bulb LINCOLN CONTINENTAL 2001 Owners Manual

[x] Cancel search | Manufacturer: LINCOLN, Model Year: 2001, Model line: CONTINENTAL, Model: LINCOLN CONTINENTAL 2001Pages: 224, PDF Size: 1.82 MB

Page 8 of 224

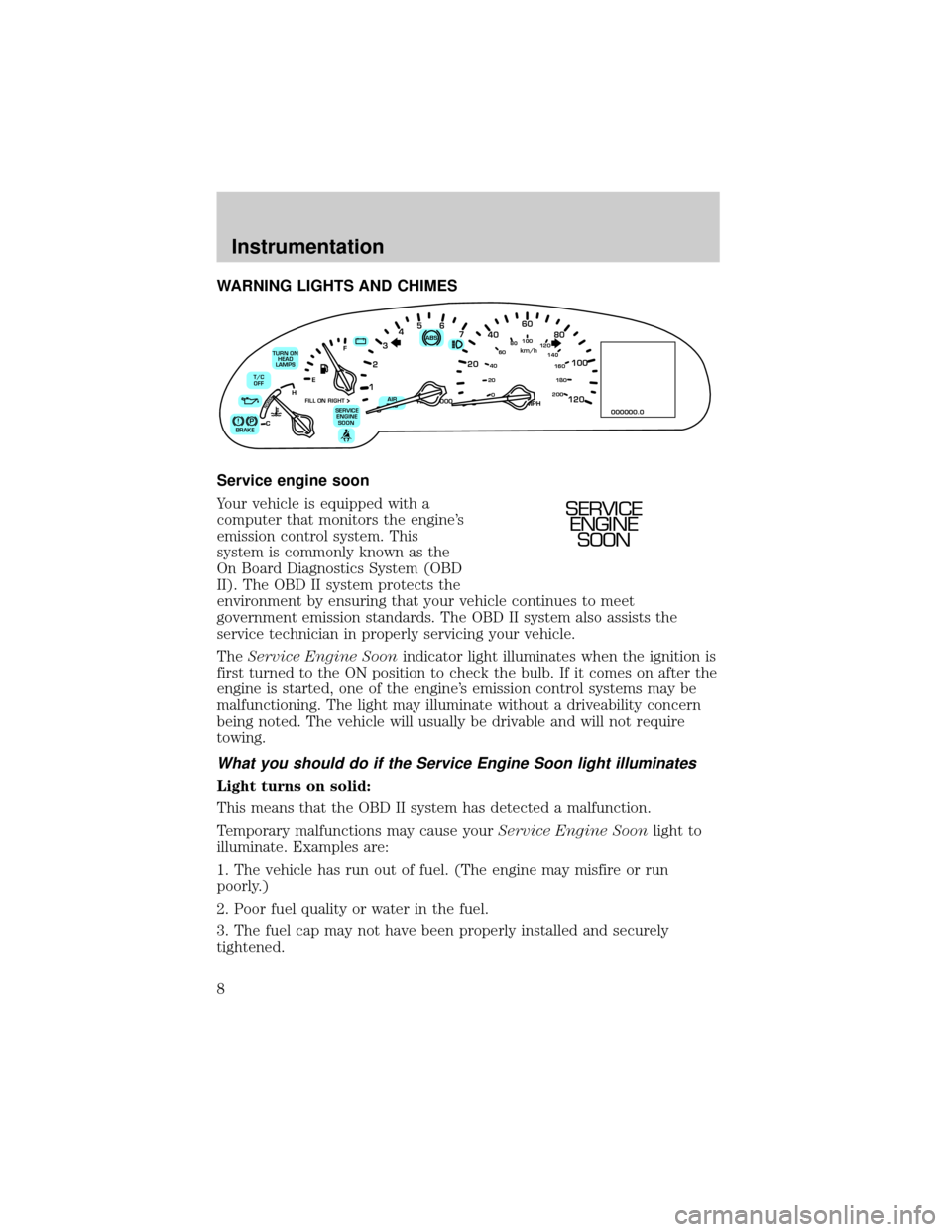

WARNING LIGHTS AND CHIMES

Service engine soon

Your vehicle is equipped with a

computer that monitors the engine's

emission control system. This

system is commonly known as the

On Board Diagnostics System (OBD

II). The OBD II system protects the

environment by ensuring that your vehicle continues to meet

government emission standards. The OBD II system also assists the

service technician in properly servicing your vehicle.

TheService Engine Soonindicator light illuminates when the ignition is

first turned to the ON position to check the bulb. If it comes on after the

engine is started, one of the engine's emission control systems may be

malfunctioning. The light may illuminate without a driveability concern

being noted. The vehicle will usually be drivable and will not require

towing.

What you should do if the Service Engine Soon light illuminates

Light turns on solid:

This means that the OBD II system has detected a malfunction.

Temporary malfunctions may cause yourService Engine Soonlight to

illuminate. Examples are:

1. The vehicle has run out of fuel. (The engine may misfire or run

poorly.)

2. Poor fuel quality or water in the fuel.

3. The fuel cap may not have been properly installed and securely

tightened.

80

MPH km/h

ABS

P!BRAKE

+ –

RPMx1000NORM

T/C

OFF

CHEF

FILL ON RIGHT

SERVICE

ENGINE

SOON AIR

BAG TURN ON

HEAD

LAMPS0 123456

7

0 2060

80

100

120

0 204060100

120

140

160

180

200

40

000000.0

SERVICE

ENGINE

SOON

Instrumentation

8

Page 10 of 224

Brake system warning

Momentarily illuminates when the

ignition is turned to the ON position

to indicate a system check. Also

illuminates if the parking brake is

engaged. If the brake warning lamp

does not illuminate at these times, seek service immediately. Illumination

after releasing the parking brake indicates low brake fluid level and the

brake system should be inspected immediately.

Anti-lock brake system (ABS)

Momentarily illuminates when the

ignition is turned to the ON position

to indicate a system check. If the

light remains on, continues to flash

or fails to illuminate, have the

system serviced immediately. With the ABS light on, the anti-lock brake

system is disabled and normal braking is still effective unless the brake

warning light also remains illuminated with the parking brake released.

Turn signal

Illuminates when the left or right

turn signal or the hazard lights are

turned on. If one or both of the

indicators stay on continuously or

flash faster, check for a burned-out

turn signal bulb. Refer toBulbsin theMaintenance and carechapter.

High beams

Illuminates when the high beam

headlamps are turned on.

Turn on headlamps (if equipped)

Illuminates to remind the driver to

turn the headlamps on when:

²the daytime running lamps are on

(if equipped)

P!

BRAKE

ABS

TURN ON

HEAD

LAMPS

Instrumentation

10

Page 50 of 224

Cornering lamps

When the turn signal is used and the headlamps are on, the cornering

lamps will light either the right or left side depending on the direction of

the turn.

The flash rate of the turn signal will speed up considerably if the

Lighting Control Module detects a left or right turn lamp bulb (front or

rear) is burned out.

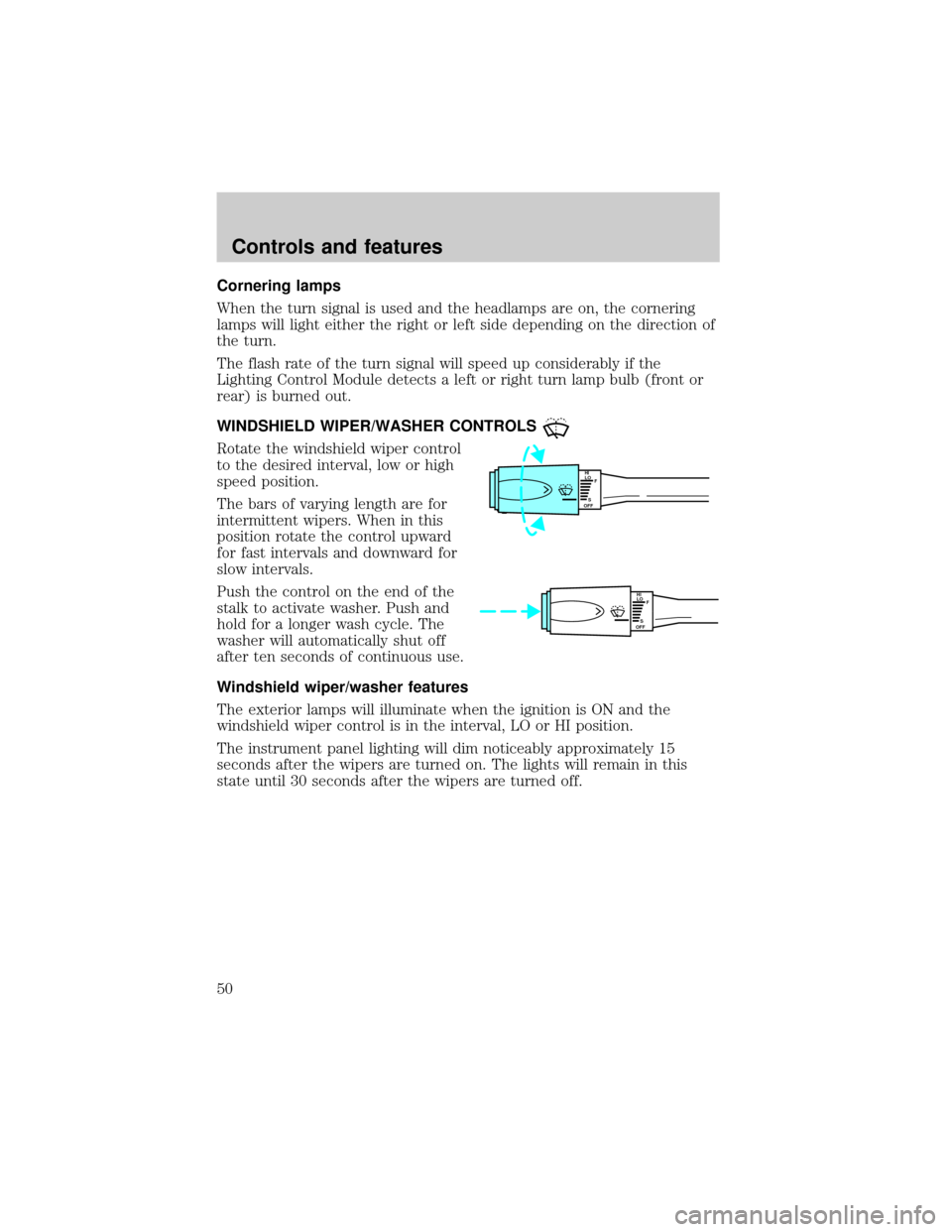

WINDSHIELD WIPER/WASHER CONTROLS

Rotate the windshield wiper control

to the desired interval, low or high

speed position.

The bars of varying length are for

intermittent wipers. When in this

position rotate the control upward

for fast intervals and downward for

slow intervals.

Push the control on the end of the

stalk to activate washer. Push and

hold for a longer wash cycle. The

washer will automatically shut off

after ten seconds of continuous use.

Windshield wiper/washer features

The exterior lamps will illuminate when the ignition is ON and the

windshield wiper control is in the interval, LO or HI position.

The instrument panel lighting will dim noticeably approximately 15

seconds after the wipers are turned on. The lights will remain in this

state until 30 seconds after the wipers are turned off.

HI

LO

F

S

OFF

HI

LO

F

S

OFF

Controls and features

50

Page 186 of 224

engine must warm up to its normal operating temperature. Once started,

do not turn off the engine until the above driving cycle is complete.

REPLACING EXTERIOR BULBS

Check the operation of the following lamps frequently:

²Headlamps

²Tail lamps

²Brakelamps

²High-mount brakelamp

²Turn signals

²Backup lamps

²License plate lamp

Do not remove lamp bulbs unless they will be replaced immediately. If a

bulb is removed for an extended period of time, contaminants may enter

the lamp housings and affect performance.

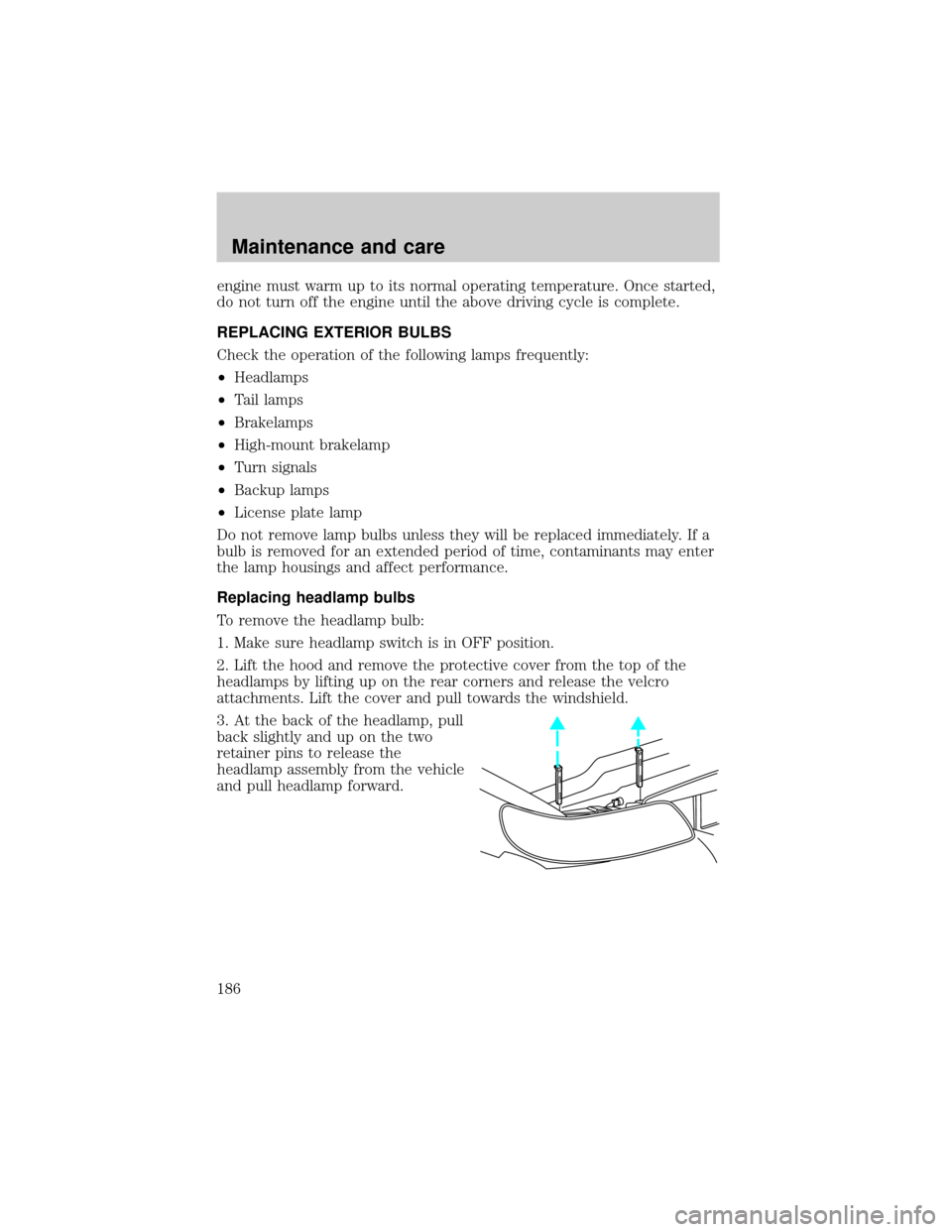

Replacing headlamp bulbs

To remove the headlamp bulb:

1. Make sure headlamp switch is in OFF position.

2. Lift the hood and remove the protective cover from the top of the

headlamps by lifting up on the rear corners and release the velcro

attachments. Lift the cover and pull towards the windshield.

3. At the back of the headlamp, pull

back slightly and up on the two

retainer pins to release the

headlamp assembly from the vehicle

and pull headlamp forward.

Maintenance and care

186

Page 187 of 224

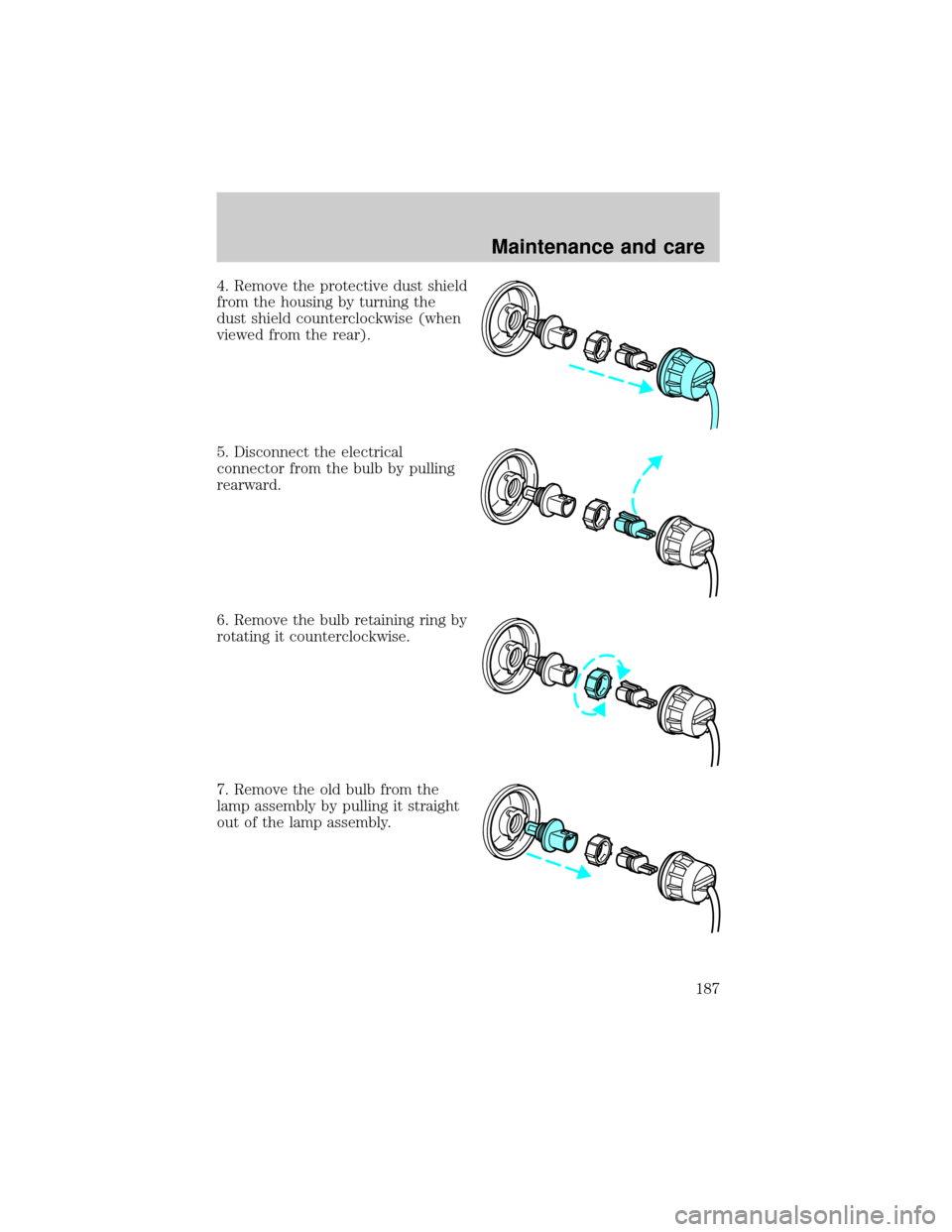

4. Remove the protective dust shield

from the housing by turning the

dust shield counterclockwise (when

viewed from the rear).

5. Disconnect the electrical

connector from the bulb by pulling

rearward.

6. Remove the bulb retaining ring by

rotating it counterclockwise.

7. Remove the old bulb from the

lamp assembly by pulling it straight

out of the lamp assembly.

Maintenance and care

187

Page 188 of 224

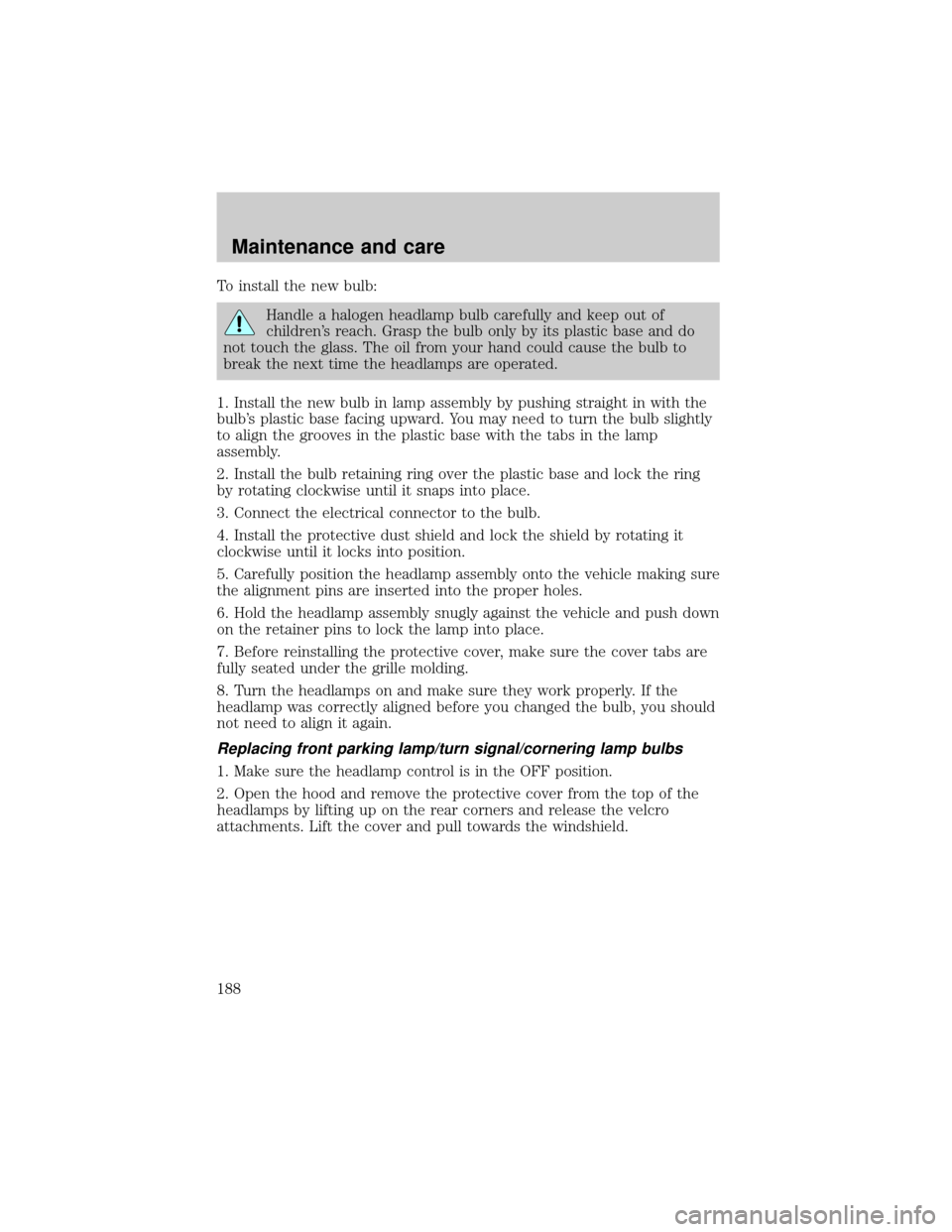

To install the new bulb:

Handle a halogen headlamp bulb carefully and keep out of

children's reach. Grasp the bulb only by its plastic base and do

not touch the glass. The oil from your hand could cause the bulb to

break the next time the headlamps are operated.

1. Install the new bulb in lamp assembly by pushing straight in with the

bulb's plastic base facing upward. You may need to turn the bulb slightly

to align the grooves in the plastic base with the tabs in the lamp

assembly.

2. Install the bulb retaining ring over the plastic base and lock the ring

by rotating clockwise until it snaps into place.

3. Connect the electrical connector to the bulb.

4. Install the protective dust shield and lock the shield by rotating it

clockwise until it locks into position.

5. Carefully position the headlamp assembly onto the vehicle making sure

the alignment pins are inserted into the proper holes.

6. Hold the headlamp assembly snugly against the vehicle and push down

on the retainer pins to lock the lamp into place.

7. Before reinstalling the protective cover, make sure the cover tabs are

fully seated under the grille molding.

8. Turn the headlamps on and make sure they work properly. If the

headlamp was correctly aligned before you changed the bulb, you should

not need to align it again.

Replacing front parking lamp/turn signal/cornering lamp bulbs

1. Make sure the headlamp control is in the OFF position.

2. Open the hood and remove the protective cover from the top of the

headlamps by lifting up on the rear corners and release the velcro

attachments. Lift the cover and pull towards the windshield.

Maintenance and care

188

Page 189 of 224

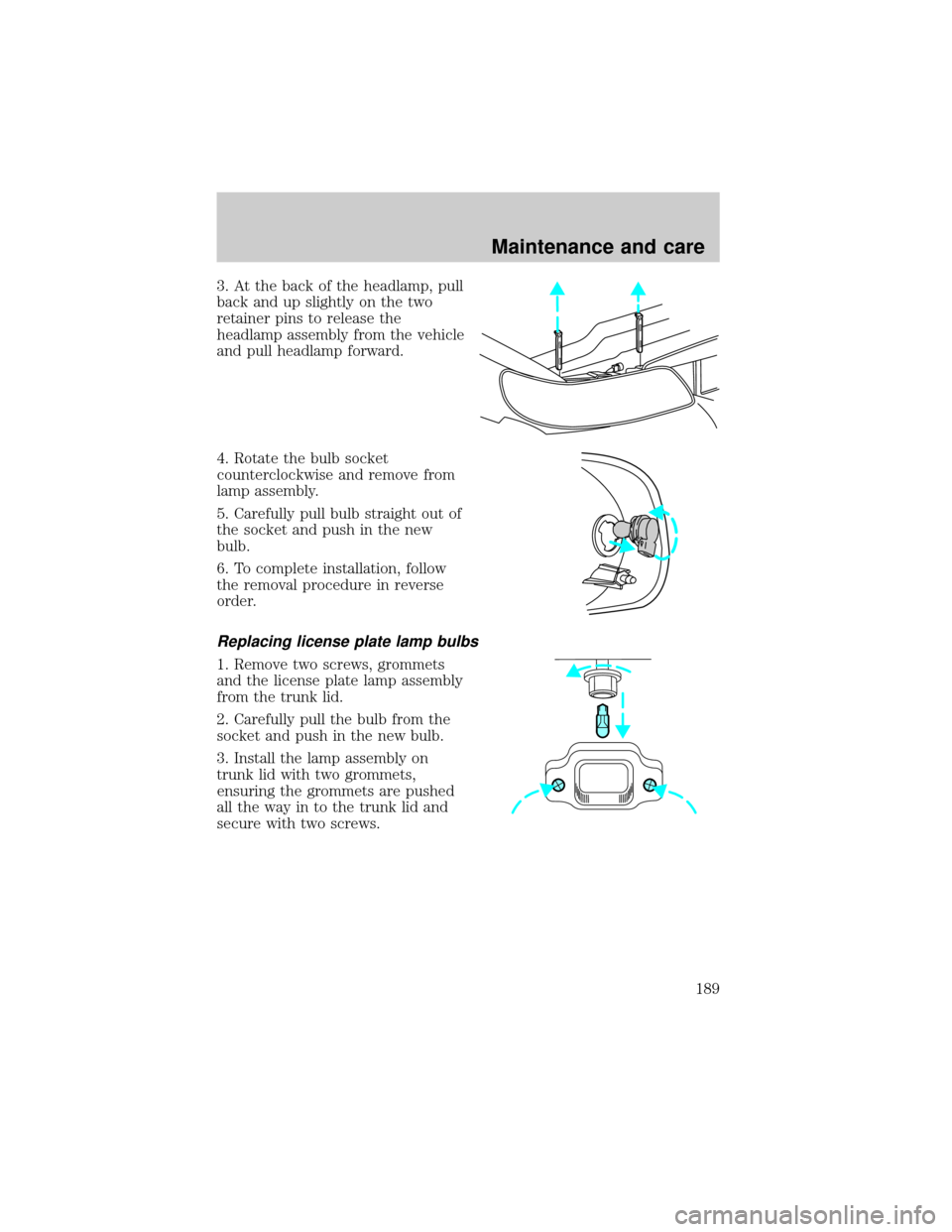

3. At the back of the headlamp, pull

back and up slightly on the two

retainer pins to release the

headlamp assembly from the vehicle

and pull headlamp forward.

4. Rotate the bulb socket

counterclockwise and remove from

lamp assembly.

5. Carefully pull bulb straight out of

the socket and push in the new

bulb.

6. To complete installation, follow

the removal procedure in reverse

order.

Replacing license plate lamp bulbs

1. Remove two screws, grommets

and the license plate lamp assembly

from the trunk lid.

2. Carefully pull the bulb from the

socket and push in the new bulb.

3. Install the lamp assembly on

trunk lid with two grommets,

ensuring the grommets are pushed

all the way in to the trunk lid and

secure with two screws.

Maintenance and care

189

Page 190 of 224

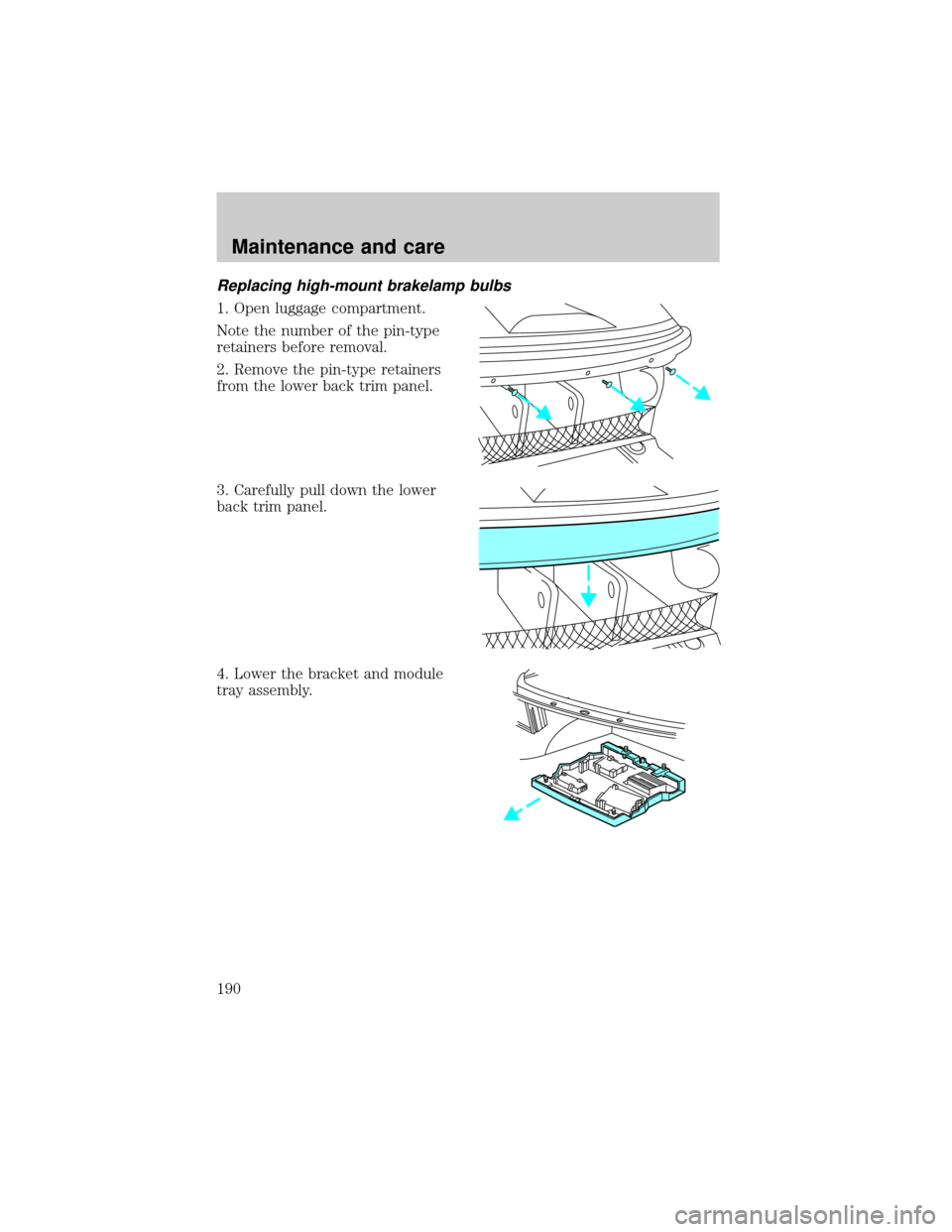

Replacing high-mount brakelamp bulbs

1. Open luggage compartment.

Note the number of the pin-type

retainers before removal.

2. Remove the pin-type retainers

from the lower back trim panel.

3. Carefully pull down the lower

back trim panel.

4. Lower the bracket and module

tray assembly.

Maintenance and care

190

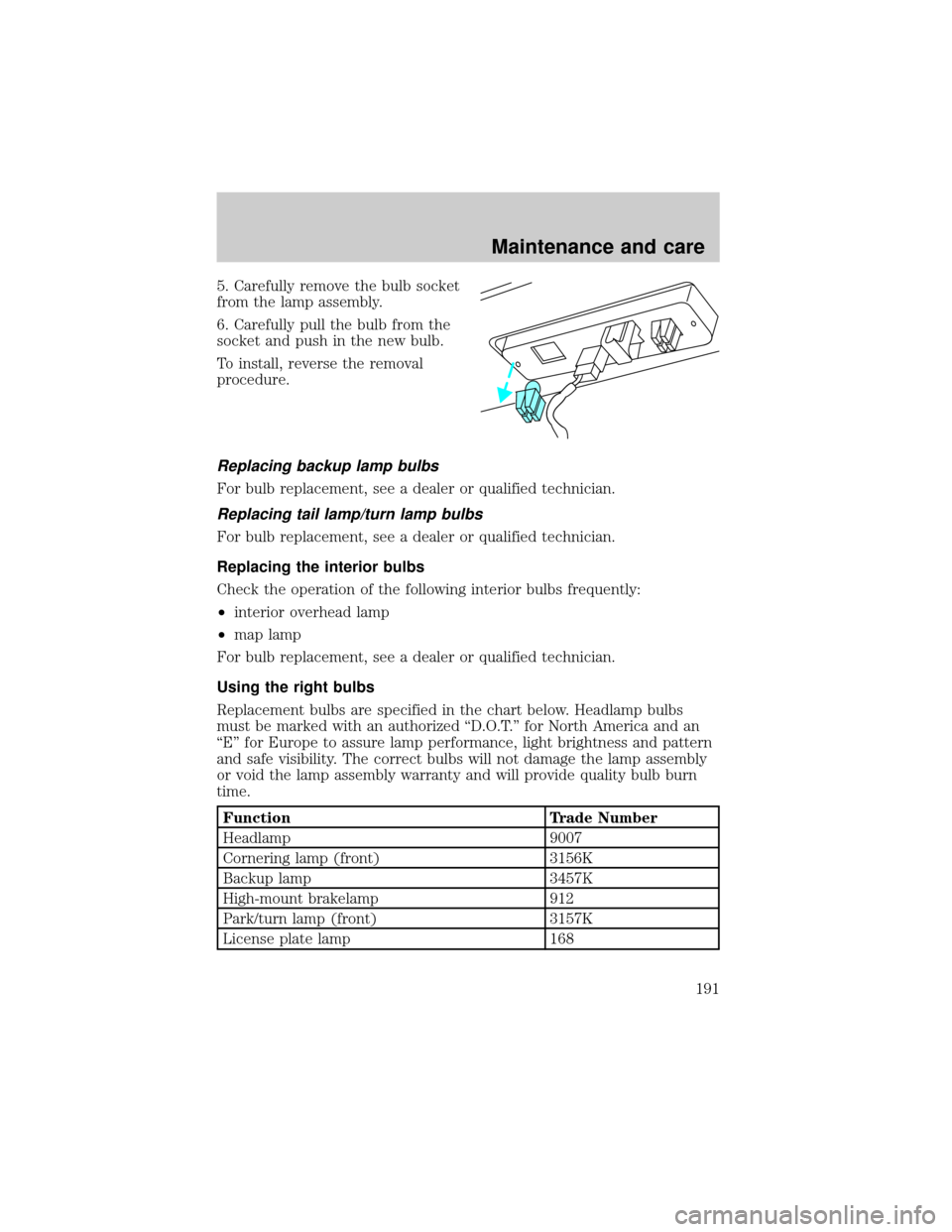

Page 191 of 224

5. Carefully remove the bulb socket

from the lamp assembly.

6. Carefully pull the bulb from the

socket and push in the new bulb.

To install, reverse the removal

procedure.

Replacing backup lamp bulbs

For bulb replacement, see a dealer or qualified technician.

Replacing tail lamp/turn lamp bulbs

For bulb replacement, see a dealer or qualified technician.

Replacing the interior bulbs

Check the operation of the following interior bulbs frequently:

²interior overhead lamp

²map lamp

For bulb replacement, see a dealer or qualified technician.

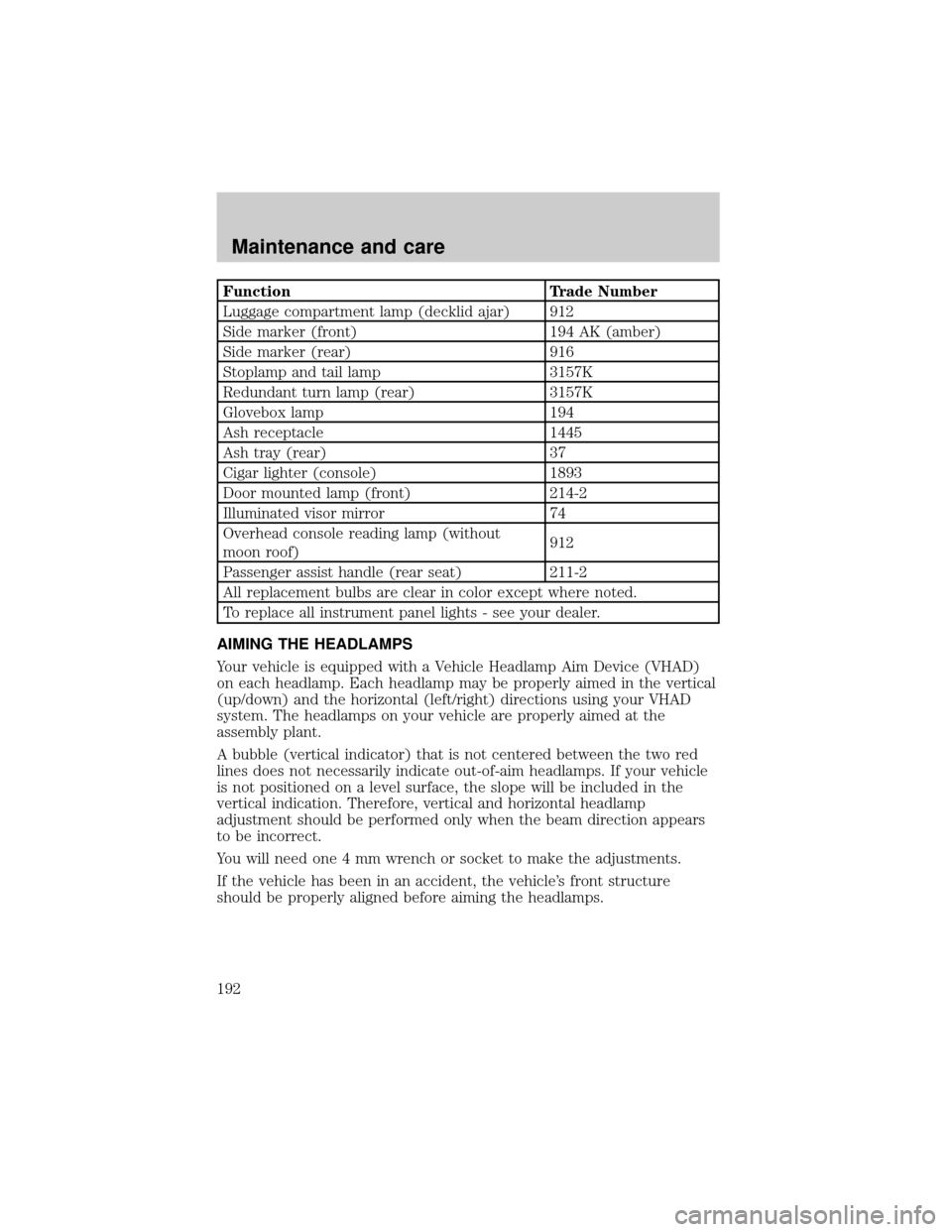

Using the right bulbs

Replacement bulbs are specified in the chart below. Headlamp bulbs

must be marked with an authorized ªD.O.T.º for North America and an

ªEº for Europe to assure lamp performance, light brightness and pattern

and safe visibility. The correct bulbs will not damage the lamp assembly

or void the lamp assembly warranty and will provide quality bulb burn

time.

Function Trade Number

Headlamp 9007

Cornering lamp (front) 3156K

Backup lamp 3457K

High-mount brakelamp 912

Park/turn lamp (front) 3157K

License plate lamp 168

Maintenance and care

191

Page 192 of 224

Function Trade Number

Luggage compartment lamp (decklid ajar) 912

Side marker (front) 194 AK (amber)

Side marker (rear) 916

Stoplamp and tail lamp 3157K

Redundant turn lamp (rear) 3157K

Glovebox lamp 194

Ash receptacle 1445

Ash tray (rear) 37

Cigar lighter (console) 1893

Door mounted lamp (front) 214-2

Illuminated visor mirror 74

Overhead console reading lamp (without

moon roof)912

Passenger assist handle (rear seat) 211-2

All replacement bulbs are clear in color except where noted.

To replace all instrument panel lights - see your dealer.

AIMING THE HEADLAMPS

Your vehicle is equipped with a Vehicle Headlamp Aim Device (VHAD)

on each headlamp. Each headlamp may be properly aimed in the vertical

(up/down) and the horizontal (left/right) directions using your VHAD

system. The headlamps on your vehicle are properly aimed at the

assembly plant.

A bubble (vertical indicator) that is not centered between the two red

lines does not necessarily indicate out-of-aim headlamps. If your vehicle

is not positioned on a level surface, the slope will be included in the

vertical indication. Therefore, vertical and horizontal headlamp

adjustment should be performed only when the beam direction appears

to be incorrect.

You will need one 4 mm wrench or socket to make the adjustments.

If the vehicle has been in an accident, the vehicle's front structure

should be properly aligned before aiming the headlamps.

Maintenance and care

192