LINCOLN AVIATOR 2003 Owners Manual

Manufacturer: LINCOLN, Model Year: 2003, Model line: AVIATOR, Model: LINCOLN AVIATOR 2003Pages: 288, PDF Size: 3.32 MB

Page 211 of 288

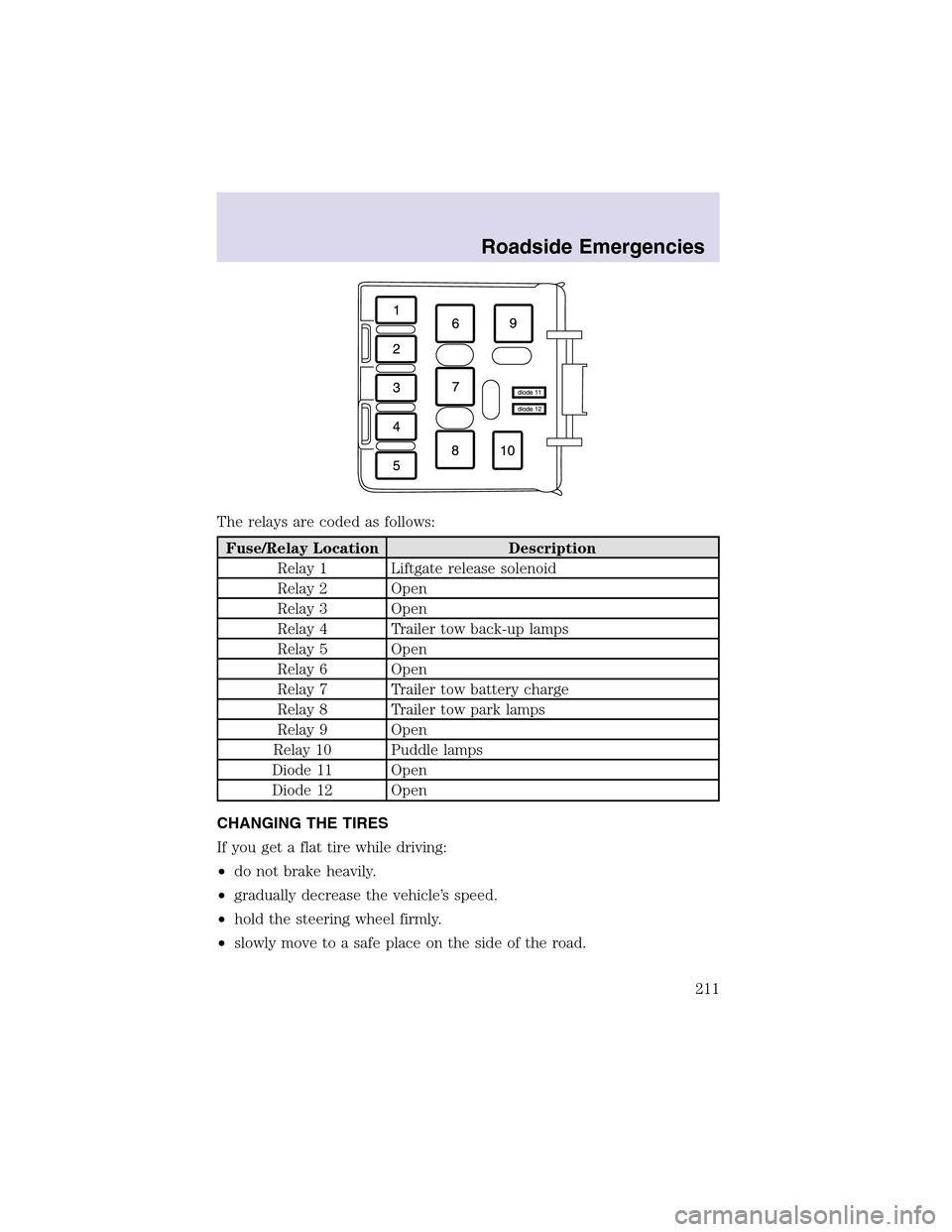

The relays are coded as follows:

Fuse/Relay Location Description

Relay 1 Liftgate release solenoid

Relay 2 Open

Relay 3 Open

Relay 4 Trailer tow back-uplamps

Relay 5 Open

Relay 6 Open

Relay 7 Trailer tow battery charge

Relay 8 Trailer tow park lamps

Relay 9 Open

Relay 10 Puddle lamps

Diode 11 Open

Diode 12 Open

CHANGING THE TIRES

If you get a flat tire while driving:

•do not brake heavily.

•gradually decrease the vehicle’s speed.

•hold the steering wheel firmly.

•slowly move to a safe place on the side of the road.

Roadside Emergencies

211

Page 212 of 288

The use of tire sealants is not recommended and may

compromise the integrity of your tires. The use of tire sealants

may also affect your tire pressure monitoring system (if equipped).

If your vehicle is equipped with a tire pressure monitoring

system, refer toTire Pressure Monitoring System (if

equipped)in theMaintenance and specificationssection for

important information. If the tire pressure monitor sensor becomes

damaged, it will no longer function.

Spare tire information

The spare tire can be used as a spare or a regular tire and is identical to

the other tires on your vehicle.

If your vehicle is equipped with AWD, a spare tire of a different

size than the road tires should not be used. Such a tire could

make the vehicle difficult to control as well as result in damage to

driveline components.

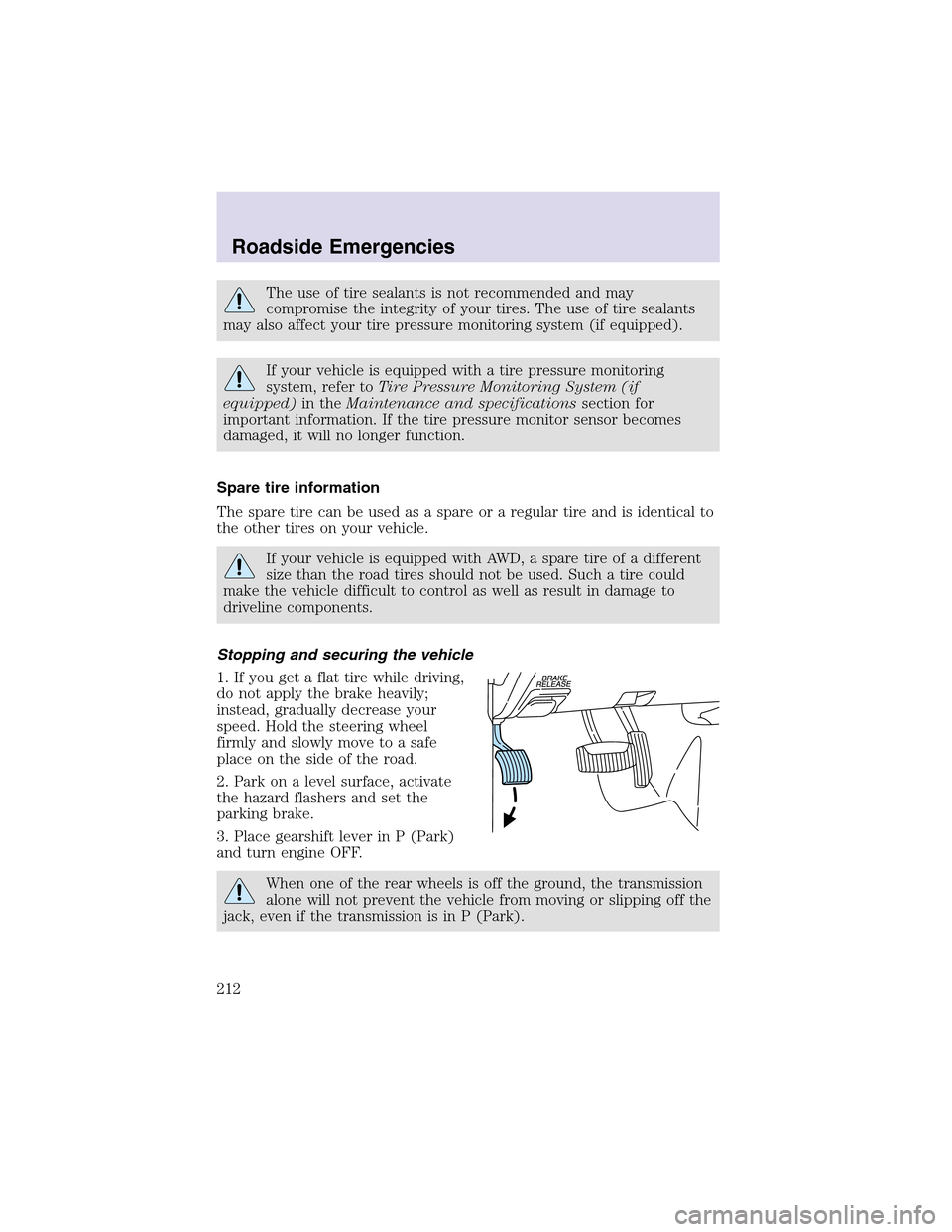

Stopping and securing the vehicle

1. If you get a flat tire while driving,

do not apply the brake heavily;

instead, gradually decrease your

speed. Hold the steering wheel

firmly and slowly move to a safe

place on the side of the road.

2. Park on a level surface, activate

the hazard flashers and set the

parking brake.

3. Place gearshift lever in P (Park)

and turn engine OFF.

When one of the rear wheels is off the ground, the transmission

alone will not prevent the vehicle from moving or slipping off the

jack, even if the transmission is in P (Park).

Roadside Emergencies

212

Page 213 of 288

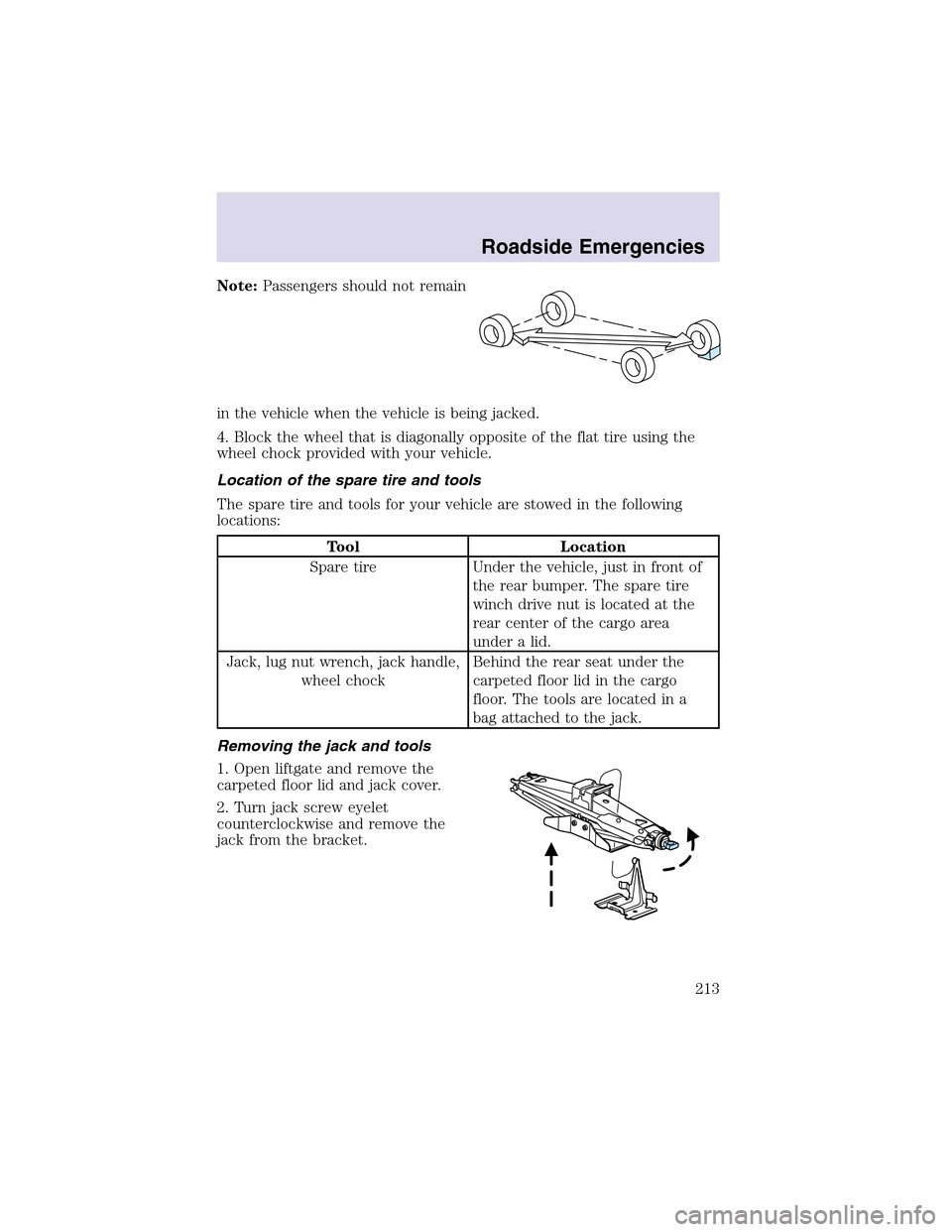

Note:Passengers should not remain

in the vehicle when the vehicle is being jacked.

4. Block the wheel that is diagonally opposite of the flat tire using the

wheel chock provided with your vehicle.

Location of the spare tire and tools

The spare tire and tools for your vehicle are stowed in the following

locations:

Tool Location

Spare tire Under the vehicle, just in front of

the rear bumper. The spare tire

winch drive nut is located at the

rear center of the cargo area

under a lid.

Jack, lug nut wrench, jack handle,

wheel chockBehind the rear seat under the

carpeted floor lid in the cargo

floor. The tools are located in a

bag attached to the jack.

Removing the jack and tools

1. Open liftgate and remove the

carpeted floor lid and jack cover.

2. Turn jack screw eyelet

counterclockwise and remove the

jack from the bracket.

Roadside Emergencies

213

Page 214 of 288

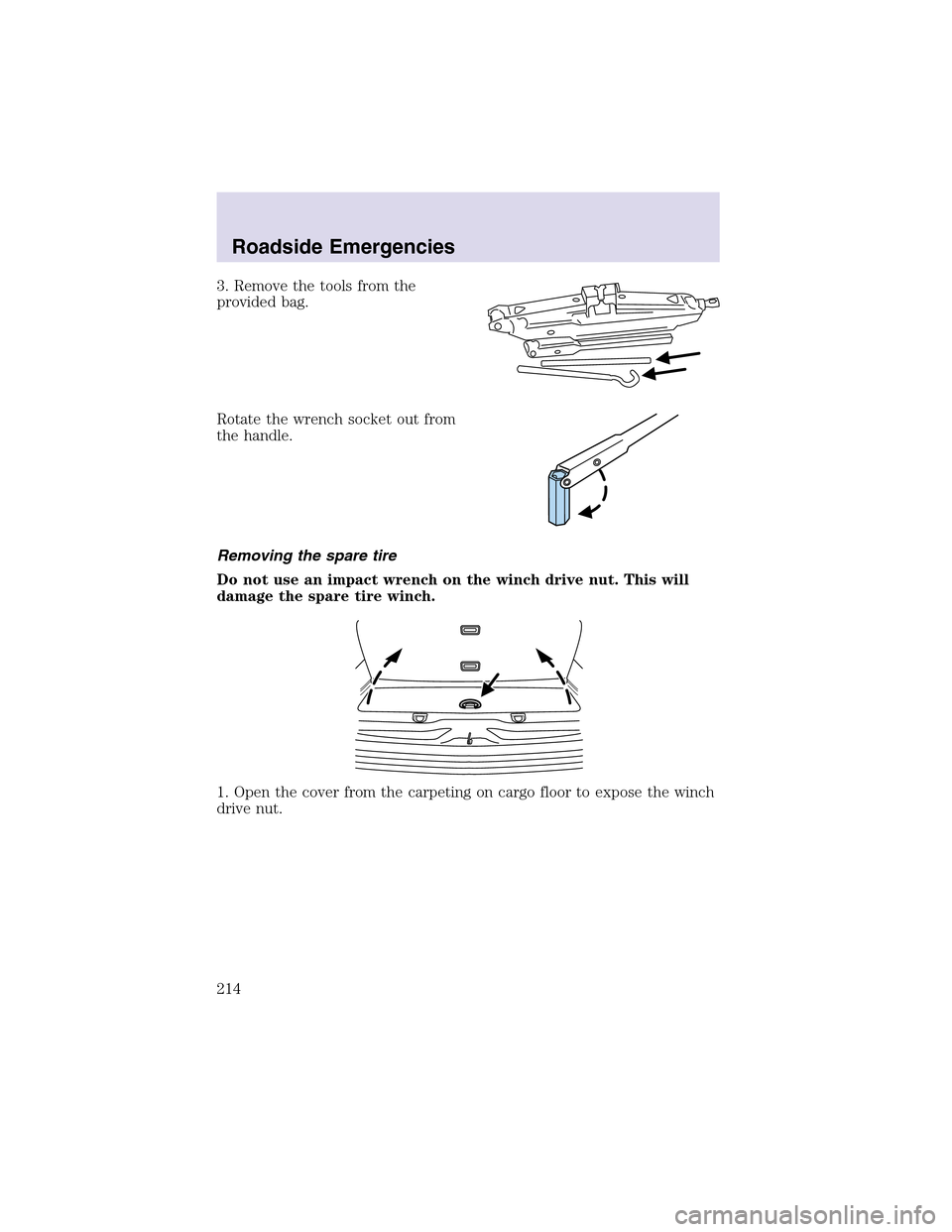

3. Remove the tools from the

provided bag.

Rotate the wrench socket out from

the handle.

Removing the spare tire

Do not use an impact wrench on the winch drive nut. This will

damage the spare tire winch.

1. Open the cover from the carpeting on cargo floor to expose the winch

drive nut.

Roadside Emergencies

214

Page 215 of 288

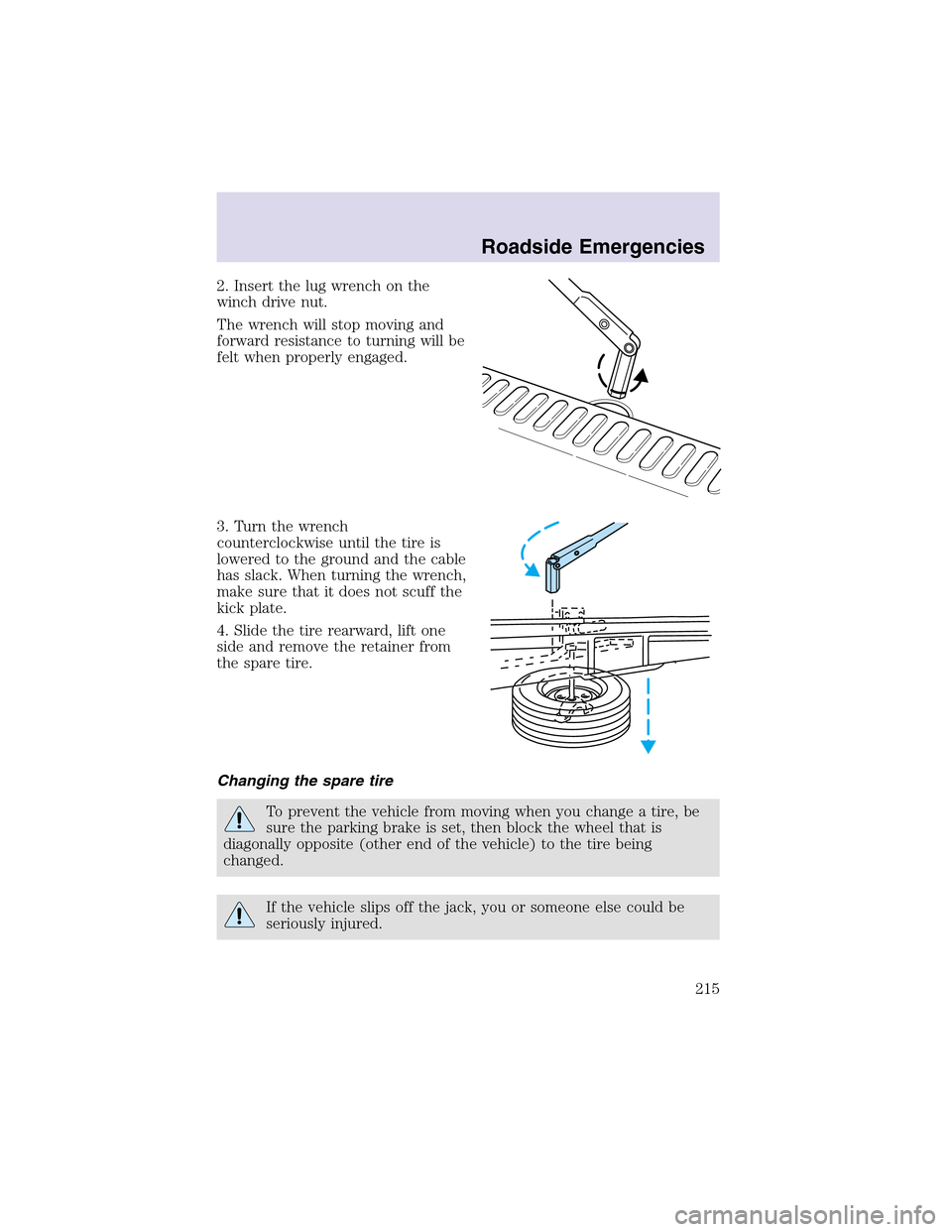

2. Insert the lug wrench on the

winch drive nut.

The wrench will stopmoving and

forward resistance to turning will be

felt when properly engaged.

3. Turn the wrench

counterclockwise until the tire is

lowered to the ground and the cable

has slack. When turning the wrench,

make sure that it does not scuff the

kick plate.

4. Slide the tire rearward, lift one

side and remove the retainer from

the spare tire.

Changing the spare tire

To prevent the vehicle from moving when you change a tire, be

sure the parking brake is set, then block the wheel that is

diagonally opposite (other end of the vehicle) to the tire being

changed.

If the vehicle slips off the jack, you or someone else could be

seriously injured.

Roadside Emergencies

215

Page 216 of 288

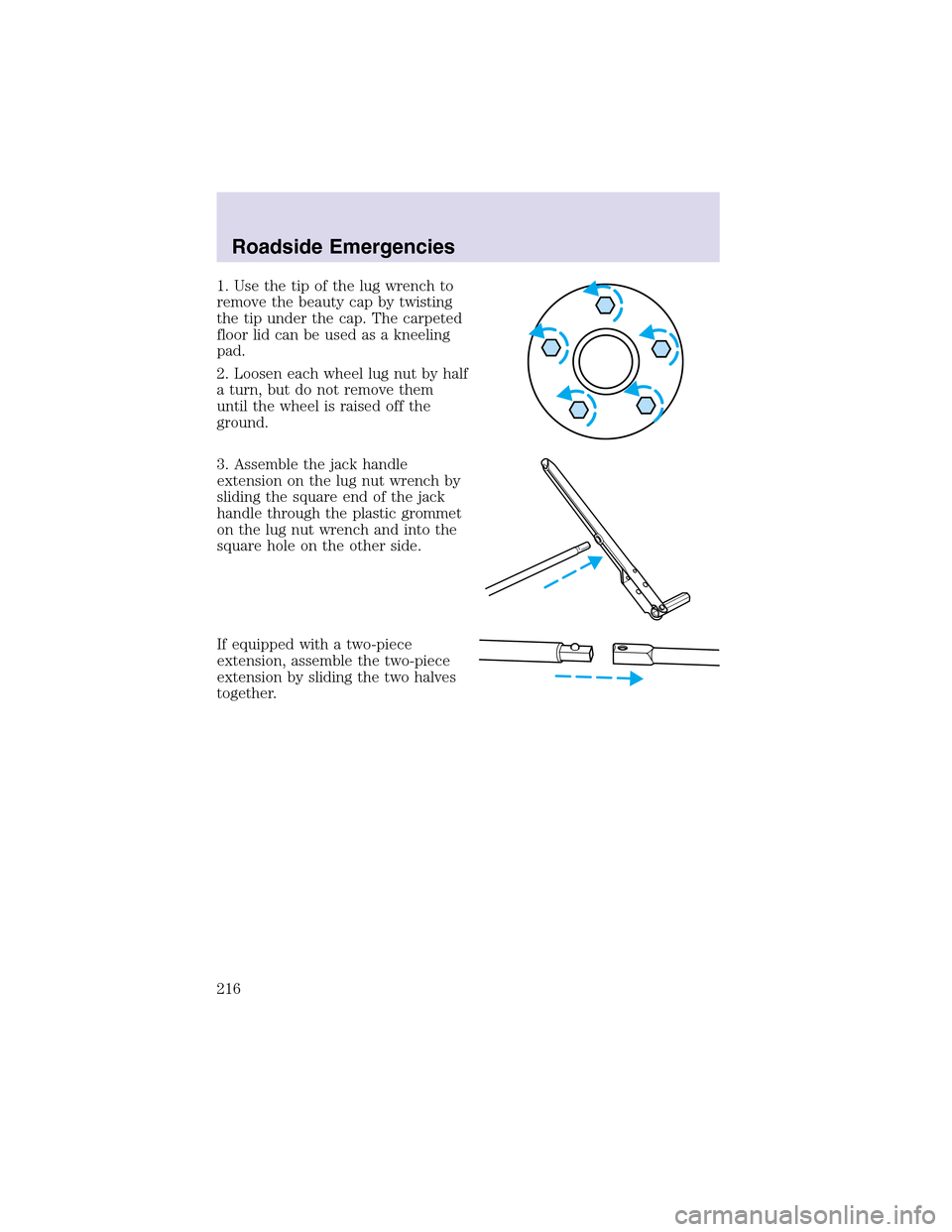

1. Use the tipof the lug wrench to

remove the beauty capby twisting

the tip under the cap. The carpeted

floor lid can be used as a kneeling

pad.

2. Loosen each wheel lug nut by half

a turn, but do not remove them

until the wheel is raised off the

ground.

3. Assemble the jack handle

extension on the lug nut wrench by

sliding the square end of the jack

handle through the plastic grommet

on the lug nut wrench and into the

square hole on the other side.

If equipped with a two-piece

extension, assemble the two-piece

extension by sliding the two halves

together.

Roadside Emergencies

216

Page 217 of 288

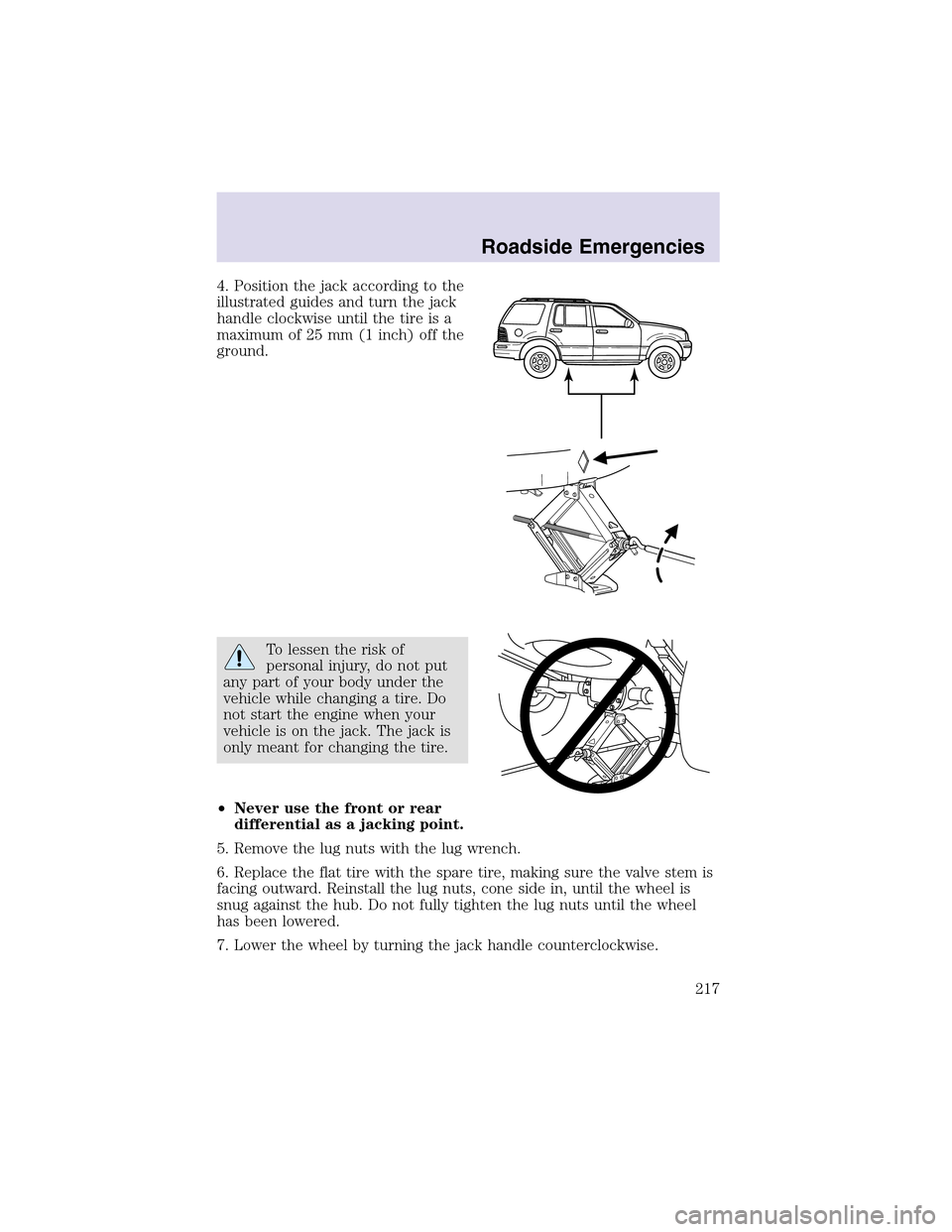

4. Position the jack according to the

illustrated guides and turn the jack

handle clockwise until the tire is a

maximum of 25 mm (1 inch) off the

ground.

To lessen the risk of

personal injury, do not put

any part of your body under the

vehicle while changing a tire. Do

not start the engine when your

vehicle is on the jack. The jack is

only meant for changing the tire.

•Never use the front or rear

differential as a jacking point.

5. Remove the lug nuts with the lug wrench.

6. Replace the flat tire with the spare tire, making sure the valve stem is

facing outward. Reinstall the lug nuts, cone side in, until the wheel is

snug against the hub. Do not fully tighten the lug nuts until the wheel

has been lowered.

7. Lower the wheel by turning the jack handle counterclockwise.

Roadside Emergencies

217

Page 218 of 288

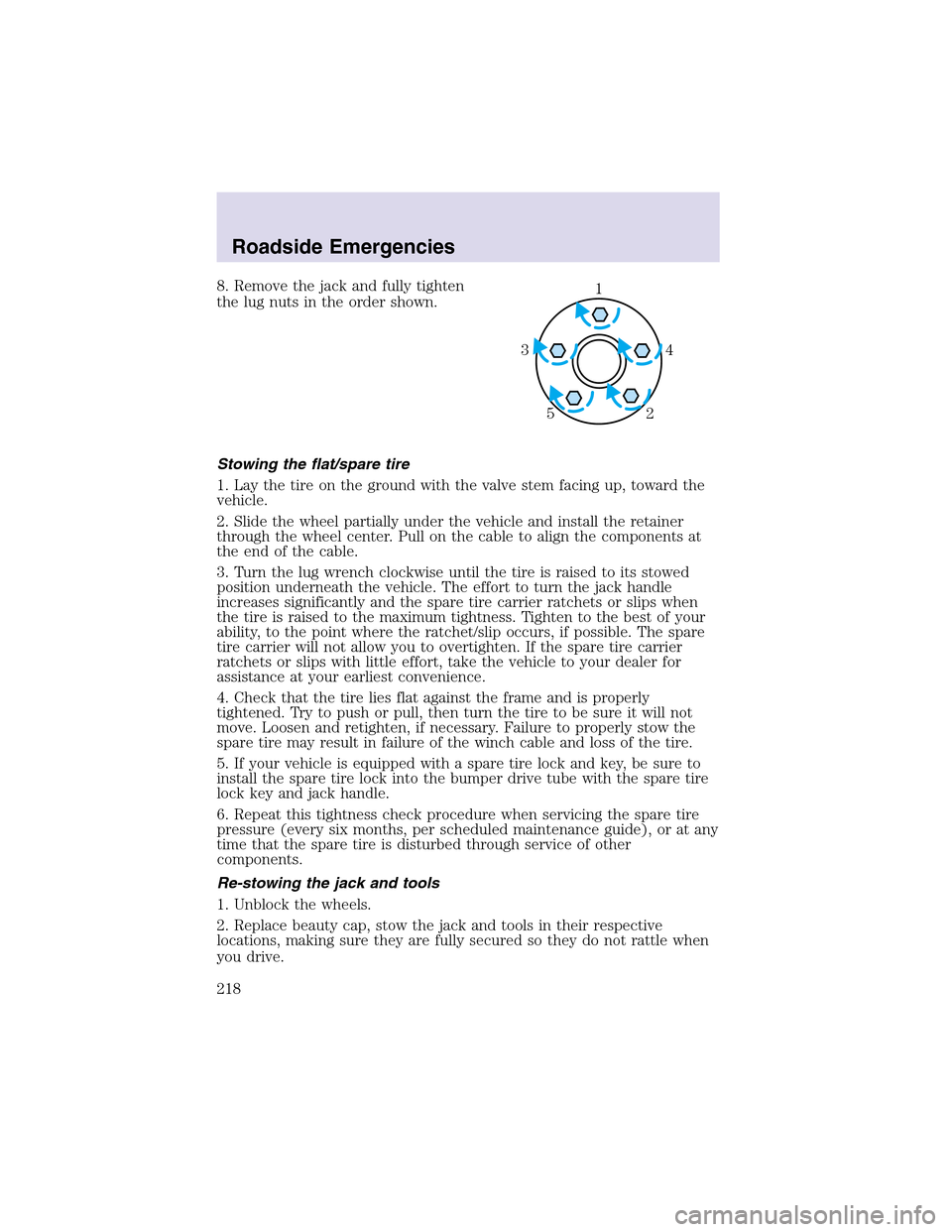

8. Remove the jack and fully tighten

the lug nuts in the order shown.

Stowing the flat/spare tire

1. Lay the tire on the ground with the valve stem facing up, toward the

vehicle.

2. Slide the wheel partially under the vehicle and install the retainer

through the wheel center. Pull on the cable to align the components at

the end of the cable.

3. Turn the lug wrench clockwise until the tire is raised to its stowed

position underneath the vehicle. The effort to turn the jack handle

increases significantly and the spare tire carrier ratchets or slips when

the tire is raised to the maximum tightness. Tighten to the best of your

ability, to the point where the ratchet/slip occurs, if possible. The spare

tire carrier will not allow you to overtighten. If the spare tire carrier

ratchets or slips with little effort, take the vehicle to your dealer for

assistance at your earliest convenience.

4. Check that the tire lies flat against the frame and is properly

tightened. Try to push or pull, then turn the tire to be sure it will not

move. Loosen and retighten, if necessary. Failure to properly stow the

spare tire may result in failure of the winch cable and loss of the tire.

5. If your vehicle is equipped with a spare tire lock and key, be sure to

install the spare tire lock into the bumper drive tube with the spare tire

lock key and jack handle.

6. Repeat this tightness check procedure when servicing the spare tire

pressure (every six months, per scheduled maintenance guide), or at any

time that the spare tire is disturbed through service of other

components.

Re-stowing the jack and tools

1. Unblock the wheels.

2. Replace beauty cap, stow the jack and tools in their respective

locations, making sure they are fully secured so they do not rattle when

you drive.1

4 3

2 5

Roadside Emergencies

218

Page 219 of 288

JUMP STARTING YOUR VEHICLE

The gases around the battery can explode if exposed to flames,

sparks, or lit cigarettes. An explosion could result in injury or

vehicle damage.

Batteries contain sulfuric acid which can burn skin, eyes and

clothing, if contacted.

Do not attempt to push-start your vehicle. Automatic

transmissions do not have push-start capability; also, the

catalytic converter may become damaged.

Preparing your vehicle

When the battery is disconnected or a new battery is installed, the

transmission must relearn its shift strategy. As a result, the transmission

may have firm and/or soft shifts. This operation is considered normal and

will not affect function or durability of the transmission. Over time, the

adaptive learning process will fully update transmission operation.

1.Use only a 12–volt supply to start your vehicle.

2. Do not disconnect the battery of the disabled vehicle as this could

damage the vehicle’s electrical system.

3. Park the booster vehicle close to the hood of the disabled vehicle

making sure the two vehiclesdo nottouch. Set the parking brake on

both vehicles and stay clear of the engine cooling fan and other moving

parts.

4. Check all battery terminals and remove any excessive corrosion before

you attach the battery cables. Ensure that vent caps are tight and level.

5. Turn the heater fan on in both vehicles to protect any electrical

surges. Turn all other accessories off.

Roadside Emergencies

219

Page 220 of 288

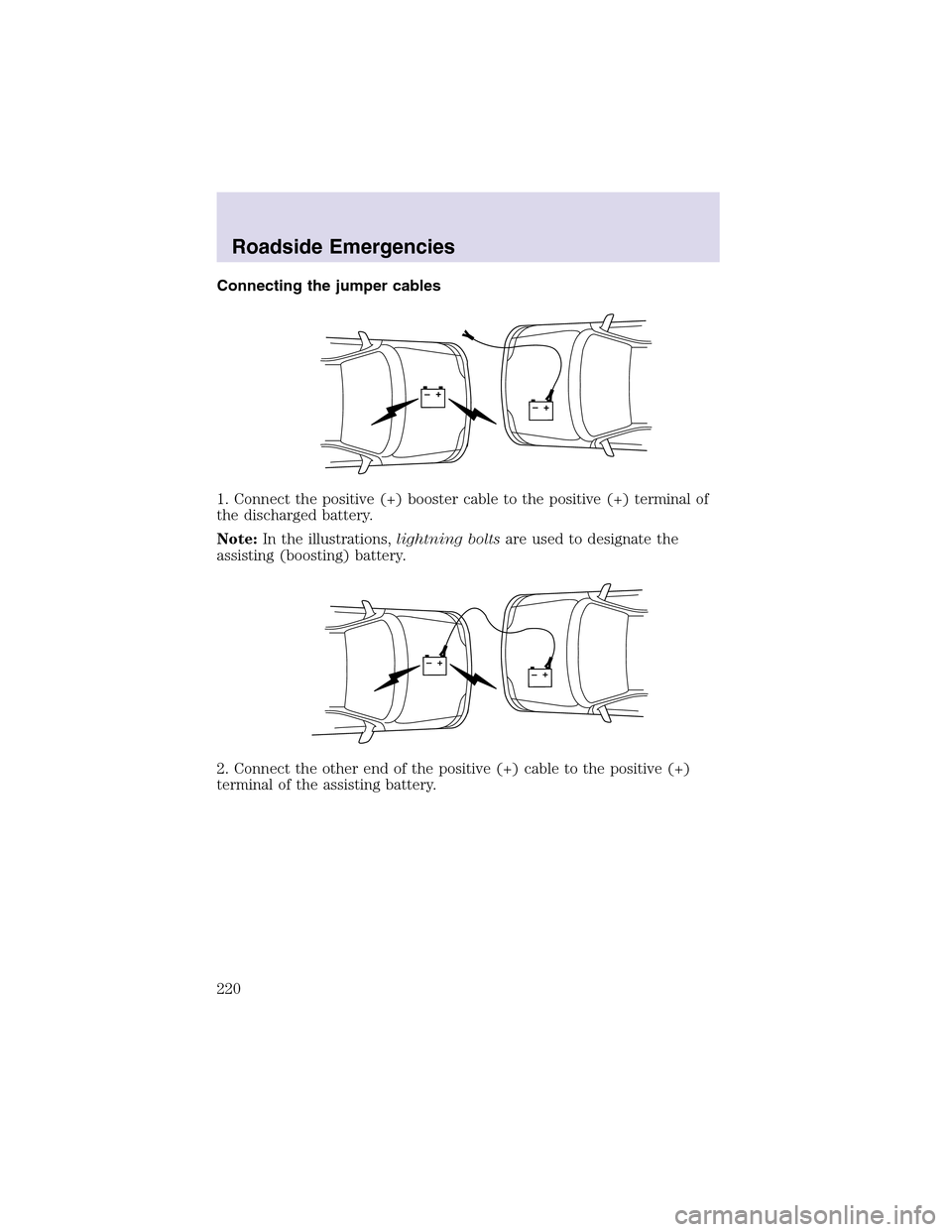

Connecting the jumper cables

1. Connect the positive (+) booster cable to the positive (+) terminal of

the discharged battery.

Note:In the illustrations,lightning boltsare used to designate the

assisting (boosting) battery.

2. Connect the other end of the positive (+) cable to the positive (+)

terminal of the assisting battery.

+–+–

+–+–

Roadside Emergencies

220