roof LEXUS SC400 1991 Service Manual PDF

[x] Cancel search | Manufacturer: LEXUS, Model Year: 1991, Model line: SC400, Model: LEXUS SC400 1991Pages: 4087, PDF Size: 75.75 MB

Page 2886 of 4087

The 1 UZ±FE engine has 8±cylinders in a V±arrangement at a bank an\

gle of 905. From the front of the RH

bank cylinders are numbered 2±4±6±8, and from the front of the LH b\

ank cylinders are numbered 1 ±3±5±7.

The crankshaft is supported by 5 bearings specified by the inside of the cr\

ankcase. These bearings are made

of a copper and lead alloy. The crankshaft is integrated with 8 weights which are cast along with it\

for balancing. Oil holes are built

into the center of the crankshaft for supplying oil to the connecting ro\

ds, pistons and other components. The ignition order is 1±8±4±3±6±5±7±2. The cylinder\

head is made of aluminum alloy, with a cross flow

type intake and exhaust layout and with pent±roof type combustion chambers. The spark plugs are loca\

ted in

the center of the combustion chambers.

At the front and rear of the intake manifold, a water passage has been p\

rovided which connects the RH

and LH cylinder heads. Exhaust and intake valves are equipped with irregular pitch springs made\

of special valve spring carbon

steel which are capable of following no matter what the engine speed.

The RH and LH intake camshafts are driven by a single timing belt, and a ge\

ar on the intake camshaft en-

gages with a gear on the exhaust camshaft to drive it. The camshaft jour\

nal is supported at 5 (intake) or 4 (ex-

haust) places between the valve lifters of each cylinder and on the front end of the cylinder \

head. Lubrication

of the cam journal gear is accomplished by oil being supplied through the \

oiler port in the center of the camshaft. Adjustment of the valve clearance is done by means of an outer shim type\

system, in which valve adjusting

shims are located above the valve lifters. This permits replacement of the sh\

ims without removal of the cam-

shafts. Pistons are made of high temperature±resistant aluminum alloy, and a depression is built into the piston

head to prevent interference with valves.

Piston pins are the full±floating type, with the pins fastened to neither the piston boss nor the connecting

rods. Instead, snap rings are fitted on both ends of the pins, preventing the\

pins from falling out. The No.1 compression ring is made of steel and the No.2 compression ring\

is made of cast iron. The oil

ring is m ade of a combination of steel and stainless steel. The outer diameter of\

each piston ring is slightly larger

than the diameter of the piston and the flexibility of the rings allows them\

to hug the cylinder walls when they

are mounted on the piston. Compression rings No.1 and No.2 work to prevent \

the leakage of gas from the cylin-

der and the oil ring works to scrape oil off the cylinder walls to prevent it from entering the combustion chamber. The cylinder block is made of aluminum alloy with a bank angle of 90 5. Cast iron cylinders are installed

inside the cylinder block. It has 8 cylinders which are approximately twice the length of th\

e piston stroke. The

top of each cylinder is closed off by the cylinder heads and the lower end of the cylinders becomes the crank-

case, in which the crankshaft is installed. In addition, the cylinder bl\

ock contains a water jacket, through which

coolant is pumped to cool the cylinders. The No.1 and No.2 oil pans are bolted onto the bottom of the cylinder block\

. The No.1 oil pan is made of

aluminum alloy. The No.2 oil pan is an oil reservoir made of pressed steel sheet. An o\

il level sensor is installed

in the No.1 oil pan (If the oil level drops below a set level, a warnin\

g light lights up.). A oil pan baffle plate keeps

sufficient oil in the bottom of the No.2 oil pan even when the vehicle is tilted. \

This dividing plate also prevents

the oil from making waves when the vehicle is stopped suddenly and the oil \

shifts away from the oil pump suction

pipe. Plastic region tightening bolts are used for the cylinder head, main bearing ca\

p and connecting rod.

EM±4

±

ENGINE MECHANICAL Operation

WhereEverybodyKnowsYourName

Page 3404 of 4087

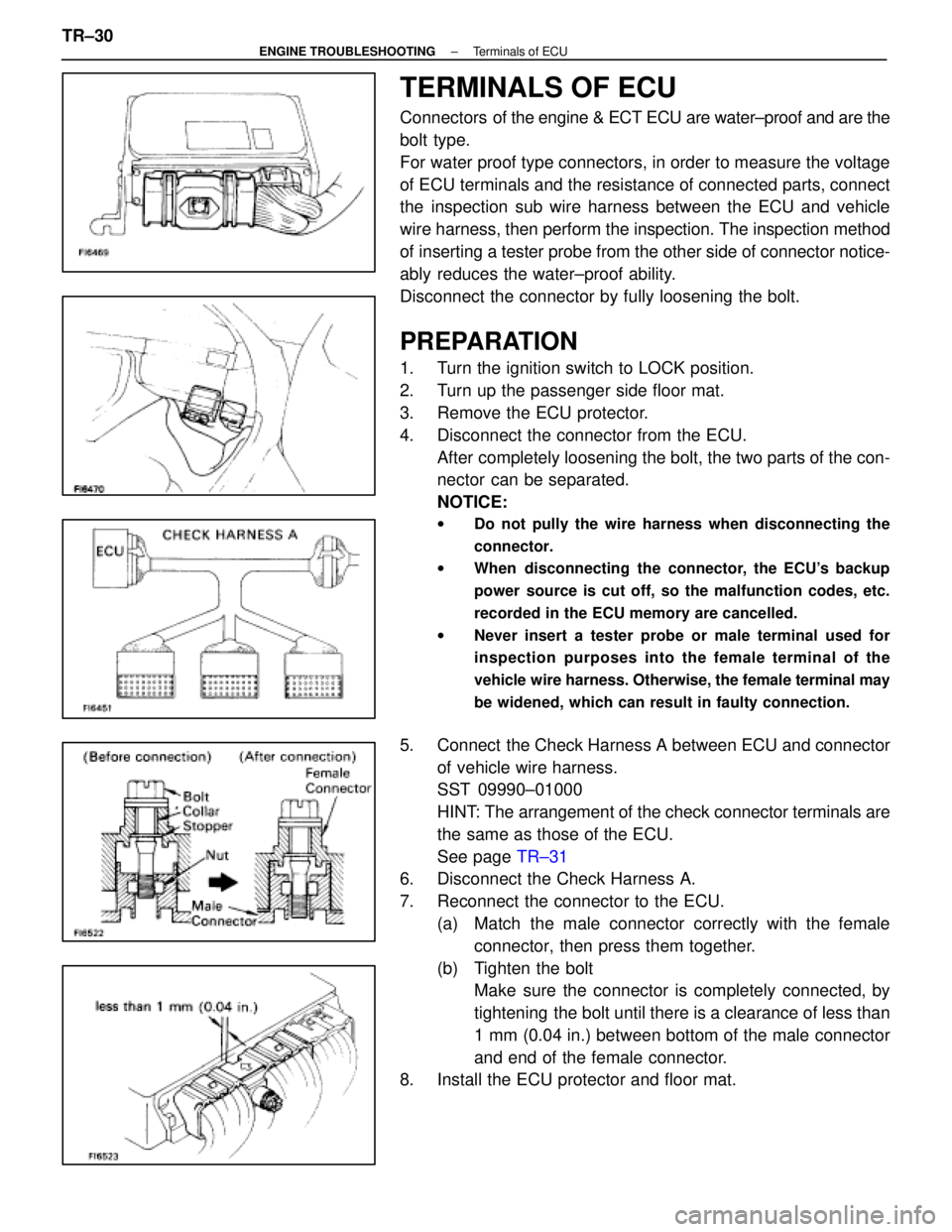

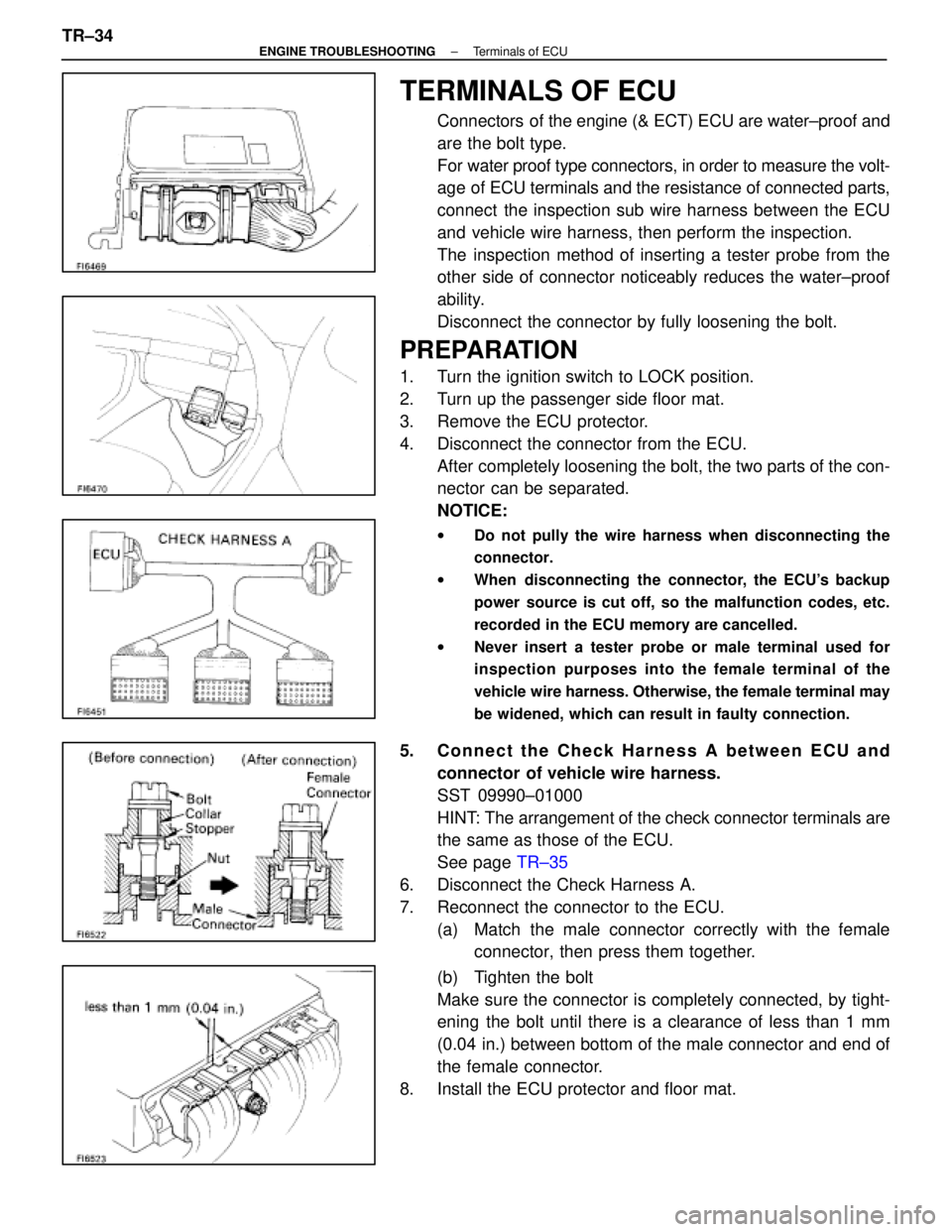

TERMINALS OF ECU

Connectors of the engine & ECT ECU are water±proof and are the

bolt type.

For water proof type connectors, in order to measure the voltage

of ECU terminals and the resistance of connected parts, connect

the inspection sub wire harness between the ECU and vehicle

wire harness, then perform the inspection. The inspection method

of inserting a tester probe from the other side of connector notice-

ably reduces the water±proof ability.

Disconnect the connector by fully loosening the bolt.

PREPARATION

1. Turn the ignition switch to LOCK position.

2. Turn up the passenger side floor mat.

3. Remove the ECU protector.

4. Disconnect the connector from the ECU. After completely loosening the bolt, the two parts of the con-

nector can be separated.

NOTICE:

w Do not pully the wire harness when disconnecting the

connector.

w When disconnecting the connector, the ECU's backup

power source is cut off, so the malfunction codes, etc.

recorded in the ECU memory are cancelled.

w Never insert a tester probe or male terminal used for

inspection purposes into the female terminal of the

vehicle wire harness. Otherwise, the female terminal may

be widened, which can result in faulty connection.

5. Connect the Check Harness A between ECU and connector

of vehicle wire harness.

SST 09990±01000

HINT: The arrangement of the check connector terminals are

the same as those of the ECU.

See page TR±31

6. Disconnect the Check Harness A.

7. Reconnect the connector to the ECU.

(a) Match the male connector correctly with the femaleconnector, then press them together.

(b) Tighten the bolt Make sure the connector is completely connected, by

tightening the bolt until there is a clearance of less than

1 mm (0.04 in.) between bottom of the male connector

and end of the female connector.

8. Install the ECU protector and floor mat.

TR±30

±

ENGINE TROUBLESHOOTING Terminals of ECU

WhereEverybodyKnowsYourName

Page 3412 of 4087

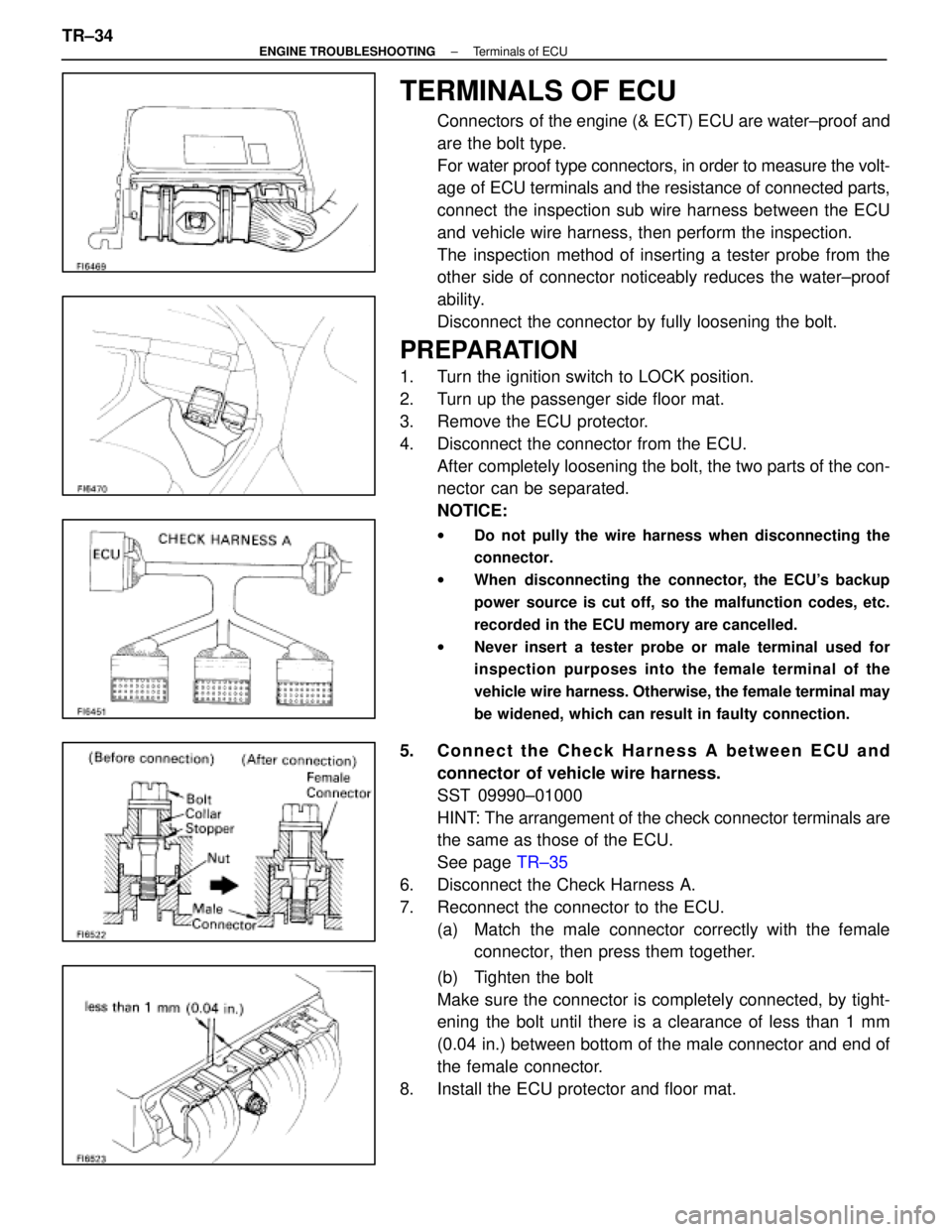

TERMINALS OF ECU

Connectors of the engine (& ECT) ECU are water±proof and

are the bolt type.

For water proof type connectors, in order to measure the volt-

age of ECU terminals and the resistance of connected parts,

connect the inspection sub wire harness between the ECU

and vehicle wire harness, then perform the inspection.

The inspection method of inserting a tester probe from the

other side of connector noticeably reduces the water±proof

ability.

Disconnect the connector by fully loosening the bolt.

PREPARATION

1. Turn the ignition switch to LOCK position.

2. Turn up the passenger side floor mat.

3. Remove the ECU protector.

4. Disconnect the connector from the ECU.After completely loosening the bolt, the two parts of the con-

nector can be separated.

NOTICE:

w Do not pully the wire harness when disconnecting the

connector.

w When disconnecting the connector, the ECU's backup

power source is cut off, so the malfunction codes, etc.

recorded in the ECU memory are cancelled.

w Never insert a tester probe or male terminal used for

inspection purposes into the female terminal of the

vehicle wire harness. Otherwise, the female terminal may

be widened, which can result in faulty connection.

5. Connect the Check Harness A between ECU and

connector of vehicle wire harness.

SST 09990±01000

HINT: The arrangement of the check connector terminals are

the same as those of the ECU.

See page TR±35

6. Disconnect the Check Harness A.

7. Reconnect the connector to the ECU. (a) Match the male connector correctly with the femaleconnector, then press them together.

(b) Tighten the bolt

Make sure the connector is completely connected, by tight-

ening the bolt until there is a clearance of less than 1 mm

(0.04 in.) between bottom of the male connector and end of

the female connector.

8. Install the ECU protector and floor mat.

TR±34

±

ENGINE TROUBLESHOOTING Terminals of ECU

WhereEverybodyKnowsYourName

Page 3616 of 4087

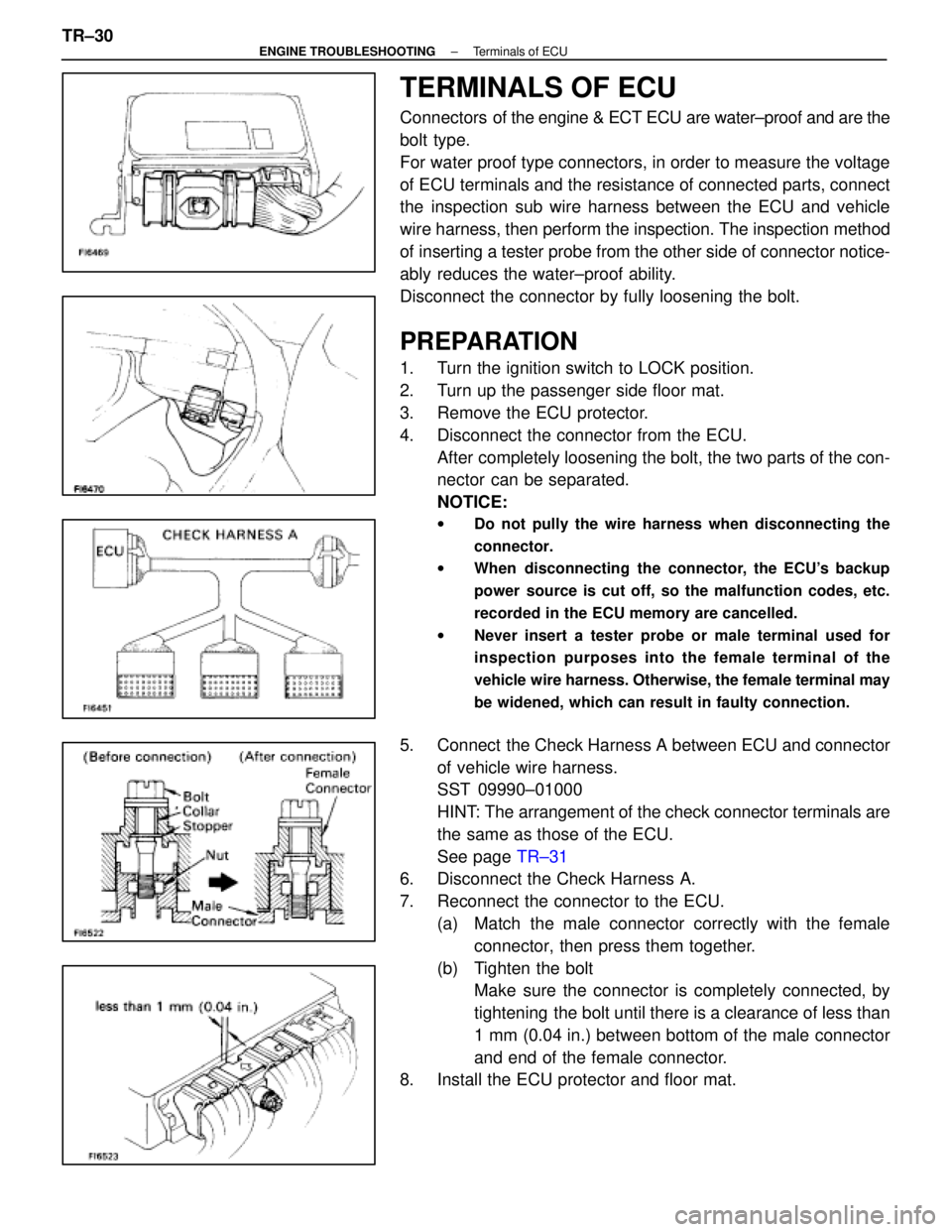

TERMINALS OF ECU

Connectors of the engine & ECT ECU are water±proof and are the

bolt type.

For water proof type connectors, in order to measure the voltage

of ECU terminals and the resistance of connected parts, connect

the inspection sub wire harness between the ECU and vehicle

wire harness, then perform the inspection. The inspection method

of inserting a tester probe from the other side of connector notice-

ably reduces the water±proof ability.

Disconnect the connector by fully loosening the bolt.

PREPARATION

1. Turn the ignition switch to LOCK position.

2. Turn up the passenger side floor mat.

3. Remove the ECU protector.

4. Disconnect the connector from the ECU. After completely loosening the bolt, the two parts of the con-

nector can be separated.

NOTICE:

w Do not pully the wire harness when disconnecting the

connector.

w When disconnecting the connector, the ECU's backup

power source is cut off, so the malfunction codes, etc.

recorded in the ECU memory are cancelled.

w Never insert a tester probe or male terminal used for

inspection purposes into the female terminal of the

vehicle wire harness. Otherwise, the female terminal may

be widened, which can result in faulty connection.

5. Connect the Check Harness A between ECU and connector

of vehicle wire harness.

SST 09990±01000

HINT: The arrangement of the check connector terminals are

the same as those of the ECU.

See page TR±31

6. Disconnect the Check Harness A.

7. Reconnect the connector to the ECU.

(a) Match the male connector correctly with the femaleconnector, then press them together.

(b) Tighten the bolt Make sure the connector is completely connected, by

tightening the bolt until there is a clearance of less than

1 mm (0.04 in.) between bottom of the male connector

and end of the female connector.

8. Install the ECU protector and floor mat.

TR±30

±

ENGINE TROUBLESHOOTING Terminals of ECU

WhereEverybodyKnowsYourName

Page 3624 of 4087

TERMINALS OF ECU

Connectors of the engine (& ECT) ECU are water±proof and

are the bolt type.

For water proof type connectors, in order to measure the volt-

age of ECU terminals and the resistance of connected parts,

connect the inspection sub wire harness between the ECU

and vehicle wire harness, then perform the inspection.

The inspection method of inserting a tester probe from the

other side of connector noticeably reduces the water±proof

ability.

Disconnect the connector by fully loosening the bolt.

PREPARATION

1. Turn the ignition switch to LOCK position.

2. Turn up the passenger side floor mat.

3. Remove the ECU protector.

4. Disconnect the connector from the ECU.After completely loosening the bolt, the two parts of the con-

nector can be separated.

NOTICE:

w Do not pully the wire harness when disconnecting the

connector.

w When disconnecting the connector, the ECU's backup

power source is cut off, so the malfunction codes, etc.

recorded in the ECU memory are cancelled.

w Never insert a tester probe or male terminal used for

inspection purposes into the female terminal of the

vehicle wire harness. Otherwise, the female terminal may

be widened, which can result in faulty connection.

5. Connect the Check Harness A between ECU and

connector of vehicle wire harness.

SST 09990±01000

HINT: The arrangement of the check connector terminals are

the same as those of the ECU.

See page TR±35

6. Disconnect the Check Harness A.

7. Reconnect the connector to the ECU. (a) Match the male connector correctly with the femaleconnector, then press them together.

(b) Tighten the bolt

Make sure the connector is completely connected, by tight-

ening the bolt until there is a clearance of less than 1 mm

(0.04 in.) between bottom of the male connector and end of

the female connector.

8. Install the ECU protector and floor mat.

TR±34

±

ENGINE TROUBLESHOOTING Terminals of ECU

WhereEverybodyKnowsYourName

Page 3813 of 4087

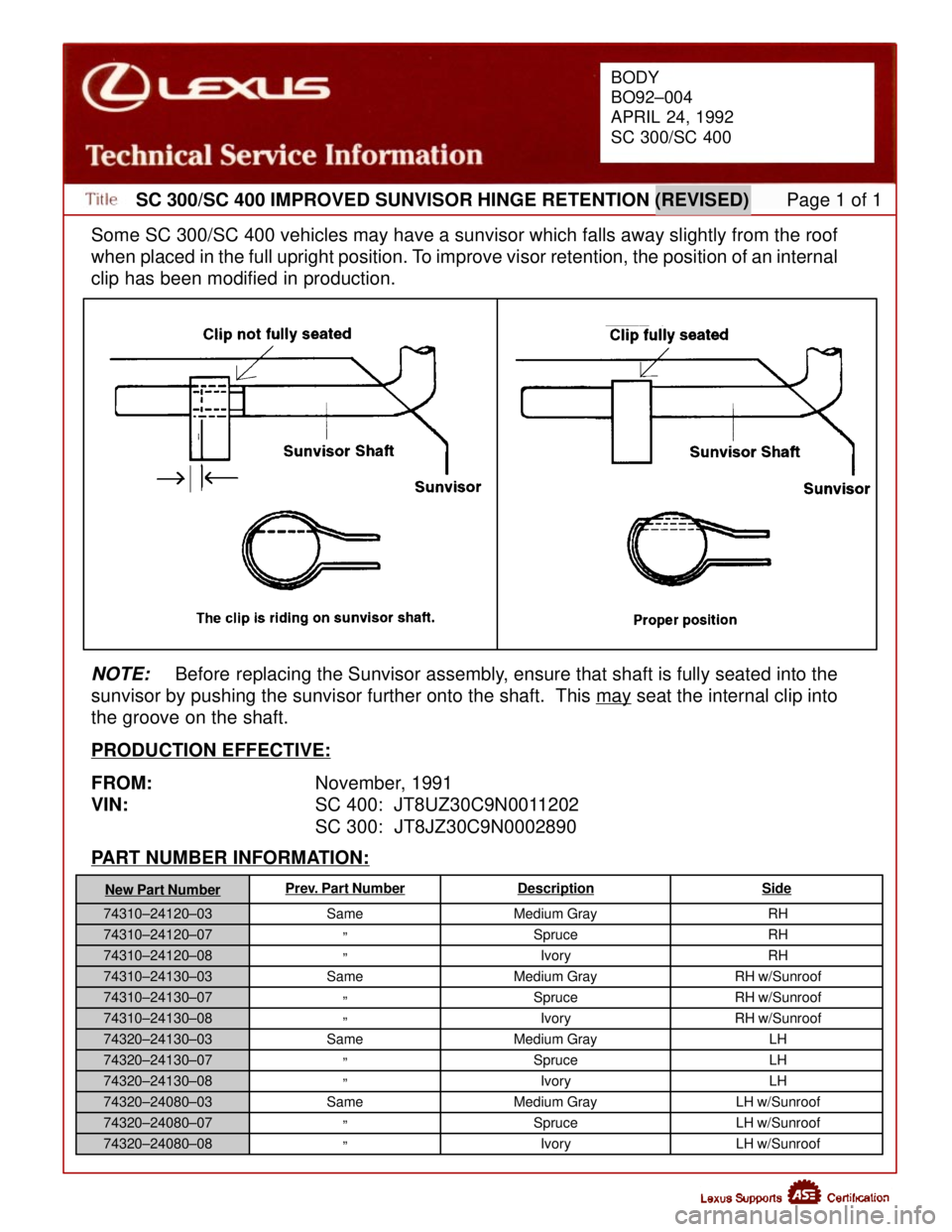

Some SC 300/SC 400 vehicles may have a sunvisor which falls away slightly from the roof

when placed in the full upright position. To improve visor retention, the position of an internal

clip has been modified in production.

BODY

BO92±004

APRIL 24, 1992

SC 300/SC 400

PART NUMBER INFORMATION:

New Part NumberPrev. Part NumberDescriptionSide

NOTE:Before replacing the Sunvisor assembly, ensure that shaft is fully seated into the

sunvisor by pushing the sunvisor further onto the shaft. This may

seat the internal clip into

the groove on the shaft.

PRODUCTION EFFECTIVE:

FROM: November, 1991

VIN: SC 400: JT8UZ30C9N0011202

SC 300: JT8JZ30C9N0002890

Same

º

º

Same

º

º

Same

º

º

Same

º

º Medium Gray

SpruceIvory

SC 300/SC 400 IMPROVED SUNVISOR HINGE RETENTION (REVISED) Page 1 of 1

Medium Gray

SpruceIvory

Medium Gray SpruceIvory

Medium Gray SpruceIvory RH

RH

RH

RH w/Sunroof

RH w/Sunroof

RH w/Sunroof LH

LH

LH

LH w/Sunroof

LH w/Sunroof

LH w/Sunroof

74310±24120±03

74310±24120±07

74310±24120±08

74310±24130±03

74310±24130±07

74310±24130±08

74320±24130±03

74320±24130±07

74320±24130±08

74320±24080±03

74320±24080±07

74320±24080±08

WhereEverybodyKnowsYourName

Page 3873 of 4087

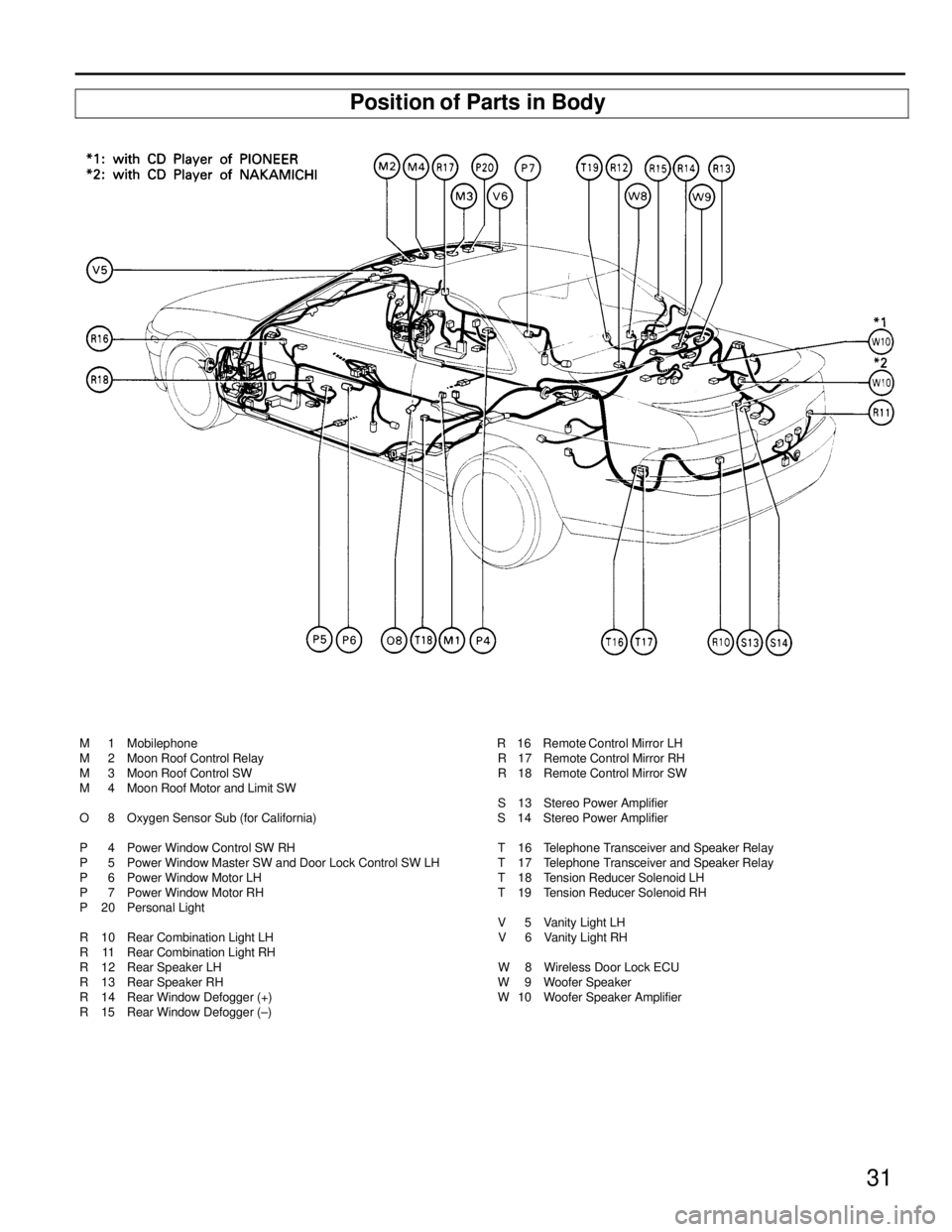

31

Position of Parts in Body

M 1 Mobilephone R 16 Remote Control Mirror LH

M 2 Moon Roof Control Relay R 17 Remote Control Mirror RH

M 3 Moon Roof Control SW R 18 Remote Control Mirror SW

M 4 Moon Roof Motor and Limit SWS 13 Stereo Power Amplifier

O 8 Oxygen Sensor Sub (for California) S 14 Stereo Power Amplifier

P 4 Power Window Control SW RH T 16 Telephone Transceiver and Speaker Relay

P 5 Power Window Master SW and Door Lock Control SW LH T 17 Telephone Transceiver and Speaker Relay

P 6 Power Window Motor LH T 18 Tension Reducer Solenoid LH

P 7 Power Window Motor RH T 19 Tension Reducer Solenoid RH

P 20 Personal Light V 5 Vanity Light LH

R 10 Rear Combination Light LH V 6 Vanity Light RH

R 11 Rear Combination Light RH

R 12 Rear Speaker LH W 8 Wireless Door Lock ECU

R 13 Rear Speaker RH W 9 Woofer Speaker

R 14 Rear Window Defogger (+) W 10 Woofer Speaker Amplifier

R 15 Rear Window Defogger (±)

WhereEverybodyKnowsYourName

Page 3882 of 4087

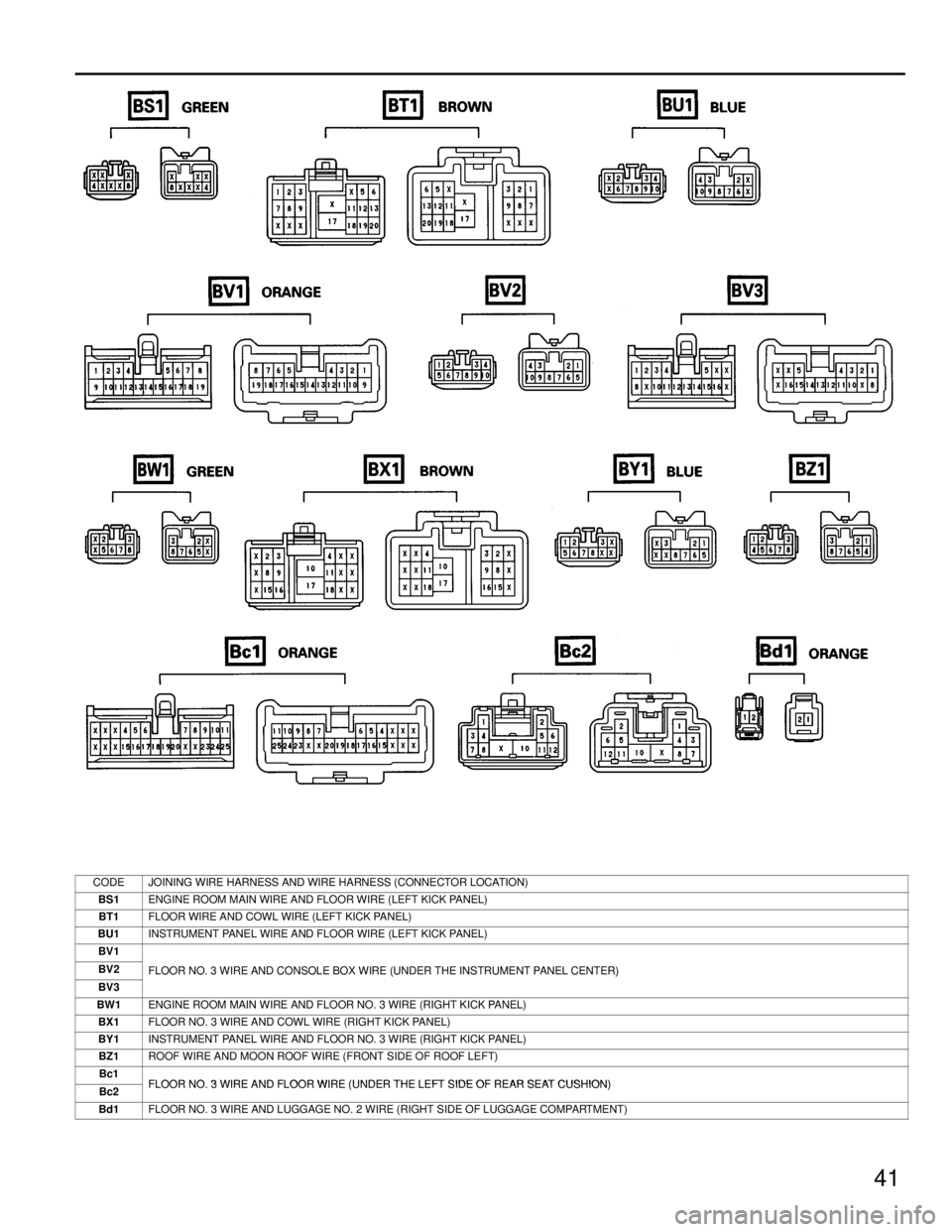

41

CODEJOINING WIRE HARNESS AND WIRE HARNESS (CONNECTOR LOCATION)

BS1ENGINE ROOM MAIN WIRE AND FLOOR WIRE (LEFT KICK PANEL)

BT1FLOOR WIRE AND COWL WIRE (LEFT KICK PANEL)

BU1INSTRUMENT PANEL WIRE AND FLOOR WIRE (LEFT KICK PANEL)

BV1

BV2FLOOR NO. 3 WIRE AND CONSOLE BOX WIRE (UNDER THE INSTRUMENT PANEL CENTER)

BV3

FLOOR NO. 3 WIRE AND CONSOLE BOX WIRE (UNDER THE INSTRUMENT PANEL CENTER)

BW1ENGINE ROOM MAIN WIRE AND FLOOR NO. 3 WIRE (RIGHT KICK PANEL)

BX1FLOOR NO. 3 WIRE AND COWL WIRE (RIGHT KICK PANEL)

BY1INSTRUMENT PANEL WIRE AND FLOOR NO. 3 WIRE (RIGHT KICK PANEL)

BZ1ROOF WIRE AND MOON ROOF WIRE (FRONT SIDE OF ROOF LEFT)

Bc1FLOOR NO 3 WIRE AND FLOOR WIRE (UNDER THE LEFT SIDE OF REAR SEAT CUSHION)Bc2FLOOR NO. 3 WIRE AND FLOOR WIRE (UNDER THE LEFT SIDE OF REAR SEAT CUSHION)

Bd1FLOOR NO. 3 WIRE AND LUGGAGE NO. 2 WIRE (RIGHT SIDE OF LUGGAGE COMPARTMENT)

WhereEverybodyKnowsYourName

Page 3920 of 4087

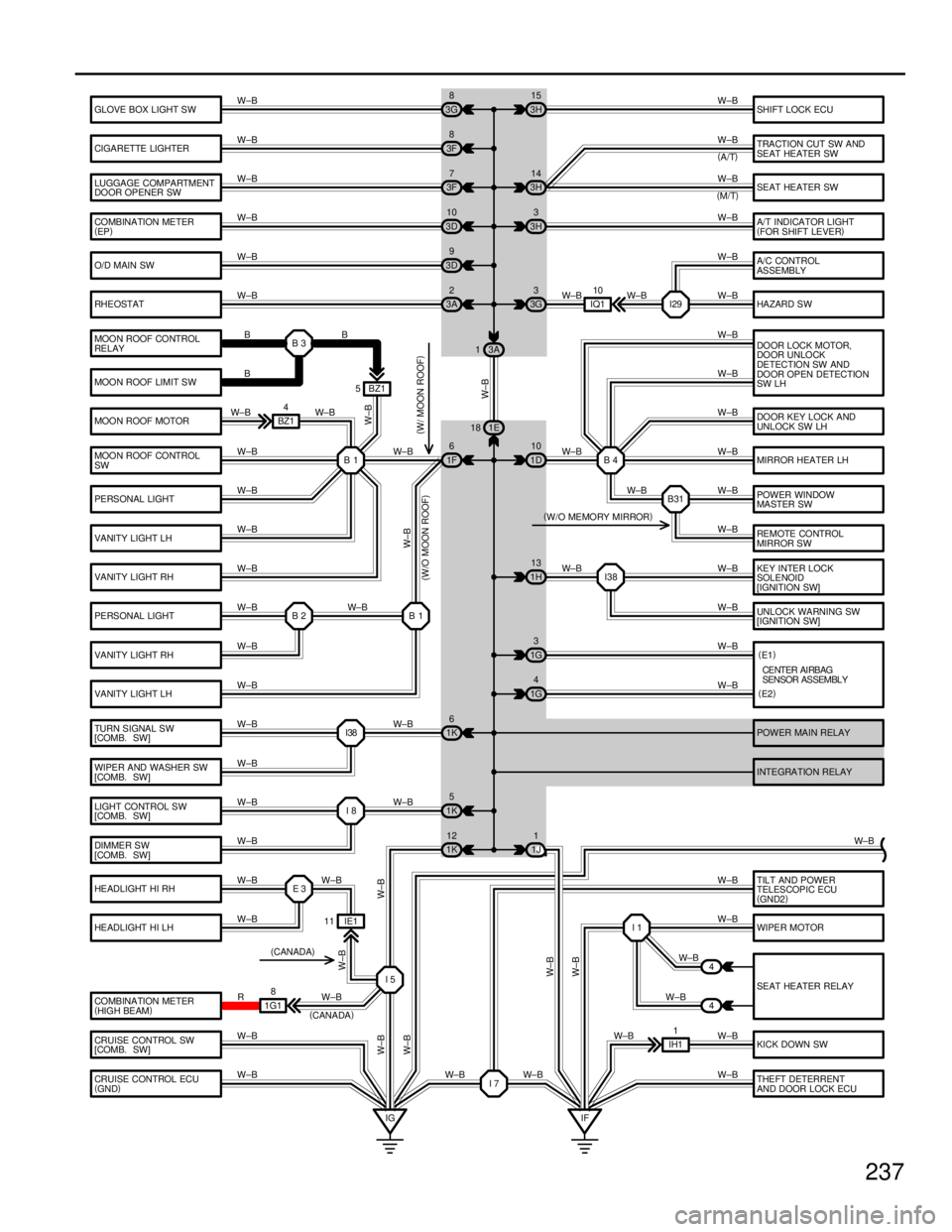

237

GLOVE BOX LIGHT SW

CIGARETTE LIGHTER

LUGGAGE COMPARTMENT

DOOR OPENER SW

COMBINATION METER

(EP )

O/D MAIN SW

RHEOSTAT

DO OR LOCK MOTOR,

DOOR UNLOCK

DETECTION SW AND

DOOR OPEN DETECTION

SW LH

MIRROR HEATER LH DOOR KEY LOCK AND

UNLOCK SW LH

POWER WINDOW

MASTER SW

RE MOTE CO NTROL

MIRROR SW

KEY INTER LOCK

SOLENOID

[IGNITION SW]

UNLOCK WA RNING SW

[IGNITION SW]

TURN SIGNAL SW

[COMB. SW]

WIPER AND WASHER SW

[COMB. SW]

LIGHT CONTROL SW

[COMB. SW]

DIMMER SW

[COMB. SW] INTEGRATION RELAY POWER MAIN RELAY HA ZARD S W A/C CONTROL

ASSEMBLY A/T INDICATOR LIGHT

(

FOR SHIFT LEVER )

SEAT HEATER SW TRACTION CUT SW AND

SEAT HEATER SW SHIFT LOCK ECU

3G 8

3F 8

3F 7

3D 10

3D 9

3A 2

1F 6

1K 6 3H

15

3H 14

3H 3

1D 10

1G 3

1G 4

IF

IG 1E

18 3A

1

W±B W±B W±B

W±B

W±B

W±B W±B W±B

W±B W±B

W±B W±B W±B W±B

W±B W±B

W±B W±B

W±B

W±B

W±B

CE NTER AI RB AG

SENSOR ASSEMBLY

I29

W±B

W±B

3G

3

I38 I8 1K 5

WIPER MOTOR

SEAT HEATER RELAY

KICK DOWN SW

THEFT DETERRENT

AND DOOR LOCK ECU

HE ADLIGHT HI RH

HE ADLIGHT HI LH

COMBINATION METER

(

HIGH BEAM )

CRUISE CONTROL SW

[COMB. SW] E3

I1

4

4

1K

12

IE1

11

IH11

CRUISE CONTROL ECU

( GND ) 1J

1

I7

1G1

8

I5 W±B

W±B

W±B

W±B

W±B

W±B

W±B

W±B R

W±B

W±B W±B W±B W±B W±BW±BW±B

W±B W±B W±B

W±B W±B

W±B

W±B

W±B

W±B

W±B W±B

W±B

W±B

IQ1 10

W±B

(E1 )

( E2 )

TILT AND POWER

TELESCOPIC ECU

( GND2 )

W±B ( A/T )

( M/T )

W±B

1H 13

I38

B4

B31

MOO N ROOF CO NTROL

RE LAY

MOON ROOF LIMIT SW

MOO N ROOF MOTOR

MOO N ROOF CO NTROL

SW

PERSONAL LIGHT

VANITY LIGHT LH

VANITY LIGHT RH

PERSONAL LIGHT

VANITY LIGHT RH

VANITY LIGHT LH B3

B1

B1

B2

B

W±B B

W±B

W±B

W±B

W±B

W±B

W±B

W±B W±BW±B

BZ1

4 BZ1

5

B

W±B

W±B

( CANADA )

W±B

( W/O MOON ROOF )(

W/ MOON ROOF )

(

W/O MEMORY MIRROR )

W±B

(

CANADA )

WhereEverybodyKnowsYourName

Page 3923 of 4087

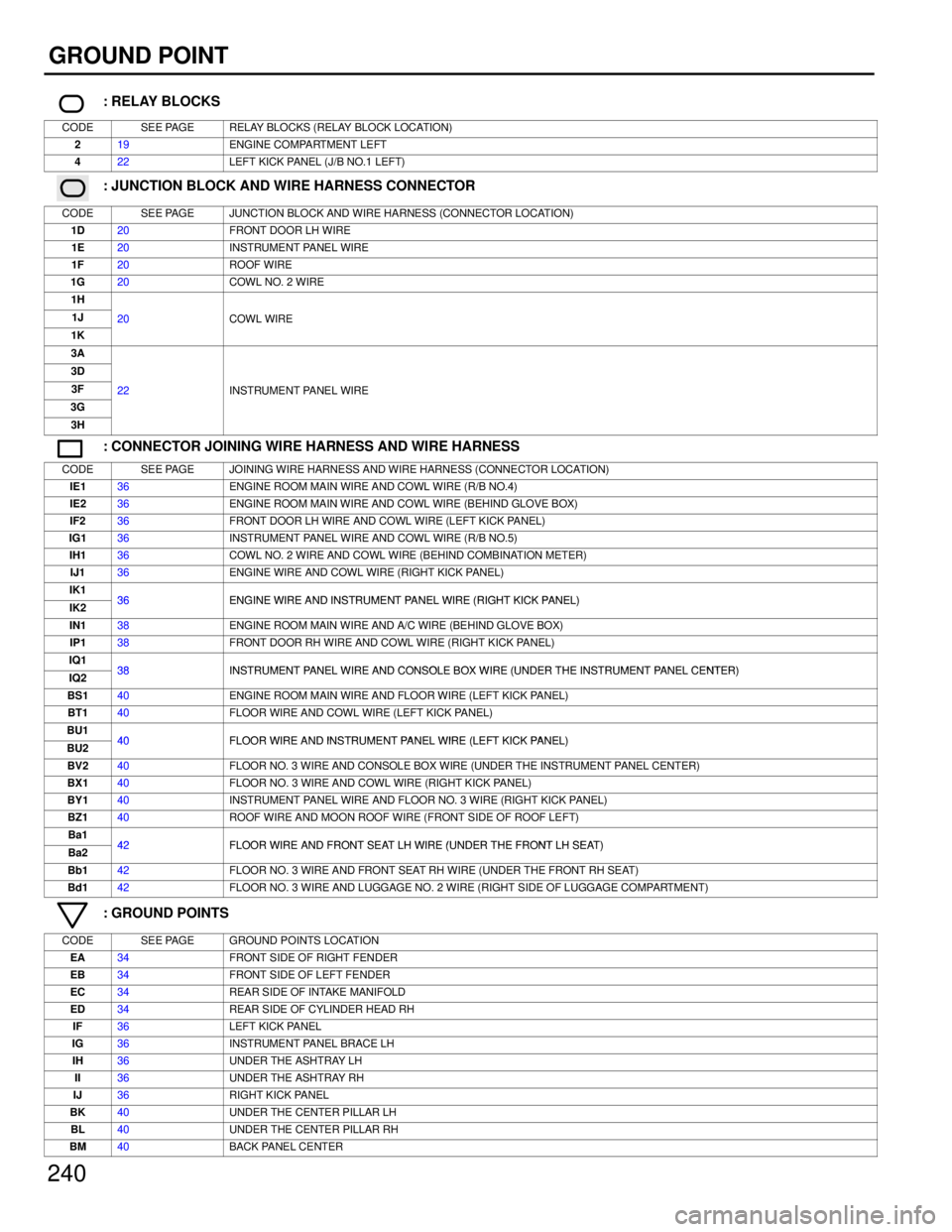

240

GROUND POINT

: RELAY BLOCKS

CODESEE PAGERELAY BLOCKS (RELAY BLOCK LOCATION)

219ENGINE COMPARTMENT LEFT

422LEFT KICK PANEL (J/B NO.1 LEFT)

: JUNCTION BLOCK AND WIRE HARNESS CONNECTOR

CODESEE PAGEJUNCTION BLOCK AND WIRE HARNESS (CONNECTOR LOCATION)

1D20FRONT DOOR LH WIRE

1E20INSTRUMENT PANEL WIRE

1F20ROOF WIRE

1G20COWL NO. 2 WIRE

1H

1J20COWL WIRE

1K

20COWL WIRE

3A

3D

3F22INSTRUMENT PANEL WIRE

3G

22INSTRUMENT PANEL WIRE

3H

: CONNECTOR JOINING WIRE HARNESS AND WIRE HARNESS

CODESEE PAGEJOINING WIRE HARNESS AND WIRE HARNESS (CONNECTOR LOCATION)

IE136ENGINE ROOM MAIN WIRE AND COWL WIRE (R/B NO.4)

IE236ENGINE ROOM MAIN WIRE AND COWL WIRE (BEHIND GLOVE BOX)

IF236FRONT DOOR LH WIRE AND COWL WIRE (LEFT KICK PANEL)

IG136INSTRUMENT PANEL WIRE AND COWL WIRE (R/B NO.5)

IH136COWL NO. 2 WIRE AND COWL WIRE (BEHIND COMBINATION METER)

IJ136ENGINE WIRE AND COWL WIRE (RIGHT KICK PANEL)

IK136ENGINE WIRE AND INSTRUMENT PANEL WIRE (RIGHT KICK PANEL)IK236ENGINE WIRE AND INSTRUMENT PANEL WIRE (RIGHT KICK PANEL)

IN138ENGINE ROOM MAIN WIRE AND A/C WIRE (BEHIND GLOVE BOX)

IP138FRONT DOOR RH WIRE AND COWL WIRE (RIGHT KICK PANEL)

IQ138INSTRUMENT PANEL WIRE AND CONSOLE BOX WIRE (UNDER THE INSTRUMENT PANEL CENTER)IQ238INSTRUMENT PANEL WIRE AND CONSOLE BOX WIRE (UNDER THE INSTRUMENT PANEL CENTER)

BS140ENGINE ROOM MAIN WIRE AND FLOOR WIRE (LEFT KICK PANEL)

BT140FLOOR WIRE AND COWL WIRE (LEFT KICK PANEL)

BU140FLOOR WIRE AND INSTRUMENT PANEL WIRE (LEFT KICK PANEL)BU240FLOOR WIRE AND INSTRUMENT PANEL WIRE (LEFT KICK PANEL)

BV240FLOOR NO. 3 WIRE AND CONSOLE BOX WIRE (UNDER THE INSTRUMENT PANEL CENTER)

BX140FLOOR NO. 3 WIRE AND COWL WIRE (RIGHT KICK PANEL)

BY140INSTRUMENT PANEL WIRE AND FLOOR NO. 3 WIRE (RIGHT KICK PANEL)

BZ140ROOF WIRE AND MOON ROOF WIRE (FRONT SIDE OF ROOF LEFT)

Ba142FLOOR WIRE AND FRONT SEAT LH WIRE (UNDER THE FRONT LH SEAT)Ba242FLOOR WIRE AND FRONT SEAT LH WIRE (UNDER THE FRONT LH SEAT)

Bb142FLOOR NO. 3 WIRE AND FRONT SEAT RH WIRE (UNDER THE FRONT RH SEAT)

Bd142FLOOR NO. 3 WIRE AND LUGGAGE NO. 2 WIRE (RIGHT SIDE OF LUGGAGE COMPARTMENT)

: GROUND POINTS

CODESEE PAGEGROUND POINTS LOCATION

EA34FRONT SIDE OF RIGHT FENDER

EB34FRONT SIDE OF LEFT FENDER

EC34REAR SIDE OF INTAKE MANIFOLD

ED34REAR SIDE OF CYLINDER HEAD RH

IF36LEFT KICK PANEL

IG36INSTRUMENT PANEL BRACE LH

IH36UNDER THE ASHTRAY LH

II36UNDER THE ASHTRAY RH

IJ36RIGHT KICK PANEL

BK40UNDER THE CENTER PILLAR LH

BL40UNDER THE CENTER PILLAR RH

BM40BACK PANEL CENTER

WhereEverybodyKnowsYourName