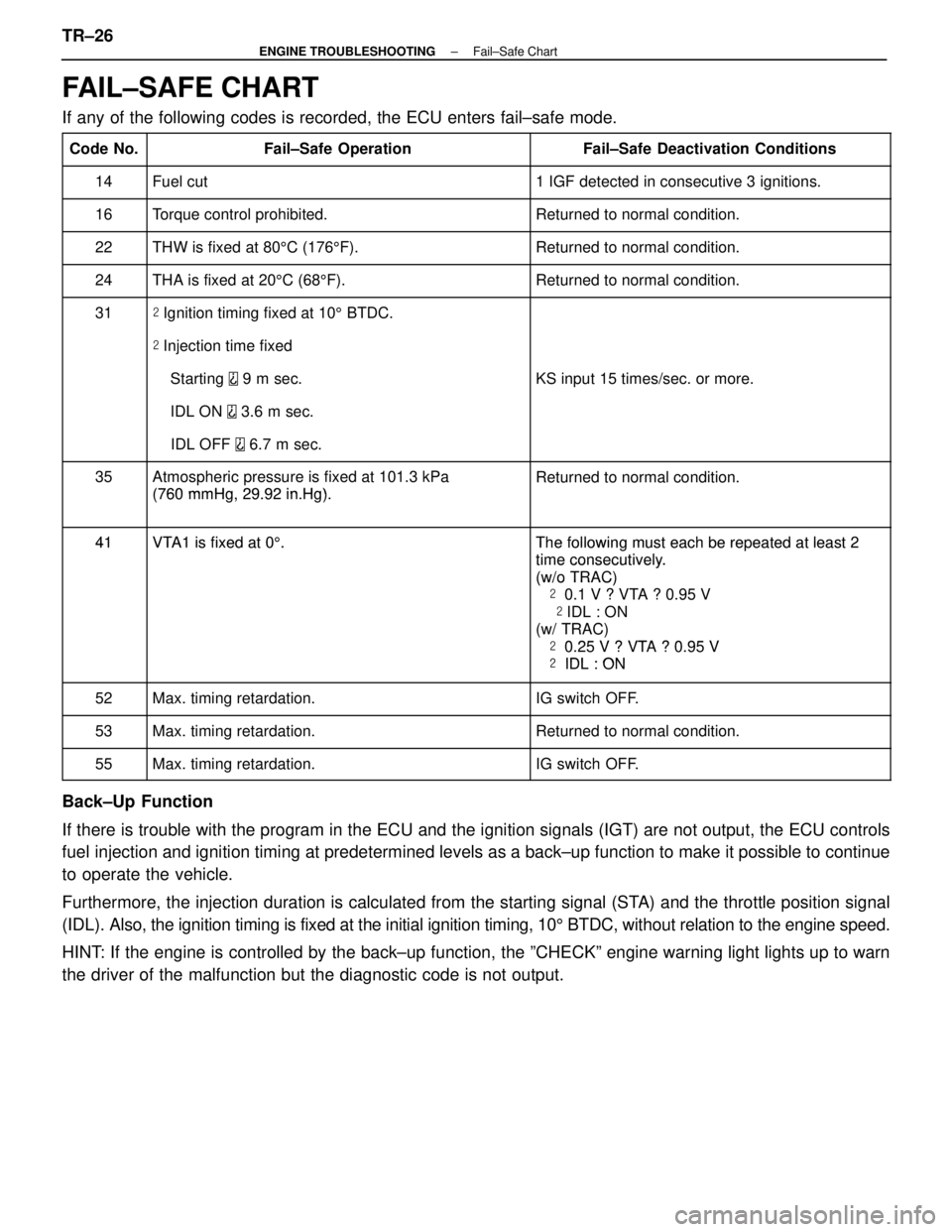

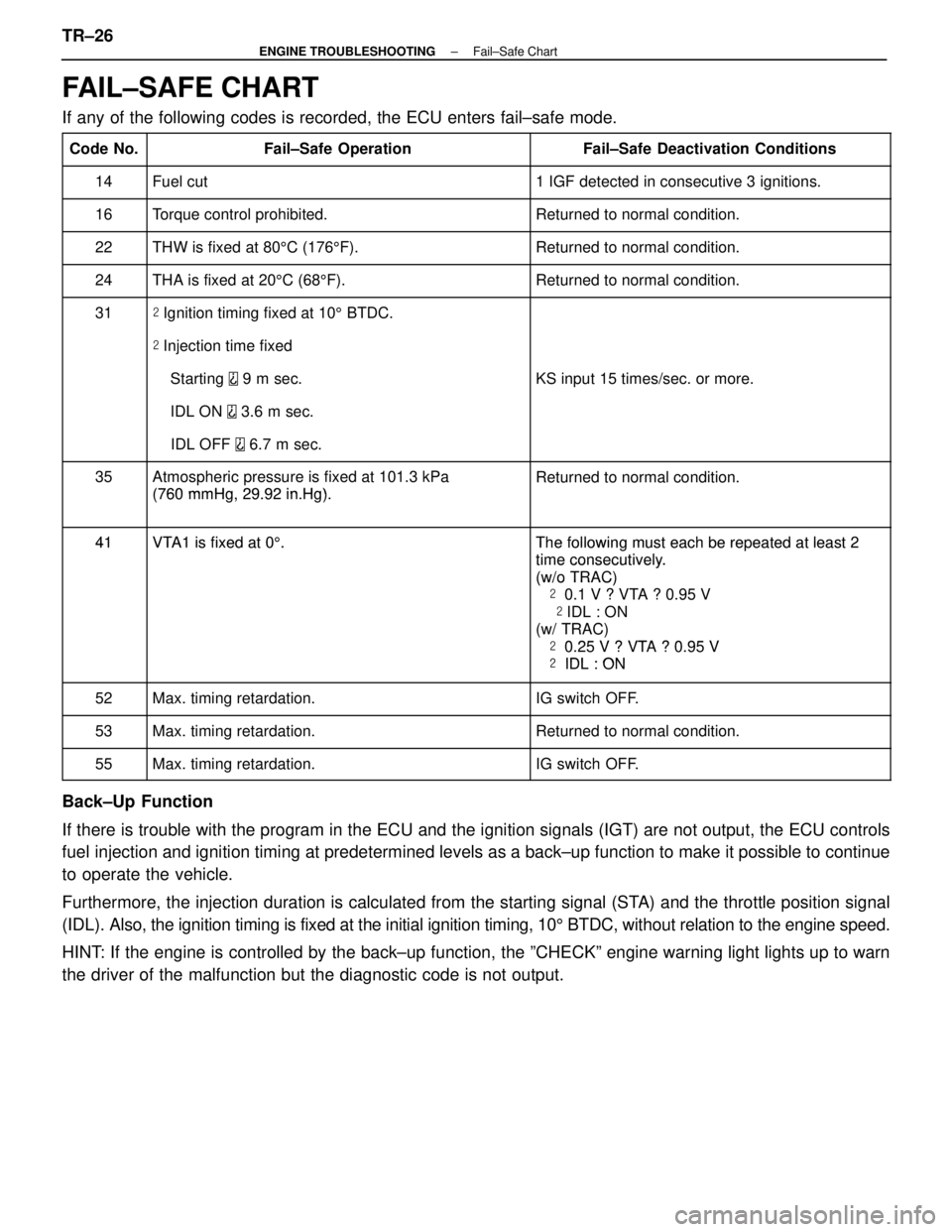

FAIL±SAFE CHART

If any of the following codes is recorded, the ECU enters fail±safe mod\

e.

Code No.Fail±Safe OperationFail±Safe Deactivation Conditions

14Fuel cut1 IGF detected in consecutive 3 ignitions.

16Torque control prohibited.Returned to normal condition.

22THW is fixed at 805C (176 5F).Returned to normal condition.

24THA is fixed at 20 5C (68 5F).Returned to normal condition.

31� Ignition timing fixed at 10 5 BTDC.

� Injection time fixed

Starting 9 m sec.KS input 15 times/sec. or more.

IDL ON 3.6 m sec.

IDL OFF 6.7 m sec.

35Atmospheric pressure is fixed at 101.3 kPa

(760 mmHg 29 92 in Hg)

Returned to normal condition.

(760 mmHg, 29.92 in.Hg).

41VTA1 is fixed at 05.The following must each be repeated at least 241VTA1 is fixed at 0 5.The following must each be re eated at least 2

time consecutively.time consecutively.

(w/o TRAC)(w/o TRAC)

� 0.1 V ? VTA ? 0.95 V 0.1 V ? VTA ? 0.95 V

�� IDL : ON

( / TRAC)(w/ TRAC)

025V?VTA?095V � 0.25 V ? VTA ? 0.95 V

� IDL:ON � IDL : ON

52Max. timing retardation.IG switch OFF.

53Max. timing retardation.Returned to normal condition.

55Max. timing retardation.IG switch OFF.

Back±Up Function

If there is trouble with the program in the ECU and the ignition signals\

(IGT) are not output, the ECU controls

fuel injection and ignition timing at predetermined levels as a back±up f\

unction to make it possible to continue

to operate the vehicle.

Furthermore, the injection duration is calculated from the starting sign\

al (STA) and the throttle position signal

(IDL). Also, the ignition timing is fixed at the initial ignition timing, 10 5 BTDC, without relation to the engine speed.

HINT: If the engine is controlled by the back±up function, the ºCHECKº\

engine warning light lights up to warn

the driver of the malfunction but the diagnostic code is not output. TR±26

±

ENGINE TROUBLESHOOTING Fail±Safe Chart

WhereEverybodyKnowsYourName

Page 3613 of 4087

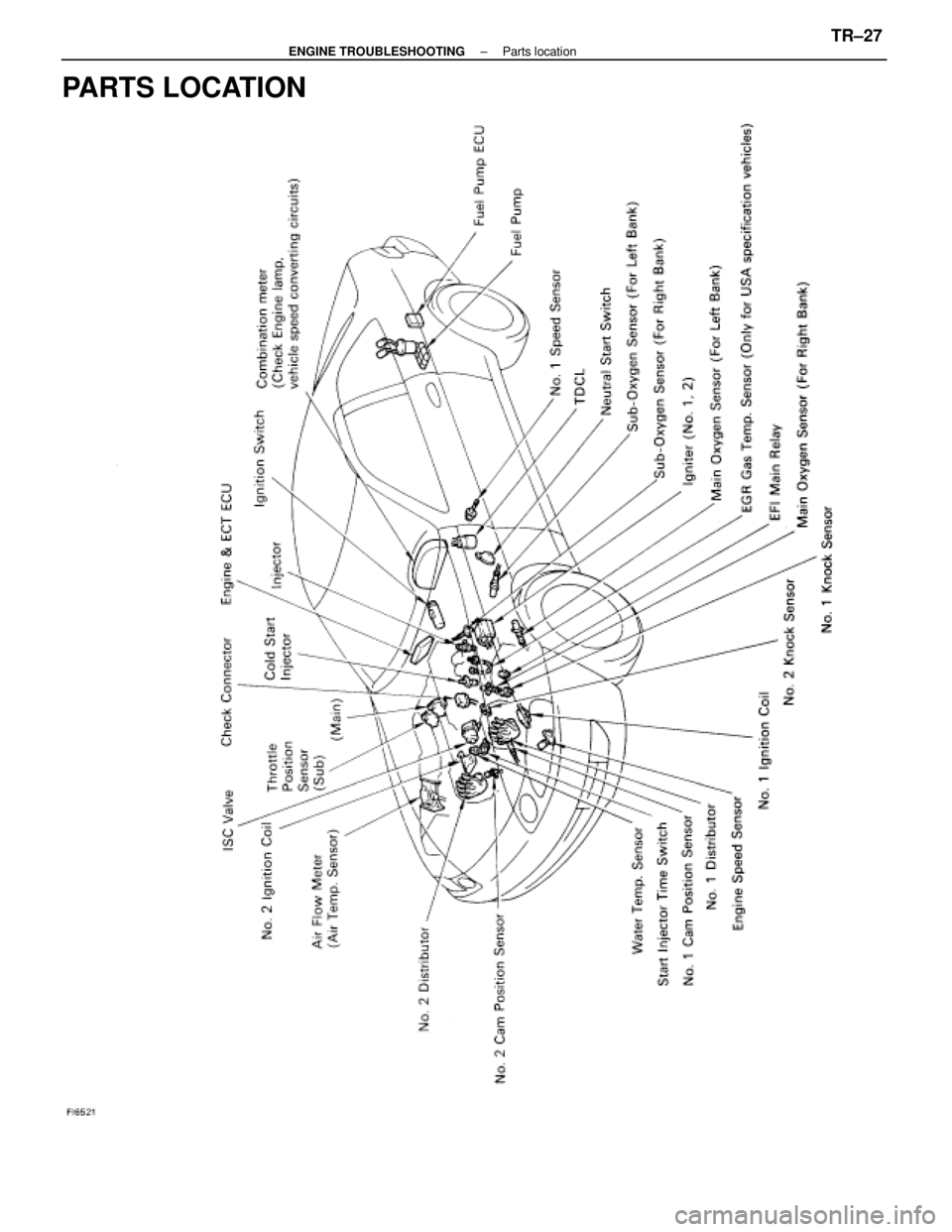

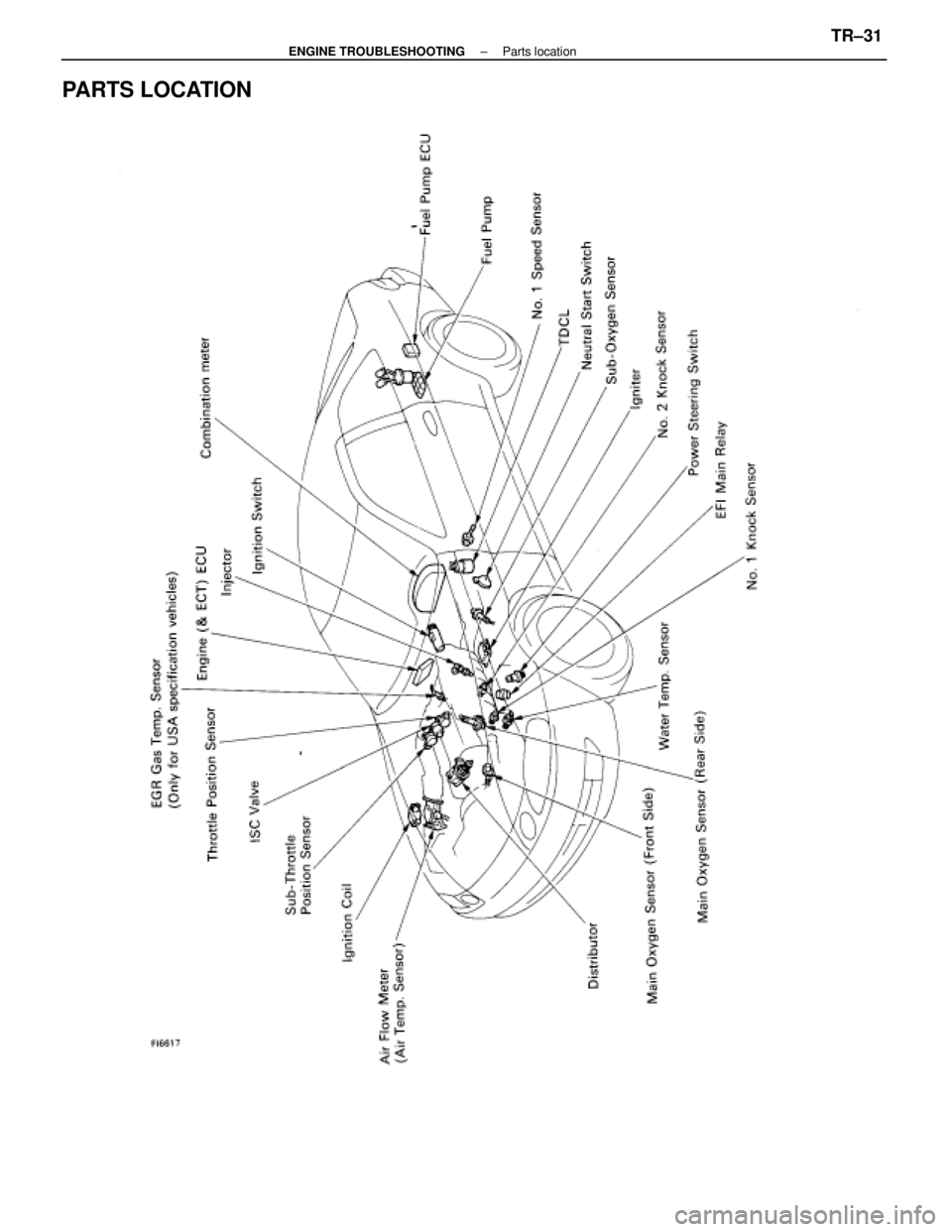

PARTS LOCATION

±

ENGINE TROUBLESHOOTING Parts locationTR±27

WhereEverybodyKnowsYourName

Page 3614 of 4087

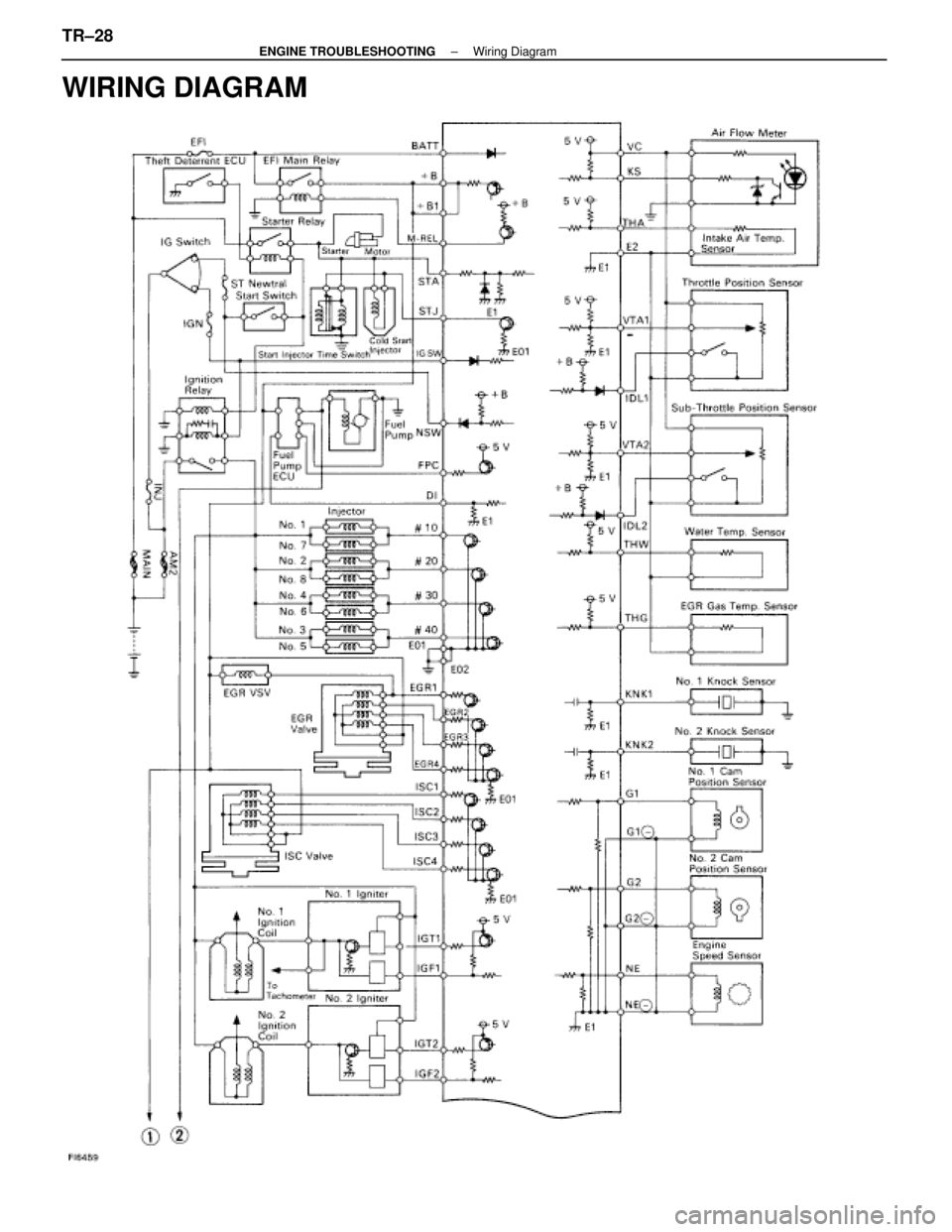

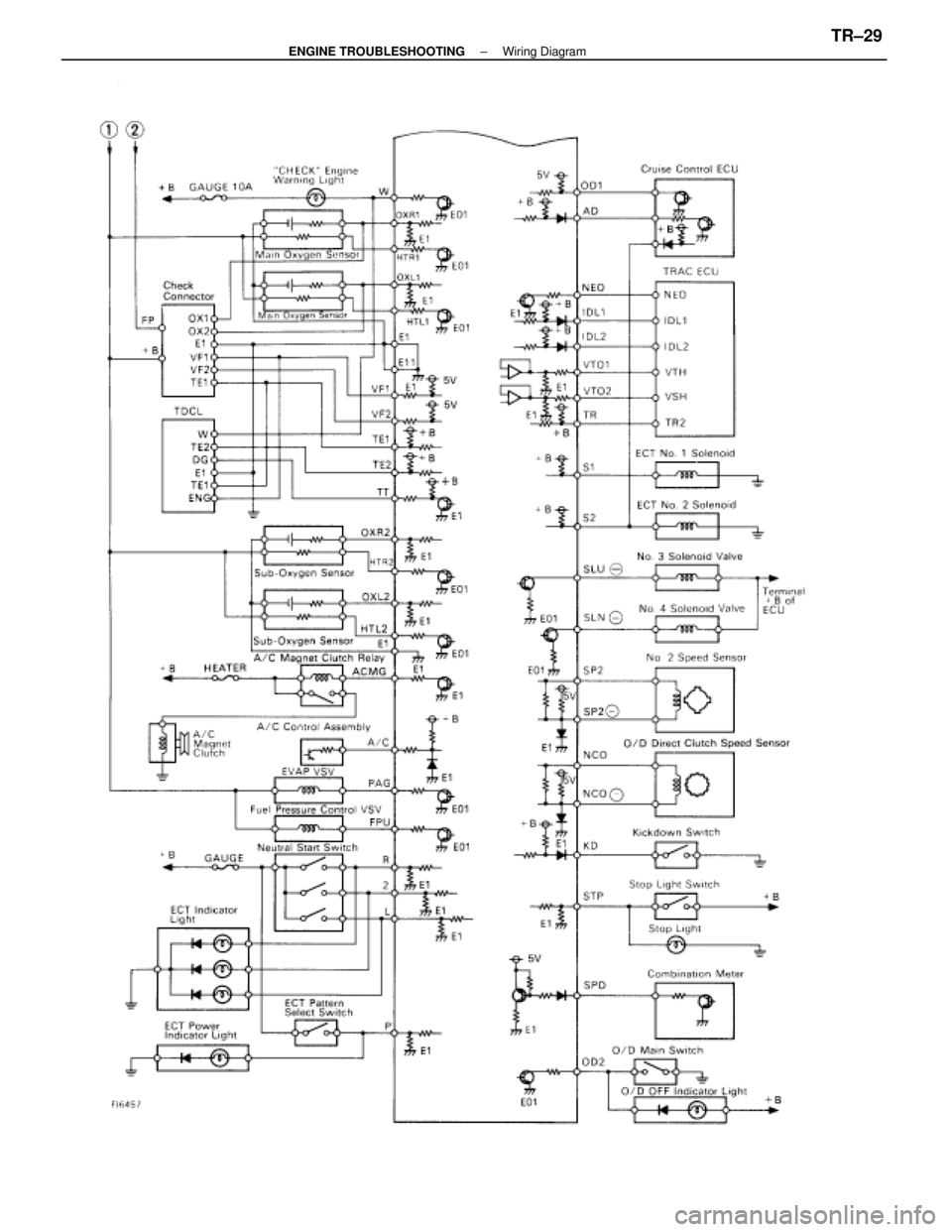

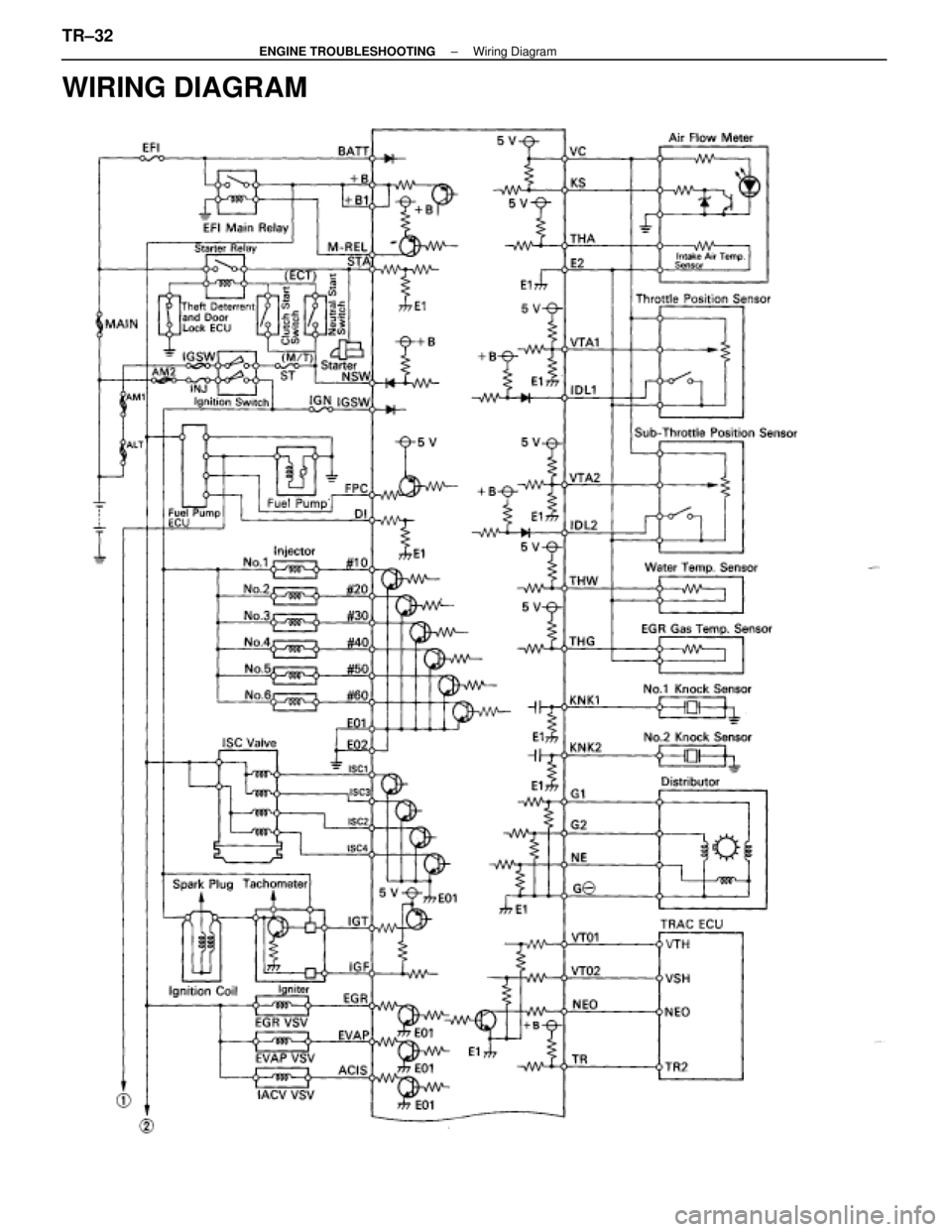

WIRING DIAGRAM

TR±28±

ENGINE TROUBLESHOOTING Wiring Diagram

WhereEverybodyKnowsYourName

Page 3615 of 4087

±

ENGINE TROUBLESHOOTING Wiring DiagramTR±29

WhereEverybodyKnowsYourName

Page 3616 of 4087

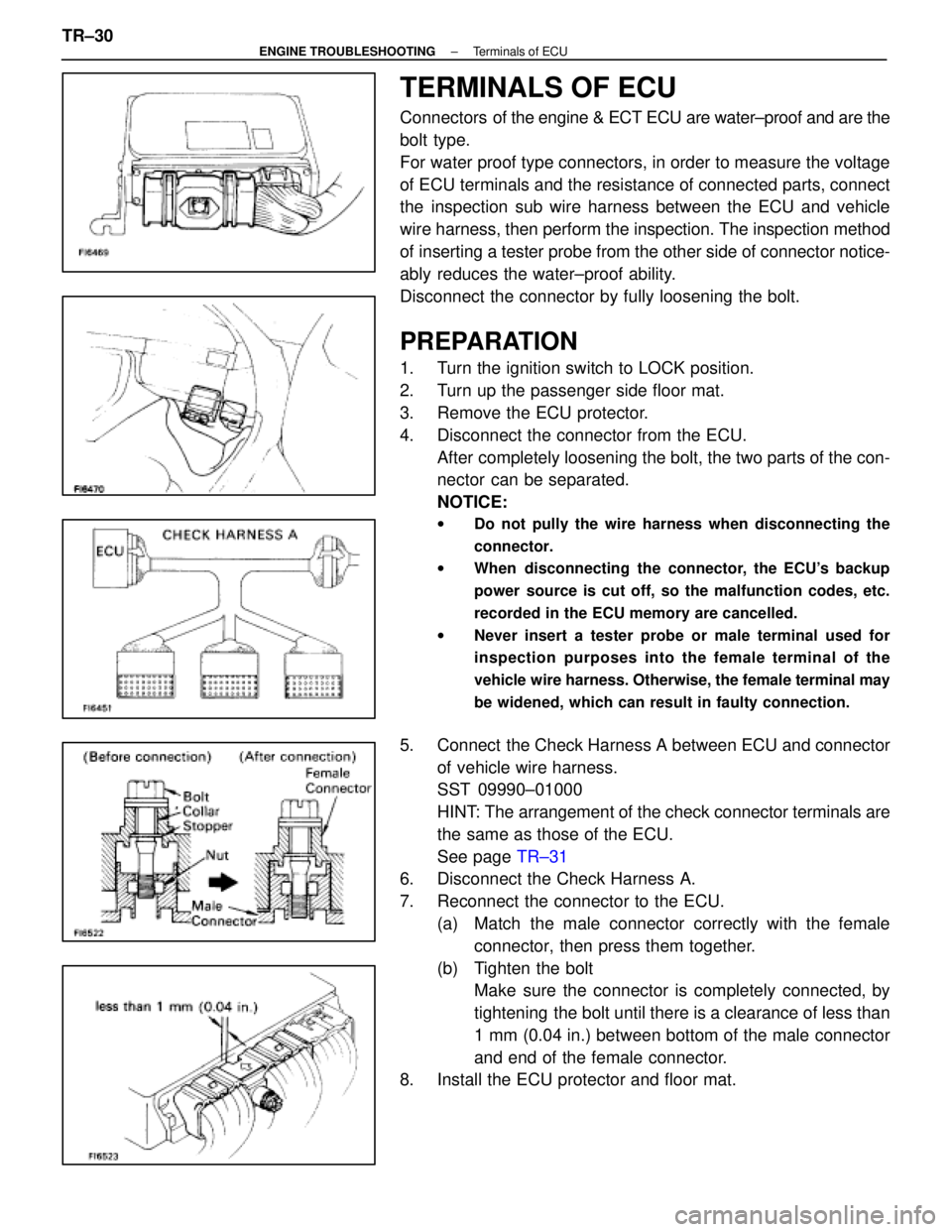

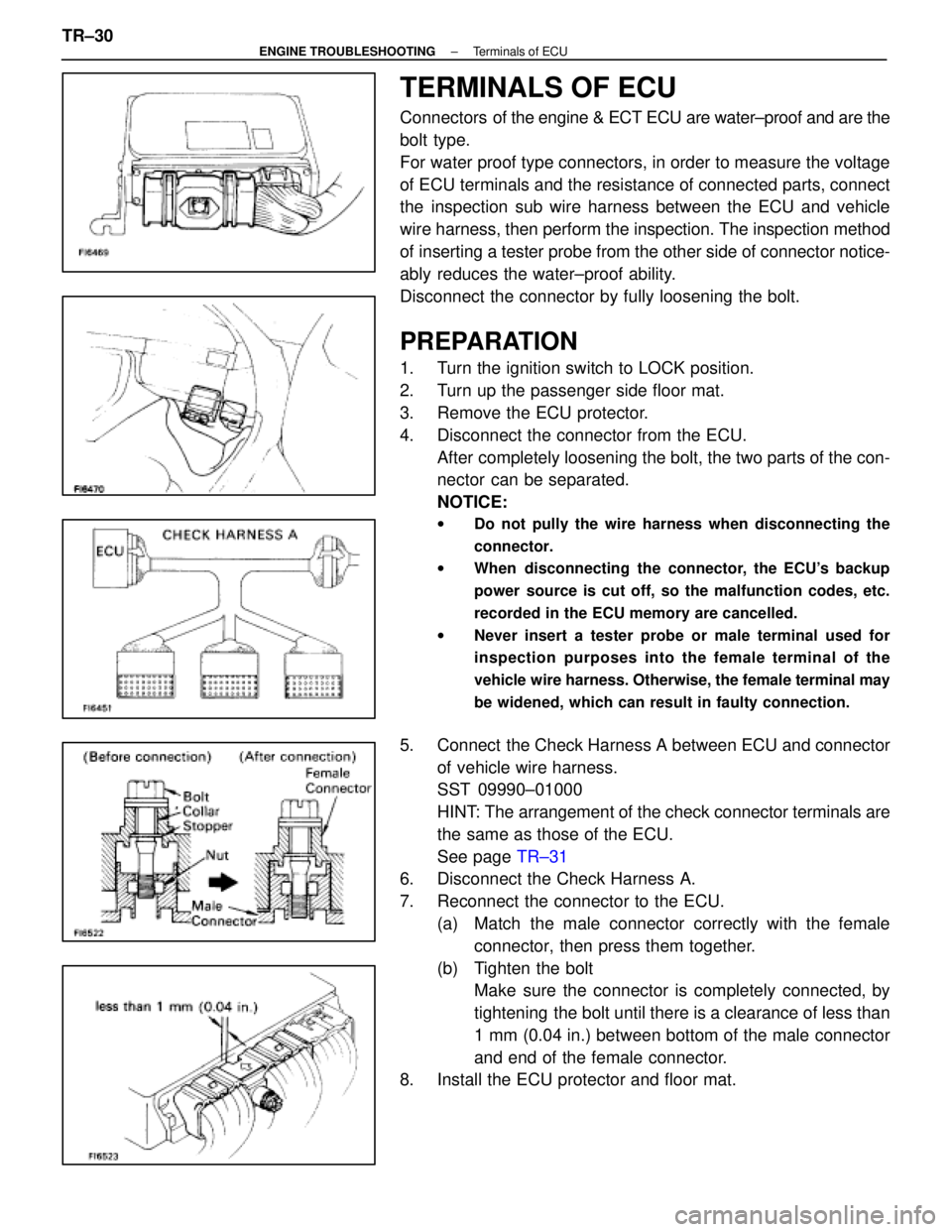

TERMINALS OF ECU

Connectors of the engine & ECT ECU are water±proof and are the

bolt type.

For water proof type connectors, in order to measure the voltage

of ECU terminals and the resistance of connected parts, connect

the inspection sub wire harness between the ECU and vehicle

wire harness, then perform the inspection. The inspection method

of inserting a tester probe from the other side of connector notice-

ably reduces the water±proof ability.

Disconnect the connector by fully loosening the bolt.

PREPARATION

1. Turn the ignition switch to LOCK position.

2. Turn up the passenger side floor mat.

3. Remove the ECU protector.

4. Disconnect the connector from the ECU. After completely loosening the bolt, the two parts of the con-

nector can be separated.

NOTICE:

w Do not pully the wire harness when disconnecting the

connector.

w When disconnecting the connector, the ECU's backup

power source is cut off, so the malfunction codes, etc.

recorded in the ECU memory are cancelled.

w Never insert a tester probe or male terminal used for

inspection purposes into the female terminal of the

vehicle wire harness. Otherwise, the female terminal may

be widened, which can result in faulty connection.

5. Connect the Check Harness A between ECU and connector

of vehicle wire harness.

SST 09990±01000

HINT: The arrangement of the check connector terminals are

the same as those of the ECU.

See page TR±31

6. Disconnect the Check Harness A.

7. Reconnect the connector to the ECU.

(a) Match the male connector correctly with the femaleconnector, then press them together.

(b) Tighten the bolt Make sure the connector is completely connected, by

tightening the bolt until there is a clearance of less than

1 mm (0.04 in.) between bottom of the male connector

and end of the female connector.

8. Install the ECU protector and floor mat.

TR±30

±

ENGINE TROUBLESHOOTING Terminals of ECU

WhereEverybodyKnowsYourName

Page 3617 of 4087

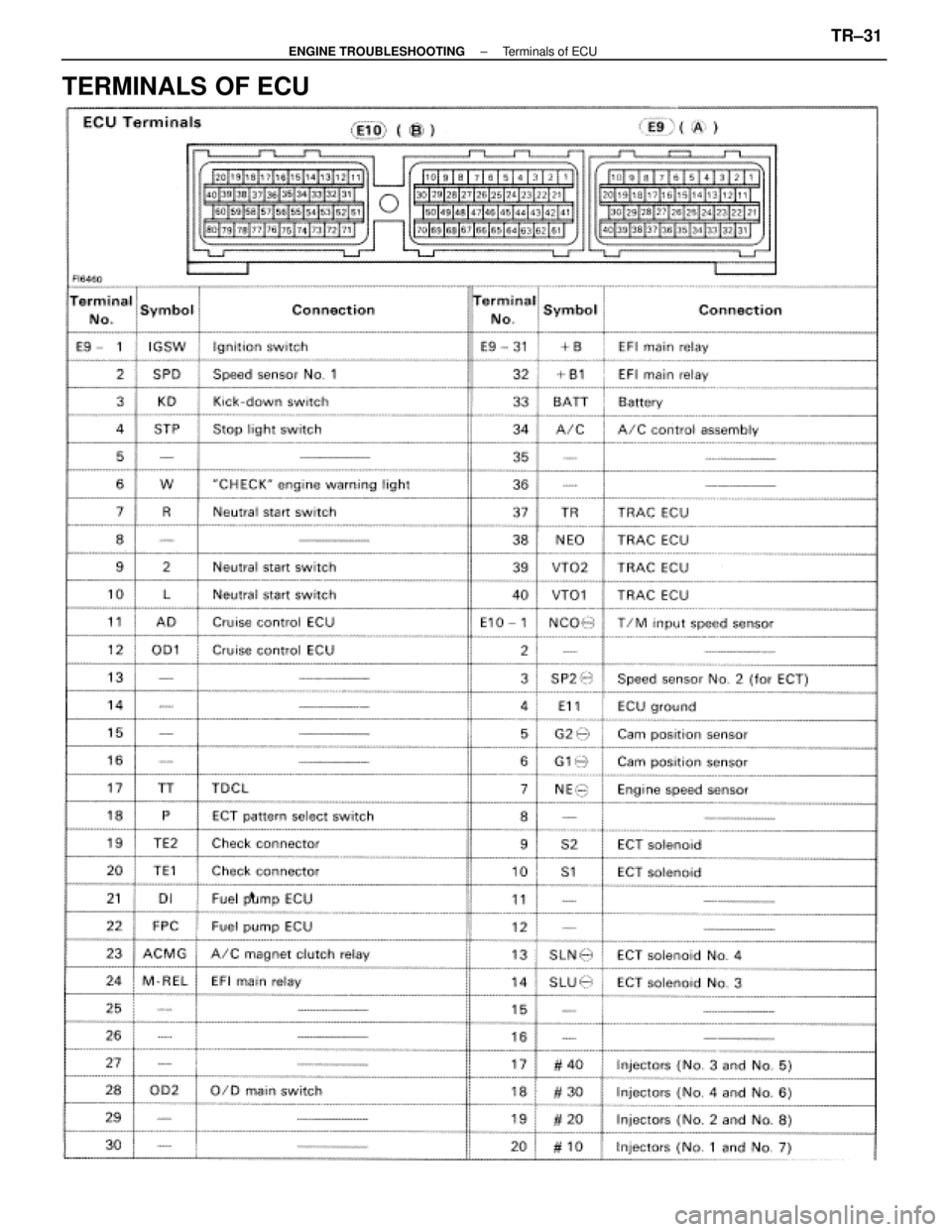

TERMINALS OF ECU

±

ENGINE TROUBLESHOOTING Terminals of ECUTR±31

WhereEverybodyKnowsYourName

Page 3618 of 4087

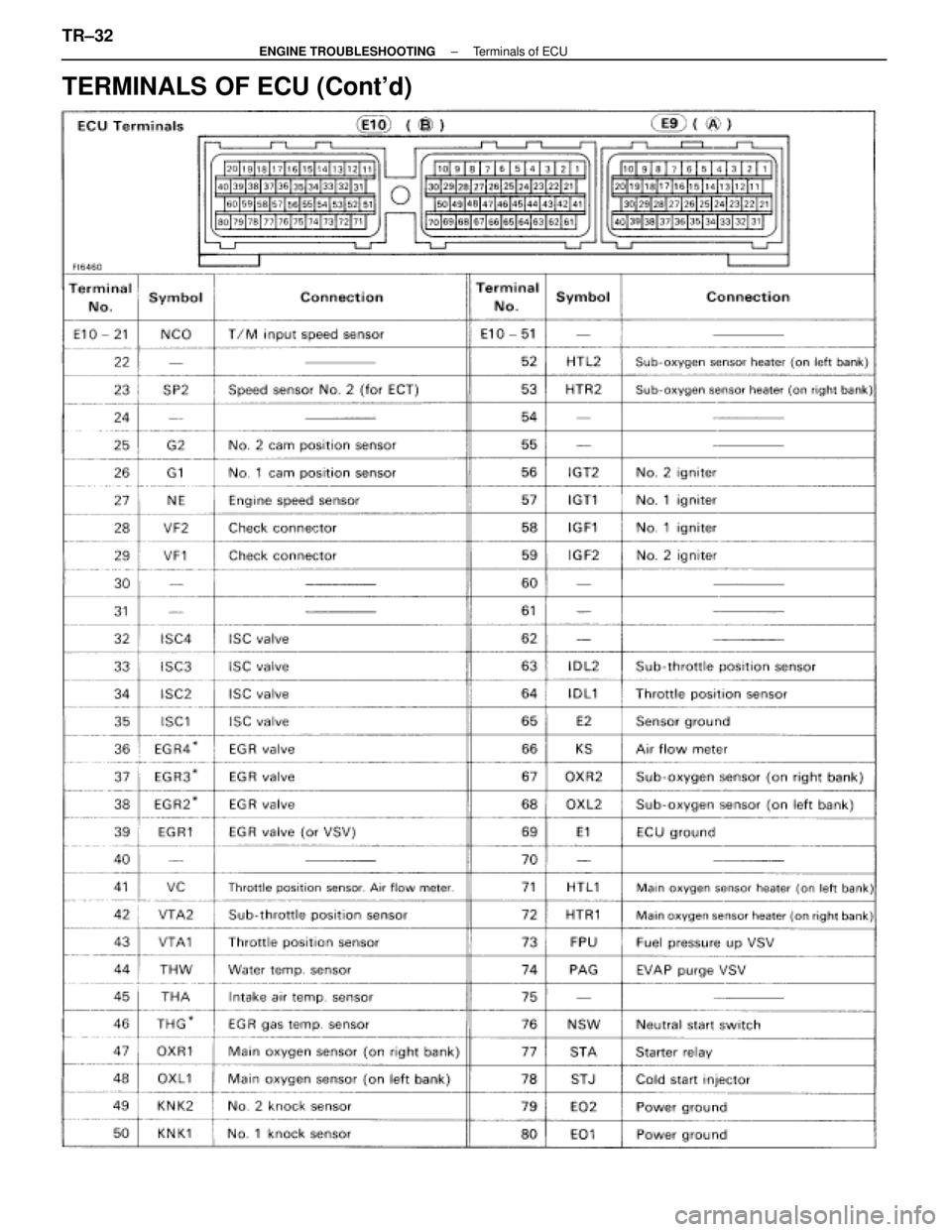

TERMINALS OF ECU (Cont'd)

TR±32±

ENGINE TROUBLESHOOTING Terminals of ECU

WhereEverybodyKnowsYourName

Page 3619 of 4087

PARTS LOCATION

±

ENGINE TROUBLESHOOTING Parts locationTR±31

WhereEverybodyKnowsYourName

Page 3620 of 4087

WIRING DIAGRAM

TR±32±

ENGINE TROUBLESHOOTING Wiring Diagram

WhereEverybodyKnowsYourName

Trending: headlights, ignition, display, fuse box diagram, radio, wheel, Throttle Position sensor