light LINCOLN CONTINENTAL 2000 Service Manual

[x] Cancel search | Manufacturer: LINCOLN, Model Year: 2000, Model line: CONTINENTAL, Model: LINCOLN CONTINENTAL 2000Pages: 232, PDF Size: 1.7 MB

Page 108 of 232

Several air bag system components get hot after inflation. Do not

touch them after inflation.

If the air bag is inflated,the air bag will not function again

and must be replaced immediately.If the air bag is not

replaced, the unrepaired area will increase the risk of injury in a

collision.

The SRS consists of:

²driver and passenger air bag modules (which include the inflators and

air bags),

²one or more impact and safing sensors,

²a readiness light and tone

²and the electrical wiring which connects the components.

The diagnostic module monitors its own internal circuits and the

supplemental air bag electrical system warning (including the impact

sensors), the system wiring, the air bag system readiness light, the air

bag back up power and the air bag ignitors.

Determining if the system is operational

The SRS uses a readiness light in the instrument cluster or a tone to

indicate the condition of the system. Refer to theAir bag readiness

section in theInstrumentationchapter. Routine maintenance of the air

bag is not required.

A difficulty with the system is indicated by one or more of the following:

²The readiness light will either

flash or stay lit.

²The readiness light will not

illuminate immediately after

ignition is turned on.

²A series of five beeps will be heard. The tone pattern will repeat

periodically until the problem and light are repaired.

If any of these things happen, even intermittently, have the SRS serviced

at your dealership or by a qualified technician immediately. Unless

serviced, the system may not function properly in the event of a

collision.

AIR

BAG

Seating and safety restraints

108

Page 110 of 232

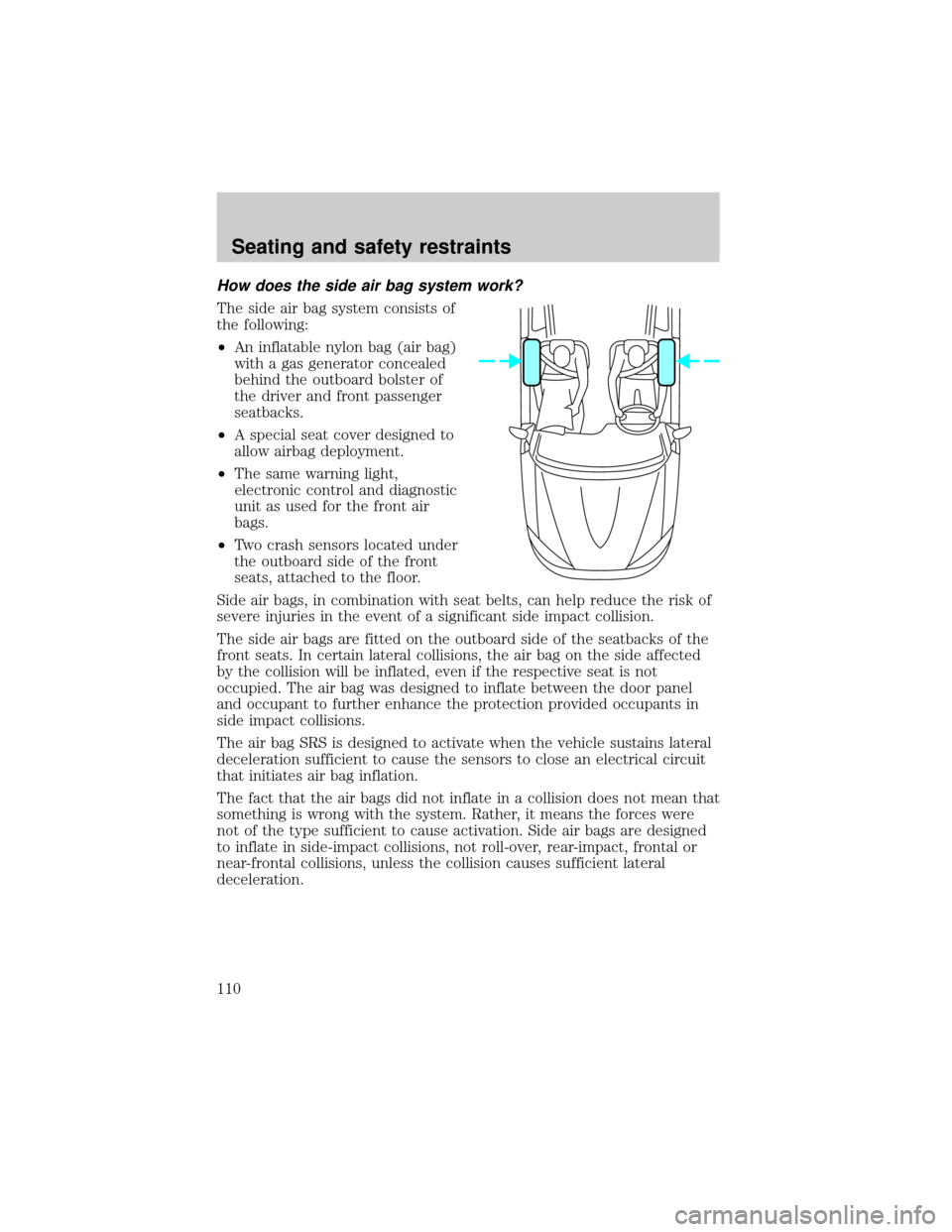

How does the side air bag system work?

The side air bag system consists of

the following:

²An inflatable nylon bag (air bag)

with a gas generator concealed

behind the outboard bolster of

the driver and front passenger

seatbacks.

²A special seat cover designed to

allow airbag deployment.

²The same warning light,

electronic control and diagnostic

unit as used for the front air

bags.

²Two crash sensors located under

the outboard side of the front

seats, attached to the floor.

Side air bags, in combination with seat belts, can help reduce the risk of

severe injuries in the event of a significant side impact collision.

The side air bags are fitted on the outboard side of the seatbacks of the

front seats. In certain lateral collisions, the air bag on the side affected

by the collision will be inflated, even if the respective seat is not

occupied. The air bag was designed to inflate between the door panel

and occupant to further enhance the protection provided occupants in

side impact collisions.

The air bag SRS is designed to activate when the vehicle sustains lateral

deceleration sufficient to cause the sensors to close an electrical circuit

that initiates air bag inflation.

The fact that the air bags did not inflate in a collision does not mean that

something is wrong with the system. Rather, it means the forces were

not of the type sufficient to cause activation. Side air bags are designed

to inflate in side-impact collisions, not roll-over, rear-impact, frontal or

near-frontal collisions, unless the collision causes sufficient lateral

deceleration.

Seating and safety restraints

110

Page 111 of 232

Several air bag system

components get hot after

inflation. Do not touch them after

inflation.

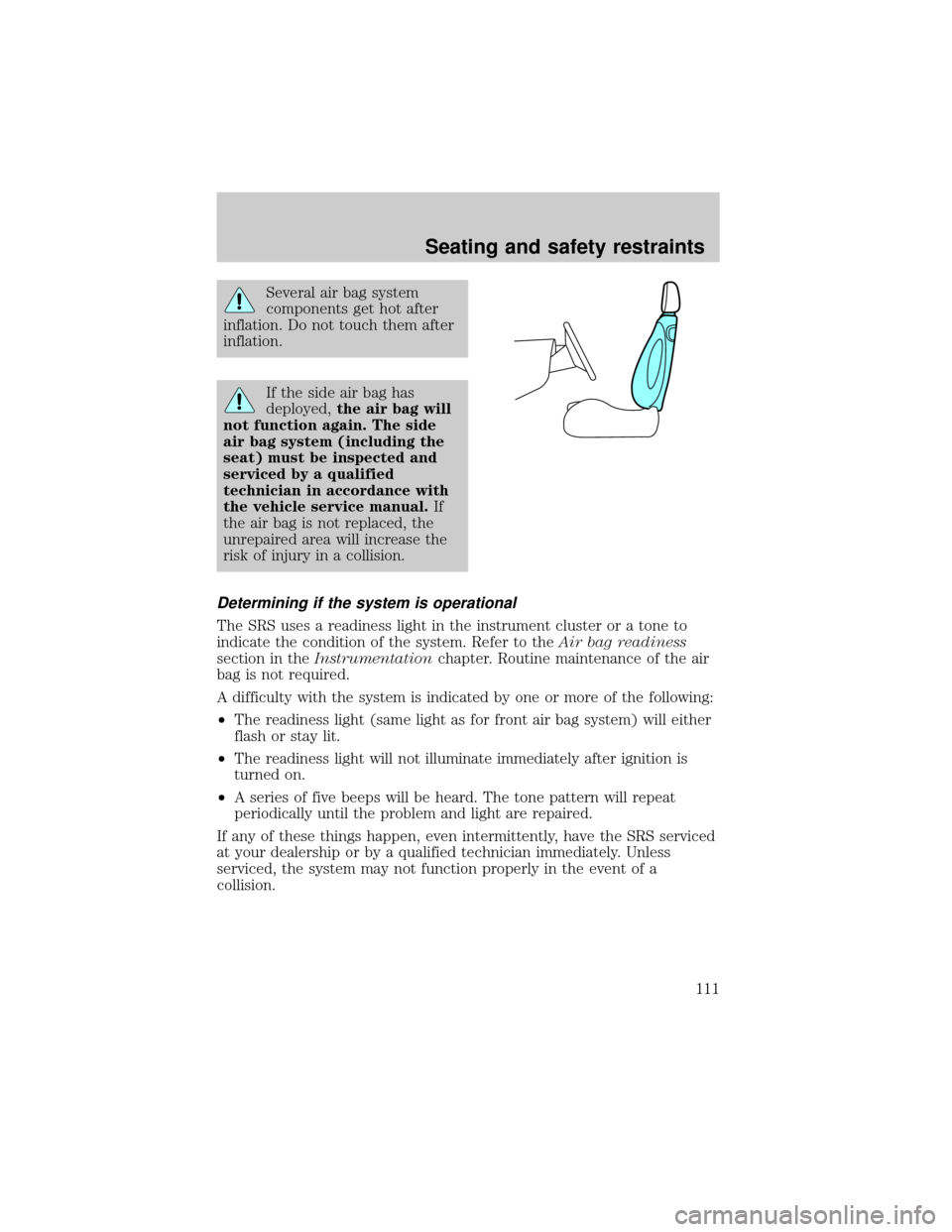

If the side air bag has

deployed,the air bag will

not function again. The side

air bag system (including the

seat) must be inspected and

serviced by a qualified

technician in accordance with

the vehicle service manual.If

the air bag is not replaced, the

unrepaired area will increase the

risk of injury in a collision.

Determining if the system is operational

The SRS uses a readiness light in the instrument cluster or a tone to

indicate the condition of the system. Refer to theAir bag readiness

section in theInstrumentationchapter. Routine maintenance of the air

bag is not required.

A difficulty with the system is indicated by one or more of the following:

²The readiness light (same light as for front air bag system) will either

flash or stay lit.

²The readiness light will not illuminate immediately after ignition is

turned on.

²A series of five beeps will be heard. The tone pattern will repeat

periodically until the problem and light are repaired.

If any of these things happen, even intermittently, have the SRS serviced

at your dealership or by a qualified technician immediately. Unless

serviced, the system may not function properly in the event of a

collision.

Seating and safety restraints

111

Page 122 of 232

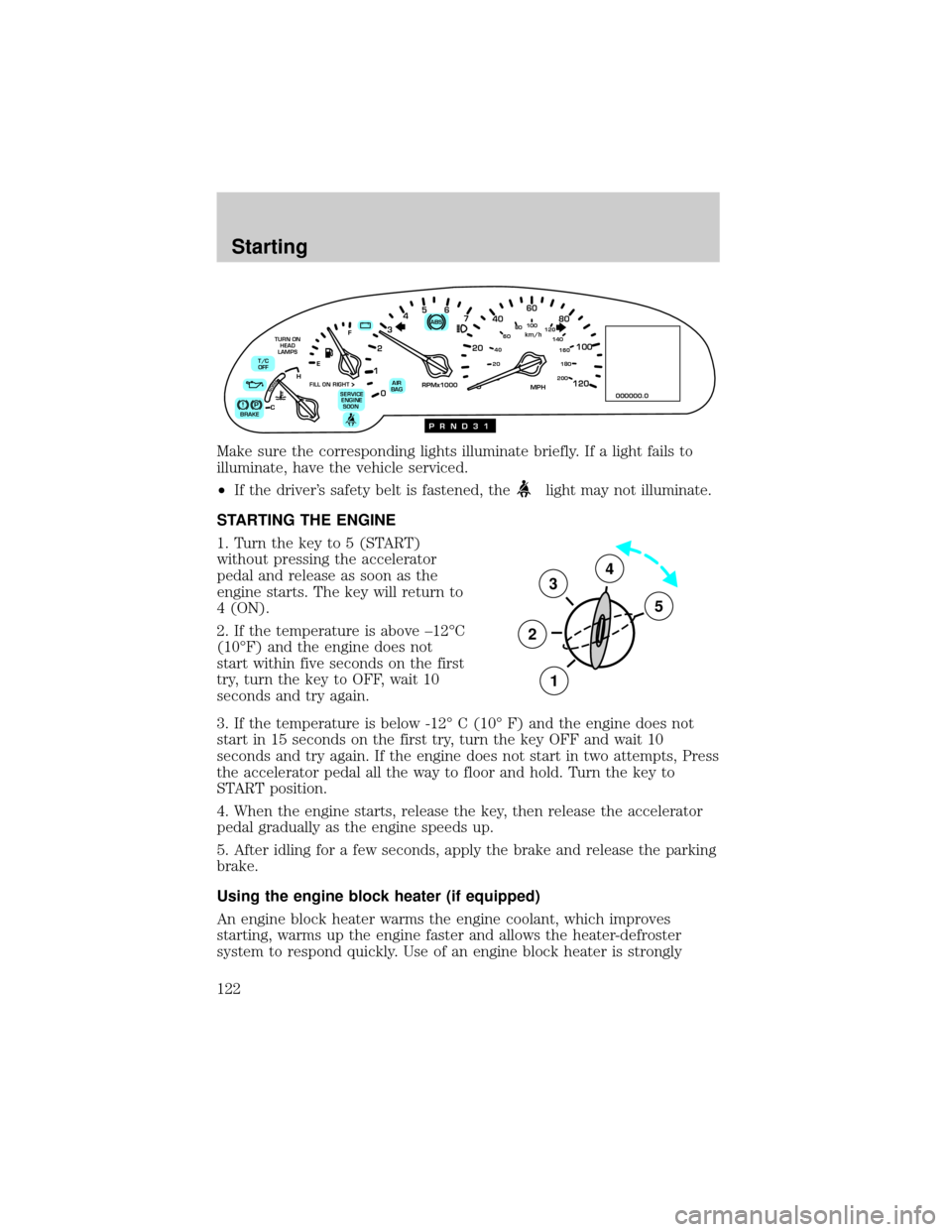

Make sure the corresponding lights illuminate briefly. If a light fails to

illuminate, have the vehicle serviced.

²If the driver's safety belt is fastened, the

light may not illuminate.

STARTING THE ENGINE

1. Turn the key to 5 (START)

without pressing the accelerator

pedal and release as soon as the

engine starts. The key will return to

4 (ON).

2. If the temperature is above ±12ÉC

(10ÉF) and the engine does not

start within five seconds on the first

try, turn the key to OFF, wait 10

seconds and try again.

3. If the temperature is below -12É C (10É F) and the engine does not

start in 15 seconds on the first try, turn the key OFF and wait 10

seconds and try again. If the engine does not start in two attempts, Press

the accelerator pedal all the way to floor and hold. Turn the key to

START position.

4. When the engine starts, release the key, then release the accelerator

pedal gradually as the engine speeds up.

5. After idling for a few seconds, apply the brake and release the parking

brake.

Using the engine block heater (if equipped)

An engine block heater warms the engine coolant, which improves

starting, warms up the engine faster and allows the heater-defroster

system to respond quickly. Use of an engine block heater is strongly

80

MPH km/h

ABS

P!BRAKE

+ –

RPMx1000NORM

T/C

OFF

CHEF

FILL ON RIGHT

SERVICE

ENGINE

SOON AIR

BAG TURN ON

HEAD

LAMPS0 123456

7

0 2060

80

100

120

0 204060100

120

140

160

180

200

40

000000.0

P R N D 3 1

3

2

1

5

4

Starting

122

Page 125 of 232

BRAKES

Your service brakes are self-adjusting. Refer to the scheduled

maintenance guide for scheduled maintenance.

Occasional brake noise is normal and often does not indicate a

performance concern with the vehicle's brake system. In normal

operation, automotive brake systems may emit occasional or intermittent

squeal or groan noises when the brakes are applied. Such noises are

usually heard during the first few brake applications in the morning;

however, they may be heard at any time while braking and can be

aggravated by environmental conditions such as cold, heat, moisture,

road dust, salt or mud. If a ªmetal-to-metal,º ªcontinuous grindingº or

ªcontinuous squealº sound is present while braking, the brake linings

may be worn-out and should be inspected by a qualified service

technician.

Anti-lock brake system (ABS)

On vehicles equipped with an anti-lock braking system (ABS), a noise

from the hydraulic pump motor and pulsation in the pedal may be

observed during ABS braking events. Pedal pulsation coupled with noise

while braking under panic conditions or on loose gravel, bumps, wet or

snowy roads is normal and indicates proper functioning of the vehicle's

anti-lock brake system. The ABS performs a self-check after you start

the engine and begin to drive away. A brief mechanical noise may be

heard during this test. This is normal. If a malfunction is found, the ABS

warning light will come on. If the vehicle has continuous vibration or

shudder in the steering wheel while braking, the vehicle should be

inspected by a qualified service technician.

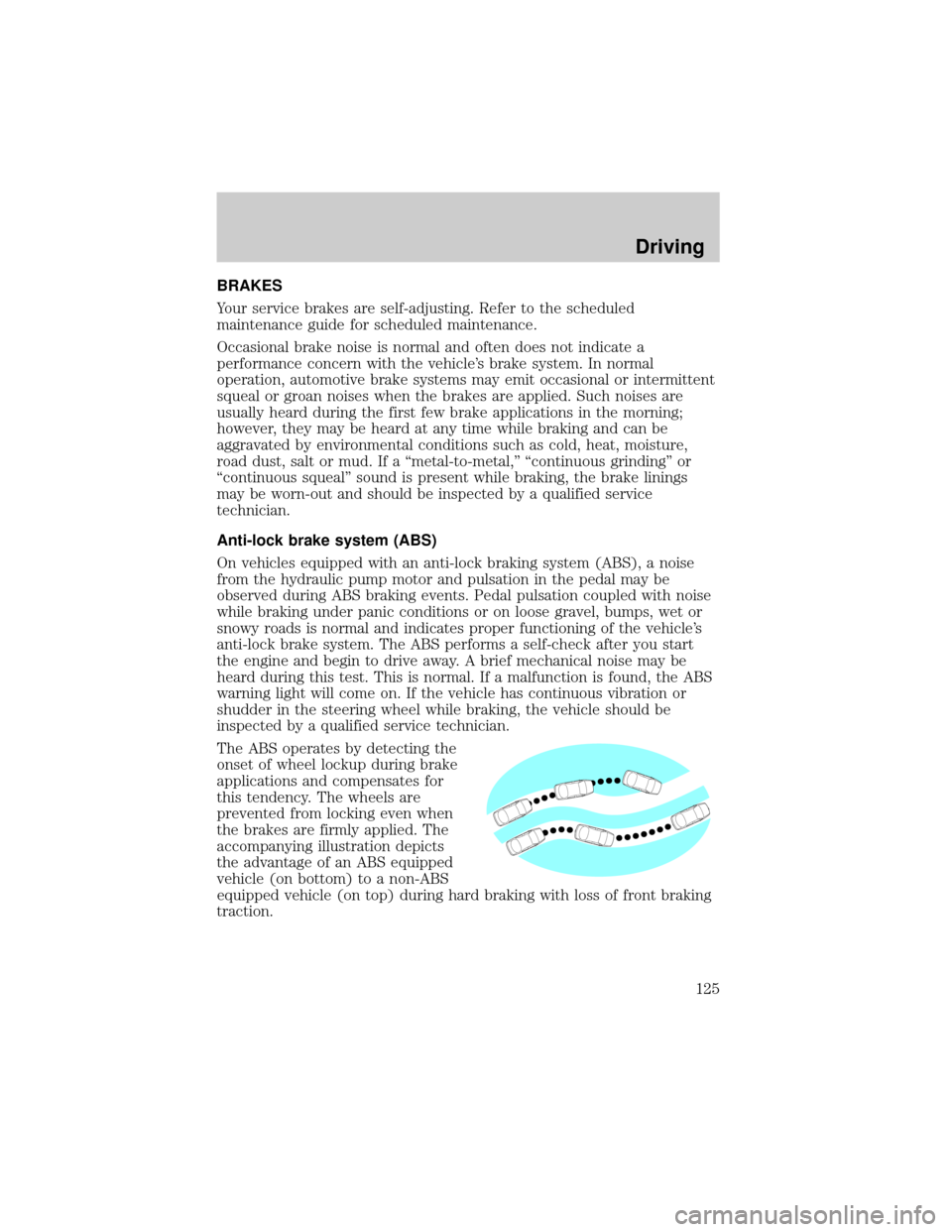

The ABS operates by detecting the

onset of wheel lockup during brake

applications and compensates for

this tendency. The wheels are

prevented from locking even when

the brakes are firmly applied. The

accompanying illustration depicts

the advantage of an ABS equipped

vehicle (on bottom) to a non-ABS

equipped vehicle (on top) during hard braking with loss of front braking

traction.

Driving

125

Page 126 of 232

ABS warning lampABS

TheABSwarning lamp in the instrument cluster momentarily illuminates

when the ignition is turned to the ON position. If the light does not

illuminate momentarily at start up, remains on or continues to flash, the

ABS needs to be serviced.

With the ABS light on, the anti-lock

brake system is disabled and normal

braking is still effective unless the

brake warning light also remains

illuminated with parking brake

released. (If your brake warning lamp illuminates, have your vehicle

serviced immediately.)

Using ABS

²In an emergency or when maximum efficiency from the ABS is

required, apply continuous force on the brake. The ABS will be

activated immediately, thus allowing you to retain full steering control

of your vehicle and, providing there is sufficient space, will enable you

to avoid obstacles and bring the vehicle to a controlled stop.

²The Anti-Lock system does not decrease the time necessary to apply

the brakes or always reduce stopping distance. Always leave enough

room between your vehicle and the vehicle in front of you to stop.

²We recommend that you familiarize yourself with this braking

technique. However, avoid taking any unnecessary risks.

Parking brake with auto-release

Apply the parking brake whenever

the vehicle is parked.

To set the parking brake:

1. Move the gearshift to P (Park).

2. Push pedal downward.

The BRAKE warning lamp in the

instrument cluster illuminates and

remains illuminated (when the

ignition is turned ON) until the

parking brake is fully released.

P!

BRAKE

BRAKE RELEASEHOOD

P!

BRAKE

Driving

126

Page 130 of 232

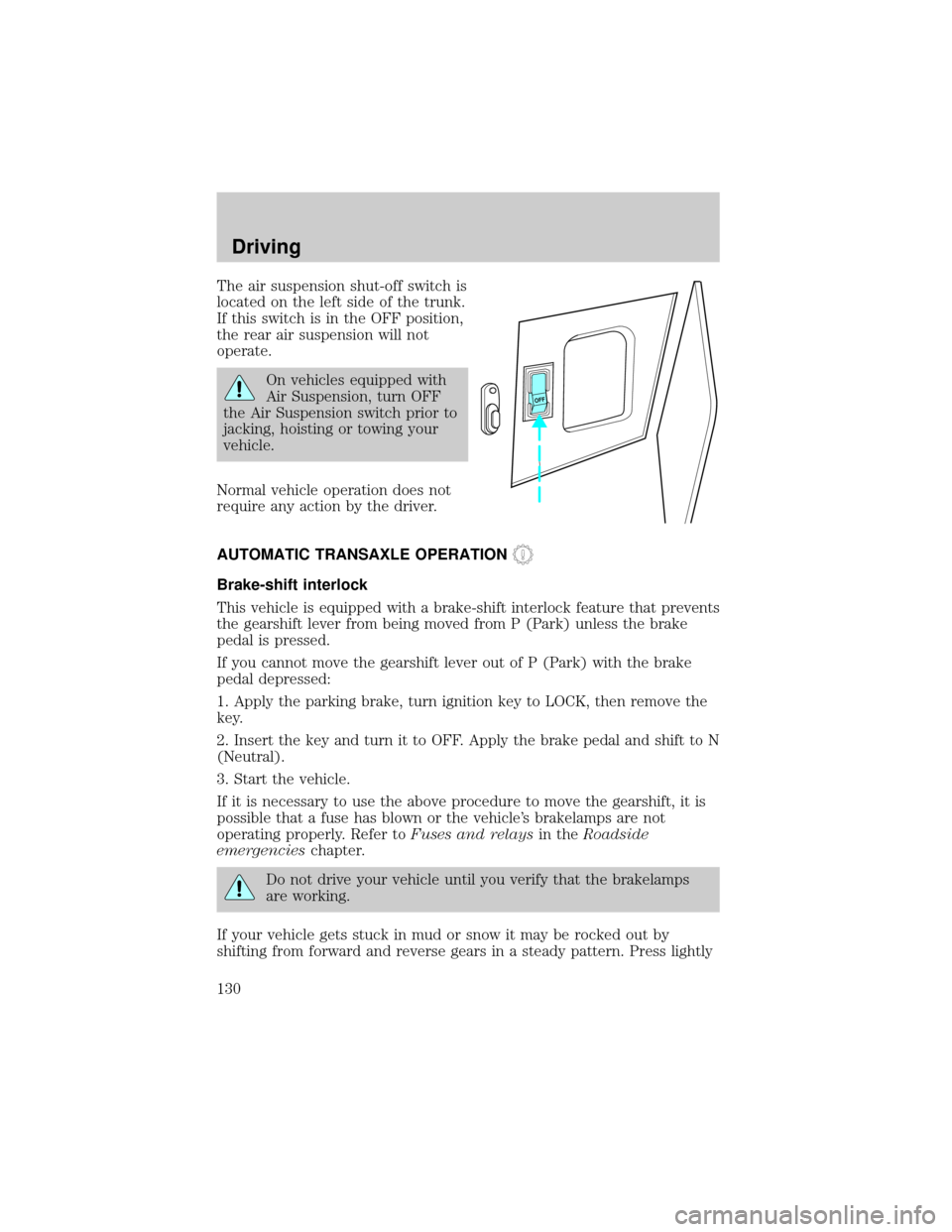

The air suspension shut-off switch is

located on the left side of the trunk.

If this switch is in the OFF position,

the rear air suspension will not

operate.

On vehicles equipped with

Air Suspension, turn OFF

the Air Suspension switch prior to

jacking, hoisting or towing your

vehicle.

Normal vehicle operation does not

require any action by the driver.

AUTOMATIC TRANSAXLE OPERATION

Brake-shift interlock

This vehicle is equipped with a brake-shift interlock feature that prevents

the gearshift lever from being moved from P (Park) unless the brake

pedal is pressed.

If you cannot move the gearshift lever out of P (Park) with the brake

pedal depressed:

1. Apply the parking brake, turn ignition key to LOCK, then remove the

key.

2. Insert the key and turn it to OFF. Apply the brake pedal and shift to N

(Neutral).

3. Start the vehicle.

If it is necessary to use the above procedure to move the gearshift, it is

possible that a fuse has blown or the vehicle's brakelamps are not

operating properly. Refer toFuses and relaysin theRoadside

emergencieschapter.

Do not drive your vehicle until you verify that the brakelamps

are working.

If your vehicle gets stuck in mud or snow it may be rocked out by

shifting from forward and reverse gears in a steady pattern. Press lightly

OFF

Driving

130

Page 135 of 232

When parking, do not use the gearshift in place of the parking

brake. Always set the parking brake fully and make sure that the

gearshift is securely latched in Park (P). Turn off the ignition

whenever you leave your vehicle. Never leave your vehicle unattended

while it is running. If you do not take these precautions, your vehicle

may move unexpectedly and injure someone.

DRIVING THROUGH WATER

Do not drive quickly through standing water, especially if the depth is

unknown. Traction or brake capability may be limited and if the ignition

system gets wet, your engine may stall. Water may also enter your

engine's air intake and severely damage your engine.

If driving through deep or standing water is unavoidable, proceed very

slowly. Never drive through water that is higher than the bottom of the

hubs (for trucks) or the bottom of the wheel rims (for cars).

Once through the water, always try the brakes. Wet brakes do not stop

the vehicle as effectively as dry brakes. Drying can be improved by

moving your vehicle slowly while applying light pressure on the brake

pedal.

Driving through deep water where the transmission/transmission

vent tube is submerged may allow water into the transmission

and cause internal transmission damage.

VEHICLE LOADING

Before loading a vehicle, familiarize yourself with the following terms:

²Base Curb Weight:Weight of the vehicle including any standard

equipment, fluids, lubricants, etc. It does not include passengers or

aftermarket equipment.

²Payload:Combined maximum allowable weight of cargo, passengers

and optional equipment. The payload equals the gross vehicle weight

rating minus base curb weight.

²GVW (Gross Vehicle Weight):Base curb weight plus payload

weight. The GVW is not a limit or a specification.

²GVWR (Gross Vehicle Weight Rating):Maximum total weight of

the base vehicle, passengers, optional equipment and cargo. The

GVWR is specific to each vehicle and is listed on the Safety

Compliance Label on the driver's door pillar.

Driving

135

Page 137 of 232

You may add equipment throughout your vehicle if the total weight

added is equal to or less than the total axle reserve capacity (TARC)

weight. You should NEVER exceed the total axle reserve capacity.

Always ensure that the weight of passengers, cargo and equipment being

carried is within the weight limitations that have been established for

your vehicle including both gross vehicle weight and Front and rear

gross axle weight rating limits. Under no circumstance should these

limitations be exceeded. Exceeding any vehicle weight rating limitation

could result in serious damage to the vehicle and/or personal injury.

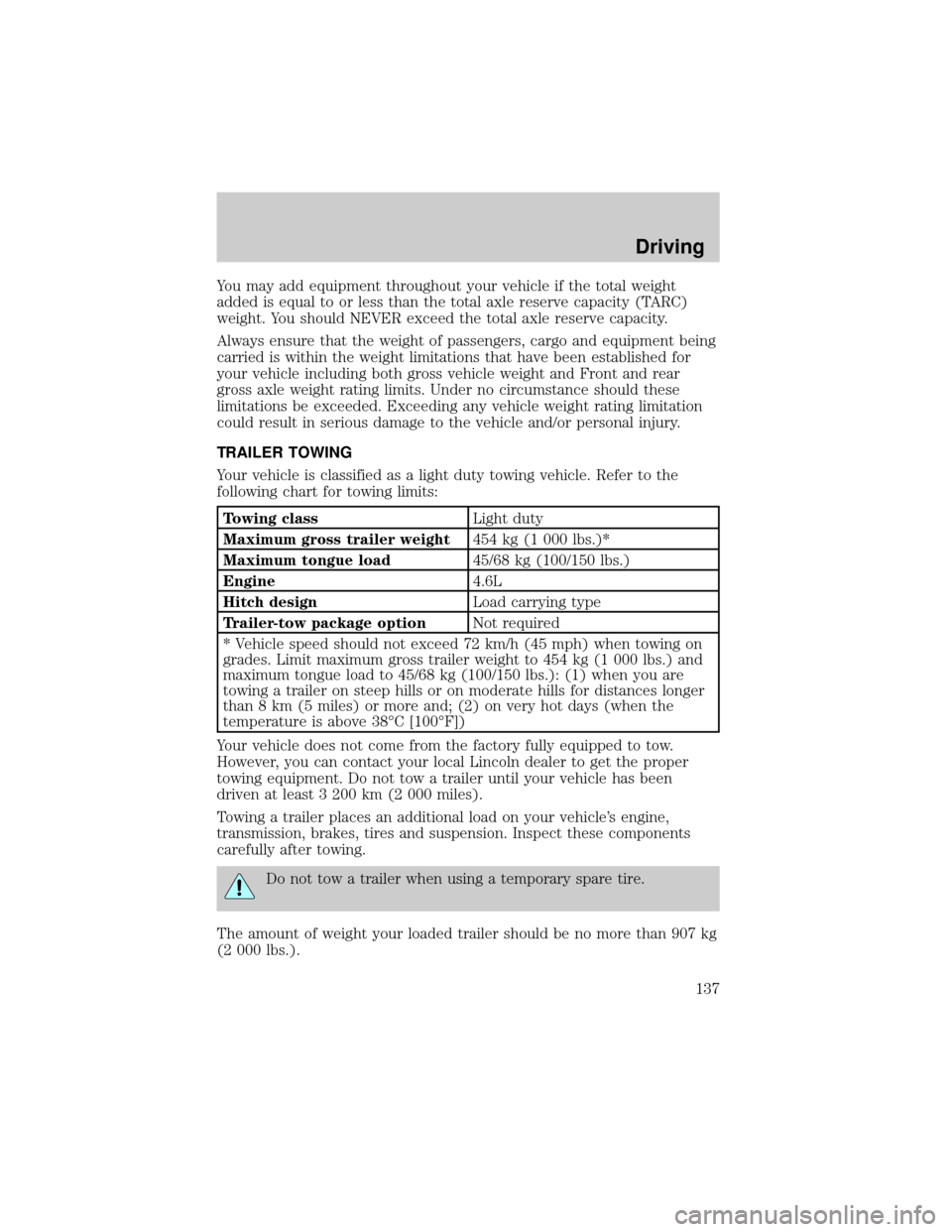

TRAILER TOWING

Your vehicle is classified as a light duty towing vehicle. Refer to the

following chart for towing limits:

Towing classLight duty

Maximum gross trailer weight454 kg (1 000 lbs.)*

Maximum tongue load45/68 kg (100/150 lbs.)

Engine4.6L

Hitch designLoad carrying type

Trailer-tow package optionNot required

* Vehicle speed should not exceed 72 km/h (45 mph) when towing on

grades. Limit maximum gross trailer weight to 454 kg (1 000 lbs.) and

maximum tongue load to 45/68 kg (100/150 lbs.): (1) when you are

towing a trailer on steep hills or on moderate hills for distances longer

than 8 km (5 miles) or more and; (2) on very hot days (when the

temperature is above 38ÉC [100ÉF])

Your vehicle does not come from the factory fully equipped to tow.

However, you can contact your local Lincoln dealer to get the proper

towing equipment. Do not tow a trailer until your vehicle has been

driven at least 3 200 km (2 000 miles).

Towing a trailer places an additional load on your vehicle's engine,

transmission, brakes, tires and suspension. Inspect these components

carefully after towing.

Do not tow a trailer when using a temporary spare tire.

The amount of weight your loaded trailer should be no more than 907 kg

(2 000 lbs.).

Driving

137

Page 139 of 232

Trailer lamps

Do not connect a trailer's lighting system directly to your vehicle's

lighting system. To get the proper equipment for hooking up your

trailer's lamps, see your Lincoln Mercury dealer. Be sure to follow their

instructions carefully.

If you do not install trailer lights correctly, you may cause damage to the

vehicle's lighting system or other vehicle systems.

Driving while you tow

When towing a trailer:

²Ensure that you turn off your speed control. The speed control may

shut off automatically when you are towing on long, steep grades.

²Consult your local motor vehicle speed regulations for towing a trailer.

²Shift out of D (Overdrive) and into 3 (Third) or a lower gear when

towing up or down steep hills. This will eliminate excessive

downshifting and upshifting for optimum fuel economy and transaxle

cooling.

²Anticipate stops and brake gradually.

Servicing after towing

If you tow a trailer for long distances, your vehicle will require more

frequent service intervals. Refer to your Scheduled Maintenance Guide

for more information.

Trailer towing tips

²Practice turning, stopping and backing up in an area before starting on

a trip to get the feel of the vehicle trailer combination. When turning,

make wider turns so the trailer wheels will clear curbs and other

obstacles.

²Allow more distance for stopping with a trailer attached.

²The trailer tongue weight should be 10% of the loaded trailer weight.

²After you have traveled 80 km (50 miles), thoroughly check your

hitch, electrical connections and trailer wheel lug nuts.

²When stopped in traffic for long periods of time in hot weather, place

the gearshift in P (Park) and increase idle speed. This aids engine

cooling and air conditioner efficiency.

Driving

139