warning LINCOLN CONTINENTAL 2000 Owner's Manual

[x] Cancel search | Manufacturer: LINCOLN, Model Year: 2000, Model line: CONTINENTAL, Model: LINCOLN CONTINENTAL 2000Pages: 232, PDF Size: 1.7 MB

Page 103 of 232

²all vehicle doors are closed

²the driver's safety belt is unbuckled

²the parklamps/headlamps are in OFF position (If vehicle is equipped

with Autolamps, this will not affect the procedure.)

To reduce the risk of injury, do not deactivate/activate the Belt

Minder feature while driving the vehicle.

1. Turn the ignition switch to the RUN (or ON) position. (DO NOT

START THE ENGINE)

2. Wait until the safety belt warning light turns off. (Approximately 1±2

minutes)

²Steps 3±5 must be completed within 60 seconds or the procedure will

have to be repeated.

3. Buckle then unbuckle the safety belt three times, ending with the

safety belt unbuckled. This can be done before or during Belt Minder

warning activation.

4. Turn on the parklamps/headlamps, turn off the parklamps/headlamps.

5. Buckle then unbuckle the safety belt three times, ending with the

safety belt unbuckled.

²After step 5 the safety belt warning light will be turned on for three

seconds.

6. Within seven seconds of the safety belt warning light turning off,

buckle then unbuckle the safety belt.

²This will disable Belt Minder if it is currently enabled, or enable Belt

Minder if it is currently disabled.

7. Confirmation of disabling Belt Minder is provided by flashing the

safety belt warning light four times per second for three seconds.

8. Confirmation of enabling Belt Minder is provided by flashing the safety

belt warning light four times per second for three seconds, followed by

three seconds with the safety belt warning light off, then followed by

flashing the safety belt warning light four times per second for three

seconds again.

9. After receiving confirmation, the deactivation/activation procedure is

complete.

Seating and safety restraints

103

Page 108 of 232

Several air bag system components get hot after inflation. Do not

touch them after inflation.

If the air bag is inflated,the air bag will not function again

and must be replaced immediately.If the air bag is not

replaced, the unrepaired area will increase the risk of injury in a

collision.

The SRS consists of:

²driver and passenger air bag modules (which include the inflators and

air bags),

²one or more impact and safing sensors,

²a readiness light and tone

²and the electrical wiring which connects the components.

The diagnostic module monitors its own internal circuits and the

supplemental air bag electrical system warning (including the impact

sensors), the system wiring, the air bag system readiness light, the air

bag back up power and the air bag ignitors.

Determining if the system is operational

The SRS uses a readiness light in the instrument cluster or a tone to

indicate the condition of the system. Refer to theAir bag readiness

section in theInstrumentationchapter. Routine maintenance of the air

bag is not required.

A difficulty with the system is indicated by one or more of the following:

²The readiness light will either

flash or stay lit.

²The readiness light will not

illuminate immediately after

ignition is turned on.

²A series of five beeps will be heard. The tone pattern will repeat

periodically until the problem and light are repaired.

If any of these things happen, even intermittently, have the SRS serviced

at your dealership or by a qualified technician immediately. Unless

serviced, the system may not function properly in the event of a

collision.

AIR

BAG

Seating and safety restraints

108

Page 110 of 232

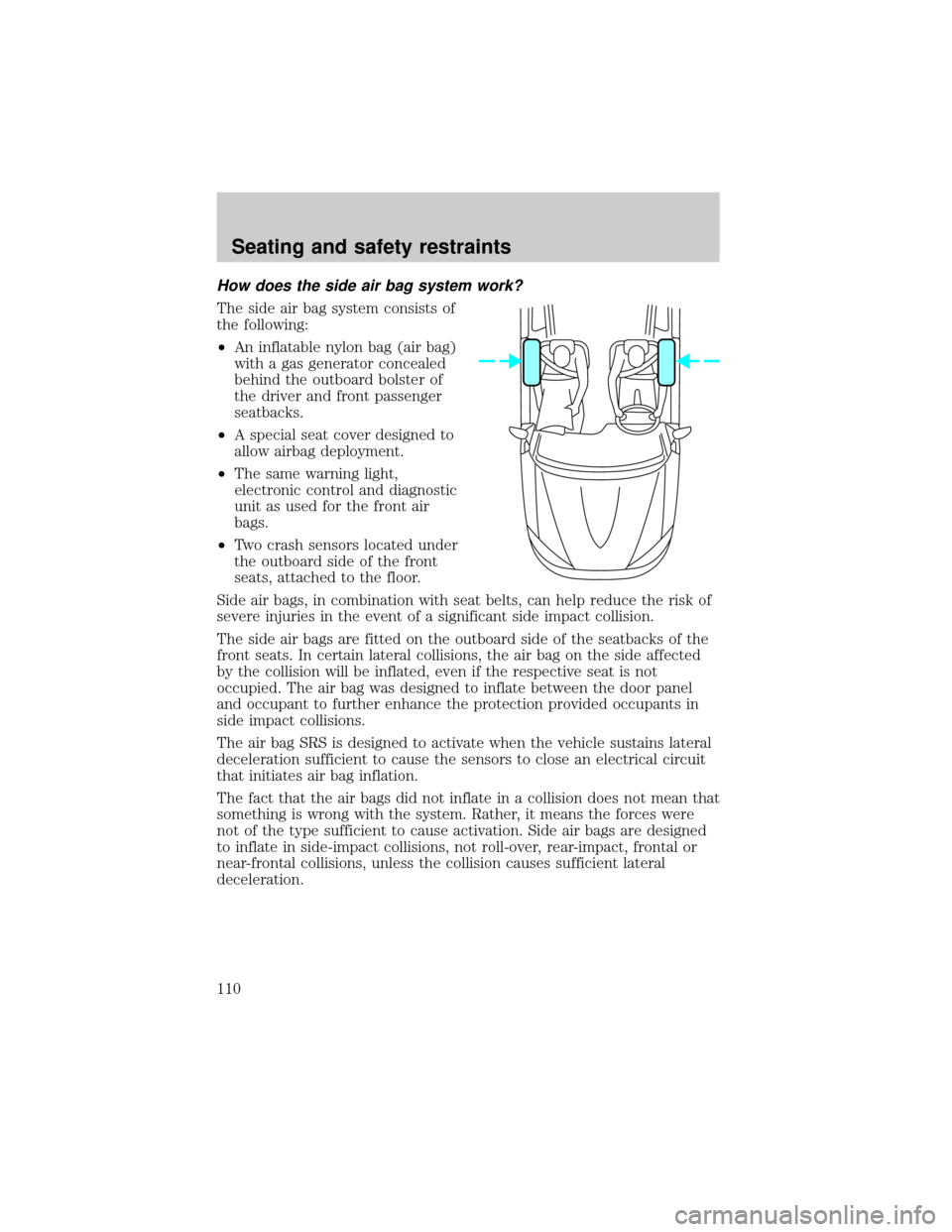

How does the side air bag system work?

The side air bag system consists of

the following:

²An inflatable nylon bag (air bag)

with a gas generator concealed

behind the outboard bolster of

the driver and front passenger

seatbacks.

²A special seat cover designed to

allow airbag deployment.

²The same warning light,

electronic control and diagnostic

unit as used for the front air

bags.

²Two crash sensors located under

the outboard side of the front

seats, attached to the floor.

Side air bags, in combination with seat belts, can help reduce the risk of

severe injuries in the event of a significant side impact collision.

The side air bags are fitted on the outboard side of the seatbacks of the

front seats. In certain lateral collisions, the air bag on the side affected

by the collision will be inflated, even if the respective seat is not

occupied. The air bag was designed to inflate between the door panel

and occupant to further enhance the protection provided occupants in

side impact collisions.

The air bag SRS is designed to activate when the vehicle sustains lateral

deceleration sufficient to cause the sensors to close an electrical circuit

that initiates air bag inflation.

The fact that the air bags did not inflate in a collision does not mean that

something is wrong with the system. Rather, it means the forces were

not of the type sufficient to cause activation. Side air bags are designed

to inflate in side-impact collisions, not roll-over, rear-impact, frontal or

near-frontal collisions, unless the collision causes sufficient lateral

deceleration.

Seating and safety restraints

110

Page 112 of 232

Disposal of air bags and air bag equipped vehicles (including

pretensioners)

For disposal of air bags or air bag equipped vehicles, see your local

dealership or qualified technician. Air bags MUST BE disposed of by

qualified personnel.

SAFETY RESTRAINTS FOR CHILDREN

See the following sections for directions on how to properly use safety

restraints for children. Also seeAir Bag Supplemental Restraint

System (SRS)in this chapter for special instructions about using air

bags.

Important child restraint precautions

You are required by law to use safety restraints for children in the U.S.

and Canada. If small children ride in your vehicle (generally children who

are four years old or younger and who weigh 18 kg [40 lbs] or less), you

must put them in safety seats made especially for children. Check your

local and state or provincial laws for specific requirements regarding the

safety of children in your vehicle.

Never let a passenger hold a child on his or her lap while the

vehicle is moving. The passenger cannot protect the child from

injury in a collision.

Always follow the instructions and warnings that come with any infant or

child restraint you might use.

When possible, always place children under age 12 in the rear seat of

your vehicle. Accident statistics suggest that children are safer when

properly restrained in the rear seating positions than in the front seating

position.

Children and safety belts

If the child is the proper size, restrain the child in a safety seat.

Children who are too large for child safety seats (as specified by your

child safety seat manufacturer) should always wear safety belts.

Follow all the important safety restraint and air bag precautions that

apply to adult passengers in your vehicle.

If the shoulder belt portion of a combination lap and shoulder belt can

be positioned so it does not cross or rest in front of the child's face or

Seating and safety restraints

112

Page 125 of 232

BRAKES

Your service brakes are self-adjusting. Refer to the scheduled

maintenance guide for scheduled maintenance.

Occasional brake noise is normal and often does not indicate a

performance concern with the vehicle's brake system. In normal

operation, automotive brake systems may emit occasional or intermittent

squeal or groan noises when the brakes are applied. Such noises are

usually heard during the first few brake applications in the morning;

however, they may be heard at any time while braking and can be

aggravated by environmental conditions such as cold, heat, moisture,

road dust, salt or mud. If a ªmetal-to-metal,º ªcontinuous grindingº or

ªcontinuous squealº sound is present while braking, the brake linings

may be worn-out and should be inspected by a qualified service

technician.

Anti-lock brake system (ABS)

On vehicles equipped with an anti-lock braking system (ABS), a noise

from the hydraulic pump motor and pulsation in the pedal may be

observed during ABS braking events. Pedal pulsation coupled with noise

while braking under panic conditions or on loose gravel, bumps, wet or

snowy roads is normal and indicates proper functioning of the vehicle's

anti-lock brake system. The ABS performs a self-check after you start

the engine and begin to drive away. A brief mechanical noise may be

heard during this test. This is normal. If a malfunction is found, the ABS

warning light will come on. If the vehicle has continuous vibration or

shudder in the steering wheel while braking, the vehicle should be

inspected by a qualified service technician.

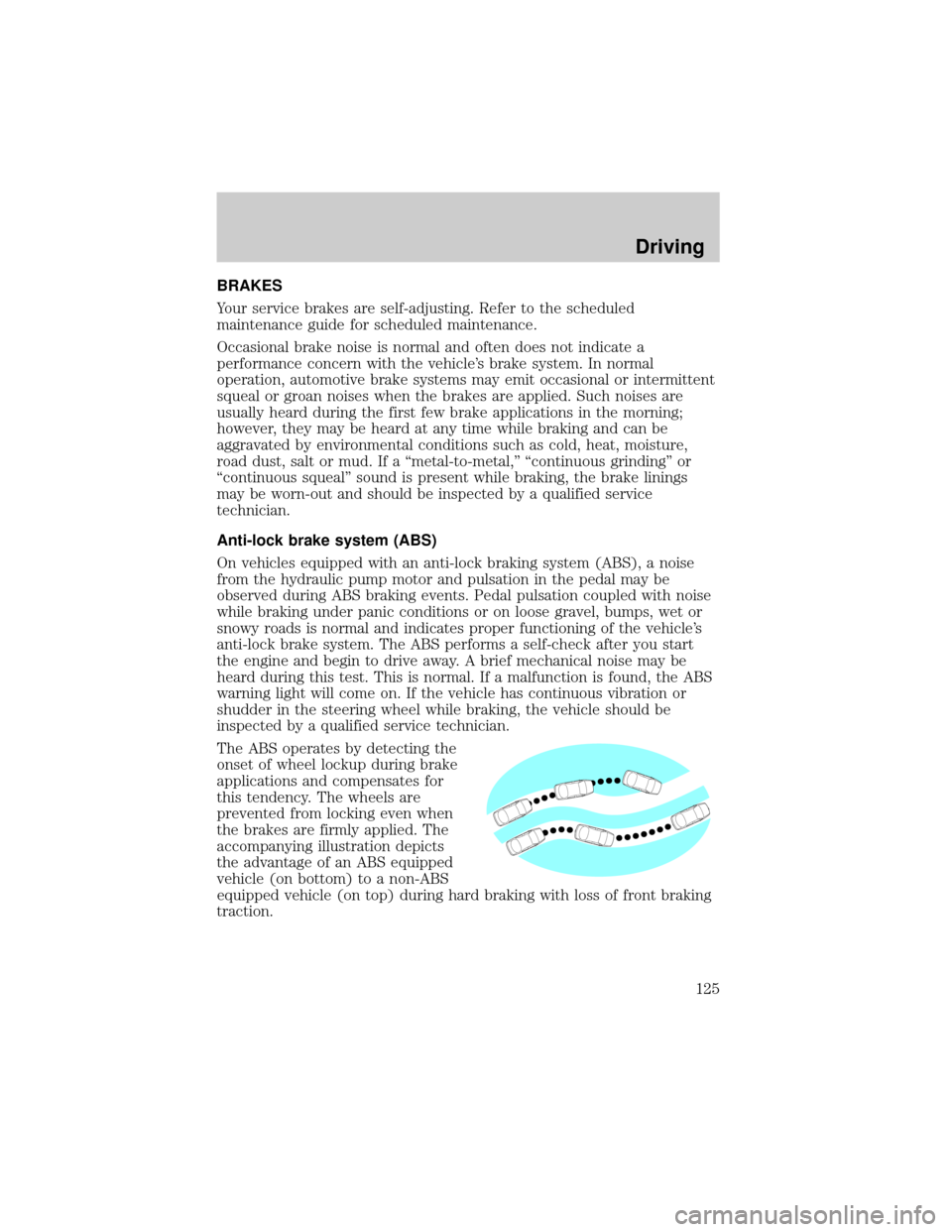

The ABS operates by detecting the

onset of wheel lockup during brake

applications and compensates for

this tendency. The wheels are

prevented from locking even when

the brakes are firmly applied. The

accompanying illustration depicts

the advantage of an ABS equipped

vehicle (on bottom) to a non-ABS

equipped vehicle (on top) during hard braking with loss of front braking

traction.

Driving

125

Page 126 of 232

ABS warning lampABS

TheABSwarning lamp in the instrument cluster momentarily illuminates

when the ignition is turned to the ON position. If the light does not

illuminate momentarily at start up, remains on or continues to flash, the

ABS needs to be serviced.

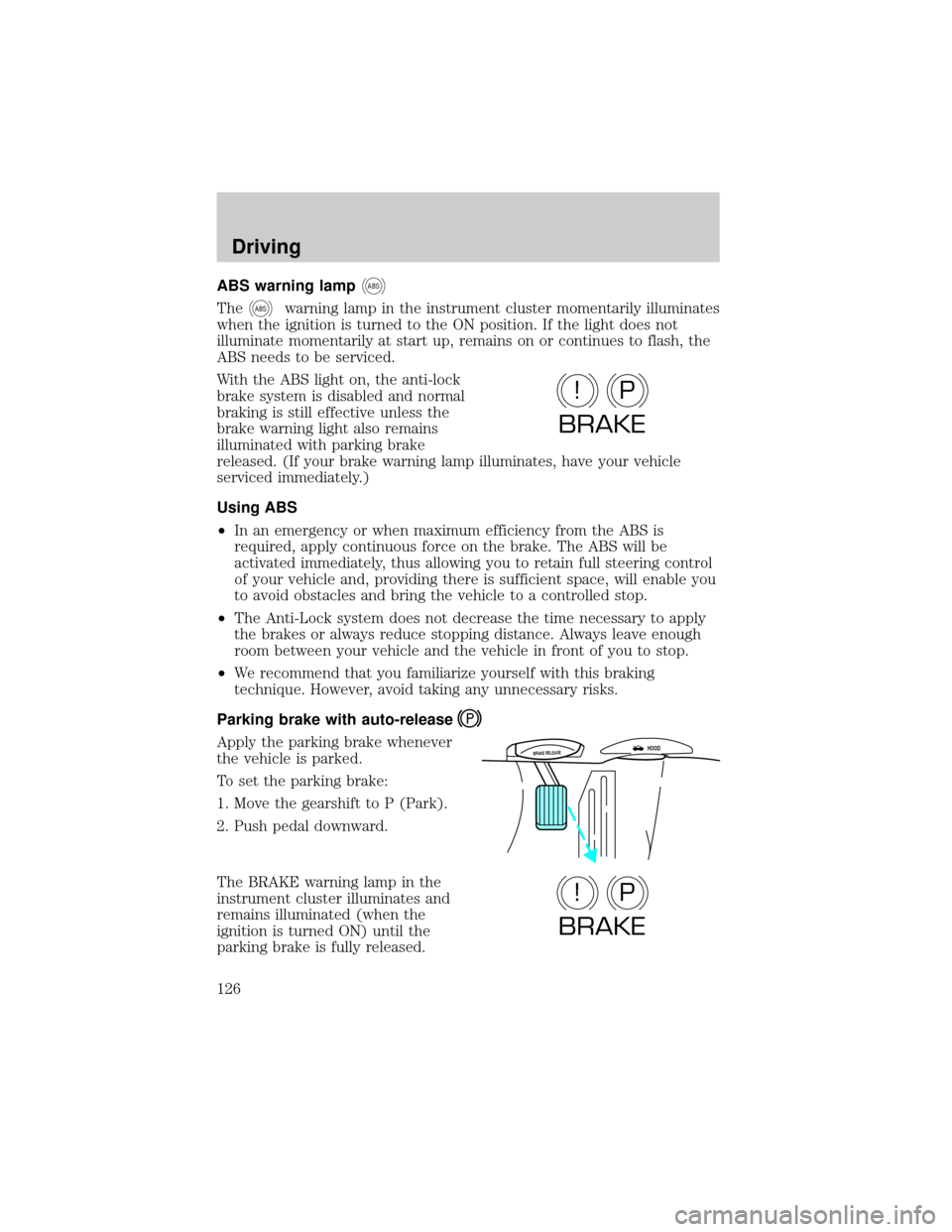

With the ABS light on, the anti-lock

brake system is disabled and normal

braking is still effective unless the

brake warning light also remains

illuminated with parking brake

released. (If your brake warning lamp illuminates, have your vehicle

serviced immediately.)

Using ABS

²In an emergency or when maximum efficiency from the ABS is

required, apply continuous force on the brake. The ABS will be

activated immediately, thus allowing you to retain full steering control

of your vehicle and, providing there is sufficient space, will enable you

to avoid obstacles and bring the vehicle to a controlled stop.

²The Anti-Lock system does not decrease the time necessary to apply

the brakes or always reduce stopping distance. Always leave enough

room between your vehicle and the vehicle in front of you to stop.

²We recommend that you familiarize yourself with this braking

technique. However, avoid taking any unnecessary risks.

Parking brake with auto-release

Apply the parking brake whenever

the vehicle is parked.

To set the parking brake:

1. Move the gearshift to P (Park).

2. Push pedal downward.

The BRAKE warning lamp in the

instrument cluster illuminates and

remains illuminated (when the

ignition is turned ON) until the

parking brake is fully released.

P!

BRAKE

BRAKE RELEASEHOOD

P!

BRAKE

Driving

126

Page 129 of 232

If the steering wanders or pulls, the condition could be caused by any of

the following:

²underinflated tire(s) on any wheel(s)

²high crown in center of road

²high crosswinds

²wheels out of alignment

²loose or worn components in steering linkage

Speed sensitive steering

The steering in your vehicle is speed sensitive. At high speeds, steering

assist will decrease to improve steering feel. At lower speeds,

maneuverability will be increased.

SeeElectronic Message Centerin theInstrumentationchapter for

personalized adjustment.

If the amount of effort required to steer your vehicle changes at a

constant vehicle speed, have the power steering system checked by your

dealer or a qualified service technician.

AIR SUSPENSION SYSTEM

The air suspension system is designed to improve ride, handling and

general vehicle performance during:

²certain road conditions

²steering maneuvers

²braking

²accelerations

This system keeps the rear of your vehicle at a constant level by

automatically adding air or releasing air from the springs.

If you exceed the load limit, the rear air suspension may not operate and

the system warning CHECK RIDE CONTROL may appear on the message

center.

Driving

129

Page 131 of 232

on the accelerator in each gear. Do not rock the vehicle for more than a

few minutes, because it could damage the vehicle.

Do not rock the vehicle if the engine is not at normal operating

temperature or damage to the transaxle may occur.

Do not rock the vehicle for more than a few minutes or damage

to the transaxle and tires may occur or the engine may overheat.

Always set the parking brake fully and make sure the gearshift is

latched in P (Park). Turn off the ignition whenever you leave

your vehicle.

If the parking brake is fully released, but the brake warning lamp

remains illuminated, the brakes may not be working properly.

See your dealer or a qualified service technician.

Driving with a 4±speed automatic transaxle

Your automatic overdrive transaxle provides fully automatic operation in

either D (Overdrive) or 3 (Third). Driving with the shift selector in D

(Overdrive) gives the best fuel economy for normal driving conditions.

For manual control start in 1 (First) and then shift manually.

To put your vehicle in gear, start the engine, depress the brake pedal,

then move gearshift lever out of P (Park).

Hold the brake pedal down while you move the gearshift lever

from P (Park) to another position. If you do not hold the brake

pedal down, your vehicle may move unexpectedly and injure someone.

Driving

131

Page 146 of 232

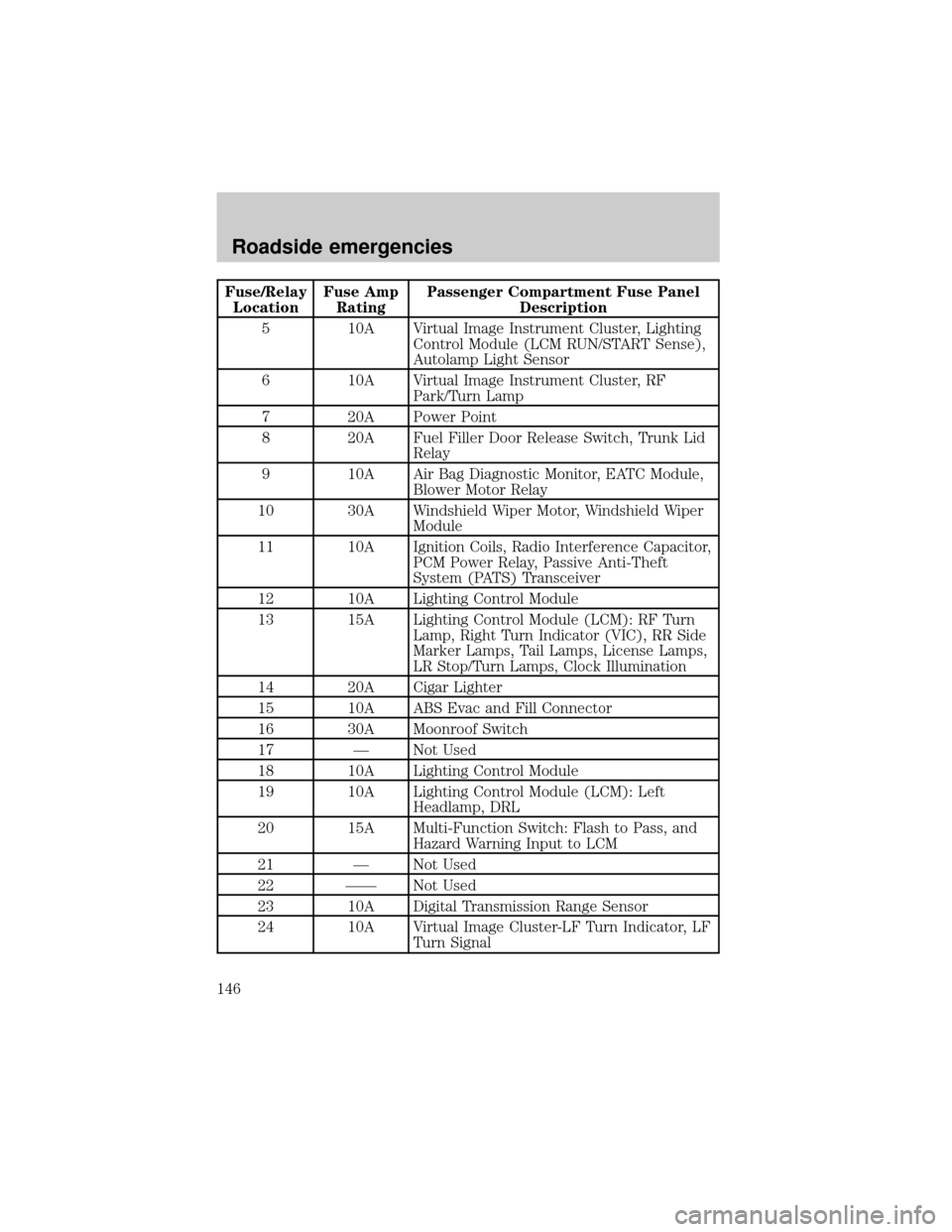

Fuse/Relay

LocationFuse Amp

RatingPassenger Compartment Fuse Panel

Description

5 10A Virtual Image Instrument Cluster, Lighting

Control Module (LCM RUN/START Sense),

Autolamp Light Sensor

6 10A Virtual Image Instrument Cluster, RF

Park/Turn Lamp

7 20A Power Point

8 20A Fuel Filler Door Release Switch, Trunk Lid

Relay

9 10A Air Bag Diagnostic Monitor, EATC Module,

Blower Motor Relay

10 30A Windshield Wiper Motor, Windshield Wiper

Module

11 10A Ignition Coils, Radio Interference Capacitor,

PCM Power Relay, Passive Anti-Theft

System (PATS) Transceiver

12 10A Lighting Control Module

13 15A Lighting Control Module (LCM): RF Turn

Lamp, Right Turn Indicator (VIC), RR Side

Marker Lamps, Tail Lamps, License Lamps,

LR Stop/Turn Lamps, Clock Illumination

14 20A Cigar Lighter

15 10A ABS Evac and Fill Connector

16 30A Moonroof Switch

17 Ð Not Used

18 10A Lighting Control Module

19 10A Lighting Control Module (LCM): Left

Headlamp, DRL

20 15A Multi-Function Switch: Flash to Pass, and

Hazard Warning Input to LCM

21 Ð Not Used

22 ÐÐ Not Used

23 10A Digital Transmission Range Sensor

24 10A Virtual Image Cluster-LF Turn Indicator, LF

Turn Signal

Roadside emergencies

146

Page 149 of 232

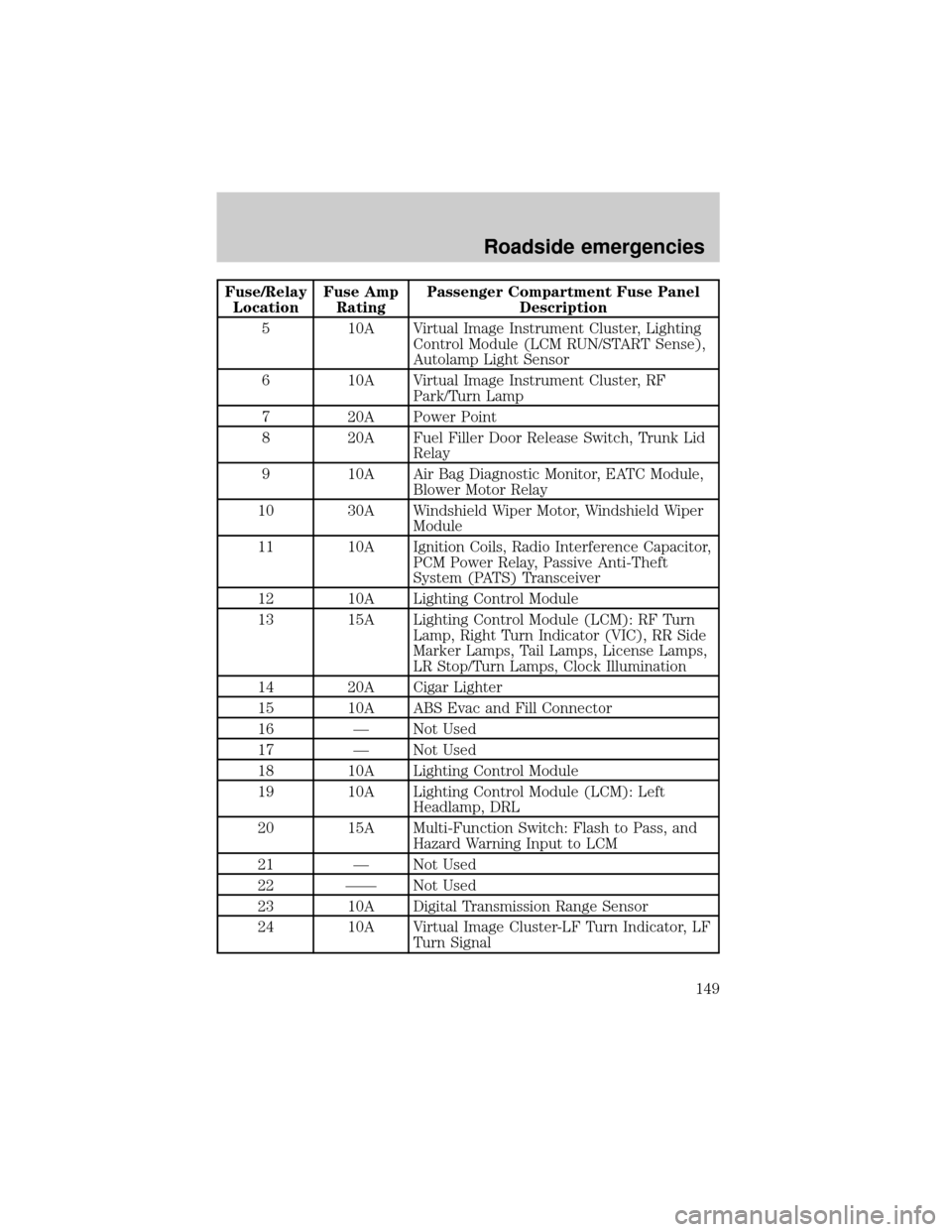

Fuse/Relay

LocationFuse Amp

RatingPassenger Compartment Fuse Panel

Description

5 10A Virtual Image Instrument Cluster, Lighting

Control Module (LCM RUN/START Sense),

Autolamp Light Sensor

6 10A Virtual Image Instrument Cluster, RF

Park/Turn Lamp

7 20A Power Point

8 20A Fuel Filler Door Release Switch, Trunk Lid

Relay

9 10A Air Bag Diagnostic Monitor, EATC Module,

Blower Motor Relay

10 30A Windshield Wiper Motor, Windshield Wiper

Module

11 10A Ignition Coils, Radio Interference Capacitor,

PCM Power Relay, Passive Anti-Theft

System (PATS) Transceiver

12 10A Lighting Control Module

13 15A Lighting Control Module (LCM): RF Turn

Lamp, Right Turn Indicator (VIC), RR Side

Marker Lamps, Tail Lamps, License Lamps,

LR Stop/Turn Lamps, Clock Illumination

14 20A Cigar Lighter

15 10A ABS Evac and Fill Connector

16 Ð Not Used

17 Ð Not Used

18 10A Lighting Control Module

19 10A Lighting Control Module (LCM): Left

Headlamp, DRL

20 15A Multi-Function Switch: Flash to Pass, and

Hazard Warning Input to LCM

21 Ð Not Used

22 ÐÐ Not Used

23 10A Digital Transmission Range Sensor

24 10A Virtual Image Cluster-LF Turn Indicator, LF

Turn Signal

Roadside emergencies

149