lock LINCOLN CONTINENTAL 2019 Owners Manual

[x] Cancel search | Manufacturer: LINCOLN, Model Year: 2019, Model line: CONTINENTAL, Model: LINCOLN CONTINENTAL 2019Pages: 627, PDF Size: 6.39 MB

Page 331 of 627

25 feet (7.6 meters)

C

Horizontal reference line

D

Vertical Aim Adjustment

1. Park the vehicle directly in front of a wall

or screen on a level surface,

approximately 25 ft (7.6 m) away.

2. Measure the height from the center of your headlamp indicated by a 3.0

millimeter circle on the lens to the ground

and mark an

8 ft (2.4 m) horizontal

reference line on the vertical wall or

screen at this height (a piece of masking

tape works well).

Note: To see a clearer light pattern for

adjusting, you may want to block the light

from one headlamp while adjusting the

other.

3. Turn on the low beam headlamps to illuminate the wall or screen and open

the hood. Cover one of the headlamps

so no light hits the wall. 4. There is a distinct cut-off (change from

light to dark) in the left portion of the

beam pattern. Position the top edge of

this cut-off

2 in (5 cm) below the

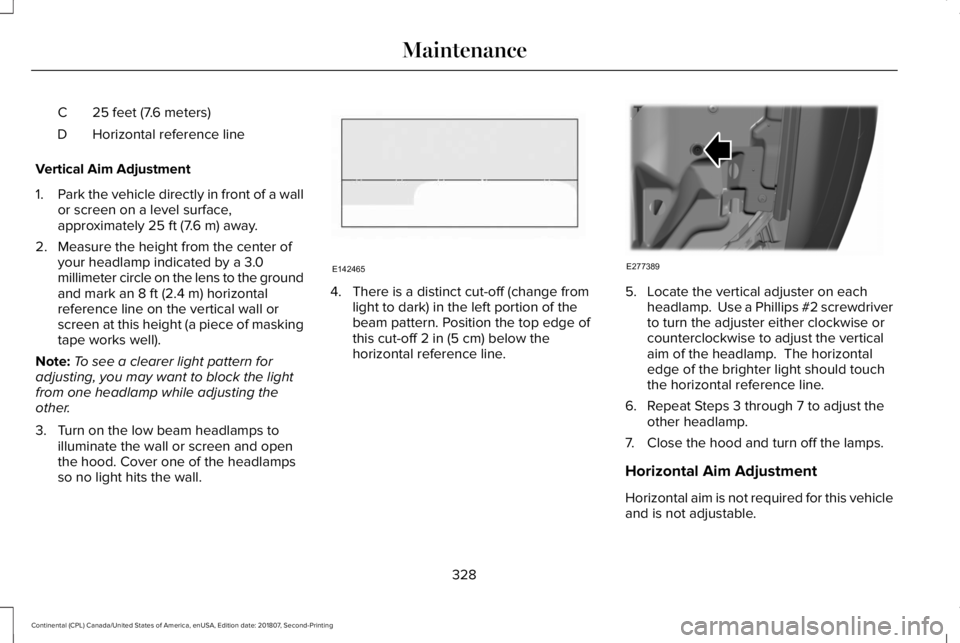

horizontal reference line. 5. Locate the vertical adjuster on each

headlamp. Use a Phillips #2 screwdriver

to turn the adjuster either clockwise or

counterclockwise to adjust the vertical

aim of the headlamp. The horizontal

edge of the brighter light should touch

the horizontal reference line.

6. Repeat Steps 3 through 7 to adjust the other headlamp.

7. Close the hood and turn off the lamps.

Horizontal Aim Adjustment

Horizontal aim is not required for this vehicle

and is not adjustable.

328

Continental (CPL) Canada/United States of America, enUSA, Edition date: 201807, Second-Printing MaintenanceE142465 E277389

Page 332 of 627

CHANGING A BULB

WARNING: Bulbs can become hot.

Let the bulb cool down before removing

it. Failure to do so could result in personal

injury. WARNING:

Switch the lamps and the

ignition off. Failure to follow this warning

could result in serious personal injury.

Use the correct specification bulb. See Bulb

Specification Chart

(page 403).

Install in the reverse order unless otherwise

stated.

High-Intensity Discharge Headlamps

These lamps operate at a high voltage. See

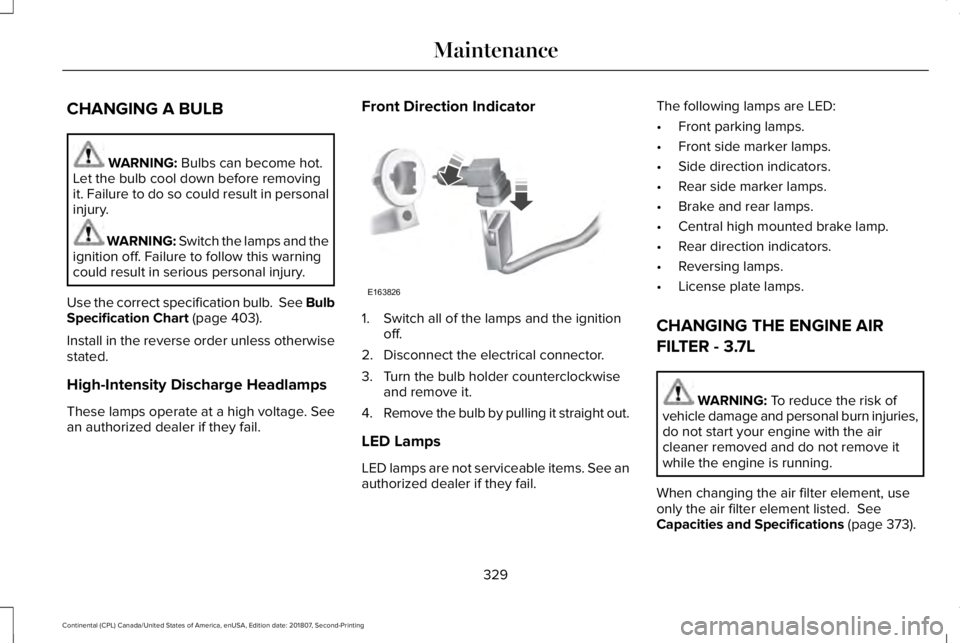

an authorized dealer if they fail. Front Direction Indicator

1. Switch all of the lamps and the ignition

off.

2. Disconnect the electrical connector.

3. Turn the bulb holder counterclockwise and remove it.

4. Remove the bulb by pulling it straight out.

LED Lamps

LED lamps are not serviceable items. See an

authorized dealer if they fail. The following lamps are LED:

•

Front parking lamps.

• Front side marker lamps.

• Side direction indicators.

• Rear side marker lamps.

• Brake and rear lamps.

• Central high mounted brake lamp.

• Rear direction indicators.

• Reversing lamps.

• License plate lamps.

CHANGING THE ENGINE AIR

FILTER - 3.7L WARNING:

To reduce the risk of

vehicle damage and personal burn injuries,

do not start your engine with the air

cleaner removed and do not remove it

while the engine is running.

When changing the air filter element, use

only the air filter element listed.

See

Capacities and Specifications (page 373).

329

Continental (CPL) Canada/United States of America, enUSA, Edition date: 201807, Second-Printing MaintenanceE163826

Page 338 of 627

•

Do not allow wax to come in contact with

any non-body (low-gloss black) colored

trim. The wax will discolor or stain the

parts over time.

•Roof racks.

• Bumpers.

• Grained door handles.

• Side moldings.

• Mirror housings.

• Windshield cowl area.

• Do not apply wax to glass areas.

• After waxing, your car's paint should feel

smooth, and be free of streaks and

smudges.

CLEANING THE ENGINE

Engines are more efficient when they are

clean because grease and dirt buildup keep

the engine warmer than normal. When washing:

•

Take care when using a power washer

to clean the engine. The high-pressure

fluid could penetrate the sealed parts

and cause damage.

• Do not spray a hot engine with cold water

to avoid cracking the engine block or

other engine components.

• Spray Motorcraft Engine Shampoo and

Degreaser on all parts that require

cleaning and pressure rinse clean. In

Canada, use Motorcraft Engine Shampoo.

Note: If your vehicle has an engine cover

remove the cover before application of

Motorcraft Engine Shampoo and Degreaser.

Immediately rinse away any over spray.

• Never wash or rinse the engine while it

is hot or running; water in the running

engine may cause internal damage.

• Never wash or rinse any ignition coil,

spark plug wire or spark plug well, or the

area in and around these locations.

• Cover the battery, power distribution box,

and air filter assembly to prevent water

damage when cleaning the engine. CLEANING THE WINDOWS AND

WIPER BLADES

Car wash chemicals and environmental

fallout can result in windshield and wiper

blade contamination. Dirty windshield and

wipers will result in poor windshield wiper

operation. Keep the windshield and wiper

blades clean to maintain windshield wiper

performance.

To clean the windshield and wiper blades:

•

Clean the windshield with a non-abrasive

glass cleaner. When cleaning the interior

of the windshield, avoid getting any glass

cleaner on the instrument panel or door

panels. Wipe any glass cleaner off these

surfaces immediately.

• For windshields contaminated with tree

sap, chemicals, wax or bugs, clean the

entire windshield using steel wool (no

greater than 0000 grade) in a circular

motion and rinse with water.

• Clean the wiper blades with isopropyl

rubbing alcohol or windshield washer

concentrate.

335

Continental (CPL) Canada/United States of America, enUSA, Edition date: 201807, Second-Printing Vehicle Care

Page 366 of 627

4.

Turn the hazard flashers on then off three

times. You must accomplish this within

10 seconds. If you successfully enter the

reset mode, the horn sounds once, the

system indicator flashes and a message

shows in the information display. If this

does not occur, please try again starting

at step 2. If after repeated attempts to

enter the reset mode, the horn does not

sound, the system indicator does not

flash and no message shows in the

information display, seek service from

your authorized dealer.

5. Train the tire pressure monitoring system

sensors in the tires using the following

system reset sequence starting with the

left front tire in the following clockwise

order: Left front - driver side front tire,

Right front - passenger side front tire,

Right rear - passenger side rear tire, Left

rear - driver side rear tire.

6. Remove the valve cap from the valve stem on the left front tire. Decrease the

air pressure until the horn sounds. Note:

The single horn tone confirms that the

sensor identification code has been learned

by the module for this position. If a double

horn is heard, the reset procedure was

unsuccessful, and you must repeat it.

7. Remove the valve cap from the valve stem on the right front tire. Decrease the

air pressure until the horn sounds.

8. Remove the valve cap from the valve stem on the right rear tire. Decrease the

air pressure until the horn sounds.

9. Remove the valve cap from the valve stem on the left rear tire. Decrease the

air pressure until the horn sounds.

Training is complete after the horn

sounds for the last tire trained, driver side

rear tire, the system indicator stops

flashing, and a message shows in the

information display.

10. Turn the ignition off. If two short horn beeps are heard, the reset procedure

was unsuccessful and you must repeat

it. If after repeating the procedure and

two short beeps are heard when the

ignition is turned to off, seek assistance

from your authorized dealer. 11. Set all four tires to the recommended

air pressure as indicated on the Safety

Compliance Certification Label, affixed

to either the door hinge pillar,

door-latch post, or the door edge that

meets the door-latch post, next to the

driver seating position or Tire Label

located on the B-Pillar or the edge of

the driver door.

CHANGING A ROAD WHEEL WARNING: If the tire pressure

monitor sensor becomes damaged it may

not function.

Note: You should only use tire sealants in

roadside emergencies as they may cause

damage to the tire pressure monitoring

system sensor.

363

Continental (CPL) Canada/United States of America, enUSA, Edition date: 201807, Second-Printing Wheels and Tires

Page 369 of 627

WARNING: To help prevent your

vehicle from moving when changing a

wheel, shift the transmission into park (P),

set the parking brake and use an

appropriate block or wheel chock to

secure the wheel diagonally opposite to

the wheel being changed. For example,

when changing the front left wheel, place

an appropriate block or wheel chock on

the right rear wheel. WARNING:

When one of the front

wheels is off the ground, the transmission

alone will not prevent the vehicle from

moving or slipping off the jack, even if the

transmission is in park (P). WARNING:

Do not get under a

vehicle that is only supported by a vehicle

jack. WARNING:

Always use the jack

provided as original equipment with your

vehicle. If using a jack other than the one

provided, make sure the jack capacity is

adequate for the vehicle weight, including

any vehicle cargo or modifications. If you

are unsure if the jack capacity is adequate,

contact the authorized dealer.

Note: The jack does not require

maintenance or additional lubrication over

the service life of your vehicle.

Note: Passengers should not remain in your

vehicle when the vehicle is being jacked.

1. Park on a level firm surface, shift the transmission into park (P), set the parking

brake and switch the ignition off. Activate

the hazard flashers and set up the

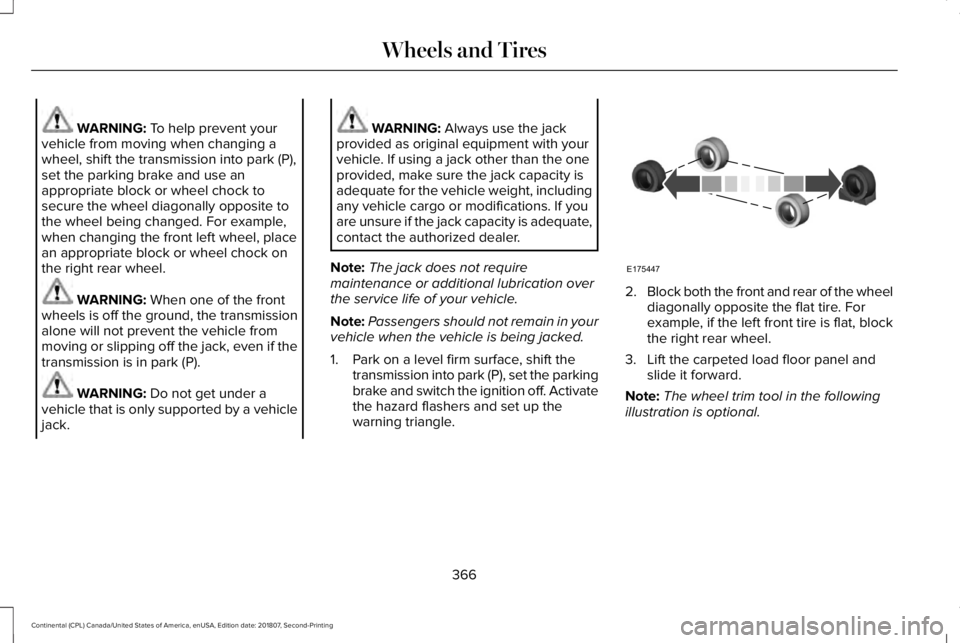

warning triangle. 2.

Block both the front and rear of the wheel

diagonally opposite the flat tire. For

example, if the left front tire is flat, block

the right rear wheel.

3. Lift the carpeted load floor panel and slide it forward.

Note: The wheel trim tool in the following

illustration is optional.

366

Continental (CPL) Canada/United States of America, enUSA, Edition date: 201807, Second-Printing Wheels and TiresE175447

Page 370 of 627

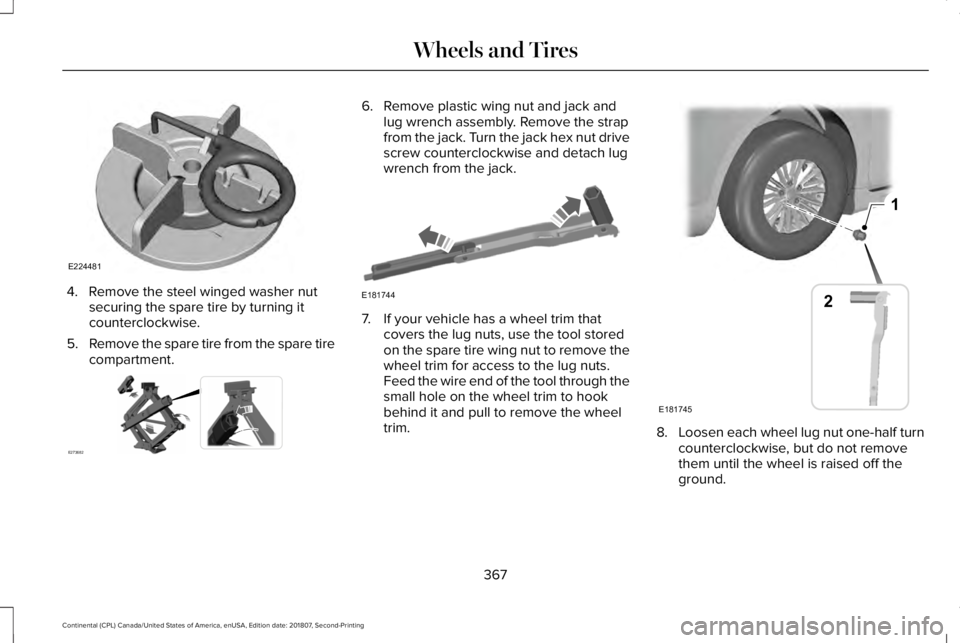

4. Remove the steel winged washer nut

securing the spare tire by turning it

counterclockwise.

5. Remove the spare tire from the spare tire

compartment. 6. Remove plastic wing nut and jack and

lug wrench assembly. Remove the strap

from the jack. Turn the jack hex nut drive

screw counterclockwise and detach lug

wrench from the jack. 7. If your vehicle has a wheel trim that

covers the lug nuts, use the tool stored

on the spare tire wing nut to remove the

wheel trim for access to the lug nuts.

Feed the wire end of the tool through the

small hole on the wheel trim to hook

behind it and pull to remove the wheel

trim. 8.

Loosen each wheel lug nut one-half turn

counterclockwise, but do not remove

them until the wheel is raised off the

ground.

367

Continental (CPL) Canada/United States of America, enUSA, Edition date: 201807, Second-Printing Wheels and TiresE224481 E273682 E181744 1

E181745

2

Page 371 of 627

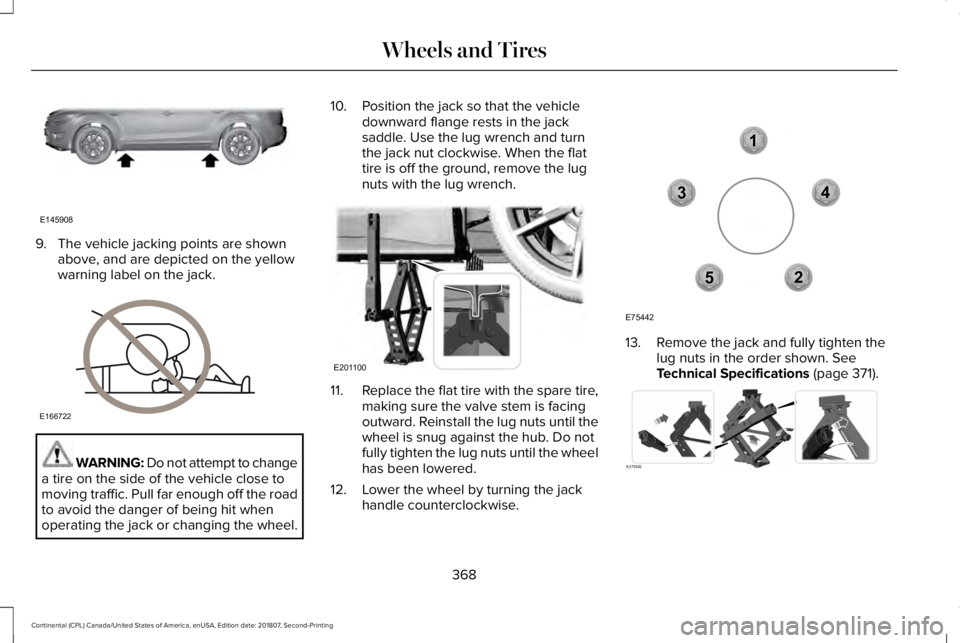

9. The vehicle jacking points are shown

above, and are depicted on the yellow

warning label on the jack. WARNING: Do not attempt to change

a tire on the side of the vehicle close to

moving traffic. Pull far enough off the road

to avoid the danger of being hit when

operating the jack or changing the wheel. 10. Position the jack so that the vehicle

downward flange rests in the jack

saddle. Use the lug wrench and turn

the jack nut clockwise. When the flat

tire is off the ground, remove the lug

nuts with the lug wrench. 11.

Replace the flat tire with the spare tire,

making sure the valve stem is facing

outward. Reinstall the lug nuts until the

wheel is snug against the hub. Do not

fully tighten the lug nuts until the wheel

has been lowered.

12. Lower the wheel by turning the jack handle counterclockwise. 13. Remove the jack and fully tighten the

lug nuts in the order shown. See

Technical Specifications (page 371). 368

Continental (CPL) Canada/United States of America, enUSA, Edition date: 201807, Second-Printing Wheels and TiresE145908 E166722 E201100 12

3

4

5

E75442 E273683

Page 372 of 627

14.

Fold up the wrench and re-attach to the

jack. Re-position the jack and wrench

assembly into the original vehicle

position and secure with the plastic

wing nut. Securely fasten the jack

before you drive.

15. Unblock the wheel and pick up the warning triangle.

Stowing the flat tire

You cannot store the full-sized road wheel

in the temporary spare tire well.

1. Find the flat tire retainer strap tucked inside the jack channel. Slide the

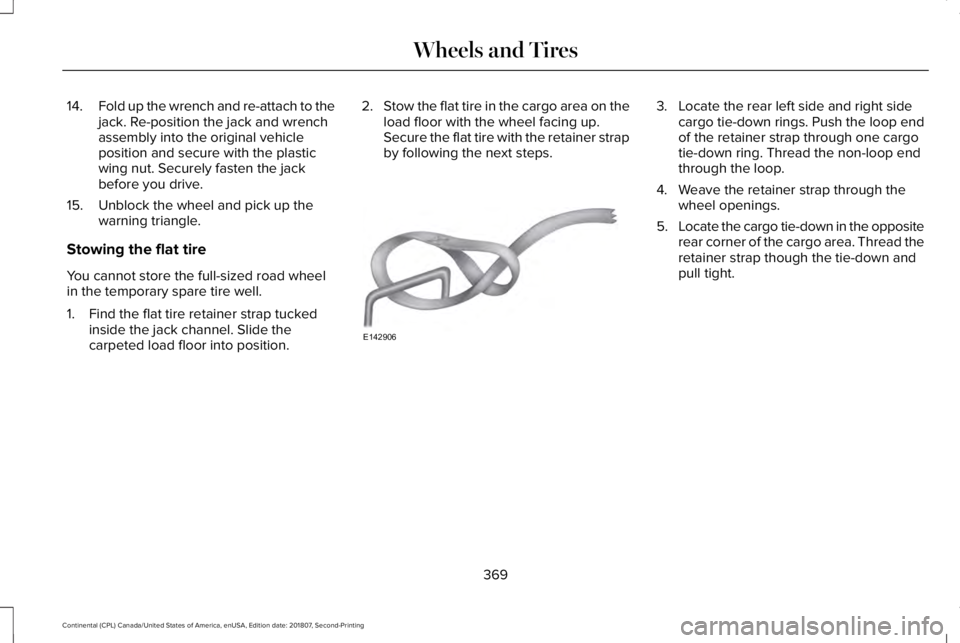

carpeted load floor into position. 2.

Stow the flat tire in the cargo area on the

load floor with the wheel facing up.

Secure the flat tire with the retainer strap

by following the next steps. 3. Locate the rear left side and right side

cargo tie-down rings. Push the loop end

of the retainer strap through one cargo

tie-down ring. Thread the non-loop end

through the loop.

4. Weave the retainer strap through the wheel openings.

5. Locate the cargo tie-down in the opposite

rear corner of the cargo area. Thread the

retainer strap though the tie-down and

pull tight.

369

Continental (CPL) Canada/United States of America, enUSA, Edition date: 201807, Second-Printing Wheels and TiresE142906

Page 389 of 627

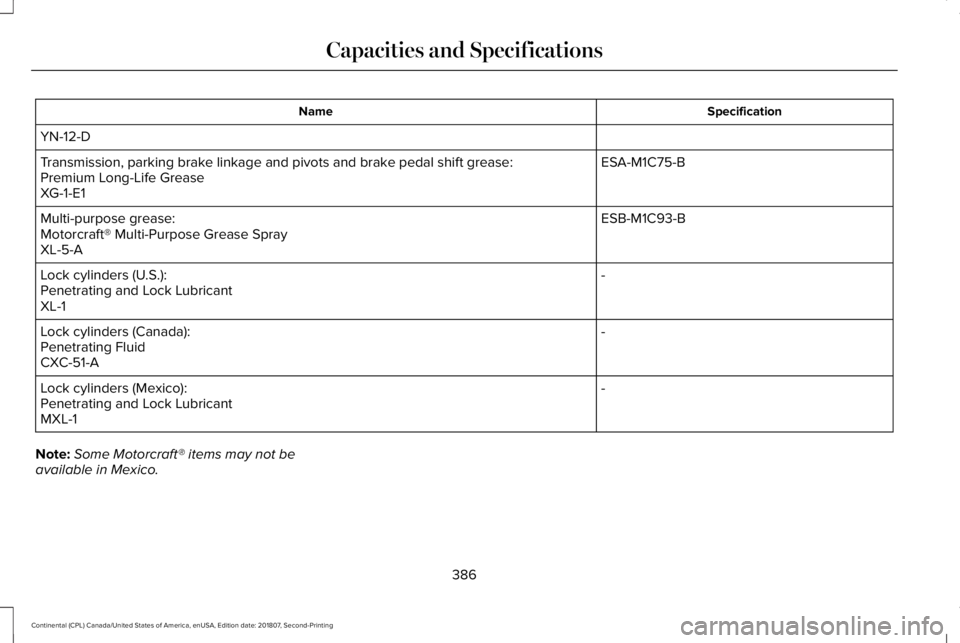

Specification

Name

YN-12-D ESA-M1C75-B

Transmission, parking brake linkage and pivots and brake pedal shift grease:

Premium Long-Life Grease

XG-1-E1

ESB-M1C93-B

Multi-purpose grease:

Motorcraft® Multi-Purpose Grease Spray

XL-5-A

-

Lock cylinders (U.S.):

Penetrating and Lock Lubricant

XL-1

-

Lock cylinders (Canada):

Penetrating Fluid

CXC-51-A

-

Lock cylinders (Mexico):

Penetrating and Lock Lubricant

MXL-1

Note: Some Motorcraft® items may not be

available in Mexico.

386

Continental (CPL) Canada/United States of America, enUSA, Edition date: 201807, Second-Printing Capacities and Specifications

Page 396 of 627

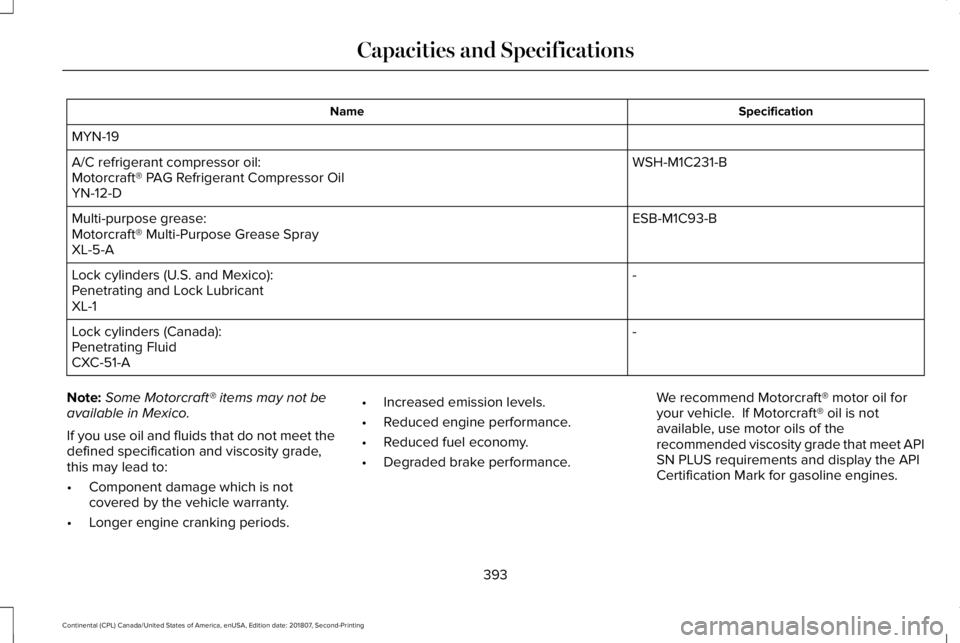

Specification

Name

MYN-19 WSH-M1C231-B

A/C refrigerant compressor oil:

Motorcraft® PAG Refrigerant Compressor Oil

YN-12-D

ESB-M1C93-B

Multi-purpose grease:

Motorcraft® Multi-Purpose Grease Spray

XL-5-A

-

Lock cylinders (U.S. and Mexico):

Penetrating and Lock Lubricant

XL-1

-

Lock cylinders (Canada):

Penetrating Fluid

CXC-51-A

Note: Some Motorcraft® items may not be

available in Mexico.

If you use oil and fluids that do not meet the

defined specification and viscosity grade,

this may lead to:

• Component damage which is not

covered by the vehicle warranty.

• Longer engine cranking periods. •

Increased emission levels.

• Reduced engine performance.

• Reduced fuel economy.

• Degraded brake performance. We recommend Motorcraft® motor oil for

your vehicle. If Motorcraft® oil is not

available, use motor oils of the

recommended viscosity grade that meet API

SN PLUS requirements and display the API

Certification Mark for gasoline engines.

393

Continental (CPL) Canada/United States of America, enUSA, Edition date: 201807, Second-Printing Capacities and Specifications