clock LINCOLN LS 2003 User Guide

[x] Cancel search | Manufacturer: LINCOLN, Model Year: 2003, Model line: LS, Model: LINCOLN LS 2003Pages: 288, PDF Size: 3.19 MB

Page 85 of 288

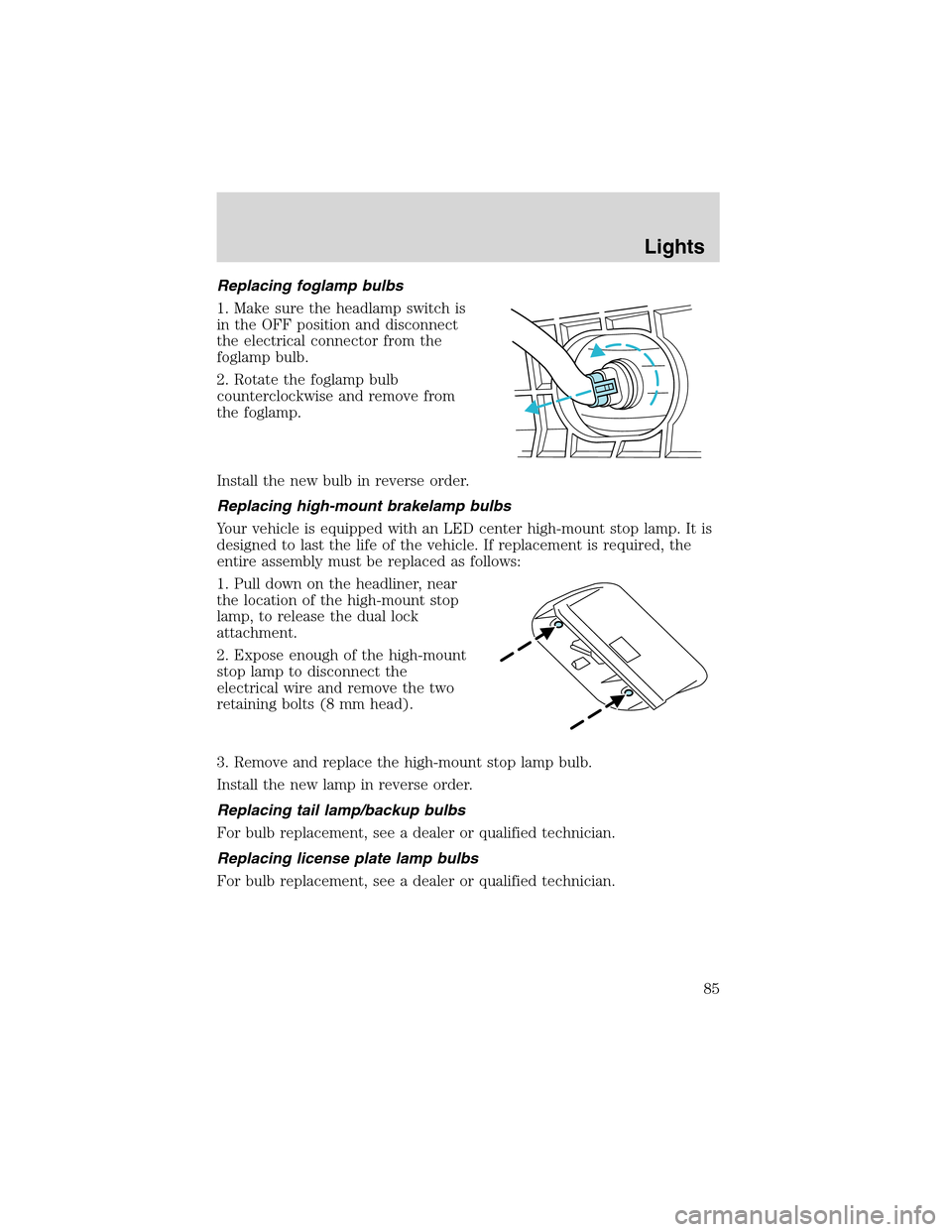

Replacing foglamp bulbs

1. Make sure the headlamp switch is

in the OFF position and disconnect

the electrical connector from the

foglamp bulb.

2. Rotate the foglamp bulb

counterclockwise and remove from

the foglamp.

Install the new bulb in reverse order.

Replacing high-mount brakelamp bulbs

Your vehicle is equipped with an LED center high-mount stop lamp. It is

designed to last the life of the vehicle. If replacement is required, the

entire assembly must be replaced as follows:

1. Pull down on the headliner, near

the location of the high-mount stop

lamp, to release the dual lock

attachment.

2. Expose enough of the high-mount

stop lamp to disconnect the

electrical wire and remove the two

retaining bolts (8 mm head).

3. Remove and replace the high-mount stop lamp bulb.

Install the new lamp in reverse order.

Replacing tail lamp/backup bulbs

For bulb replacement, see a dealer or qualified technician.

Replacing license plate lamp bulbs

For bulb replacement, see a dealer or qualified technician.

Lights

85

Page 214 of 288

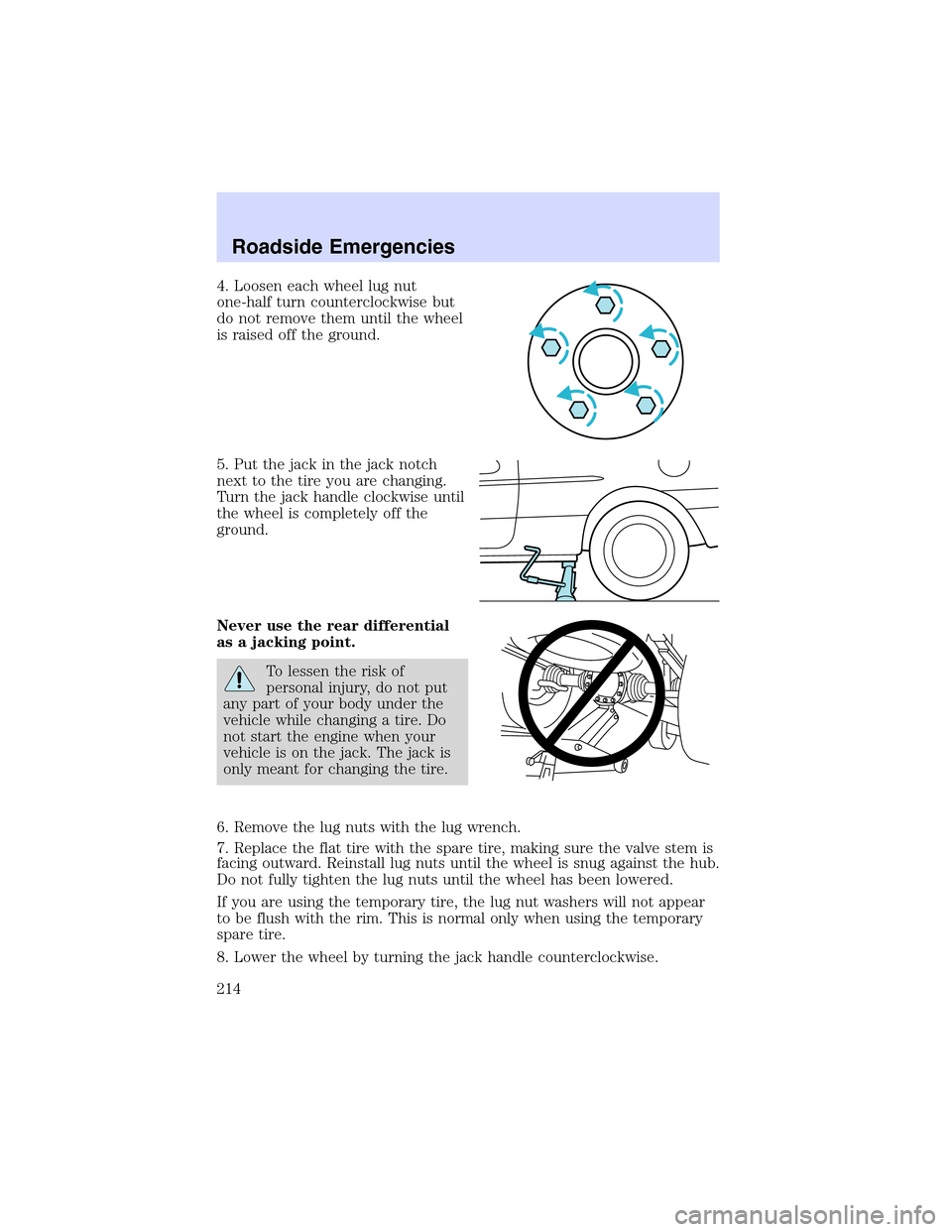

4. Loosen each wheel lug nut

one-half turn counterclockwise but

do not remove them until the wheel

is raised off the ground.

5. Put the jack in the jack notch

next to the tire you are changing.

Turn the jack handle clockwise until

the wheel is completely off the

ground.

Never use the rear differential

as a jacking point.

To lessen the risk of

personal injury, do not put

any part of your body under the

vehicle while changing a tire. Do

not start the engine when your

vehicle is on the jack. The jack is

only meant for changing the tire.

6. Remove the lug nuts with the lug wrench.

7. Replace the flat tire with the spare tire, making sure the valve stem is

facing outward. Reinstall lug nuts until the wheel is snug against the hub.

Do not fully tighten the lug nuts until the wheel has been lowered.

If you are using the temporary tire, the lug nut washers will not appear

to be flush with the rim. This is normal only when using the temporary

spare tire.

8. Lower the wheel by turning the jack handle counterclockwise.

Roadside Emergencies

214

Page 215 of 288

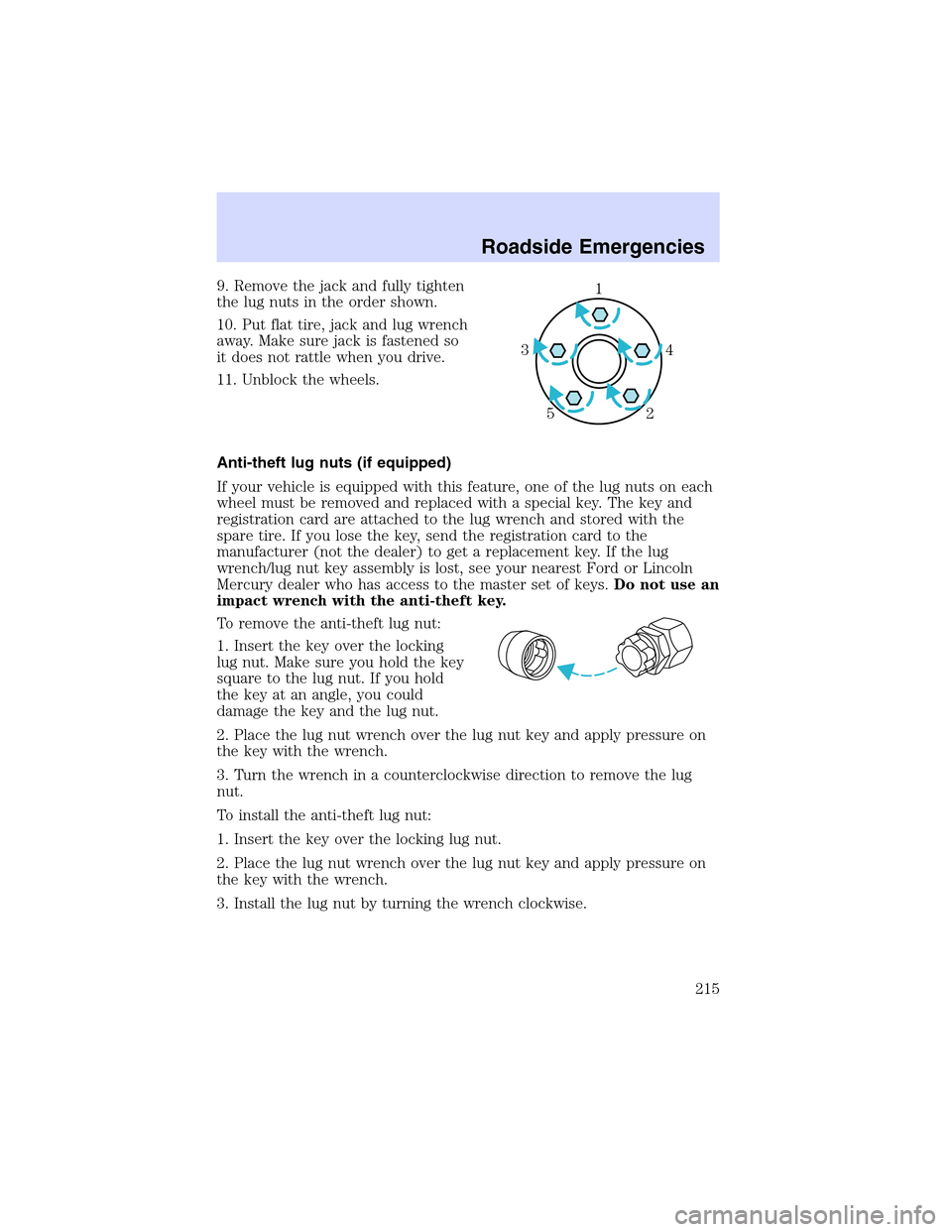

9. Remove the jack and fully tighten

the lug nuts in the order shown.

10. Put flat tire, jack and lug wrench

away. Make sure jack is fastened so

it does not rattle when you drive.

11. Unblock the wheels.

Anti-theft lug nuts (if equipped)

If your vehicle is equipped with this feature, one of the lug nuts on each

wheel must be removed and replaced with a special key. The key and

registration card are attached to the lug wrench and stored with the

spare tire. If you lose the key, send the registration card to the

manufacturer (not the dealer) to get a replacement key. If the lug

wrench/lug nut key assembly is lost, see your nearest Ford or Lincoln

Mercury dealer who has access to the master set of keys.Do not use an

impact wrench with the anti-theft key.

To remove the anti-theft lug nut:

1. Insert the key over the locking

lug nut. Make sure you hold the key

square to the lug nut. If you hold

the key at an angle, you could

damage the key and the lug nut.

2. Place the lug nut wrench over the lug nut key and apply pressure on

the key with the wrench.

3. Turn the wrench in a counterclockwise direction to remove the lug

nut.

To install the anti-theft lug nut:

1. Insert the key over the locking lug nut.

2. Place the lug nut wrench over the lug nut key and apply pressure on

the key with the wrench.

3. Install the lug nut by turning the wrench clockwise.1

4 3

2 5

Roadside Emergencies

215

Page 245 of 288

3. Recheck the engine oil level. Make sure the oil level is not above the

MAX mark on the engine oil level indicator (dipstick).

4. Install the indicator and ensure it is fully seated.

5. Fully install the engine oil filler cap by turning the filler cap clockwise

tightly until clicks are heard, or until it is snug.

To avoid possible oil loss, DO NOT operate the vehicle with the

engine oil level indicator and/or the engine oil filler cap removed.

Engine oil and filter recommendations

Look for this certification

trademark.

SAE 5W-20 engine oil is recommended.

Only use oils“Certified For Gasoline Engines”by the American

Petroleum Institute (API). Use Motorcraft or an equivalent oil meeting

Ford Specification WSS-M2C153–H.SAE 5W-20 oil provides optimum

fuel economy and durability performance meeting all

requirements for your vehicle’s engine.

Change your engine oil and filter according to the appropriate schedule

listed in the scheduled maintenance guide.

Do not use supplemental engine oil additives, oil treatments or engine

treatments. They are unnecessary and could, under certain conditions,

lead to engine damage which is not covered by your warranty.

Ford production and aftermarket (Motorcraft) oil filters are designed for

added engine protection and long life. If a replacement oil filter is used

that does not meet Ford material and design specifications, start-up

engine noises of knock may be experienced.

It is recommended you use the appropriate Motorcraft oil filter (or

another brand meeting Ford specifications) for your engine application.

Maintenance and Specifications

245

Page 247 of 288

Keep batteries out of reach of children. Batteries contain sulfuric

acid. Avoid contact with skin, eyes or clothing. Shield your eyes

when working near the battery to protect against possible splashing of

acid solution. In case of acid contact with skin or eyes, flush

immediately with water for a minimum of 15 minutes and get prompt

medical attention. If acid is swallowed, call a physician immediately.

Battery posts, terminals and related accessories contain lead and

lead compounds.Wash hands after handling.

Because your vehicle’s engine is electronically controlled by a computer,

some control conditions are maintained by power from the battery. When

the battery is disconnected or a new battery is installed, the engine must

relearn its idle and fuel trim strategy for optimum driveability and

performance. To begin this process:

1. With the vehicle at a complete stop, set the parking brake (Refer to

Parking Brakein theDrivingchapter for information on how to

properly reset parking brake.).

2. Put the gearshift lever in P (Park), turn off all accessories and start

the engine.

3. Run the engine until it reaches normal operating temperature.

4. Allow the engine to idle for at least one minute.

5. Turn the A/C on and allow the engine to idle for at least one minute.

6. Drive the vehicle to complete the relearning process.

•The vehicle may need to be driven to relearn the idle and fuel trim

strategy.

•If you do not allow the engine to relearn its idle trim, the idle

quality of your vehicle may be adversely affected until the idle

trim is eventually relearned.

When the battery is disconnected or a new battery installed, the

transmission must relearn its adaptive strategy. As a result of this, the

transmission may shift firmly. This operation is considered normal and

will not affect function or durability of the transmission. Over time the

adaptive learning process will fully update transmission operation to its

optimum shift feel.

If the battery has been disconnected or a new battery has been installed,

the clock and the preset radio stations must be reset once the battery is

reconnected.

Maintenance and Specifications

247

Page 251 of 288

•Do not mix with recycled coolant unless from a Ford-approved

recycling process (seeUse of Recycled engine coolantsection).

For vehicles with overflow coolant systems with a non-pressurized cap

on the coolant recovery system, add coolant to the coolant recovery

reservoir when the engine is cool. Add the proper mixture of coolant and

water to the“cold full”level. For all other vehicles, which have a coolant

degas system with a pressurized cap, or if it is necessary to remove the

coolant pressure relief cap on the radiator of a vehicle with an overflow

system, follow these steps to add engine coolant.

To reduce the risk of personal injury, make sure the engine is

cool before unscrewing the coolant pressure relief cap. The

cooling system is under pressure; steam and hot liquid can come out

forcefully when the cap is loosened slightly.

1. Before you begin, turn the engine off and let it cool.

2. When the engine is cool, wrap a thick cloth around the coolant

pressure relief cap on the coolant reservoir (an opaque plastic bottle).

Slowly turn cap counterclockwise (left) until pressure begins to release.

3. Step back while the pressure releases.

4. When you are sure that all the pressure has been released, use the

cloth to turn it counterclockwise and remove the cap.

5. Fill the coolant reservoir slowly with the proper coolant mixture (see

above), to within the“cold fill range”or the“cold full”level on the

reservoir. If you removed the radiator cap in an overflow system, fill the

radiator until the coolant is visible and radiator is almost full.

6. Replace the cap. Turn until tightly installed. (Cap must be tightly

installed to prevent coolant loss.)

After any coolant has been added, check the coolant concentration, refer

toChecking Engine Coolantsection. If the concentration is not 50/50

(protection to–34°F/–36°C), drain some coolant and adjust the

concentration. It may take several drains and additions to obtain a 50/50

coolant concentration.

Whenever coolant has been added, the coolant level in the coolant

reservoir should be checked the next few times you drive the vehicle. If

necessary, add enough 50/50 concentration of engine coolant and

distilled water to bring the liquid level to the proper level.

If you have to add more than 1.0 liter (1.0 quart) of engine coolant per

month, have your dealer check the engine cooling system. Your cooling

Maintenance and Specifications

251

Page 256 of 288

When refueling always shut the engine off and never allow

sparks or open flames near the filler neck. Never smoke while

refueling. Fuel vapor is extremely hazardous under certain conditions.

Care should be taken to avoid inhaling excess fumes.

The flow of fuel through a fuel pump nozzle can produce static

electricity, which can cause a fire if fuel is pumped into an

ungrounded fuel container.

Use the following guidelines to avoid static build-up when filling an

ungrounded fuel container:

•Place approved fuel container on the ground.

•DO NOT fill a fuel container while it is in the vehicle (including the

cargo area).

•Keep the fuel pump nozzle in contact with the fuel container while

filling.

•DO NOT use a device that would hold the fuel pump handle in the fill

position.

Fuel Filler Cap

Your fuel tank filler cap has an indexed design with a 1/8 turn on/off

feature.

When fueling your vehicle:

1. Turn the engine off.

2. Carefully turn the filler cap counterclockwise 1/8 of a turn until it

stops.

3. Pull to remove the cap from the fuel filler pipe.

4. To install the cap, align the tabs on the cap with the notches on the

filler pipe.

5. Turn the filler cap clockwise 1/8 of a turn until it stops.

If the“Check Fuel Cap”indicator comes on and stays on after you start

the engine, the fuel filler cap may not be properly installed. Turn off the

engine, remove the fuel filler cap, align the cap properly and reinstall it.

If you must replace the fuel filler cap, replace it with a fuel filler

cap that is designed for your vehicle. The customer warranty may

be void for any damage to the fuel tank or fuel system if the

correct genuine Ford or Motorcraft fuel filler cap is not used.

Maintenance and Specifications

256