tires LINCOLN MKX 2017 Workshop Manual

[x] Cancel search | Manufacturer: LINCOLN, Model Year: 2017, Model line: MKX, Model: LINCOLN MKX 2017Pages: 587, PDF Size: 5.4 MB

Page 377 of 587

Note:

Passengers should not remain in your

vehicle when the vehicle is being jacked.

1. Park on a level surface, set the parking brake and activate the hazard flashers.

2. Place the transmission in park (P) and turn the engine off. 3.

Block both the front and rear of the wheel

diagonally opposite the flat tire. For

example, if the left front tire is flat, block

the right rear wheel.

4. Lift and remove the carpeted load floor panel to access the minispare and jack

kit. 5. Remove the steel winged washer nut

securing the spare tire by turning it

counterclockwise.

6. Remove the spare tire from the spare tire

compartment.

7. Remove plastic wing nut and jack and lug wrench assembly. Detach lug wrench

from jack by turning the jack hex nut

drive screw counterclockwise.

8. Loosen each wheel lug nut one-half turn

counterclockwise, but do not remove

them until the wheel is raised off the

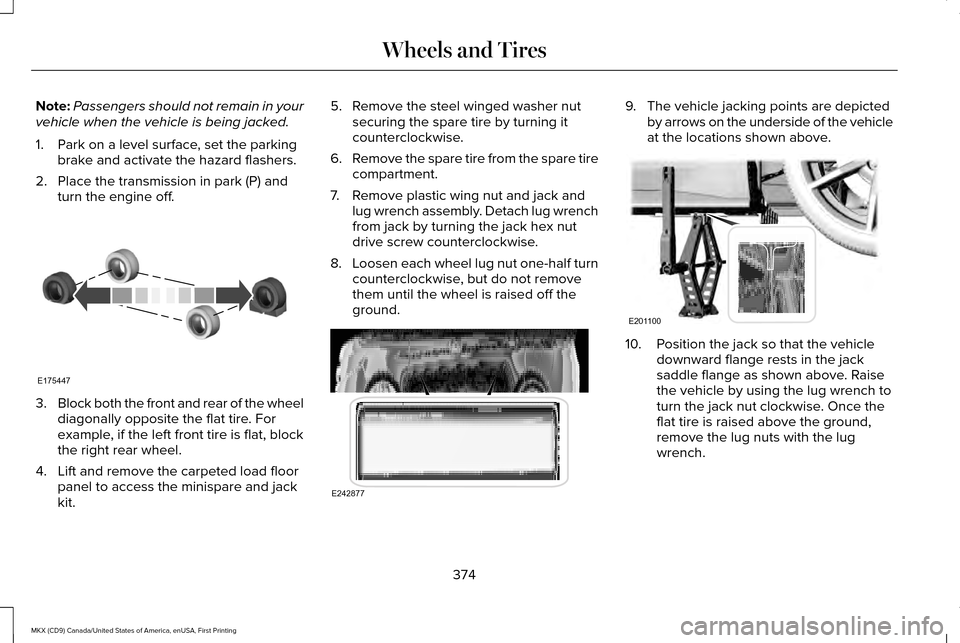

ground. 9. The vehicle jacking points are depicted

by arrows on the underside of the vehicle

at the locations shown above. 10. Position the jack so that the vehicle

downward flange rests in the jack

saddle flange as shown above. Raise

the vehicle by using the lug wrench to

turn the jack nut clockwise. Once the

flat tire is raised above the ground,

remove the lug nuts with the lug

wrench.

374

MKX (CD9) Canada/United States of America, enUSA, First Printing Wheels and TiresE175447 E242877 E201100

Page 378 of 587

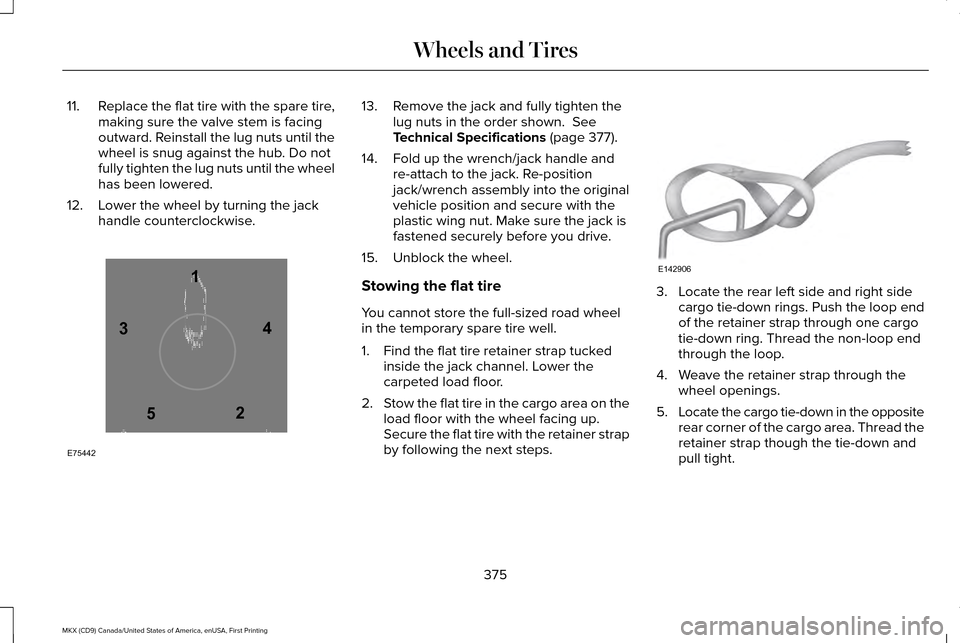

11.

Replace the flat tire with the spare tire,

making sure the valve stem is facing

outward. Reinstall the lug nuts until the

wheel is snug against the hub. Do not

fully tighten the lug nuts until the wheel

has been lowered.

12. Lower the wheel by turning the jack handle counterclockwise. 13. Remove the jack and fully tighten the

lug nuts in the order shown. See

Technical Specifications (page 377).

14. Fold up the wrench/jack handle and re-attach to the jack. Re-position

jack/wrench assembly into the original

vehicle position and secure with the

plastic wing nut. Make sure the jack is

fastened securely before you drive.

15. Unblock the wheel.

Stowing the flat tire

You cannot store the full-sized road wheel

in the temporary spare tire well.

1. Find the flat tire retainer strap tucked inside the jack channel. Lower the

carpeted load floor.

2. Stow the flat tire in the cargo area on the

load floor with the wheel facing up.

Secure the flat tire with the retainer strap

by following the next steps. 3. Locate the rear left side and right side

cargo tie-down rings. Push the loop end

of the retainer strap through one cargo

tie-down ring. Thread the non-loop end

through the loop.

4. Weave the retainer strap through the wheel openings.

5. Locate the cargo tie-down in the opposite

rear corner of the cargo area. Thread the

retainer strap though the tie-down and

pull tight.

375

MKX (CD9) Canada/United States of America, enUSA, First Printing Wheels and Tires12

3

4

5

E75442 E142906

Page 379 of 587

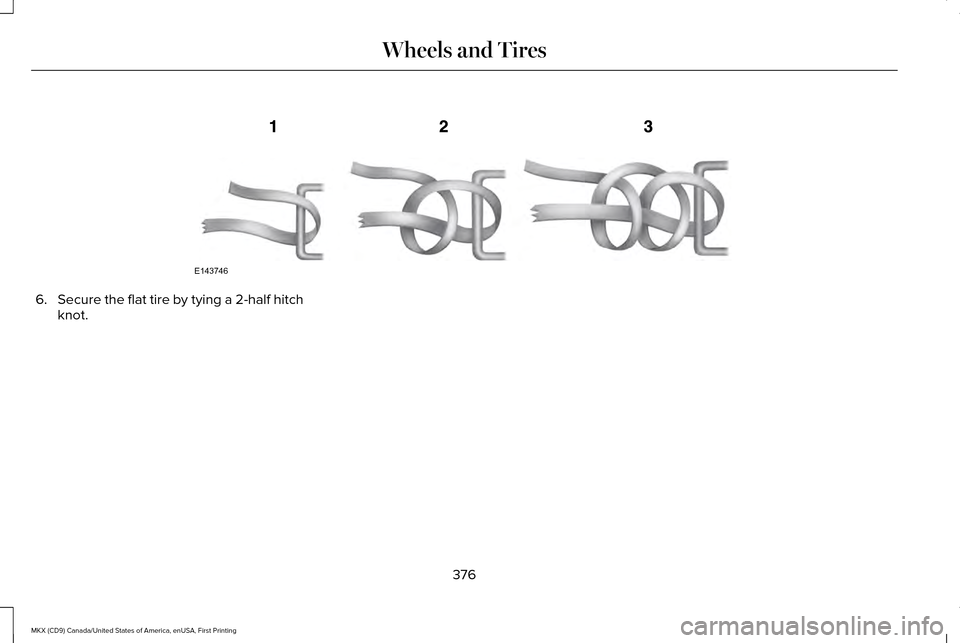

6.

Secure the flat tire by tying a 2-half hitch

knot.

376

MKX (CD9) Canada/United States of America, enUSA, First Printing Wheels and TiresE143746

Page 380 of 587

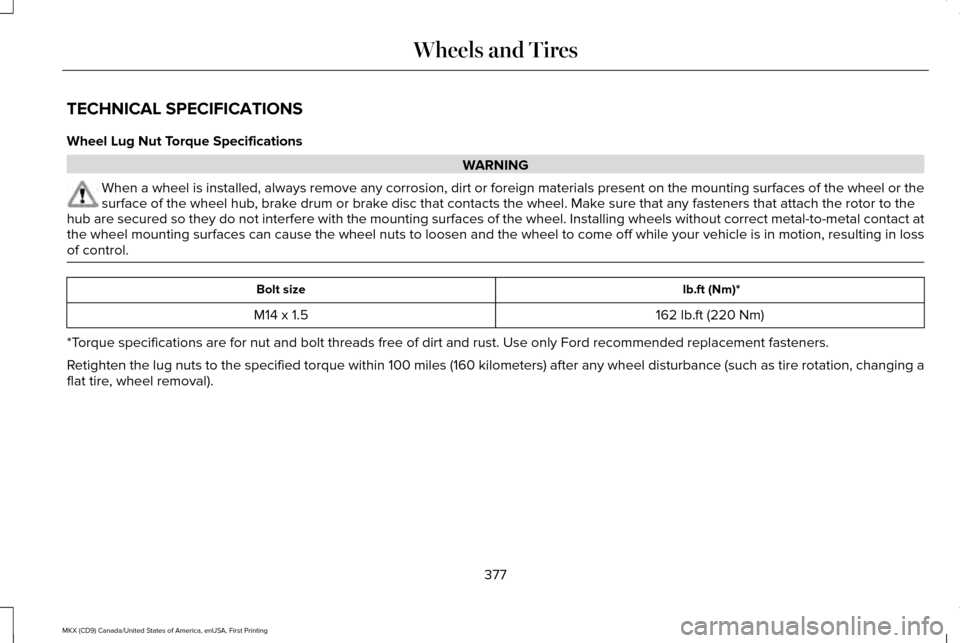

TECHNICAL SPECIFICATIONS

Wheel Lug Nut Torque Specifications

WARNING

When a wheel is installed, always remove any corrosion, dirt or foreign \

materials present on the mounting surfaces of the wheel or the

surface of the wheel hub, brake drum or brake disc that contacts the wheel. Make sure that any fasteners that attach the rotor to the

hub are secured so they do not interfere with the mounting surfaces of t\

he wheel. Installing wheels without correct metal-to-metal contact at

the wheel mounting surfaces can cause the wheel nuts to loosen and the w\

heel to come off while your vehicle is in motion, resulting in loss

of control. lb.ft (Nm)*

Bolt size

162 lb.ft (220 Nm)

M14 x 1.5

*Torque specifications are for nut and bolt threads free of dirt and rust.\

Use only Ford recommended replacement fasteners.

Retighten the lug nuts to the specified torque within 100 miles (160 kil\

ometers) after any wheel disturbance (such as tire rotation, changing \

a

flat tire, wheel removal).

377

MKX (CD9) Canada/United States of America, enUSA, First Printing Wheels and Tires

Page 381 of 587

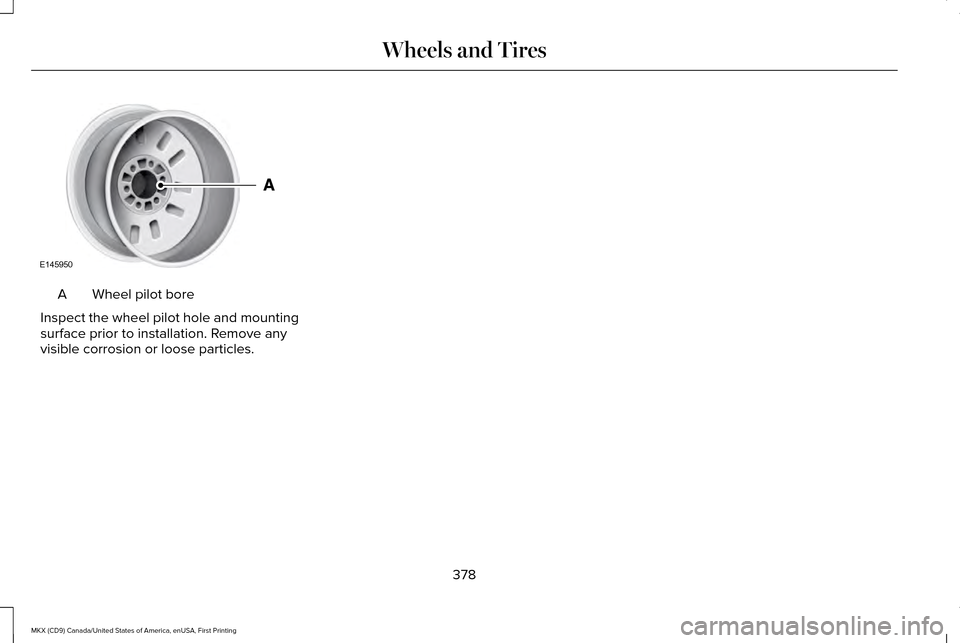

Wheel pilot bore

A

Inspect the wheel pilot hole and mounting

surface prior to installation. Remove any

visible corrosion or loose particles.

378

MKX (CD9) Canada/United States of America, enUSA, First Printing Wheels and TiresE145950

Page 515 of 587

Make sure to change your vehicle

’s oils and

fluids at the specified intervals or in

conjunction with a repair. Flushing is a viable

way to change fluid for many vehicle

sub-systems during scheduled maintenance. It is critical that systems are flushed only with

new fluid that is the same as that required

to fill and operate the system or using a

Ford-approved flushing chemical.

Owner Checks and Services

Make sure you perform the following basic

maintenance checks and inspections every

month or at six-month intervals. Check every month

Engine oil level.

Function of all interior and exterior lights.

Tires (including spare) for wear and proper pressure. Windshield washer fluid level. Check every six months

Battery connections. Clean if necessary.

Body and door drain holes for obstructions. Clean if necessary. Cooling system fluid level and coolant strength.

Door weatherstrips for wear. Lubricate if necessary.

Hinges, latches and outside locks for proper operation. Lubricate if necessary. Parking brake for proper operation.

512

MKX (CD9) Canada/United States of America, enUSA, First Printing Scheduled Maintenance

Page 517 of 587

Multi-Point inspection

Steering and linkage

Exterior lamps operation

Tires (including spare) for wear and proper pressure**

Fluid levels *

; fill if necessary

Windshield for cracks, chips or pits

For oil and fluid leaks

Washer spray and wiper operation

Half-shaft dust boots

* Brake, coolant recovery reservoir, automatic transmission and window washer

** If your vehicle is equipped with a temporary mobility kit, check the tir\

e sealant expiration Use By date on the canister. Replace as needed.

Be sure to ask your dealership service

advisor or technician about the multi-point

vehicle inspection. It is a comprehensive way

to perform a thorough inspection of your

vehicle. Your checklist gives you immediate

feedback on the overall condition of your

vehicle. NORMAL SCHEDULED

MAINTENANCE

Intelligent Oil-Life Monitor™

Your vehicle is equipped with an Intelligent

Oil-Life Monitor that determines when you

should change the engine oil based on how

you use your vehicle. By using several

important factors in its calculations, the

monitor helps reduce the cost of owning your

vehicle and reduces environmental waste at

the same time.This means you do not have to remember to

change the oil on a mileage-based schedule.

Your vehicle lets you know when an oil

change is due by displaying a message in

the information display.

The following table provides examples of

vehicle use and its impact on oil change

intervals. It is a guideline only. Actual oil

change intervals depend on several factors

and generally decrease with severity of use.

514

MKX (CD9) Canada/United States of America, enUSA, First Printing Scheduled Maintenance

Page 519 of 587

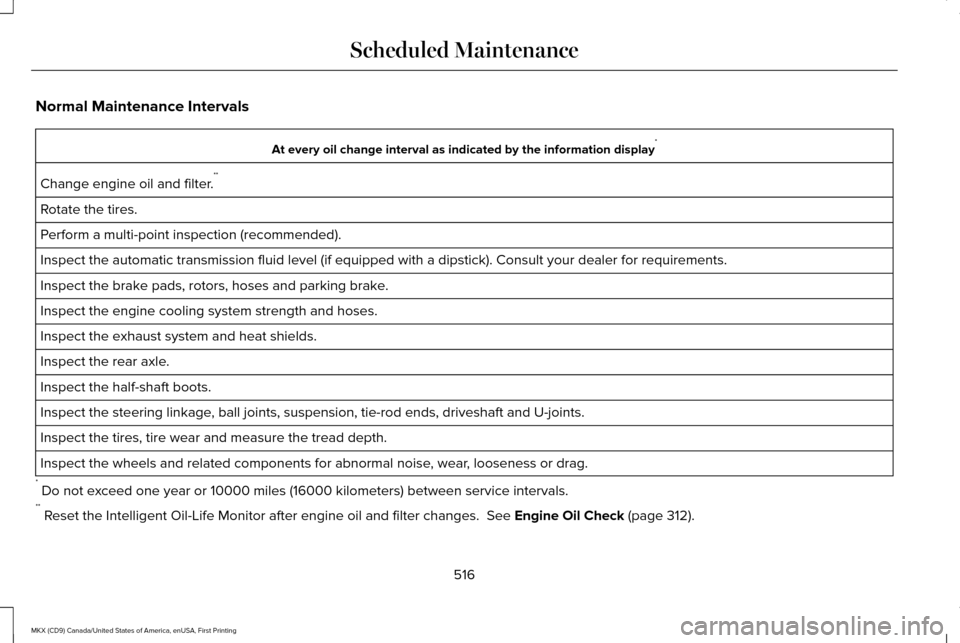

Normal Maintenance Intervals

At every oil change interval as indicated by the information display

*

Change engine oil and filter. **

Rotate the tires.

Perform a multi-point inspection (recommended).

Inspect the automatic transmission fluid level (if equipped with a dips\

tick). Consult your dealer for requirements.

Inspect the brake pads, rotors, hoses and parking brake.

Inspect the engine cooling system strength and hoses.

Inspect the exhaust system and heat shields.

Inspect the rear axle.

Inspect the half-shaft boots.

Inspect the steering linkage, ball joints, suspension, tie-rod ends, driveshaft and U-joints.

Inspect the tires, tire wear and measure the tread depth.

Inspect the wheels and related components for abnormal noise, wear, looseness or drag.

* Do not exceed one year or 10000 miles (16000 kilometers) between service interv\

als.

** Reset the Intelligent Oil-Life Monitor after engine oil and filter change\

s. See Engine Oil Check (page 312).

516

MKX (CD9) Canada/United States of America, enUSA, First Printing Scheduled Maintenance

Page 523 of 587

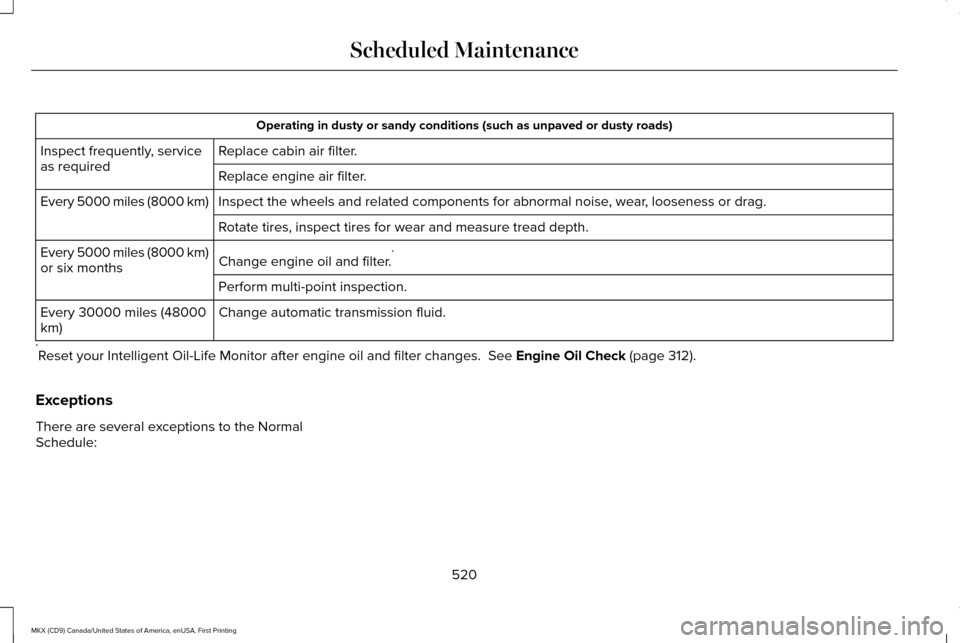

Operating in dusty or sandy conditions (such as unpaved or dusty roads)\

Replace cabin air filter.

Inspect frequently, service

as required

Replace engine air filter.

Inspect the wheels and related components for abnormal noise, wear, looseness or drag.

Every 5000 miles (8000 km)

Rotate tires, inspect tires for wear and measure tread depth.

Change engine oil and filter.*

Every 5000 miles (8000 km)

or six months

Perform multi-point inspection.

Change automatic transmission fluid.

Every 30000 miles (48000

km)

* Reset your Intelligent Oil-Life Monitor after engine oil and filter chang\

es. See Engine Oil Check (page 312).

Exceptions

There are several exceptions to the Normal

Schedule:

520

MKX (CD9) Canada/United States of America, enUSA, First Printing Scheduled Maintenance

Page 585 of 587

Supplementary Restraints System.............45

Principle of Operation..........................................45

Symbols Glossary..............................................7

SYNC™ 3..........................................................403

General Information...........................................403

SYNC™ 3 Troubleshooting..........................488

T

Tailgate See: Manual Liftgate............................................72

See: Power Liftgate..............................................74

Technical Specifications See: Capacities and Specifications................379

The Better Business Bureau (BBB) Auto Line Program (U.S. Only).........................280

Tire Care

.........................................................350

Glossary of Tire Terminology..........................353

Important Information About Low-Profile Tires..................................................................350

Important Information About Sport Tires and Wheels...............................................................351

Information About Uniform Tire Quality Grading.............................................................352

Information Contained on the Tire Sidewall............................................................354

Notice to Crossover Vehicle Owners.............

351

Temperature A B C.............................................353 Tire Rotation........................................................364

Traction AA A B C...............................................353

Treadwear............................................................352

Tire Inflation When Punctured See: Tire Sealant and Inflator Kit....................343

Tire Pressure Monitoring System

.............367

Changing Tires With a Tire Pressure

Monitoring System........................................368

Understanding Your Tire Pressure Monitoring System .............................................................368

Tire Repair Kit See: Tire Sealant and Inflator Kit....................343

Tire Sealant and Inflator Kit.......................343 First Stage: Inflating the Tire with Sealing

Compound and Air........................................345

General Information...........................................344

Second Stage: Checking Tire Pressure........348

Tips for Use of the Kit........................................344

What to Do After the Tire has Been Sealed...............................................................348

What to do When a Tire Is Punctured...........345

Tires See: Wheels and Tires.......................................341

Towing a Trailer

..............................................261

Load Placement...................................................261

Towing the Vehicle on Four Wheels.......266 Emergency Towing............................................266

Recreational Towing..........................................266 Towing..............................................................261

Traction Control

............................................202

Principle of Operation.......................................202

Trailer Sway Control

....................................262

Transmission Code Designation..............384

Transmission...................................................183

Transmission See: Transmission...............................................183

Transporting the Vehicle............................276

U

Under Hood Overview - 2.7L EcoBoost™...................................................308

Under Hood Overview - 3.7L.....................310

Universal Garage Door Opener................158 HomeLink Wireless Control System...............

158

Using Adaptive Cruise Control.................225 Automatic Cancellation....................................229

Blocked Sensor....................................................231

Canceling the Set Speed.................................229

Changing the Set Speed..................................229

Detection Issues.................................................230

Following a Vehicle...........................................226

Hilly Condition Usage.......................................229

Overriding the System......................................228

Resuming the Set Speed.................................229

Setting the Adaptive Cruise Speed...............

226

582

MKX (CD9) Canada/United States of America, enUSA, First Printing Index