check engine LINCOLN MKT 2014 Owner's Guide

[x] Cancel search | Manufacturer: LINCOLN, Model Year: 2014, Model line: MKT, Model: LINCOLN MKT 2014Pages: 498, PDF Size: 7.3 MB

Page 302 of 498

You have limited engine power when in the fail-safe mode, so drive the

vehicle with caution. The vehicle will not be able to maintain high-speed

operation and the engine will run rough. Remember that the engine is

capable of completely shutting down automatically to prevent engine

damage, therefore:

1. Pull off the road as soon as safely possible and turn off the engine.

2. Arrange for the vehicle to be taken to an authorized dealer.

3. If this is not possible, wait a short period for the engine to cool.

4. Check the coolant level and replenish if low.

5. Restart the engine and take your vehicle to an authorized dealer.

Note:Driving the vehicle without repairing the engine problem increases

the chance of engine damage. Take your vehicle to an authorized dealer

as soon as possible.

TRANSMISSION FLUID CHECK

6F35 transmission (if equipped)

Note:Transmission fluid should be checked by an authorized dealer.

If required, fluid should be added by an authorized dealer.

The automatic transmission does not have a transmission fluid dipstick.

Refer to yourscheduled maintenance informationfor scheduled

intervals for fluid checks and changes. Your transmission does not

consume fluid. However, the fluid level should be checked if the

transmission is not working properly, (i.e., if the transmission slips or

shifts slowly) or if you notice some sign of fluid leakage.

Do not use supplemental transmission fluid additives, treatments or

cleaning agents. The use of these materials may affect transmission

operation and result in damage to internal transmission components.

6F50/6F55 Transmission

WARNING:The dipstick cap and surrounding components may

be hot; gloves are recommended.

WARNING:Use gloves when moving the air filter assembly;

components will be hot.

Maintenance301

2014 MKT(mkt)

Owners Guide gf, 1st Printing, April 2013

USA(fus)

Page 303 of 498

![LINCOLN MKT 2014 Owners Guide Note:Automatic transmission fluid expands when warmed. To obtain an

accurate fluid check, drive the vehicle until it is warmed up (approximately

20 miles [30 km]). If your vehicle has been operated fo LINCOLN MKT 2014 Owners Guide Note:Automatic transmission fluid expands when warmed. To obtain an

accurate fluid check, drive the vehicle until it is warmed up (approximately

20 miles [30 km]). If your vehicle has been operated fo](/img/15/6932/w960_6932-302.png)

Note:Automatic transmission fluid expands when warmed. To obtain an

accurate fluid check, drive the vehicle until it is warmed up (approximately

20 miles [30 km]). If your vehicle has been operated for an extended

period at high speeds, in city traffic during hot weather or pulling a trailer,

the vehicle should be turned off until normal operating temperatures are

reached to allow the fluid to cool before checking. Depending on vehicle

use, cooling times could take up to 30 minutes or longer.

Refer to yourscheduled maintenance informationfor scheduled

intervals for fluid checks and changes. Your transmission does not

consume fluid. However, the fluid level should be checked if the

transmission is not working properly, i.e., if the transmission slips or

shifts slowly or if you notice some sign of fluid leakage.

1. Drive the vehicle 20 miles (30 km) or until it reaches normal operating

temperature.

2. Park the vehicle on a level surface and engage the parking brake.

3. With the parking brake engaged and your foot on the brake pedal,

start the engine and move the gearshift lever through all of the gear

ranges. Allow a minimum of 10 seconds for each gear to engage.

4. Latch the gearshift lever inP(Park) and leave the engine running.

5. Remove the dipstick, wiping it clean with a clean, dry lintfree rag. If

necessary, refer toUnder hood overviewin this chapter for the location

of the dipstick. (For vehicles with the EcoBoost engine, move the air

filter assembly aside to access the transmission dipstick. SeeMoving the

Air Filter Assembly (EcoBoost engine)for more information.

6. Install the dipstick making sure it is fully seated in the filler tube by

turning it to the locked position.

7. Remove the dipstick and inspect the fluid level. The fluid should be in

the designated areas for normal operating temperature.

302Maintenance

2014 MKT(mkt)

Owners Guide gf, 1st Printing, April 2013

USA(fus)

Page 306 of 498

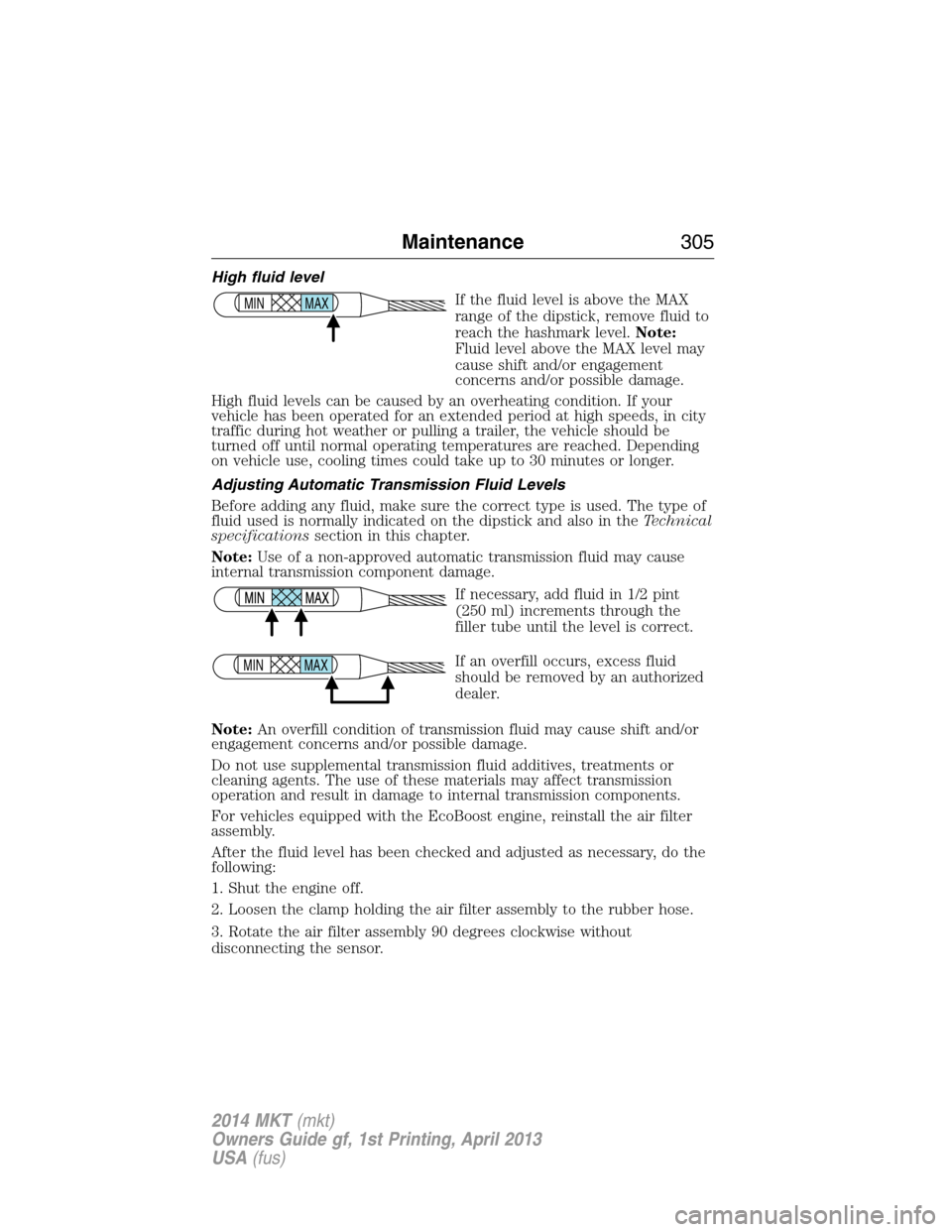

High fluid level

If the fluid level is above the MAX

range of the dipstick, remove fluid to

reach the hashmark level.Note:

Fluid level above the MAX level may

cause shift and/or engagement

concerns and/or possible damage.

High fluid levels can be caused by an overheating condition. If your

vehicle has been operated for an extended period at high speeds, in city

traffic during hot weather or pulling a trailer, the vehicle should be

turned off until normal operating temperatures are reached. Depending

on vehicle use, cooling times could take up to 30 minutes or longer.

Adjusting Automatic Transmission Fluid Levels

Before adding any fluid, make sure the correct type is used. The type of

fluid used is normally indicated on the dipstick and also in theTechnical

specificationssection in this chapter.

Note:Use of a non-approved automatic transmission fluid may cause

internal transmission component damage.

If necessary, add fluid in 1/2 pint

(250 ml) increments through the

filler tube until the level is correct.

If an overfill occurs, excess fluid

should be removed by an authorized

dealer.

Note:An overfill condition of transmission fluid may cause shift and/or

engagement concerns and/or possible damage.

Do not use supplemental transmission fluid additives, treatments or

cleaning agents. The use of these materials may affect transmission

operation and result in damage to internal transmission components.

For vehicles equipped with the EcoBoost engine, reinstall the air filter

assembly.

After the fluid level has been checked and adjusted as necessary, do the

following:

1. Shut the engine off.

2. Loosen the clamp holding the air filter assembly to the rubber hose.

3. Rotate the air filter assembly 90 degrees clockwise without

disconnecting the sensor.

MAX MIN

MAX MIN

Maintenance305

2014 MKT(mkt)

Owners Guide gf, 1st Printing, April 2013

USA(fus)

Page 311 of 498

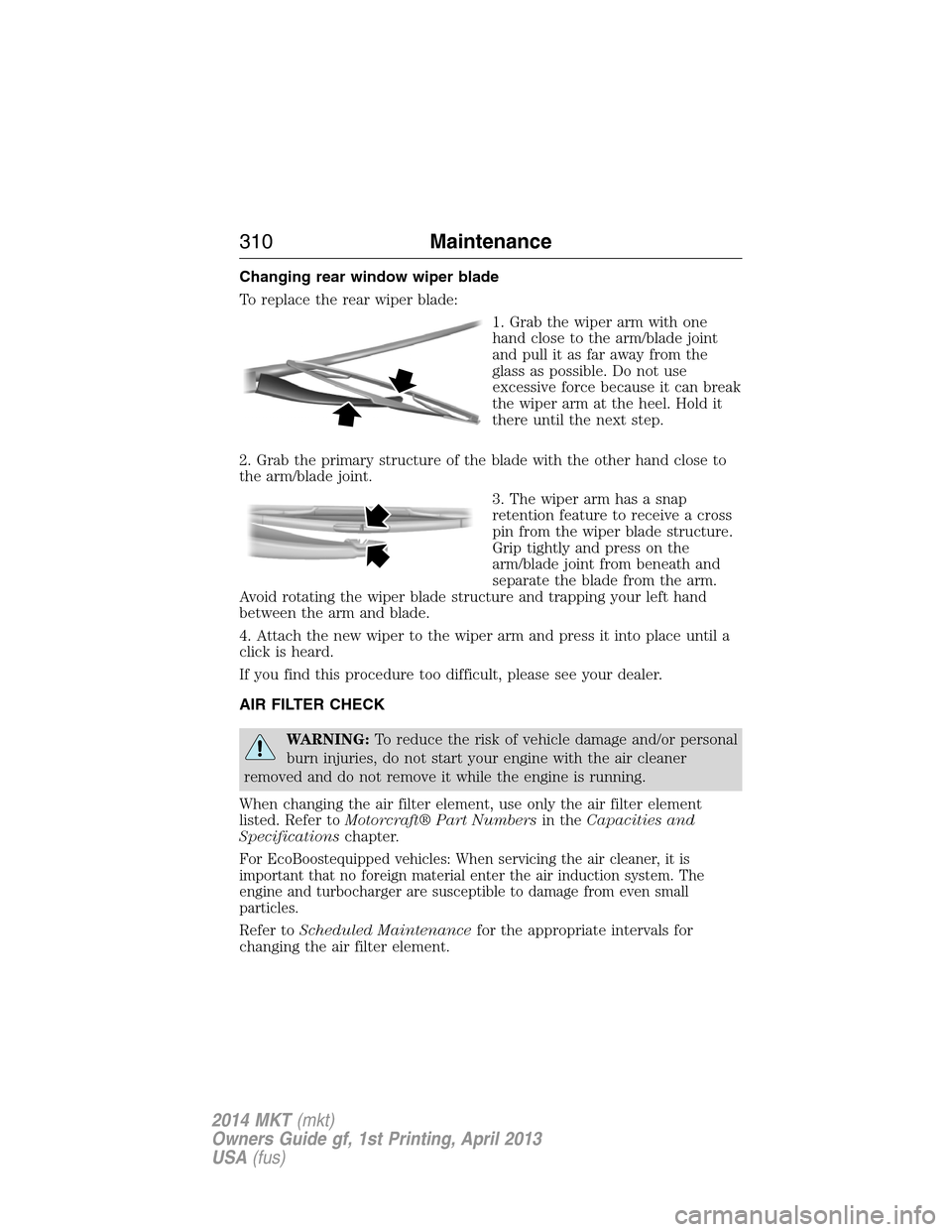

Changing rear window wiper blade

To replace the rear wiper blade:

1. Grab the wiper arm with one

hand close to the arm/blade joint

and pull it as far away from the

glass as possible. Do not use

excessive force because it can break

the wiper arm at the heel. Hold it

there until the next step.

2. Grab the primary structure of the blade with the other hand close to

the arm/blade joint.

3. The wiper arm has a snap

retention feature to receive a cross

pin from the wiper blade structure.

Grip tightly and press on the

arm/blade joint from beneath and

separate the blade from the arm.

Avoid rotating the wiper blade structure and trapping your left hand

between the arm and blade.

4. Attach the new wiper to the wiper arm and press it into place until a

click is heard.

If you find this procedure too difficult, please see your dealer.

AIR FILTER CHECK

WARNING:To reduce the risk of vehicle damage and/or personal

burn injuries, do not start your engine with the air cleaner

removed and do not remove it while the engine is running.

When changing the air filter element, use only the air filter element

listed. Refer toMotorcraft® Part Numbersin theCapacities and

Specificationschapter.

For EcoBoostequipped vehicles: When servicing the air cleaner, it is

important that no foreign material enter the air induction system. The

engine and turbocharger are susceptible to damage from even small

particles.

Refer toScheduled Maintenancefor the appropriate intervals for

changing the air filter element.

310Maintenance

2014 MKT(mkt)

Owners Guide gf, 1st Printing, April 2013

USA(fus)

Page 313 of 498

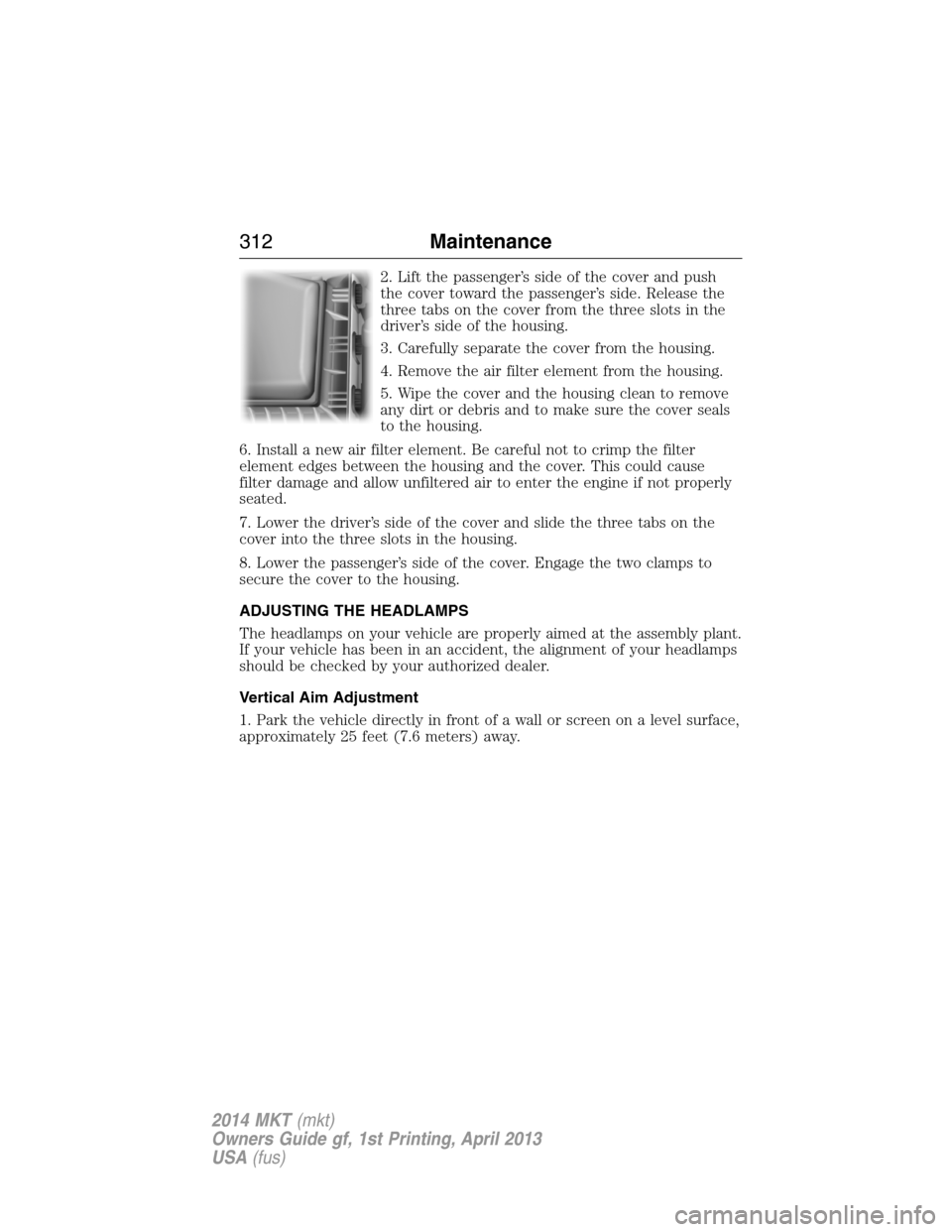

2. Lift the passenger’s side of the cover and push

the cover toward the passenger’s side. Release the

three tabs on the cover from the three slots in the

driver’s side of the housing.

3. Carefully separate the cover from the housing.

4. Remove the air filter element from the housing.

5. Wipe the cover and the housing clean to remove

any dirt or debris and to make sure the cover seals

to the housing.

6. Install a new air filter element. Be careful not to crimp the filter

element edges between the housing and the cover. This could cause

filter damage and allow unfiltered air to enter the engine if not properly

seated.

7. Lower the driver’s side of the cover and slide the three tabs on the

cover into the three slots in the housing.

8. Lower the passenger’s side of the cover. Engage the two clamps to

secure the cover to the housing.

ADJUSTING THE HEADLAMPS

The headlamps on your vehicle are properly aimed at the assembly plant.

If your vehicle has been in an accident, the alignment of your headlamps

should be checked by your authorized dealer.

Vertical Aim Adjustment

1. Park the vehicle directly in front of a wall or screen on a level surface,

approximately 25 feet (7.6 meters) away.

312Maintenance

2014 MKT(mkt)

Owners Guide gf, 1st Printing, April 2013

USA(fus)

Page 325 of 498

Body

•Wash vehicle thoroughly to remove dirt, grease, oil, tar or mud from

exterior surfaces, rear-wheel housing and underside of front fenders.

•Periodically wash vehicles stored in exposed locations.

•Touch up raw or primed metal to prevent rust.

•Cover chrome and stainless steel parts with a thick coat of auto wax

to prevent discoloration. Re-wax as necessary when the vehicle is

washed.

•Lubricate hood latch, all door latches and trunk lid hinges with a light

grade oil.

•Cover interior trim to prevent fading.

•Keep all rubber parts free from oil and solvents.

Engine

•The engine oil and filter should be changed prior to storage, as used

engine oil contains contaminates that may cause engine damage.

•Start the engine every 15 days. Run at fast idle until it reaches normal

operating temperature.

•With your foot on the brake, shift through all the gears while the

engine is running.

Fuel system

•Fill the fuel tank with high-quality fuel until the first automatic shutoff

of the fuel pump nozzle.

Note:During extended periods of vehicle storage (30 days or more),

fuel may deteriorate due to oxidation. Add a quality gas stabilizer

product to the vehicle fuel system whenever actual or expected storage

periods exceed 30 days. Follow the instructions on the additive label.

The vehicle should then be operated at idle speed to circulate the

additive throughout the fuel system.

Cooling system

•Protect against freezing temperatures.

•When removing vehicle from storage, check coolant fluid level.

Confirm there are no cooling system leaks, and fluid is at the

recommended level.

324Vehicle Care

2014 MKT(mkt)

Owners Guide gf, 1st Printing, April 2013

USA(fus)

Page 366 of 498

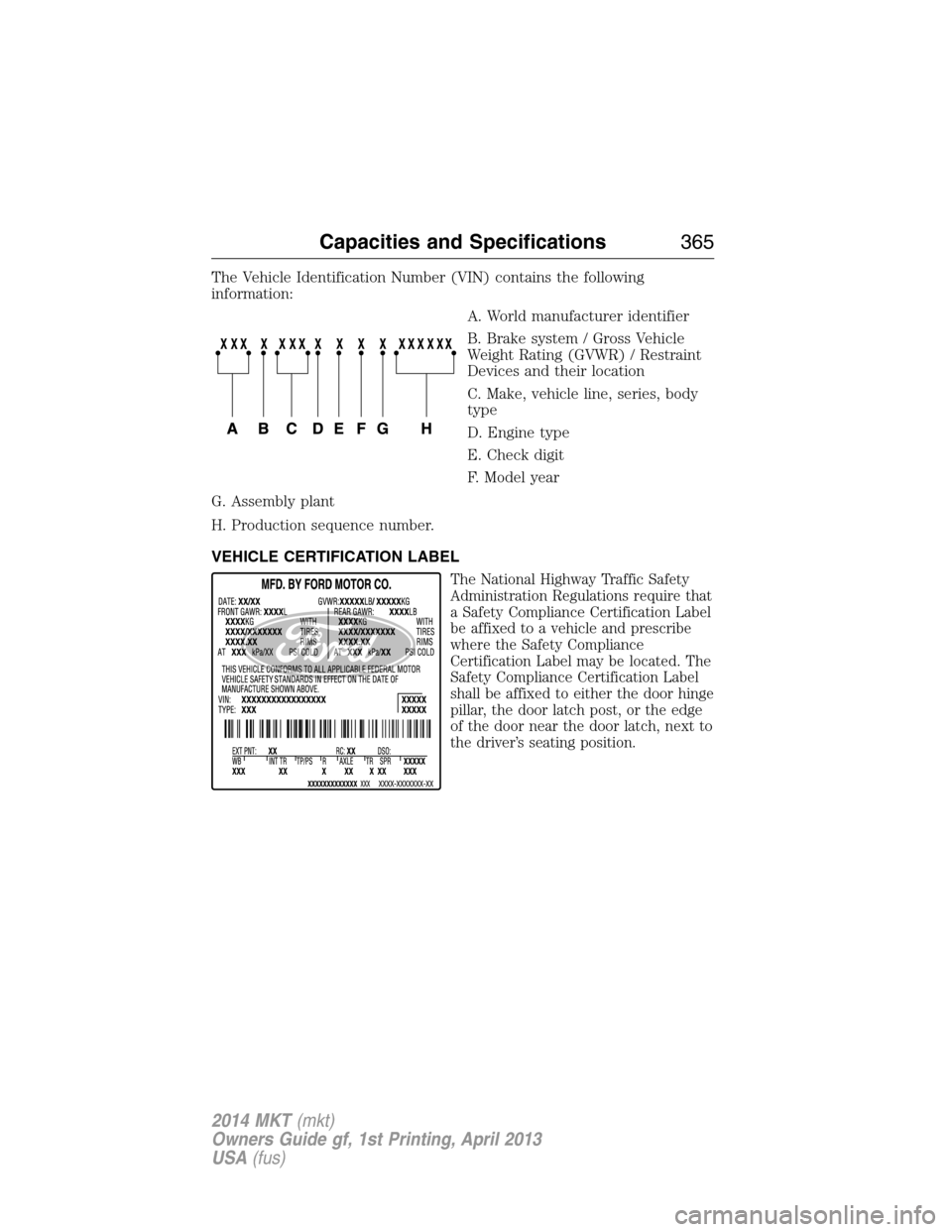

The Vehicle Identification Number (VIN) contains the following

information:

A. World manufacturer identifier

B. Brake system / Gross Vehicle

Weight Rating (GVWR) / Restraint

Devices and their location

C. Make, vehicle line, series, body

type

D. Engine type

E. Check digit

F. Model year

G. Assembly plant

H. Production sequence number.

VEHICLE CERTIFICATION LABEL

The National Highway Traffic Safety

Administration Regulations require that

a Safety Compliance Certification Label

be affixed to a vehicle and prescribe

where the Safety Compliance

Certification Label may be located. The

Safety Compliance Certification Label

shall be affixed to either the door hinge

pillar, the door latch post, or the edge

of the door near the door latch, next to

the driver’s seating position.

Capacities and Specifications365

2014 MKT(mkt)

Owners Guide gf, 1st Printing, April 2013

USA(fus)

Page 477 of 498

Oils, Fluids and Flushing

In many cases, fluid discoloration is a normal operating characteristic

and, by itself, does not necessarily indicate a concern or that the fluid

needs to be changed. However, discolored fluids that also show signs of

overheating and foreign material contamination should be inspected

immediately by a qualified expert, such as the factory-trained technicians

at your dealership. Your vehicle’s oils and fluids should be changed at the

specified intervals or in conjunction with a repair. Flushing is a viable

way to change fluid for many vehicle sub-systems during scheduled

maintenance. It is critical that systems are flushed only with new fluid

that is the same as that required to fill and operate the system, or using

a Ford-approved flushing chemical.

Owner Checks and Services

Certain basic maintenance checks and inspections should be performed

every month or at six month intervals.

Check every month

Engine oil level.

Function of all interior and exterior lights.

Tires (including spare) for wear and proper pressure.

Windshield washer fluid level.

Check every six months

Battery connections. Clean if necessary.

Body and door drain holes for obstructions. Clean if necessary.

Cooling system fluid level and coolant strength.

Door weatherstrips for wear. Lubricate if necessary.

Hinges, latches and outside locks for proper operation. Lubricate if

necessary.

Parking brake for proper operation.

Safety belts and seat latches for wear and function.

Safety warning lamps (brake, ABS, airbag, safety belt) for operation.

Washer spray and wiper operation. Clean or replace blades as

necessary.

476Scheduled Maintenance

2014 MKT(mkt)

Owners Guide gf, 1st Printing, April 2013

USA(fus)

Page 478 of 498

Multi-point Inspection

In order to keep your vehicle running right, it is important to have the

systems on your vehicle checked regularly. This can help identify

potential issues and prevent major problems. Ford Motor Company

recommends the following multi-point inspection be performed at every

scheduled maintenance interval to help make sure your vehicle keeps

running great.

Multi-point Inspection

Accessory drive belt(s) Half-shaft dust boots (if equipped)

Battery performance Horn operation

Clutch operation (if equipped) Radiator, cooler, heater and A/C hoses

Engine air filter Suspension component for leaks or

damage

Exhaust system Steering and linkage

Exterior lamps and hazard

warning system operationTires (including spare) for wear and

proper pressure

**

Fluid levels*; fill if necessary Windshield for cracks, chips or pits

For oil and fluid leaks Washer spray and wiper operation

*Brake, coolant recovery reservoir, manual and automatic transmission

(with an underhood dipstick), power steering (if equipped) and window

washer

**If your vehicle is equipped with a temporary mobility kit, check the tire

sealant expiration Use By date on the canister. Replace as needed.

Be sure to ask your dealership service advisor or technician about the

multi-point vehicle inspection. It’s a comprehensive way to perform a

thorough inspection of your vehicle. It’s your checklist that gives you

immediate feedback on the overall condition of your vehicle. You’ll know

what’s been checked, what’s okay, as well as those things that may

require future or immediate attention. The multi-point vehicle inspection

is one more way to keep your vehicle running great!

Scheduled Maintenance477

2014 MKT(mkt)

Owners Guide gf, 1st Printing, April 2013

USA(fus)

Page 490 of 498

EXCEPTIONS

There are several exceptions to the Normal Schedule. They are listed

below:

Normal vehicle axle maintenance:Rear axles and power take-off

(PTO) units with synthetic fluid and light-duty trucks equipped with

Ford-design axles are lubricated for life; do not check or change fluid

unless a leak is suspected, service is required or the assembly has been

submerged in water. During long periods of trailer towing with outside

temperatures above 70°F (21°C) and at wide-open throttle for long

periods above 45 mph (72 km/h), non-synthetic rear axle fluids should

be changed every 3000 miles (4800 kilometers) or three months,

whichever comes first. This interval can be waived if the axle is filled

with 75W140 synthetic gear fluid meeting Ford specification

WSL-M2C192-A, part number F1TZ-19580-B or equivalent. Add friction

modifier XL-3 (EST-M2C118-A) or equivalent for complete refill of

Traction-Lok rear axles (seeTechnical specificationsin theCapacities

and Specificationschapter for details).

Police/Taxi/Livery vehicle axle maintenance:Change rear axle fluid

every 100000 miles (160000 kilometers). Rear axle fluid change may be

waived if the axle was filled with 75W140 synthetic gear fluid meeting

Ford specification WSL-M2C192-A, part number FITZ-19580-B or

equivalent. Add four ounces (118 mL) of additive friction modifier XL-3

(EST-M2C118-A) or equivalent for complete refill of Traction-Lok rear

axles. The axle fluid should be changed anytime the axle has been

submerged in water.

California fuel filter replacement:If the vehicle is registered in

California, the California Air Resources Board has determined that the

failure to perform this maintenance item will not nullify the emission

warranty or limit recall liability prior to the completion of the vehicle’s

useful life. Ford Motor Company, however, urges you to have all

recommended maintenance services performed at the specified intervals

and to record all vehicle service.

Class A Motorhome:Change brake fluid every two years.

Hot climate oil change intervals:Vehicles operating in the Middle

East, North Africa, Sub-Saharan Africa or locations with similar climates

using an American Petroleum Institute (API) Certified for Gasoline

Engines (Certification mark) oil of SM or SN quality, the normal oil

change interval is 5000 miles (8000 kilometers).

If the available API SM or SN oils are not available, then the oil change

service interval is 3000 miles (4800 kilometers).

Scheduled Maintenance489

2014 MKT(mkt)

Owners Guide gf, 1st Printing, April 2013

USA(fus)