maintenance LINCOLN BLACKWOOD 2002 Owners Manual

[x] Cancel search | Manufacturer: LINCOLN, Model Year: 2002, Model line: BLACKWOOD, Model: LINCOLN BLACKWOOD 2002Pages: 248, PDF Size: 2.33 MB

Page 1 of 248

Before driving

Introduction 2

Instrumentation 6

Controls and features 17

Seating and safety restraints 90

Starting and driving

Starting 125

Driving 129

Roadside emergencies 147

Servicing

Maintenance and care 168

Capacities and specifications 218

Customer assistance 225

Reporting safety defects 237

Index 238

All rights reserved. Reproduction by any means, electronic or mechanical including

photocopying, recording or by any information storage and retrieval system or translation

in whole or part is not permitted without written authorization from Ford Motor Company.

Ford may change the contents without notice and without incurring obligation.

Copyright 2001 Ford Motor Company

Contents

1

Page 11 of 248

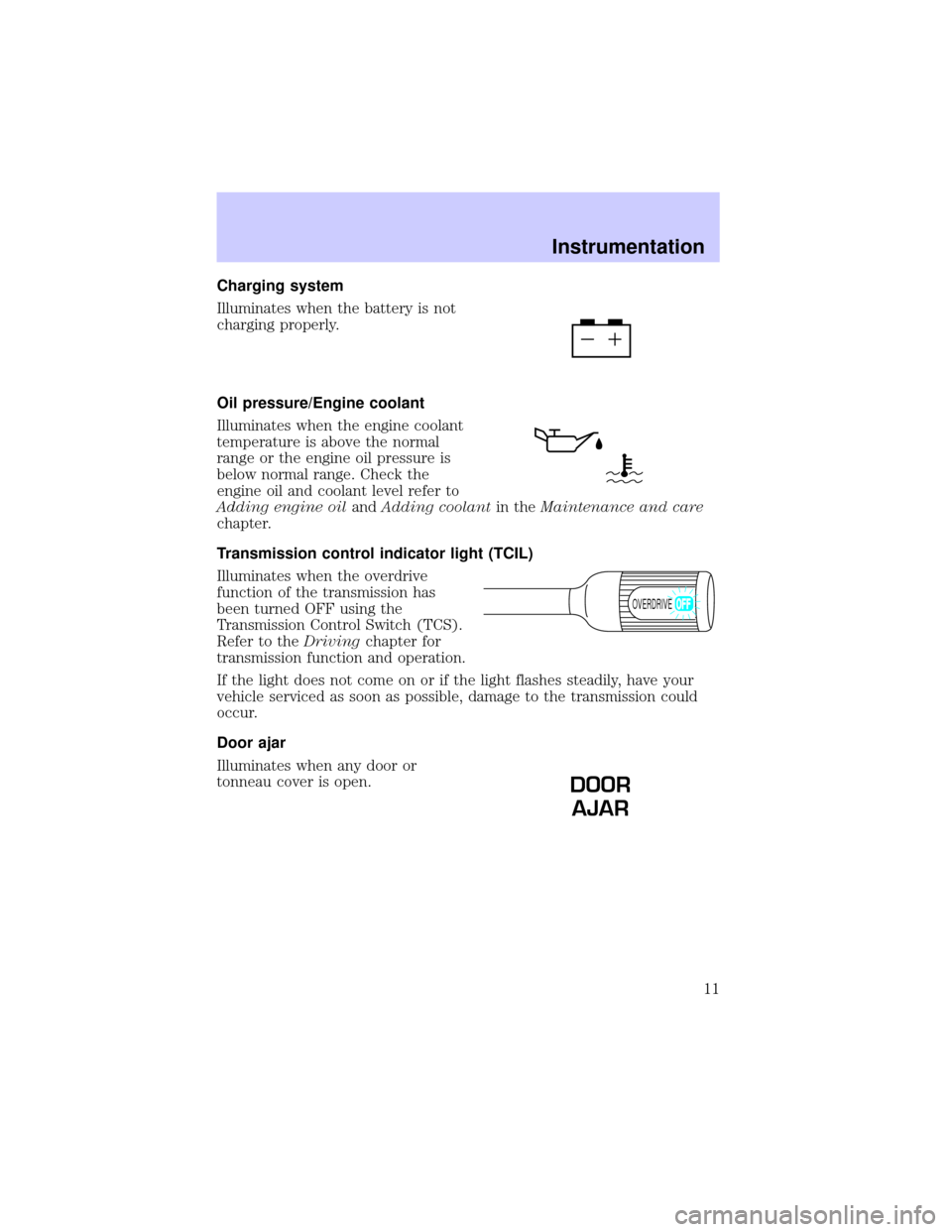

Charging system

Illuminates when the battery is not

charging properly.

Oil pressure/Engine coolant

Illuminates when the engine coolant

temperature is above the normal

range or the engine oil pressure is

below normal range. Check the

engine oil and coolant level refer to

Adding engine oilandAdding coolantin theMaintenance and care

chapter.

Transmission control indicator light (TCIL)

Illuminates when the overdrive

function of the transmission has

been turned OFF using the

Transmission Control Switch (TCS).

Refer to theDrivingchapter for

transmission function and operation.

If the light does not come on or if the light flashes steadily, have your

vehicle serviced as soon as possible, damage to the transmission could

occur.

Door ajar

Illuminates when any door or

tonneau cover is open.

OVERDRIVE

DOOR

AJAR

Instrumentation

11

Page 14 of 248

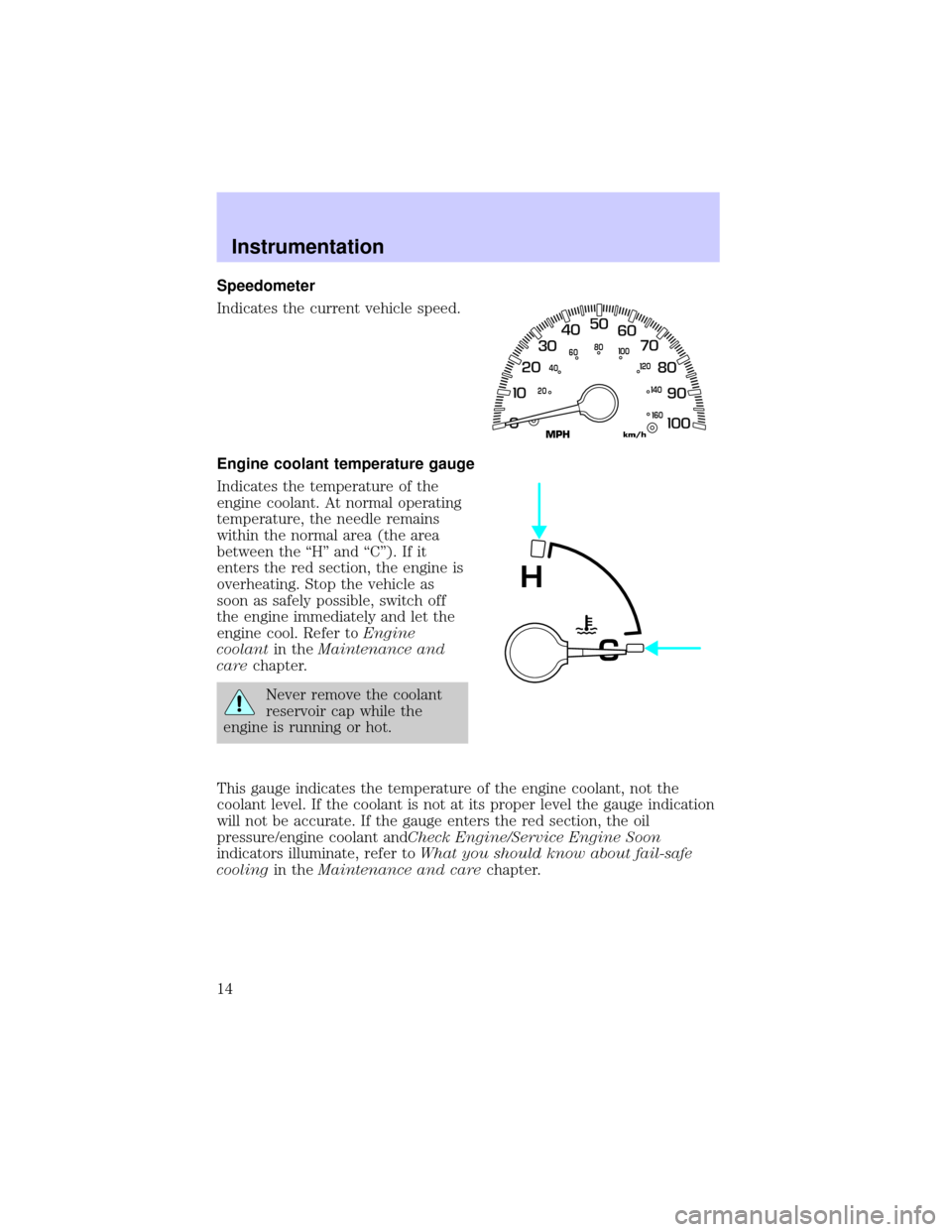

Speedometer

Indicates the current vehicle speed.

Engine coolant temperature gauge

Indicates the temperature of the

engine coolant. At normal operating

temperature, the needle remains

within the normal area (the area

between the ªHº and ªCº). If it

enters the red section, the engine is

overheating. Stop the vehicle as

soon as safely possible, switch off

the engine immediately and let the

engine cool. Refer toEngine

coolantin theMaintenance and

carechapter.

Never remove the coolant

reservoir cap while the

engine is running or hot.

This gauge indicates the temperature of the engine coolant, not the

coolant level. If the coolant is not at its proper level the gauge indication

will not be accurate. If the gauge enters the red section, the oil

pressure/engine coolant andCheck Engine/Service Engine Soon

indicators illuminate, refer toWhat you should know about fail-safe

coolingin theMaintenance and carechapter.

MPHkm/hkm/h

20406080

6040

2000

C

H

Instrumentation

14

Page 16 of 248

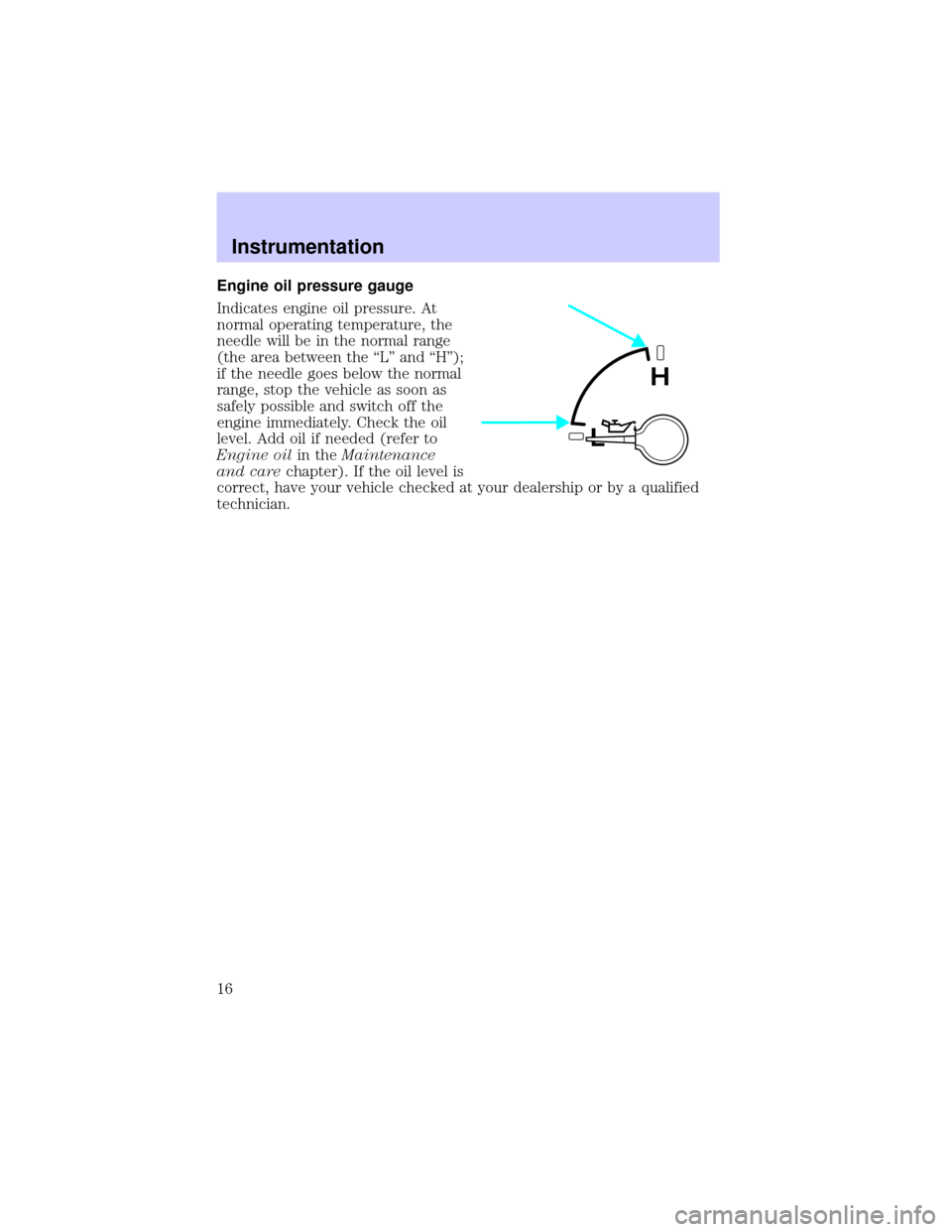

Engine oil pressure gauge

Indicates engine oil pressure. At

normal operating temperature, the

needle will be in the normal range

(the area between the ªLº and ªHº);

if the needle goes below the normal

range, stop the vehicle as soon as

safely possible and switch off the

engine immediately. Check the oil

level. Add oil if needed (refer to

Engine oilin theMaintenance

and carechapter). If the oil level is

correct, have your vehicle checked at your dealership or by a qualified

technician.

L

H

Instrumentation

16

Page 93 of 248

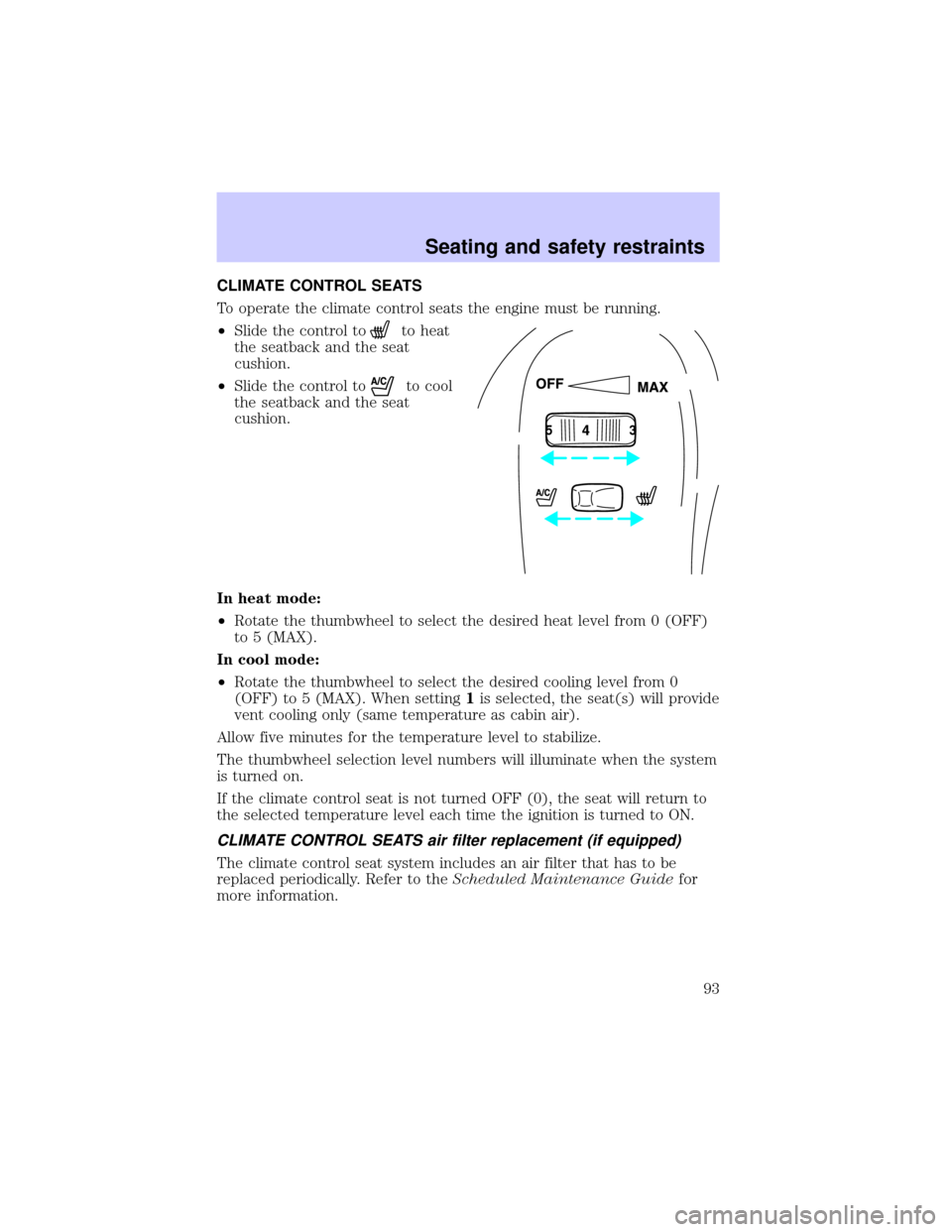

CLIMATE CONTROL SEATS

To operate the climate control seats the engine must be running.

²Slide the control to

to heat

the seatback and the seat

cushion.

²Slide the control to

to cool

the seatback and the seat

cushion.

In heat mode:

²Rotate the thumbwheel to select the desired heat level from 0 (OFF)

to 5 (MAX).

In cool mode:

²Rotate the thumbwheel to select the desired cooling level from 0

(OFF) to 5 (MAX). When setting1is selected, the seat(s) will provide

vent cooling only (same temperature as cabin air).

Allow five minutes for the temperature level to stabilize.

The thumbwheel selection level numbers will illuminate when the system

is turned on.

If the climate control seat is not turned OFF (0), the seat will return to

the selected temperature level each time the ignition is turned to ON.

CLIMATE CONTROL SEATS air filter replacement (if equipped)

The climate control seat system includes an air filter that has to be

replaced periodically. Refer to theScheduled Maintenance Guidefor

more information.

53

Seating and safety restraints

93

Page 105 of 248

Safety belt pretensioner

Your vehicle is equipped with safety belt pretensioners at the driver and

front passenger seating positions.

The safety belt pretensioner is a device which removes excess webbing

from the safety belt system. The safety belt pretensioner uses the same

crash sensor system as the front air bag supplemental restraint system

(SRS). When the safety belt pretensioner deploys, webbing from the lap

and shoulder belt is tightened. The driver and front passenger seat belt

system (including retractors, buckles and height adjusters) must be

replaced if the vehicle is involved in a collision that results in

deployment of front air bags and safety belt pretensioners. Refer to the

Safety belt maintenancesection in this chapter.

Failure to replace the safety belt assembly under the above

conditions could result in severe personal injuries in the event of

a collision.

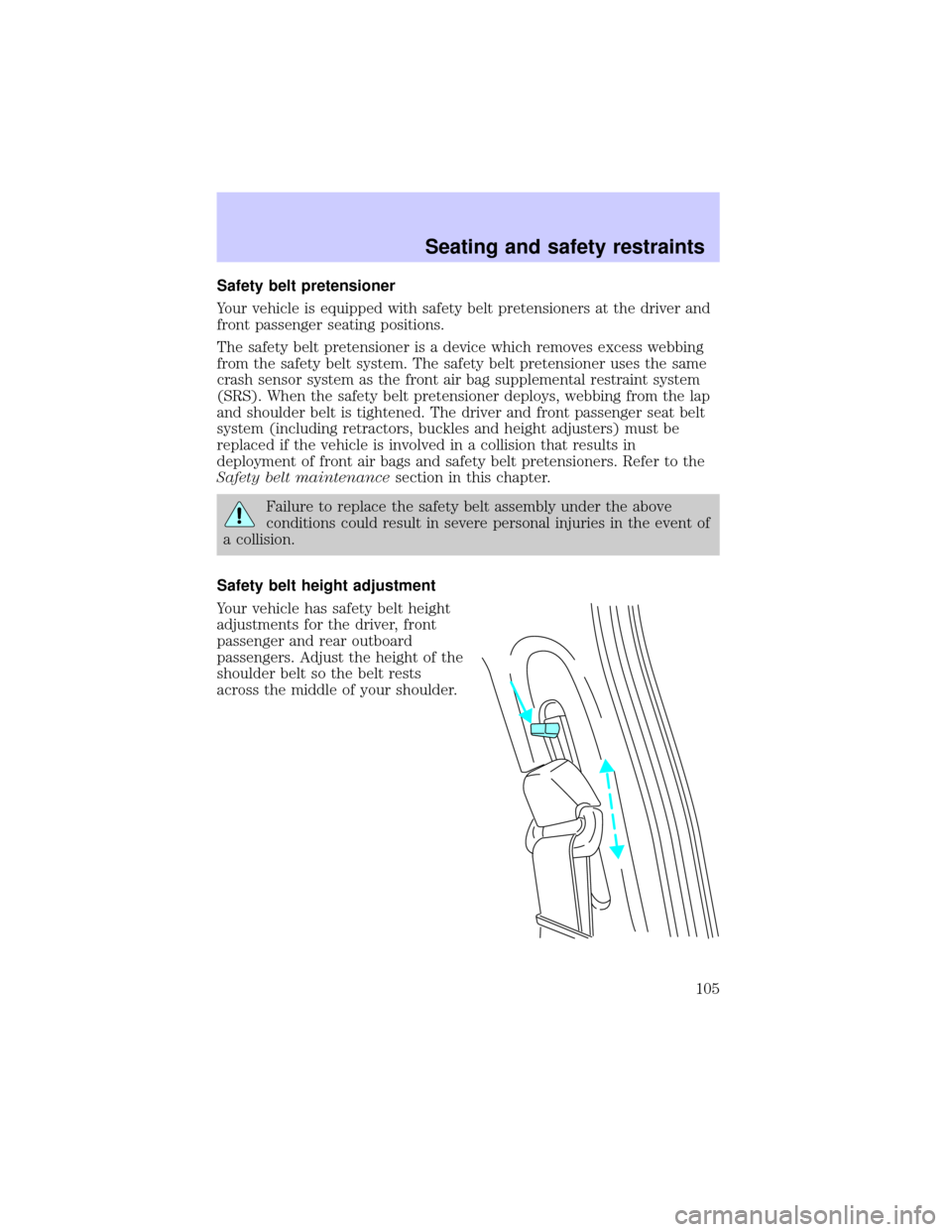

Safety belt height adjustment

Your vehicle has safety belt height

adjustments for the driver, front

passenger and rear outboard

passengers. Adjust the height of the

shoulder belt so the belt rests

across the middle of your shoulder.

Seating and safety restraints

105

Page 110 of 248

3. Buckle then unbuckle the safety belt three times, ending with the

safety belt unbuckled. Be sure that each time you unbuckle the belt that

you retract it. This can be done before or during Belt Minder warning

activation.

4. Turn on the parklamps/headlamps, turn off the parklamps/headlamps.

5. Buckle then unbuckle the safety belt three times, ending with the

safety belt unbuckled.

²After step 5 the safety belt warning light will be turned on for three

seconds.

6. Within seven seconds of the safety belt warning light turning off,

buckle then unbuckle the safety belt.

²This will disable Belt Minder if it is currently enabled, or enable Belt

Minder if it is currently disabled.

7. Confirmation of disabling Belt Minder is provided by flashing the

safety belt warning light four times per second for three seconds.

8. Confirmation of enabling Belt Minder is provided by flashing the safety

belt warning light four times per second for three seconds, followed by

three seconds with the safety belt warning light off, then followed by

flashing the safety belt warning light four times per second for three

seconds again.

9. After receiving confirmation, the deactivation/activation procedure is

complete.

Safety belt maintenance

Inspect the safety belt systems periodically to make sure they work

properly and are not damaged. Inspect the safety belts to make sure

there are no nicks, tears or cuts. Replace if necessary. All safety belt

assemblies, including retractors, buckles, front seat belt buckle

assemblies, buckle support assemblies (slide bar-if equipped), shoulder

belt height adjusters (if equipped), shoulder belt guide on seatback

(if equipped), child safety seat tether bracket assemblies (if equipped),

LATCH child seat tether anchors and lower anchors (if equipped), and

attaching hardware, should be inspected after a collision. Ford

recommends that all safety belt assemblies used in vehicles involved in a

collision be replaced. However, if the collision was minor and a qualified

technician finds that the belts do not show damage and continue to

operate properly, they do not need to be replaced. Safety belt assemblies

not in use during a collision should also be inspected and replaced if

either damage or improper operation is noted.

Seating and safety restraints

110

Page 116 of 248

The RCM (restraints control module) monitors its own internal circuits

and the supplemental air bag electrical system warning (including the

impact sensors, the system wiring, the air bag system readiness light, the

air bag back up power and the air bag ignitors).

Determining if the system is operational

The SRS uses a readiness light in the instrument cluster or a tone to

indicate the condition of the system. Refer toAir bag readinesssection

in theInstrument clusterchapter. Routine maintenance of the air bag is

not required.

A difficulty with the system is indicated by one or more of the following:

²The readiness light will either

flash or stay lit.

²The readiness light will not

illuminate immediately after ignition is turned on.

²A series of five beeps will be heard. The tone pattern will repeat

periodically until the problem and/or light are repaired.

If any of these things happen, even intermittently, have the SRS serviced

at your dealership or by a qualified technician immediately. Unless

serviced, the system may not function properly in the event of a collision.

Disposal of air bags and air bag equipped vehicles

(including pretensioners)

For disposal of air bags or air bag equipped vehicles, see your local

dealership or qualified technician. Air bags MUST BE disposed of by

qualified personnel.

SAFETY RESTRAINTS FOR CHILDREN

See the following sections for directions on how to properly use safety

restraints for children. Also seeAir Bag Supplemental Restraint System

(SRS)in this chapter for special instructions about using air bags.

Important child restraint precautions

You are required by law to use safety restraints for children in the U.S.

and Canada. If small children ride in your vehicle (generally children who

are four years old or younger and who weigh 18 kg [40 lbs] or less), you

must put them in safety seats made especially for children. Check your

local and state or provincial laws for specific requirements regarding the

safety of children in your vehicle.

Seating and safety restraints

116

Page 129 of 248

BRAKES

Your service brakes are self-adjusting. Refer to the scheduled

maintenance guide for scheduled maintenance.

Occasional brake noise is normal and often does not indicate a

performance concern with the vehicle's brake system. In normal operation,

automotive brake systems may emit occasional or intermittent squeal or

groan noises when the brakes are applied. Such noises are usually heard

during the first few brake applications in the morning; however, they may

be heard at any time while braking and can be aggravated by

environmental conditions such as cold, heat, moisture, road dust, salt or

mud. If a ªmetal-to-metal,º ªcontinuous grindingº or ªcontinuous squealº

sound is present while braking, the brake linings may be worn-out and

should be inspected by a qualified service technician.

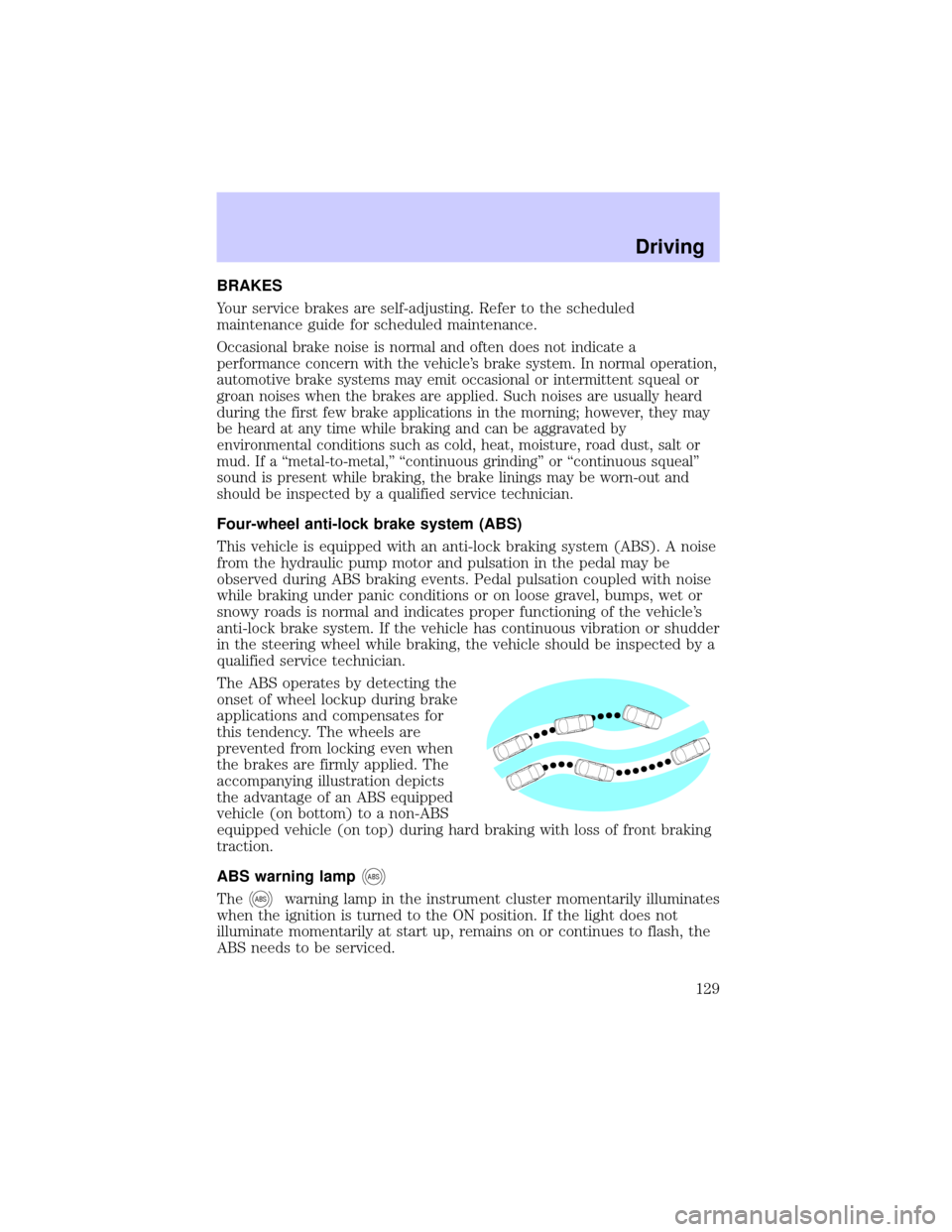

Four-wheel anti-lock brake system (ABS)

This vehicle is equipped with an anti-lock braking system (ABS). A noise

from the hydraulic pump motor and pulsation in the pedal may be

observed during ABS braking events. Pedal pulsation coupled with noise

while braking under panic conditions or on loose gravel, bumps, wet or

snowy roads is normal and indicates proper functioning of the vehicle's

anti-lock brake system. If the vehicle has continuous vibration or shudder

in the steering wheel while braking, the vehicle should be inspected by a

qualified service technician.

The ABS operates by detecting the

onset of wheel lockup during brake

applications and compensates for

this tendency. The wheels are

prevented from locking even when

the brakes are firmly applied. The

accompanying illustration depicts

the advantage of an ABS equipped

vehicle (on bottom) to a non-ABS

equipped vehicle (on top) during hard braking with loss of front braking

traction.

ABS warning lamp

ABS

TheABSwarning lamp in the instrument cluster momentarily illuminates

when the ignition is turned to the ON position. If the light does not

illuminate momentarily at start up, remains on or continues to flash, the

ABS needs to be serviced.

Driving

129

Page 142 of 248

²Thoroughly prepare your vehicle for towing. Refer toPreparing to

towin this chapter.

²Use extra caution when driving while trailer towing. Refer toDriving

while you towin this chapter.

²Service your vehicle more frequently if you tow a trailer. Refer to the

severe duty schedule in the scheduled maintenance guide.

²Do not tow a trailer until your vehicle has been driven at least 800 km

(500 miles).

²Refer to the instructions included with towing accessories for the

proper installation and adjustment specifications.

Your vehicle is pre-wired for trailer towing. An electrical connector is

provided under the instrument panel for installing a customer-supplied

electric brake controller. Another electrical connector is provided at the

hitch. This connector provides power to the trailer for taillamps, stop

and turn lamps, back up lamps, battery charge, electric brakes (when a

customer provided controller is installed) and ground. The kit included

with your vehicle provides you with adaptors to attach the brake

controller and convert the hitch connector for Class I trailer usage.

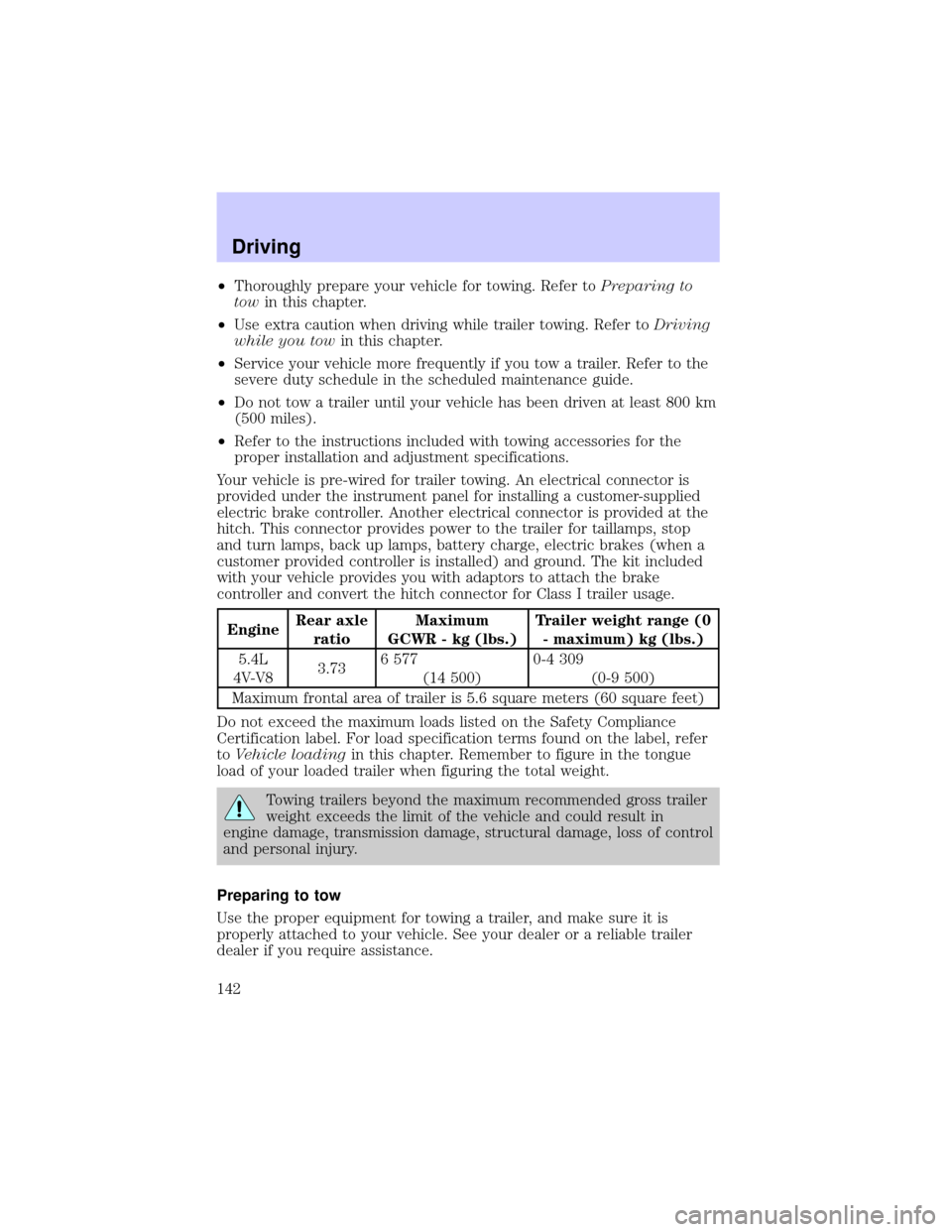

EngineRear axle

ratioMaximum

GCWR - kg (lbs.)Trailer weight range (0

- maximum) kg (lbs.)

5.4L

4V-V83.736 577

(14 500)0-4 309

(0-9 500)

Maximum frontal area of trailer is 5.6 square meters (60 square feet)

Do not exceed the maximum loads listed on the Safety Compliance

Certification label. For load specification terms found on the label, refer

toVehicle loadingin this chapter. Remember to figure in the tongue

load of your loaded trailer when figuring the total weight.

Towing trailers beyond the maximum recommended gross trailer

weight exceeds the limit of the vehicle and could result in

engine damage, transmission damage, structural damage, loss of control

and personal injury.

Preparing to tow

Use the proper equipment for towing a trailer, and make sure it is

properly attached to your vehicle. See your dealer or a reliable trailer

dealer if you require assistance.

Driving

142