stop start LINCOLN LS 2002 Owners Manual

[x] Cancel search | Manufacturer: LINCOLN, Model Year: 2002, Model line: LS, Model: LINCOLN LS 2002Pages: 288, PDF Size: 2.44 MB

Page 161 of 288

may be worn-out and should be inspected by a qualified service

technician.

Anti-lock brake system (ABS)

On vehicles equipped with an anti-lock braking system (ABS), a noise

from the hydraulic pump motor and pulsation in the pedal may be

observed during ABS braking events. Pedal pulsation coupled with noise

while braking under panic conditions or on loose gravel, bumps, wet or

snowy roads is normal and indicates proper functioning of the vehicle's

anti-lock brake system. The ABS performs a self-check after you start

the engine and begin to drive away. A brief mechanical noise may be

heard during this test. This is normal. If a malfunction is found, the ABS

warning light will come on. If the vehicle has continuous vibration or

shudder in the steering wheel while braking, the vehicle should be

inspected by a qualified service technician.

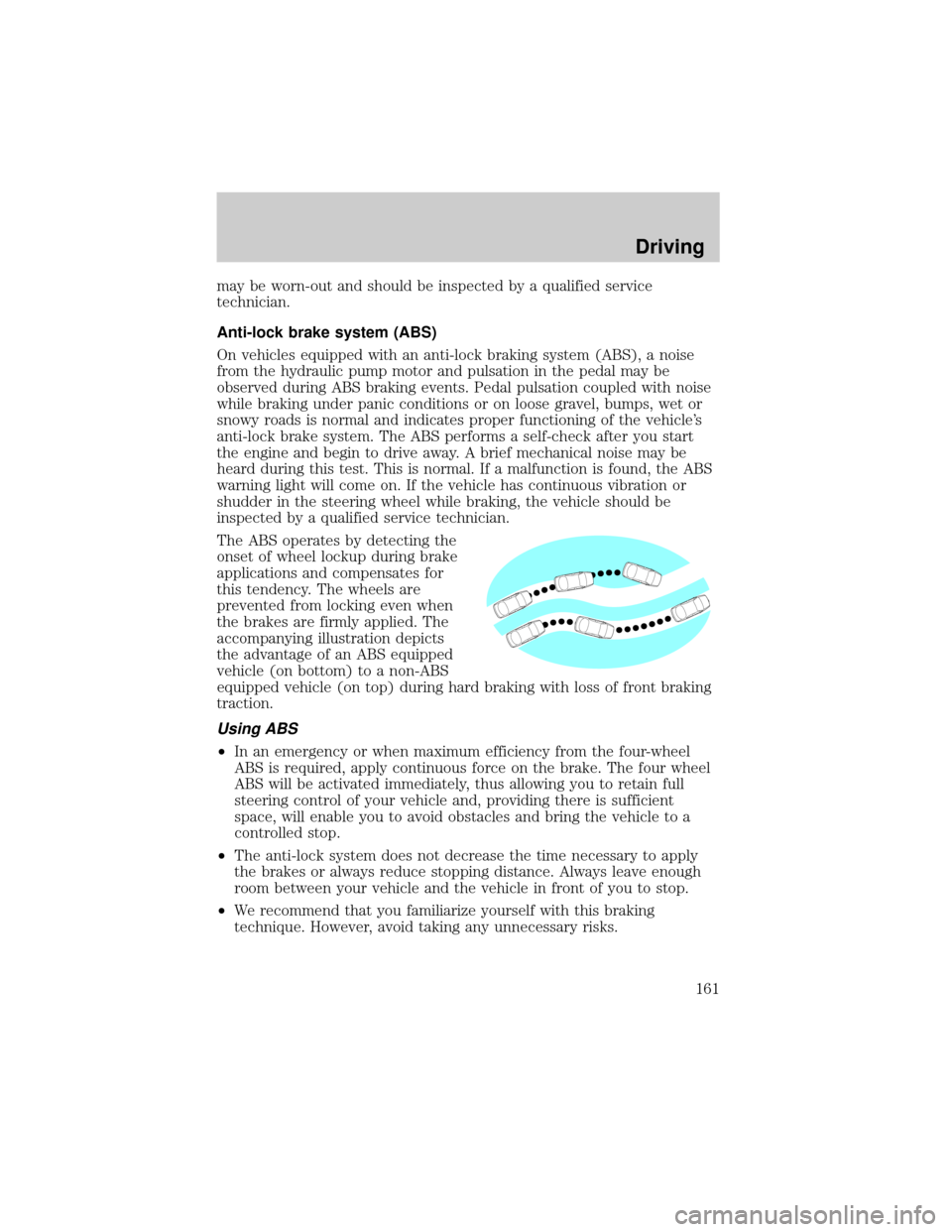

The ABS operates by detecting the

onset of wheel lockup during brake

applications and compensates for

this tendency. The wheels are

prevented from locking even when

the brakes are firmly applied. The

accompanying illustration depicts

the advantage of an ABS equipped

vehicle (on bottom) to a non-ABS

equipped vehicle (on top) during hard braking with loss of front braking

traction.

Using ABS

²In an emergency or when maximum efficiency from the four-wheel

ABS is required, apply continuous force on the brake. The four wheel

ABS will be activated immediately, thus allowing you to retain full

steering control of your vehicle and, providing there is sufficient

space, will enable you to avoid obstacles and bring the vehicle to a

controlled stop.

²The anti-lock system does not decrease the time necessary to apply

the brakes or always reduce stopping distance. Always leave enough

room between your vehicle and the vehicle in front of you to stop.

²We recommend that you familiarize yourself with this braking

technique. However, avoid taking any unnecessary risks.

Driving

161

Page 162 of 288

ABS warning lampABS

TheABSwarning lamp in the instrument cluster momentarily illuminates

when the ignition is turned to the RUN position. If the light does not

illuminate momentarily at start up, remains on or continues to flash, the

ABS needs to be serviced.

With the ABS light on, the anti-lock

brake system is disabled and normal

braking is still effective unless the

brake warning light also remains

illuminated with parking brake

released. (If your brake warning lamp illuminates, have your vehicle

serviced immediately.)

Parking brake

Apply the parking brake whenever

the vehicle is parked. To set the

parking brake, apply the brake pedal

and pull the handle up as far as

possible.

The BRAKE warning lamp in the

instrument cluster illuminates and

remains illuminated (when the

ignition is turned to to the RUN

position) until the parking brake is

released.

The parking brake is not recommended to stop a moving vehicle.

However, if the normal brakes fail, the parking brake can be used to stop

your vehicle in an emergency. Since the parking brake applies only the

rear brakes, the vehicle's stopping distance will increase greatly and the

handling of your vehicle will be adversely affected.

Always set the parking brake fully and make sure that the

gearshift is securely latched in P (Park) (automatic

transmission) or in 1 (First) (manual transmission).

P!

BRAKE

P!

BRAKE

Driving

162

Page 170 of 288

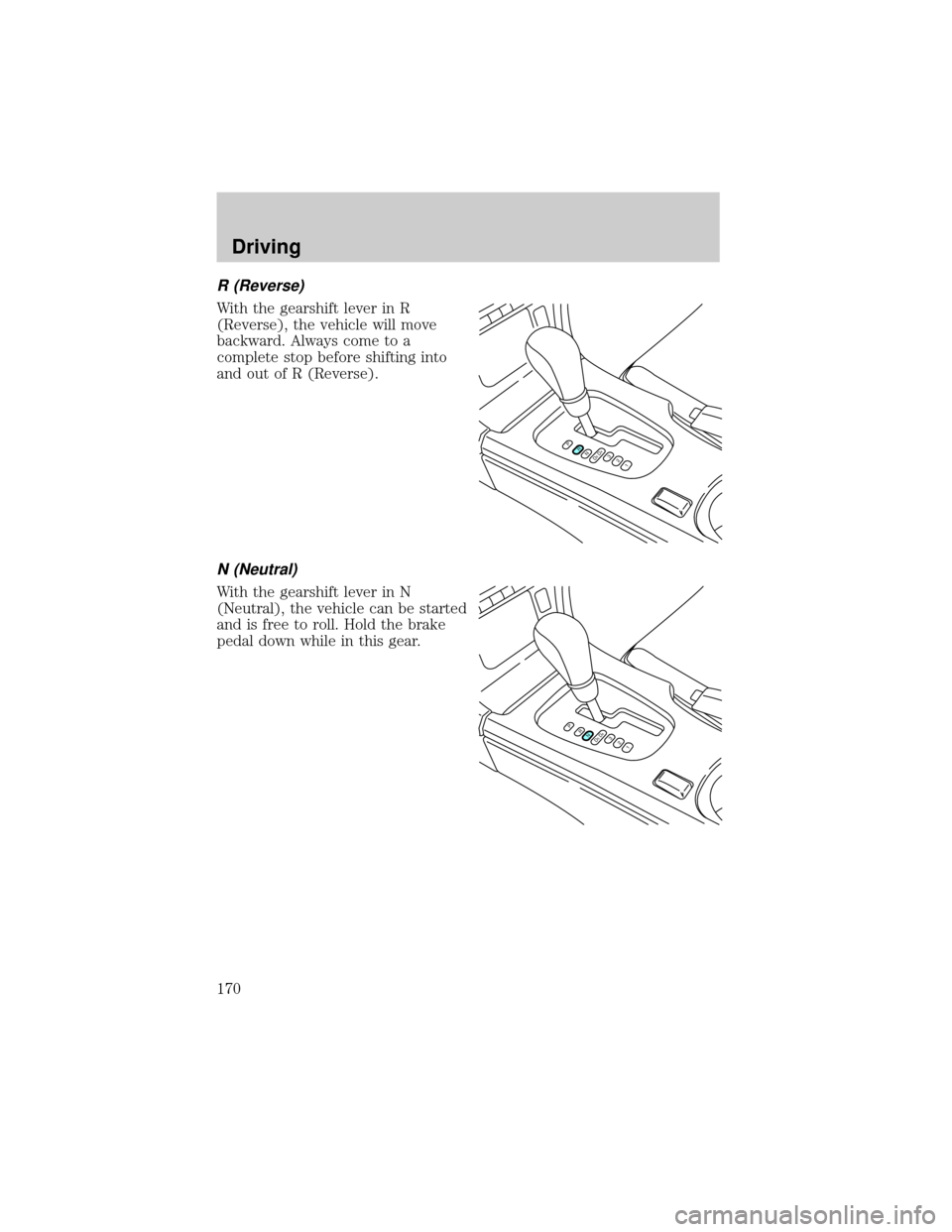

R (Reverse)

With the gearshift lever in R

(Reverse), the vehicle will move

backward. Always come to a

complete stop before shifting into

and out of R (Reverse).

N (Neutral)

With the gearshift lever in N

(Neutral), the vehicle can be started

and is free to roll. Hold the brake

pedal down while in this gear.

PRND5D4321

PRND5D4321

Driving

170

Page 175 of 288

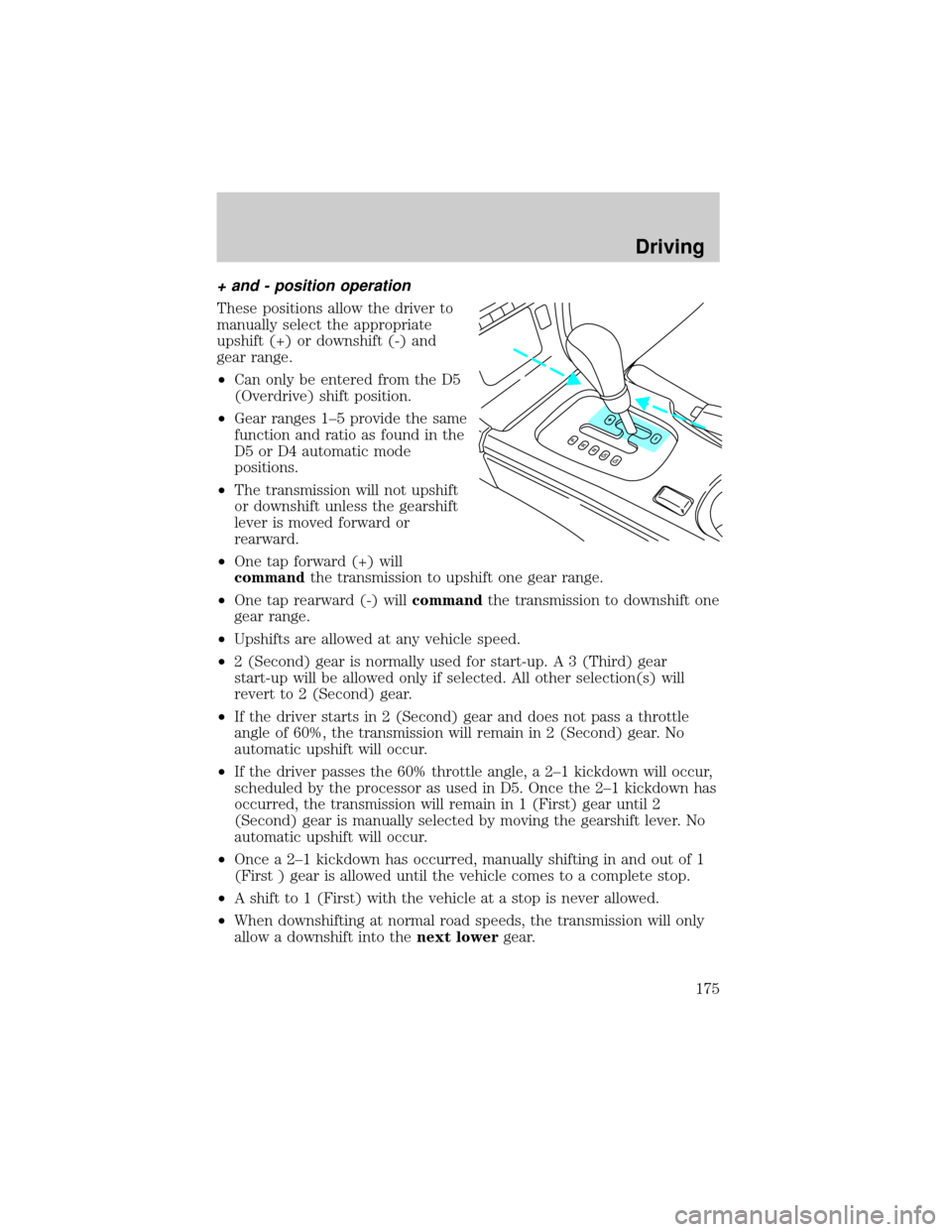

+ and - position operation

These positions allow the driver to

manually select the appropriate

upshift (+) or downshift (-) and

gear range.

²Can only be entered from the D5

(Overdrive) shift position.

²Gear ranges 1±5 provide the same

function and ratio as found in the

D5 or D4 automatic mode

positions.

²The transmission will not upshift

or downshift unless the gearshift

lever is moved forward or

rearward.

²One tap forward (+) will

commandthe transmission to upshift one gear range.

²One tap rearward (-) willcommandthe transmission to downshift one

gear range.

²Upshifts are allowed at any vehicle speed.

²2 (Second) gear is normally used for start-up. A 3 (Third) gear

start-up will be allowed only if selected. All other selection(s) will

revert to 2 (Second) gear.

²If the driver starts in 2 (Second) gear and does not pass a throttle

angle of 60%, the transmission will remain in 2 (Second) gear. No

automatic upshift will occur.

²If the driver passes the 60% throttle angle, a 2±1 kickdown will occur,

scheduled by the processor as used in D5. Once the 2±1 kickdown has

occurred, the transmission will remain in 1 (First) gear until 2

(Second) gear is manually selected by moving the gearshift lever. No

automatic upshift will occur.

²Once a 2±1 kickdown has occurred, manually shifting in and out of 1

(First ) gear is allowed until the vehicle comes to a complete stop.

²A shift to 1 (First) with the vehicle at a stop is never allowed.

²When downshifting at normal road speeds, the transmission will only

allow a downshift into thenext lowergear.

Driving

175

Page 185 of 288

Trailer lamps

Trailer lamps are required on most towed vehicles. Ensure that your

trailer lamps conform to local and Federal Regulations.

Do not splice or modify the vehicle electrical wiring or lamps for

trailer towing.

Your vehicle uses an advanced electronic module with ground side

switching to control and monitor your vehicle lamps. Splicing into the

wiring or attaching wiring to the vehicle bulbs will DISABLE the rear

vehicle lamps from functioning. Your lamp outage feature will also be

disabled or provide incorrect information.

Your vehicle is ready to install a Trailer Tow module that will provide the

proper communication with the vehicle electrical system so your trailer

lamps will function properly. See your dealer or trailer rental agency for

proper instructions and equipment for hooking up trailer lamps.

Driving while you tow

When towing a trailer:

²Ensure that you turn off your speed control. The speed control may

shut off automatically when you are towing on long, steep grades.

²Consult your local motor vehicle speed regulations for towing a trailer.

²Shift out of D5 (Overdrive) and into D4 (Drive) or a lower gear when

towing up or down steep hills. This will eliminate excessive

downshifting and upshifting for optimum fuel economy and

transmission cooling.

²Anticipate stops and brake gradually.

Servicing after towing

If you tow a trailer for long distances, your vehicle will require more

frequent service intervals. Refer to your scheduled maintenance guide for

more information.

Trailer towing tips

²Practice turning, stopping and backing up before starting on a trip to

get the feel of the vehicle trailer combination. When turning, make

wider turns so the trailer wheels will clear curbs and other obstacles.

²Allow more distance for stopping with a trailer attached.

Driving

185

Page 189 of 288

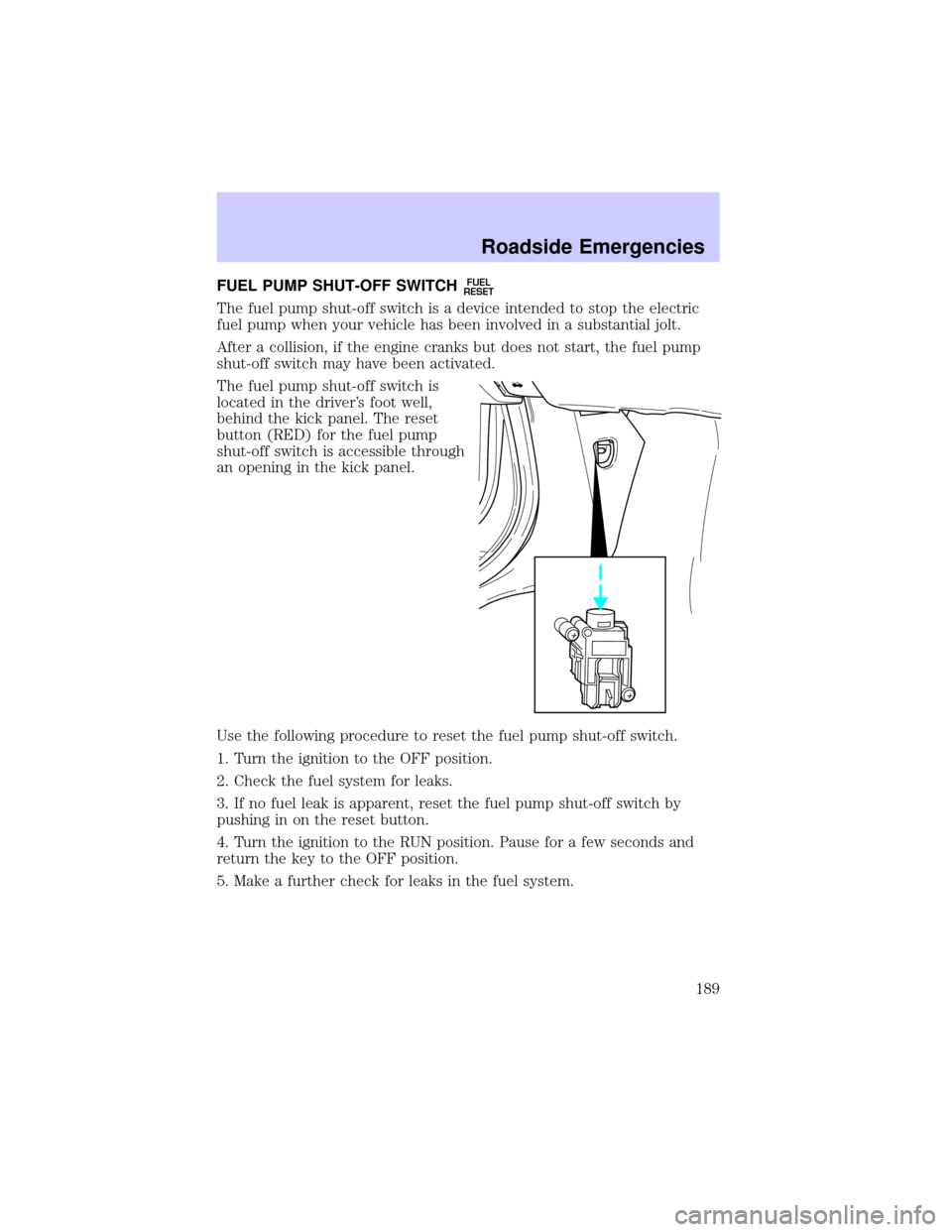

FUEL PUMP SHUT-OFF SWITCHFUEL

RESET

The fuel pump shut-off switch is a device intended to stop the electric

fuel pump when your vehicle has been involved in a substantial jolt.

After a collision, if the engine cranks but does not start, the fuel pump

shut-off switch may have been activated.

The fuel pump shut-off switch is

located in the driver's foot well,

behind the kick panel. The reset

button (RED) for the fuel pump

shut-off switch is accessible through

an opening in the kick panel.

Use the following procedure to reset the fuel pump shut-off switch.

1. Turn the ignition to the OFF position.

2. Check the fuel system for leaks.

3. If no fuel leak is apparent, reset the fuel pump shut-off switch by

pushing in on the reset button.

4. Turn the ignition to the RUN position. Pause for a few seconds and

return the key to the OFF position.

5. Make a further check for leaks in the fuel system.

Roadside Emergencies

189

Page 236 of 288

Batteries normally produce explosive gases which can cause

personal injury. Therefore, do not allow flames, sparks or lighted

substances to come near the battery. When working near the battery,

always shield your face and protect your eyes. Always provide proper

ventilation.

When lifting a plastic-cased battery, excessive pressure on the

end walls could cause acid to flow through the vent caps,

resulting in personal injury and/or damage to the vehicle or battery.

Lift the battery with a battery carrier or with your hands on opposite

corners.

Keep batteries out of reach of children. Batteries contain sulfuric

acid. Avoid contact with skin, eyes or clothing. Shield your eyes

when working near the battery to protect against possible splashing of

acid solution. In case of acid contact with skin or eyes, flush

immediately with water for a minimum of 15 minutes and get prompt

medical attention. If acid is swallowed, call a physician immediately.

Battery posts, terminals and related accessories contain lead and

lead compounds.Wash hands after handling.

Because your vehicle's engine is electronically controlled by a computer,

some control conditions are maintained by power from the battery. When

the battery is disconnected or a new battery is installed, the engine must

relearn its idle and fuel trim strategy for optimum driveability and

performance. To begin this process:

1. With the vehicle at a complete stop, set the parking brake.

2. Put the gearshift in P (Park), turn off all accessories and start the

engine.

3. Run the engine until it reaches normal operating temperature.

4. Allow the engine to idle for at least one minute.

5. Turn the A/C on and allow the engine to idle for at least one minute.

6. Drive the vehicle to complete the relearning process.

²The vehicle may need to be driven to relearn the idle and fuel trim

strategy.

Maintenance and Specifications

236

Page 247 of 288

The flow of fuel through a fuel pump nozzle can produce static

electricity, which can cause a fire if fuel is pumped into an

ungrounded fuel container.

Use the following guidelines to avoid static build-up when filling an

ungrounded fuel container:

²Place approved fuel container on the ground.

²DO NOT fill a fuel container while it is in the vehicle (including the

cargo area).

²Keep the fuel pump nozzle in contact with the fuel container while

filling.

²DO NOT use a device that would hold the fuel pump handle in the fill

position.

Fuel Filler Cap

Your fuel tank filler cap has an indexed design with a 1/8 turn on/off

feature.

When fueling your vehicle:

1. Turn the engine off.

2. Carefully turn the filler cap counterclockwise 1/8 of a turn until it

stops.

3. Pull to remove the cap from the fuel filler pipe.

4. To install the cap, align the tabs on the cap with the notches on the

filler pipe.

5. Turn the filler cap clockwise 1/8 of a turn until it stops.

If the ªCheck Fuel Capº indicator comes on and stays on after you start

the engine, the fuel filler cap may not be properly installed. Turn off the

engine, remove the fuel filler cap, align the cap properly and reinstall it.

If you must replace the fuel filler cap, replace it with a fuel filler

cap that is designed for your vehicle. The customer warranty may

be void for any damage to the fuel tank or fuel system if the

correct genuine Ford or Motorcraft fuel filler cap is not used.

Maintenance and Specifications

247

Page 266 of 288

engine. This decal identifies engine displacement and gives some tune up

specifications.

Please consult yourWarranty Guidefor complete emission warranty

information.

Readiness for Inspection/Maintenance (I/M) testing

In some localities, it may be a legal requirement to pass an I/M test of

the on-board diagnostics system. If your ªCheck Engine/Service Engine

Soonº light is on, refer to the description in theWarning lights and

chimessection of theInstrument Clusterchapter. Your vehicle may not

pass the I/M test with the ªCheck Engine/Service Engine Soonº light on.

If the vehicle's powertrain system or its battery has just been serviced,

the on-board diagnostics system is reset to a ªnot ready for I/M testº

condition. To ready the on-board diagnostics system for I/M testing, a

minimum of 30 minutes of city and highway driving is necessary as

described below:

²First, at least 10 minutes of driving on an expressway or highway.

²Next, at least 20 minutes driving in stop-and-go, city-type traffic with

at least four idle periods.

Allow the vehicle to sit for at least eight hours without starting the

engine. Then, start the engine and complete the above driving cycle. The

engine must warm up to its normal operating temperature. Once started,

do not turn off the engine until the above driving cycle is complete.

ESSENTIALS OF GOOD FUEL ECONOMY

Measuring techniques

Your best source of information about actual fuel economy is you, the

driver. You must gather information as accurately and consistently as

possible. Fuel expense, frequency of fillups or fuel gauge readings are

NOT accurate as a measure of fuel economy. We do not recommend

taking fuel economy measurements during the first 1 600 km (1 000

miles) of driving (engine break-in period). You will get a more accurate

measurement after 3 000 km±5 000 km (2 000 miles-3 000 miles).

Filling the tank

The advertised fuel capacity of the fuel tank on your vehicle is equal to

the rated refill capacity of the fuel tank as listed in theRefill capacities

section of this chapter.

Maintenance and Specifications

266