ac maintenance LINCOLN CONTINENTAL 2001 Workshop Manual

[x] Cancel search | Manufacturer: LINCOLN, Model Year: 2001, Model line: CONTINENTAL, Model: LINCOLN CONTINENTAL 2001Pages: 224, PDF Size: 1.82 MB

Page 187 of 224

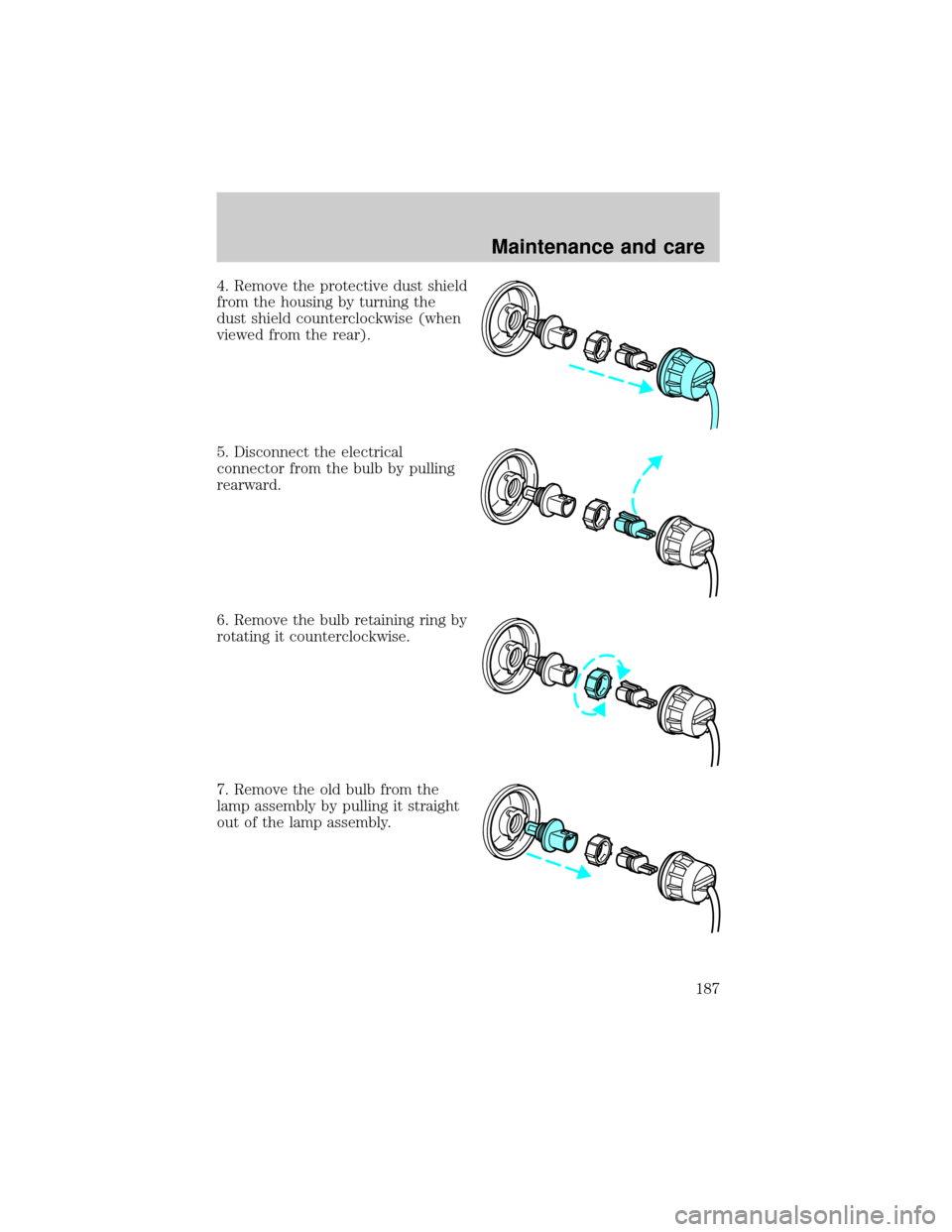

4. Remove the protective dust shield

from the housing by turning the

dust shield counterclockwise (when

viewed from the rear).

5. Disconnect the electrical

connector from the bulb by pulling

rearward.

6. Remove the bulb retaining ring by

rotating it counterclockwise.

7. Remove the old bulb from the

lamp assembly by pulling it straight

out of the lamp assembly.

Maintenance and care

187

Page 188 of 224

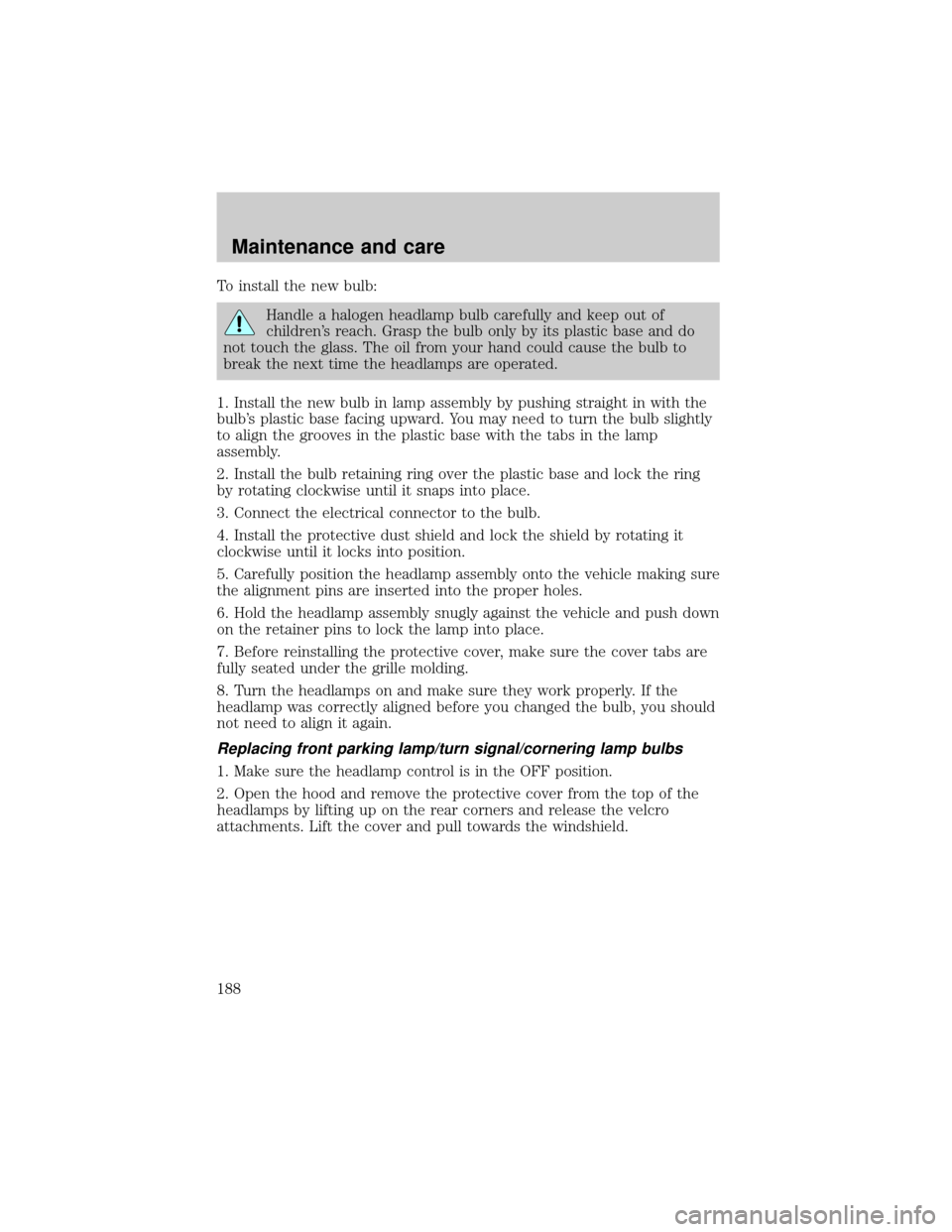

To install the new bulb:

Handle a halogen headlamp bulb carefully and keep out of

children's reach. Grasp the bulb only by its plastic base and do

not touch the glass. The oil from your hand could cause the bulb to

break the next time the headlamps are operated.

1. Install the new bulb in lamp assembly by pushing straight in with the

bulb's plastic base facing upward. You may need to turn the bulb slightly

to align the grooves in the plastic base with the tabs in the lamp

assembly.

2. Install the bulb retaining ring over the plastic base and lock the ring

by rotating clockwise until it snaps into place.

3. Connect the electrical connector to the bulb.

4. Install the protective dust shield and lock the shield by rotating it

clockwise until it locks into position.

5. Carefully position the headlamp assembly onto the vehicle making sure

the alignment pins are inserted into the proper holes.

6. Hold the headlamp assembly snugly against the vehicle and push down

on the retainer pins to lock the lamp into place.

7. Before reinstalling the protective cover, make sure the cover tabs are

fully seated under the grille molding.

8. Turn the headlamps on and make sure they work properly. If the

headlamp was correctly aligned before you changed the bulb, you should

not need to align it again.

Replacing front parking lamp/turn signal/cornering lamp bulbs

1. Make sure the headlamp control is in the OFF position.

2. Open the hood and remove the protective cover from the top of the

headlamps by lifting up on the rear corners and release the velcro

attachments. Lift the cover and pull towards the windshield.

Maintenance and care

188

Page 189 of 224

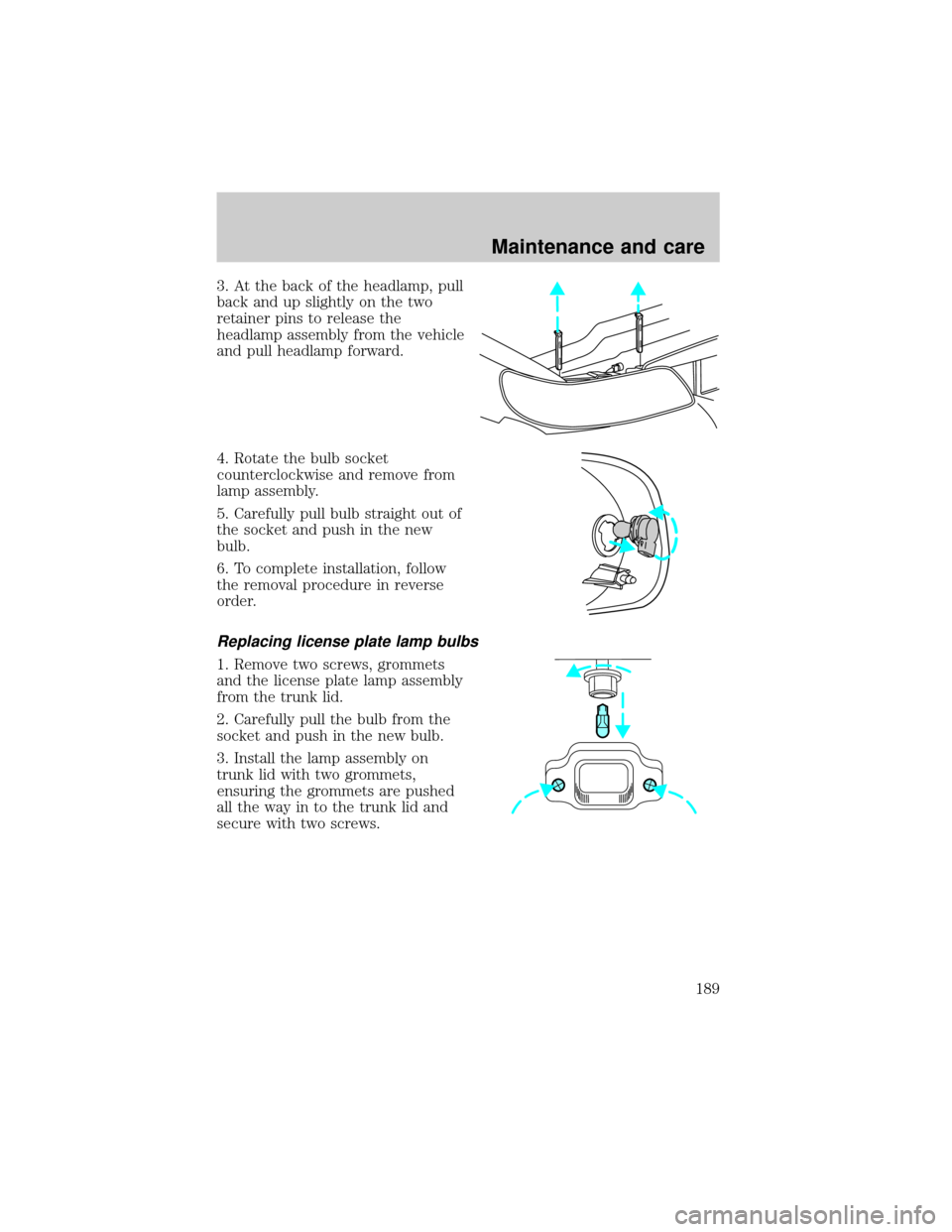

3. At the back of the headlamp, pull

back and up slightly on the two

retainer pins to release the

headlamp assembly from the vehicle

and pull headlamp forward.

4. Rotate the bulb socket

counterclockwise and remove from

lamp assembly.

5. Carefully pull bulb straight out of

the socket and push in the new

bulb.

6. To complete installation, follow

the removal procedure in reverse

order.

Replacing license plate lamp bulbs

1. Remove two screws, grommets

and the license plate lamp assembly

from the trunk lid.

2. Carefully pull the bulb from the

socket and push in the new bulb.

3. Install the lamp assembly on

trunk lid with two grommets,

ensuring the grommets are pushed

all the way in to the trunk lid and

secure with two screws.

Maintenance and care

189

Page 190 of 224

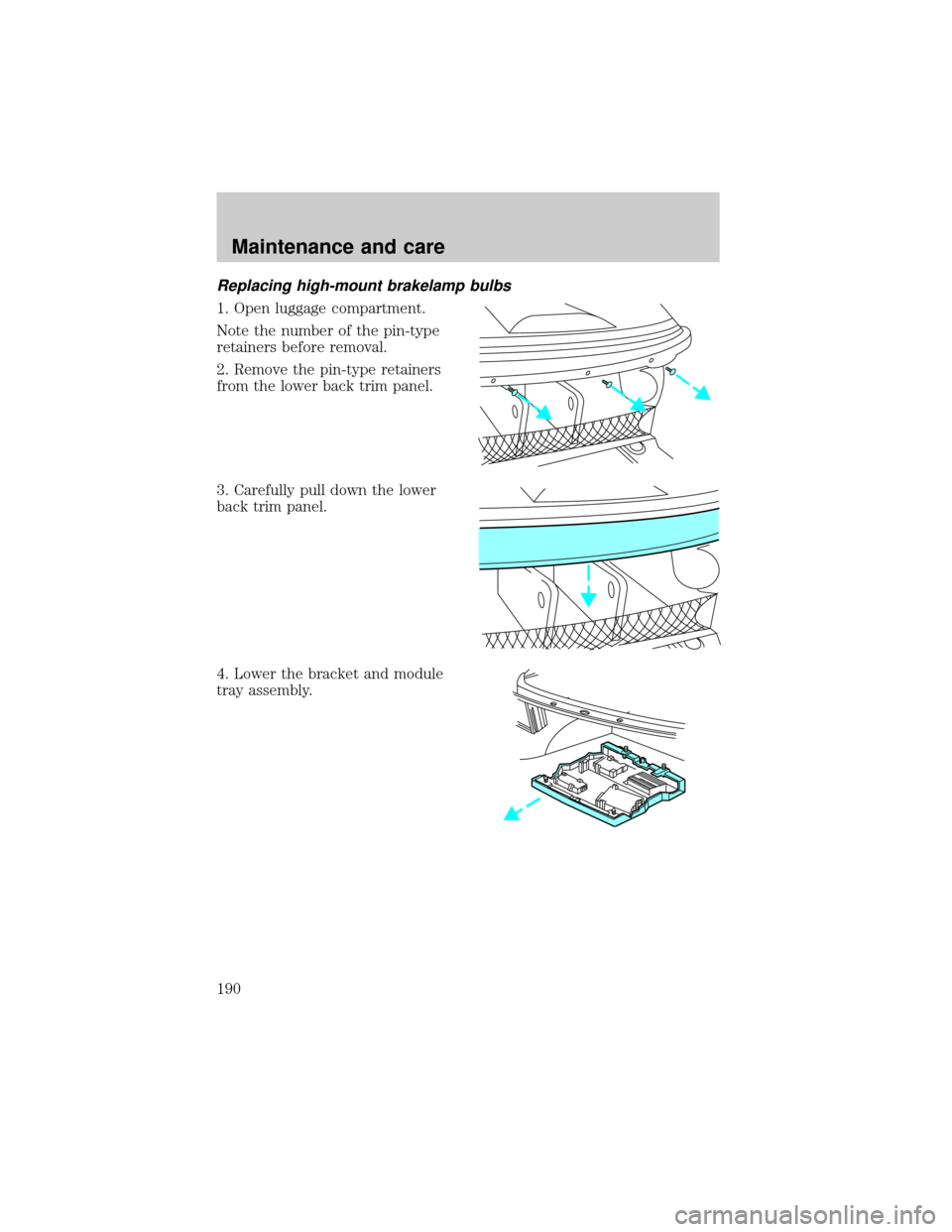

Replacing high-mount brakelamp bulbs

1. Open luggage compartment.

Note the number of the pin-type

retainers before removal.

2. Remove the pin-type retainers

from the lower back trim panel.

3. Carefully pull down the lower

back trim panel.

4. Lower the bracket and module

tray assembly.

Maintenance and care

190

Page 191 of 224

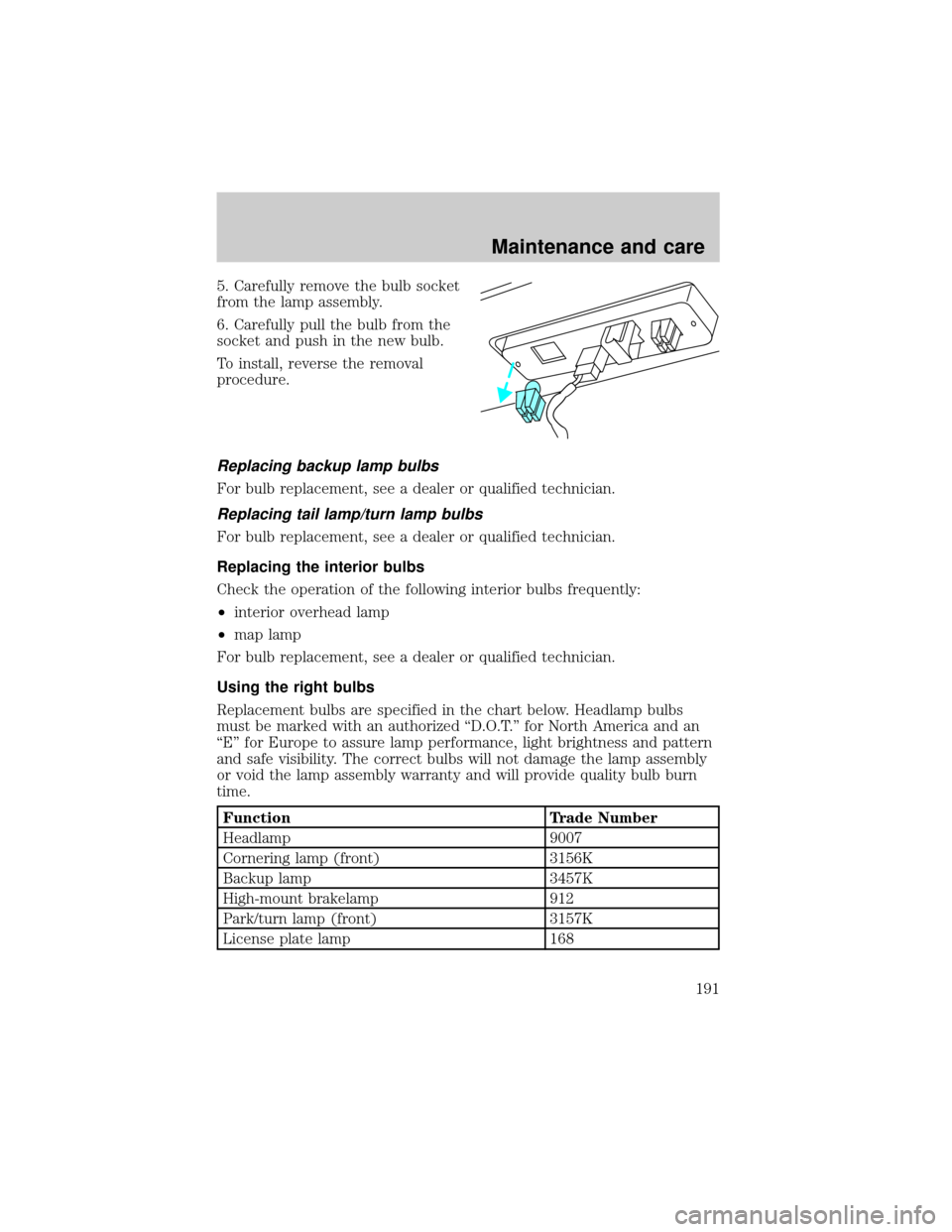

5. Carefully remove the bulb socket

from the lamp assembly.

6. Carefully pull the bulb from the

socket and push in the new bulb.

To install, reverse the removal

procedure.

Replacing backup lamp bulbs

For bulb replacement, see a dealer or qualified technician.

Replacing tail lamp/turn lamp bulbs

For bulb replacement, see a dealer or qualified technician.

Replacing the interior bulbs

Check the operation of the following interior bulbs frequently:

²interior overhead lamp

²map lamp

For bulb replacement, see a dealer or qualified technician.

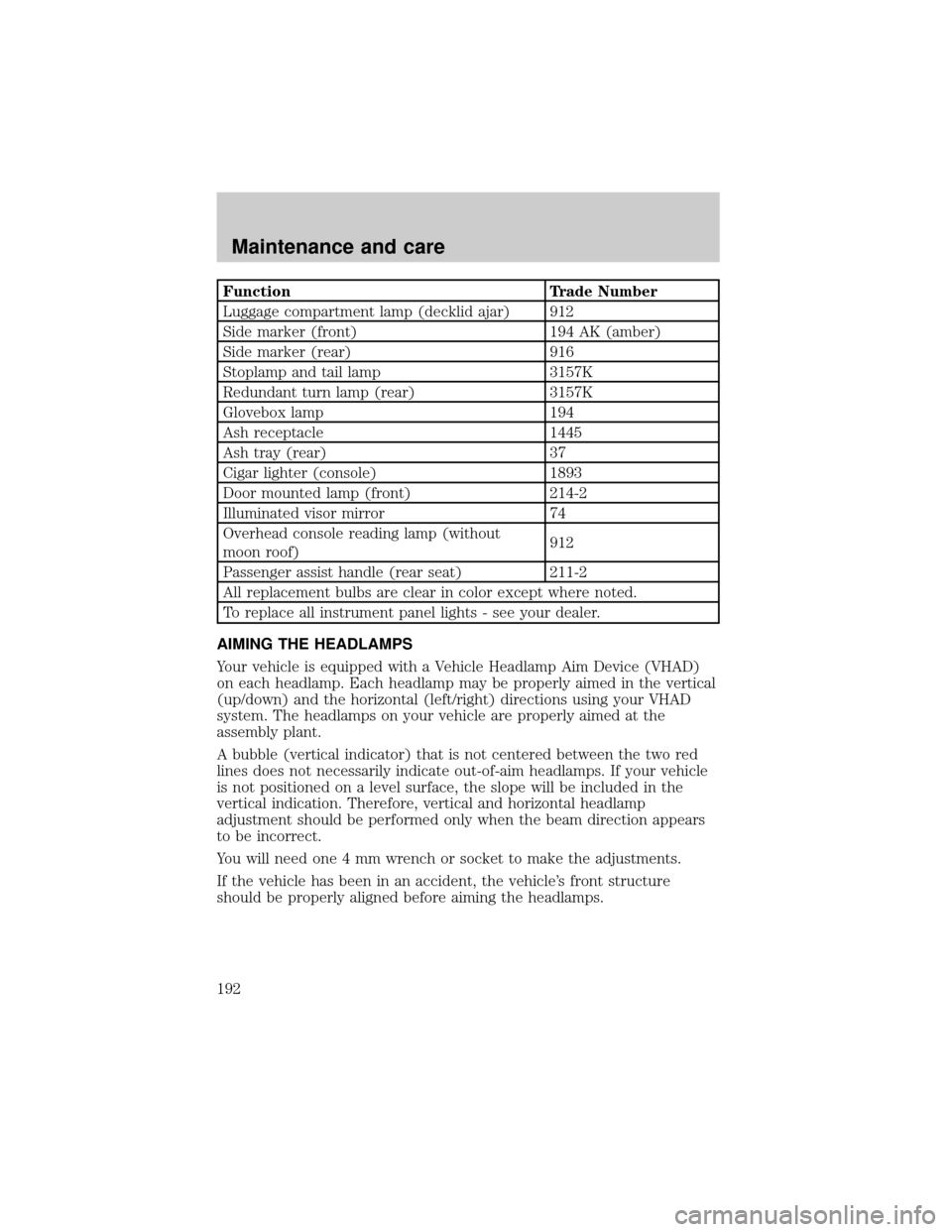

Using the right bulbs

Replacement bulbs are specified in the chart below. Headlamp bulbs

must be marked with an authorized ªD.O.T.º for North America and an

ªEº for Europe to assure lamp performance, light brightness and pattern

and safe visibility. The correct bulbs will not damage the lamp assembly

or void the lamp assembly warranty and will provide quality bulb burn

time.

Function Trade Number

Headlamp 9007

Cornering lamp (front) 3156K

Backup lamp 3457K

High-mount brakelamp 912

Park/turn lamp (front) 3157K

License plate lamp 168

Maintenance and care

191

Page 192 of 224

Function Trade Number

Luggage compartment lamp (decklid ajar) 912

Side marker (front) 194 AK (amber)

Side marker (rear) 916

Stoplamp and tail lamp 3157K

Redundant turn lamp (rear) 3157K

Glovebox lamp 194

Ash receptacle 1445

Ash tray (rear) 37

Cigar lighter (console) 1893

Door mounted lamp (front) 214-2

Illuminated visor mirror 74

Overhead console reading lamp (without

moon roof)912

Passenger assist handle (rear seat) 211-2

All replacement bulbs are clear in color except where noted.

To replace all instrument panel lights - see your dealer.

AIMING THE HEADLAMPS

Your vehicle is equipped with a Vehicle Headlamp Aim Device (VHAD)

on each headlamp. Each headlamp may be properly aimed in the vertical

(up/down) and the horizontal (left/right) directions using your VHAD

system. The headlamps on your vehicle are properly aimed at the

assembly plant.

A bubble (vertical indicator) that is not centered between the two red

lines does not necessarily indicate out-of-aim headlamps. If your vehicle

is not positioned on a level surface, the slope will be included in the

vertical indication. Therefore, vertical and horizontal headlamp

adjustment should be performed only when the beam direction appears

to be incorrect.

You will need one 4 mm wrench or socket to make the adjustments.

If the vehicle has been in an accident, the vehicle's front structure

should be properly aligned before aiming the headlamps.

Maintenance and care

192

Page 193 of 224

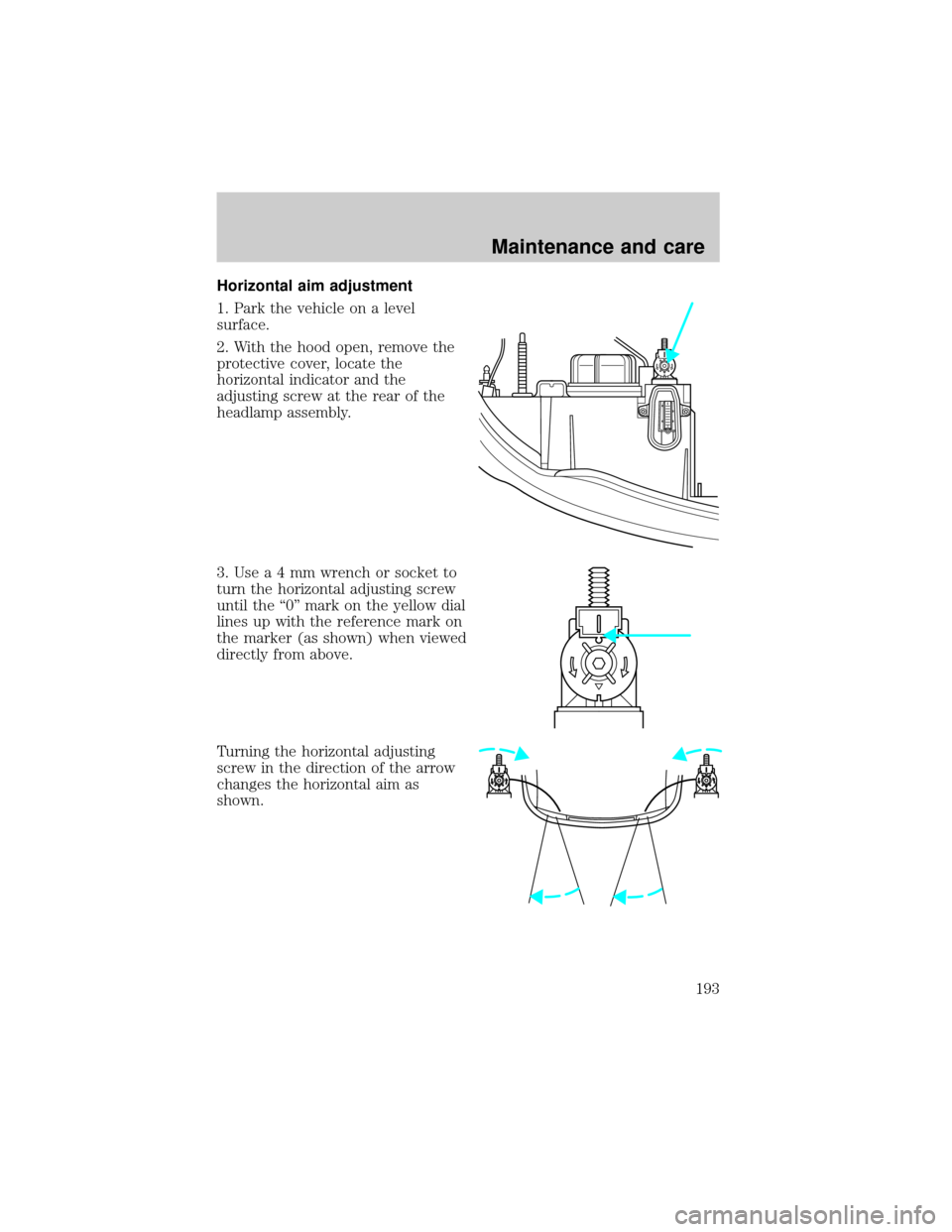

Horizontal aim adjustment

1. Park the vehicle on a level

surface.

2. With the hood open, remove the

protective cover, locate the

horizontal indicator and the

adjusting screw at the rear of the

headlamp assembly.

3.Usea4mmwrench or socket to

turn the horizontal adjusting screw

until the ª0º mark on the yellow dial

lines up with the reference mark on

the marker (as shown) when viewed

directly from above.

Turning the horizontal adjusting

screw in the direction of the arrow

changes the horizontal aim as

shown.

U

D

Maintenance and care

193

Page 194 of 224

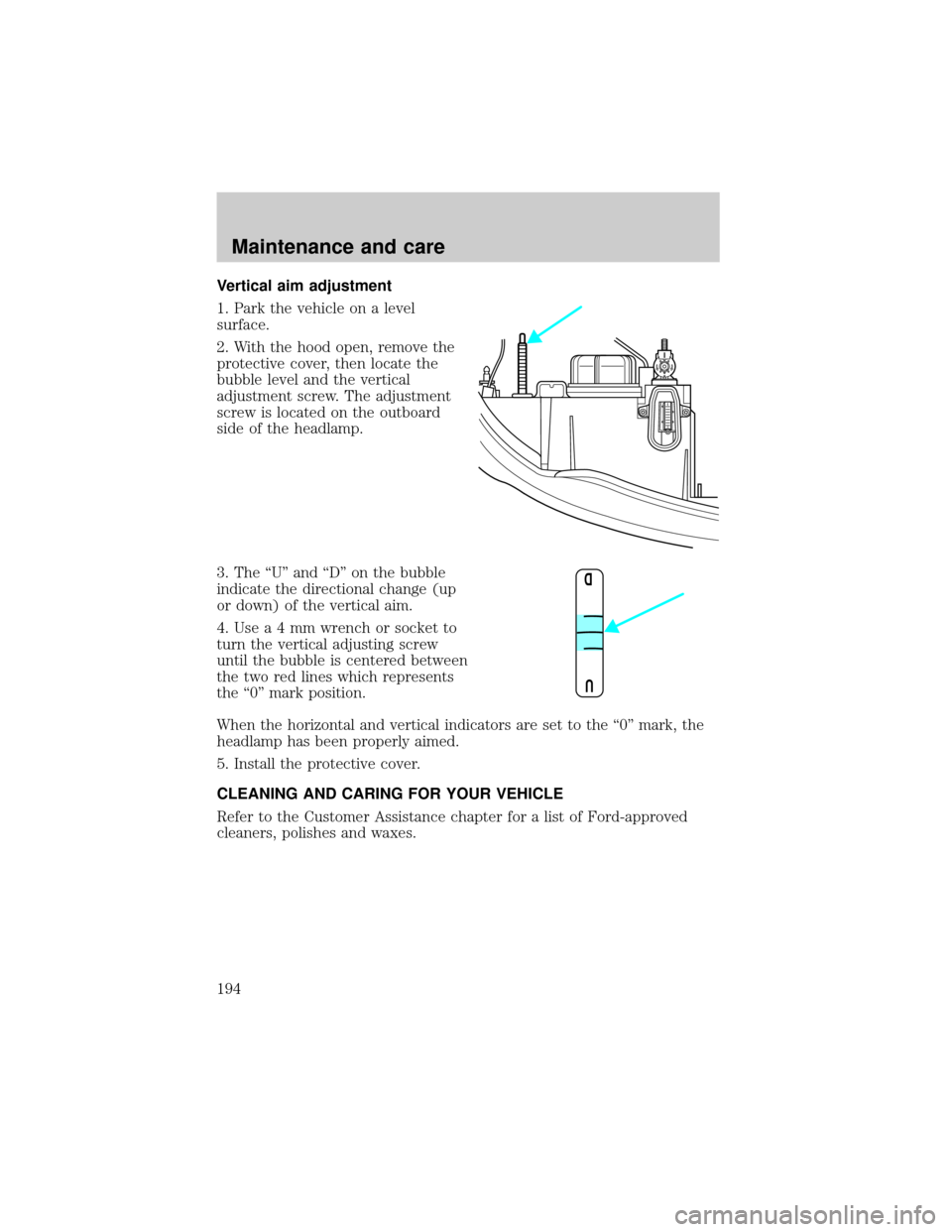

Vertical aim adjustment

1. Park the vehicle on a level

surface.

2. With the hood open, remove the

protective cover, then locate the

bubble level and the vertical

adjustment screw. The adjustment

screw is located on the outboard

side of the headlamp.

3. The ªUº and ªDº on the bubble

indicate the directional change (up

or down) of the vertical aim.

4.Usea4mmwrench or socket to

turn the vertical adjusting screw

until the bubble is centered between

the two red lines which represents

the ª0º mark position.

When the horizontal and vertical indicators are set to the ª0º mark, the

headlamp has been properly aimed.

5. Install the protective cover.

CLEANING AND CARING FOR YOUR VEHICLE

Refer to the Customer Assistance chapter for a list of Ford-approved

cleaners, polishes and waxes.

U

D

D U

Maintenance and care

194

Page 195 of 224

Washing your vehicle

Wash your vehicle regularly with

cold or lukewarm water. Never use

strong detergents or soap. If your

vehicle is particularly dirty, use a

quality car wash detergent. Always

use a clean sponge, washing glove

or similar device and plenty of water

for best results. To avoid spots,

avoid washing when the hood is still

warm, immediately after or during

exposure to strong sunlight.

During winter months, it is especially important to wash the vehicle on a

regular basis. Large quantities of dirt and road salt are difficult to

remove and also cause damage to the vehicle.

Any gasoline spilled on the vehicle or deposits such as bird droppings

should be washed and sponged off as soon as possible. Deposits not

removed promptly can cause damage to the vehicle's paintwork.

Remove any exterior accessories, such as antennas, before entering a car

wash. If you have wax applied to the vehicle at a commercial car wash, it

is recommended that you clean the wiper blades and windshield as

described inCleaning the wiper blades and windshield.

After washing, apply the brakes several times to dry them.

Underbody

Flush the complete underside of vehicle frequently. Keep body drain

holes unplugged. Inspect for road damage.

Waxing your vehicle

Waxing your vehicle on a regular basis will reduce minor scratches and

paint damage.

Wax when water stops beading on the surface. This could be every three

or four months, depending on operating conditions.

Use only carnauba or synthetic-based waxes. Use a cleaning fluid with a

clean cloth to remove any bugs before waxing your vehicle. Use tar

remover to remove any tar spots.

Avoid getting wax on the windshield, or on any surfaces which appear

coarse or bumpy. If you have wax applied at a commercial car wash, it is

Maintenance and care

195

Page 196 of 224

recommended that you clean the wiper blades and windshield as

described inCleaning the wiper blades and windshield.

Repairing paint chips

Minor scratches or paint damage from road debris may be repaired with

the Ultra Touch Prep and Finishing Kit (#F7AZ-19K507±BA), Lacquer

Touch-up Paint (#ALBZ-19500±XXXXA), or Exterior Acrylic Spray

Lacquer (#ALAZ-19500±XXXXA) from the Ford Car Care Chemicals line.

Please note that the part numbers (shown as XXXX above) will vary with

your vehicle's specific coloring. Observe the application instructions on

the products.

Remove particles such as bird droppings, tree sap, insect remains, tar

spots, road salt and industrial fallout immediately.

Cleaning the wheels

Wash with the same detergent as the body of your vehicle. Do not use

acid-based or alcohol-based wheel cleaners, steel wool, fuel or strong

detergents. Never use abrasives that will damage the finish of special

wheel surfaces. Use a tar remover to remove grease and tar.

The brushes used in some automatic car washes may damage the finish

on your wheels. Before going to a car wash, find out if the brushes are

abrasive.

Cleaning non-painted plastic exterior parts

Use vinyl cleaner for routine cleaning. Clean with a tar remover if

necessary. Do not clean plastic parts with thinners, solvents or

petroleum-based cleaners.

Cleaning mirrors

Do not clean your mirrors with a dry cloth or abrasive materials. Use a

soft cloth and mild detergent and water. Be careful when removing ice

from outside mirrors because you may damage the reflective surface.

Cleaning the exterior lamps

Wash with the same detergent as the exterior of your vehicle. If

necessary, use a tar remover such as Ford Extra Strength Tar and Road

Oil Remover (B7A-19520±AA).

To avoid scratching the lamps, do not use a dry paper towel, chemical

solvents or abrasive cleaners.

Maintenance and care

196