warning LINCOLN MKZ 2016 Owners Manual

[x] Cancel search | Manufacturer: LINCOLN, Model Year: 2016, Model line: MKZ, Model: LINCOLN MKZ 2016Pages: 544, PDF Size: 5.77 MB

Page 311 of 544

CLEANING THE INTERIOR

WARNINGS

Do not use cleaning solvents, bleach

or dye on the vehicle’s safety belts, as

these actions may weaken the belt webbing.

On vehicles equipped with

seat-mounted airbags, do not use

chemical solvents or strong detergents. Such

products could contaminate the side airbag

system and affect performance of the side

airbag in a collision.

Note: Follow the same procedure for

cleaning leather seats when cleaning leather

interior. See Cleaning Leather Seats (page

311). Note:

Do not use household cleaning

products or glass cleaners, which can stain

and discolor the fabric and affect the flame

retardant abilities of the seat materials.

For fabric, carpets, cloth seats, safety belts

and seats equipped with side airbags:

• Remove dust and loose dirt with a vacuum cleaner.

• Remove light stains and soil with Motorcraft Professional Strength Carpet

& Upholstery Cleaner.

For grease or tar stains:

• Spot clean the area with Motorcraft Spot and Stain Remover (Motorcraft

Multi-Purpose Cleaner in Canada).

• If a ring forms on the fabric after spot cleaning, clean the entire area

immediately (but do not oversaturate) or

the ring will set.

Cleaning Black Label Interior (If

Equipped)

Note: Alcantara microfiber cloth fabric is

made of polyester microfiber with

micro-porous polyurethane. Using

commercially available fabric cleaners can

cause permanent damage.

Note: Do not use commercially available

leather and vinyl cleaning products on

Alcantara microfiber cloth fabric.

Note: Lincoln Black Label vehicles may have

Alcantara microfiber cloth fabric on the

seats, headliner, floor mats and door panels.

Depending on the type of stain, use water,

lemon juice or pure ethyl alcohol when

cleaning. For cleaning Alcantara microfiber

cloth, refer to the following chart:

308

Vehicle Care

Page 313 of 544

CLEANING THE INSTRUMENT

PANEL AND INSTRUMENT

CLUSTER LENS

WARNING

Do not use chemical solvents or strong

detergents when cleaning the steering

wheel or instrument panel to avoid

contamination of the airbag system.

Note: Follow the same procedure as

cleaning leather seats for cleaning leather

instrument panels and leather interior trim

surfaces. See Cleaning Leather Seats (page

311).

Clean the instrument panel and cluster lens

with a clean, damp and soft cloth, then use

a clean, dry and soft cloth to dry these areas. • Avoid cleaners or polishes that increase

the gloss of the upper portion of the

instrument panel. The dull finish in this

area helps protect you from undesirable

windshield reflection.

• Do not use any household cleaning products or glass cleaners as these may

damage the finish of the instrument

panel, interior trim and cluster lens.

• Wash or wipe your hands clean if you have been in contact with certain

products such as insect repellent and

suntan lotion to avoid possible damage

to the interior painted surfaces.

• Do not allow air fresheners and hand sanitizers to spill onto interior surfaces.

If a spill occurs, wipe off immediately.

Your warranty may not cover these

damages.

If a staining liquid like coffee or juice has

been spilled on the instrument panel or on

interior trim surfaces:

1. Wipe up spilled liquid using a clean, soft cloth as quickly as possible. 2. Use Motorcraft Premium Leather and

Vinyl Cleaner or a commercially available

leather cleaning product for automotive

interiors. Test any cleaner or stain

remover on an inconspicuous area.

3. Alternatively, wipe the surface with a clean, soft cloth and a mild soap and

water solution. Dry the area with a clean,

soft cloth.

4. If necessary, apply more soap and water solution or cleaning product to a clean,

soft cloth and press it onto the soiled

area. Allow this to set at room

temperature for 30 minutes.

5. Remove the soaked cloth, then with a clean, damp cloth, use a rubbing motion

for 60 seconds on the soiled area.

6. Dry the area with a clean, soft cloth.

310

Vehicle Care

Page 317 of 544

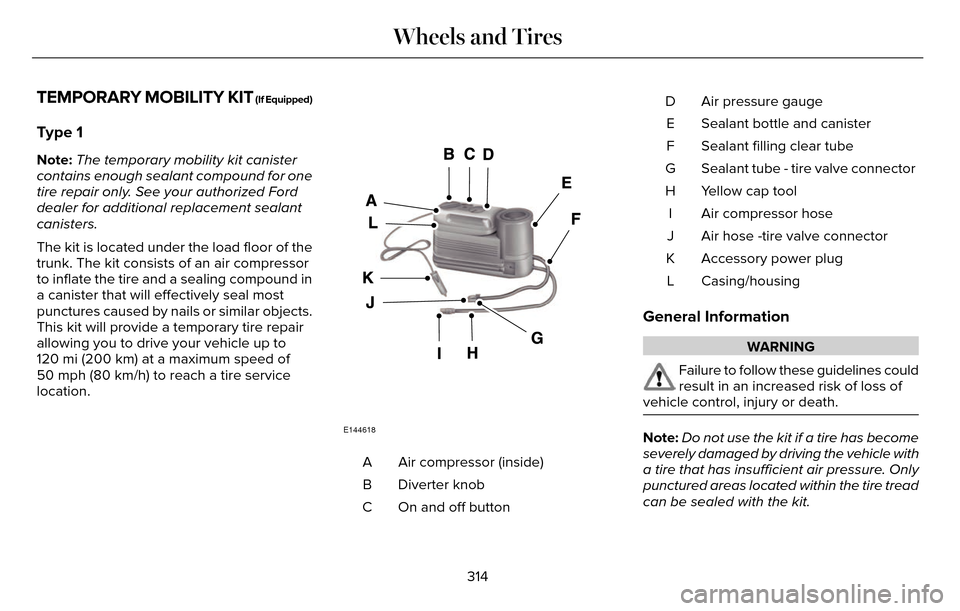

TEMPORARY MOBILITY KIT (If Equipped)

Type 1

Note:The temporary mobility kit canister

contains enough sealant compound for one

tire repair only. See your authorized Ford

dealer for additional replacement sealant

canisters.

The kit is located under the load floor of the

trunk. The kit consists of an air compressor

to inflate the tire and a sealing compound in

a canister that will effectively seal most

punctures caused by nails or similar objects.

This kit will provide a temporary tire repair

allowing you to drive your vehicle up to

120 mi (200 km) at a maximum speed of

50 mph (80 km/h) to reach a tire service

location.

E144618

Air compressor (inside)

A

Diverter knob

B

On and off button

C Air pressure gauge

D

Sealant bottle and canister

E

Sealant filling clear tube

F

Sealant tube - tire valve connector

G

Yellow cap tool

H

Air compressor hose

I

Air hose -tire valve connector

J

Accessory power plug

K

Casing/housing

L

General Information

WARNING

Failure to follow these guidelines could

result in an increased risk of loss of

vehicle control, injury or death.

Note: Do not use the kit if a tire has become

severely damaged by driving the vehicle with

a tire that has insufficient air pressure. Only

punctured areas located within the tire tread

can be sealed with the kit.

314

Wheels and Tires

Page 319 of 544

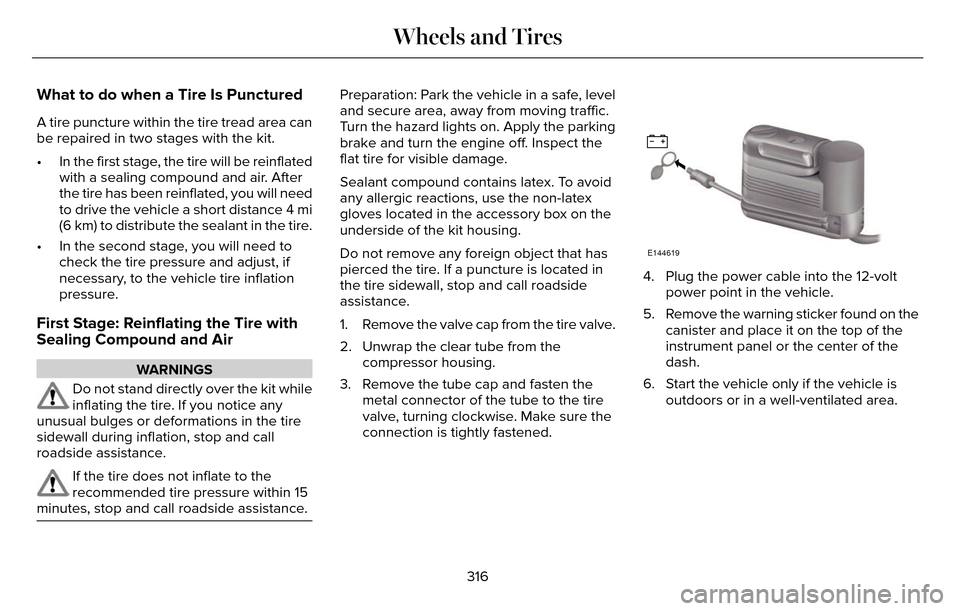

What to do when a Tire Is Punctured

A tire puncture within the tire tread area can

be repaired in two stages with the kit.

• In the first stage, the tire will be reinflatedwith a sealing compound and air. After

the tire has been reinflated, you will need

to drive the vehicle a short distance 4 mi

(6 km) to distribute the sealant in the tire.

• In the second stage, you will need to check the tire pressure and adjust, if

necessary, to the vehicle tire inflation

pressure.

First Stage: Reinflating the Tire with

Sealing Compound and Air

WARNINGS

Do not stand directly over the kit while

inflating the tire. If you notice any

unusual bulges or deformations in the tire

sidewall during inflation, stop and call

roadside assistance.

If the tire does not inflate to the

recommended tire pressure within 15

minutes, stop and call roadside assistance.

Preparation: Park the vehicle in a safe, level

and secure area, away from moving traffic.

Turn the hazard lights on. Apply the parking

brake and turn the engine off. Inspect the

flat tire for visible damage.

Sealant compound contains latex. To avoid

any allergic reactions, use the non-latex

gloves located in the accessory box on the

underside of the kit housing.

Do not remove any foreign object that has

pierced the tire. If a puncture is located in

the tire sidewall, stop and call roadside

assistance.

1. Remove the valve cap from the tire valve.

2. Unwrap the clear tube from the compressor housing.

3. Remove the tube cap and fasten the metal connector of the tube to the tire

valve, turning clockwise. Make sure the

connection is tightly fastened.

E144619

4. Plug the power cable into the 12-voltpower point in the vehicle.

5. Remove the warning sticker found on the canister and place it on the top of the

instrument panel or the center of the

dash.

6. Start the vehicle only if the vehicle is outdoors or in a well-ventilated area.

316

Wheels and Tires

Page 320 of 544

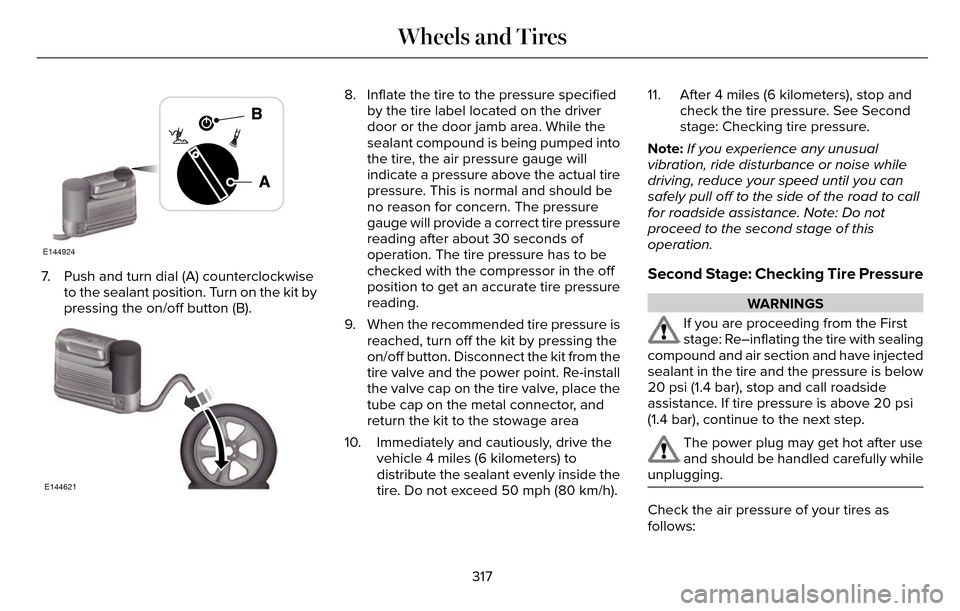

E144924

7. Push and turn dial (A) counterclockwiseto the sealant position. Turn on the kit by

pressing the on/off button (B).

E144621

8. Inflate the tire to the pressure specifiedby the tire label located on the driver

door or the door jamb area. While the

sealant compound is being pumped into

the tire, the air pressure gauge will

indicate a pressure above the actual tire

pressure. This is normal and should be

no reason for concern. The pressure

gauge will provide a correct tire pressure

reading after about 30 seconds of

operation. The tire pressure has to be

checked with the compressor in the off

position to get an accurate tire pressure

reading.

9. When the recommended tire pressure is reached, turn off the kit by pressing the

on/off button. Disconnect the kit from the

tire valve and the power point. Re-install

the valve cap on the tire valve, place the

tube cap on the metal connector, and

return the kit to the stowage area

10. Immediately and cautiously, drive the vehicle 4 miles (6 kilometers) to

distribute the sealant evenly inside the

tire. Do not exceed 50 mph (80 km/h). 11. After 4 miles (6 kilometers), stop and

check the tire pressure. See Second

stage: Checking tire pressure.

Note: If you experience any unusual

vibration, ride disturbance or noise while

driving, reduce your speed until you can

safely pull off to the side of the road to call

for roadside assistance. Note: Do not

proceed to the second stage of this

operation.

Second Stage: Checking Tire Pressure

WARNINGS

If you are proceeding from the First

stage: Re–inflating the tire with sealing

compound and air section and have injected

sealant in the tire and the pressure is below

20 psi (1.4 bar), stop and call roadside

assistance. If tire pressure is above 20 psi

(1.4 bar), continue to the next step.

The power plug may get hot after use

and should be handled carefully while

unplugging.

Check the air pressure of your tires as

follows:

317

Wheels and Tires

Page 324 of 544

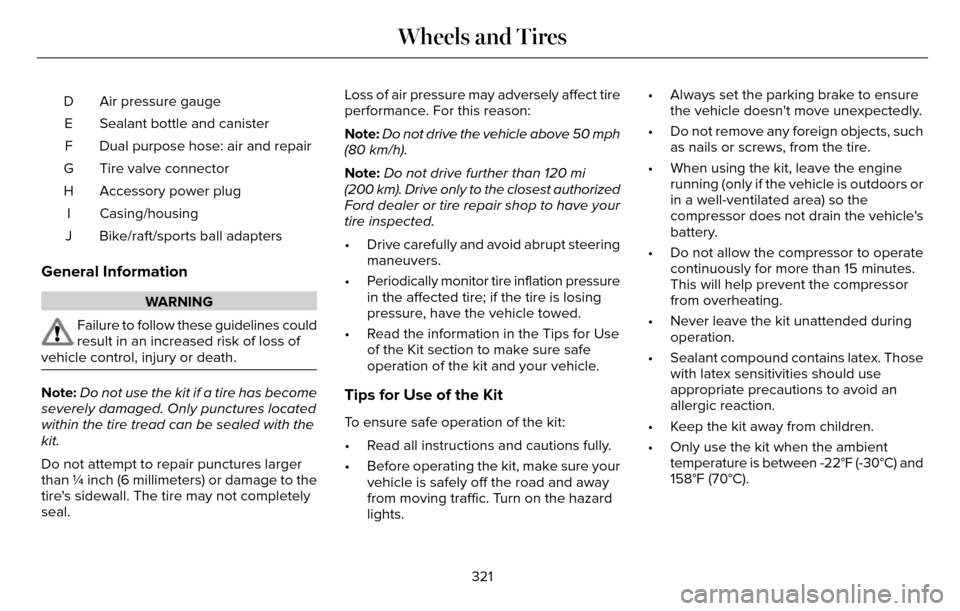

Air pressure gauge

D

Sealant bottle and canister

E

Dual purpose hose: air and repair

F

Tire valve connector

G

Accessory power plug

H

Casing/housing

I

Bike/raft/sports ball adapters

J

General Information

WARNING

Failure to follow these guidelines could

result in an increased risk of loss of

vehicle control, injury or death.

Note: Do not use the kit if a tire has become

severely damaged. Only punctures located

within the tire tread can be sealed with the

kit.

Do not attempt to repair punctures larger

than ¼ inch (6 millimeters) or damage to the

tire's sidewall. The tire may not completely

seal. Loss of air pressure may adversely affect tire

performance. For this reason:

Note:

Do not drive the vehicle above 50 mph

(80 km/h).

Note: Do not drive further than 120 mi

(200 km). Drive only to the closest authorized

Ford dealer or tire repair shop to have your

tire inspected.

• Drive carefully and avoid abrupt steering maneuvers.

• Periodically monitor tire inflation pressure in the affected tire; if the tire is losing

pressure, have the vehicle towed.

• Read the information in the Tips for Use of the Kit section to make sure safe

operation of the kit and your vehicle.Tips for Use of the Kit

To ensure safe operation of the kit:

• Read all instructions and cautions fully.

• Before operating the kit, make sure yourvehicle is safely off the road and away

from moving traffic. Turn on the hazard

lights. • Always set the parking brake to ensure

the vehicle doesn't move unexpectedly.

• Do not remove any foreign objects, such as nails or screws, from the tire.

• When using the kit, leave the engine running (only if the vehicle is outdoors or

in a well-ventilated area) so the

compressor does not drain the vehicle's

battery.

• Do not allow the compressor to operate continuously for more than 15 minutes.

This will help prevent the compressor

from overheating.

• Never leave the kit unattended during operation.

• Sealant compound contains latex. Those with latex sensitivities should use

appropriate precautions to avoid an

allergic reaction.

• Keep the kit away from children.

• Only use the kit when the ambient temperature is between -22°F (-30°C) and

158°F (70°C).

321

Wheels and Tires

Page 325 of 544

• Only use the sealing compound beforethe use-by date. The use-by date is on a

label on the sealant canister and can be

seen through the rectangular viewing

window on the bottom of the compressor.

Check the use-by date regularly and

replace the canister after four years of

non-use.

• Do not store the kit unsecured inside the passenger compartment of the vehicle

as it may cause injury during a sudden

stop or crash. Always store the kit in its

original location.

• After sealant use, the tire pressure monitoring system sensor and valve stem

on the wheel must be replaced by an

authorized Ford dealer.

• Operating the kit could cause an electrical disturbance in radio, CD, and

DVD player operation.

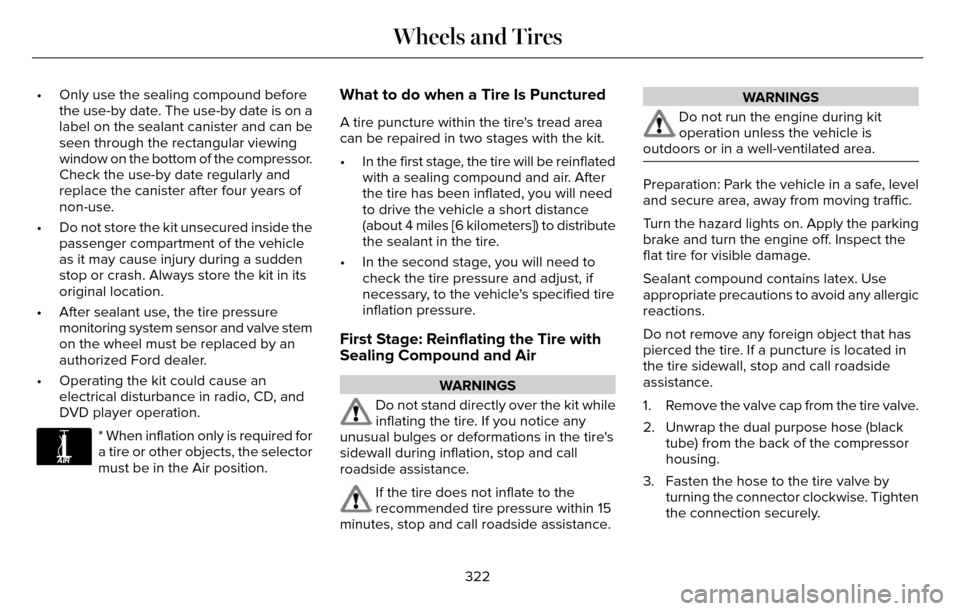

E175978

* When inflation only is required for

a tire or other objects, the selector

must be in the Air position.

What to do when a Tire Is Punctured

A tire puncture within the tire's tread area

can be repaired in two stages with the kit.

• In the first stage, the tire will be reinflatedwith a sealing compound and air. After

the tire has been inflated, you will need

to drive the vehicle a short distance

(about 4 miles [6 kilometers]) to distribute

the sealant in the tire.

• In the second stage, you will need to check the tire pressure and adjust, if

necessary, to the vehicle's specified tire

inflation pressure.

First Stage: Reinflating the Tire with

Sealing Compound and Air

WARNINGS

Do not stand directly over the kit while

inflating the tire. If you notice any

unusual bulges or deformations in the tire's

sidewall during inflation, stop and call

roadside assistance.

If the tire does not inflate to the

recommended tire pressure within 15

minutes, stop and call roadside assistance.

WARNINGS

Do not run the engine during kit

operation unless the vehicle is

outdoors or in a well-ventilated area.

Preparation: Park the vehicle in a safe, level

and secure area, away from moving traffic.

Turn the hazard lights on. Apply the parking

brake and turn the engine off. Inspect the

flat tire for visible damage.

Sealant compound contains latex. Use

appropriate precautions to avoid any allergic

reactions.

Do not remove any foreign object that has

pierced the tire. If a puncture is located in

the tire sidewall, stop and call roadside

assistance.

1. Remove the valve cap from the tire valve.

2. Unwrap the dual purpose hose (black tube) from the back of the compressor

housing.

3. Fasten the hose to the tire valve by turning the connector clockwise. Tighten

the connection securely.

322

Wheels and Tires

Page 326 of 544

E175979

4. Plug the power cable into the 12-voltpower point in the vehicle. 5. Remove the warning sticker found on the

casing/housing and place it on the top of

the instrument panel or the center of the

dash.

6. Start the vehicle leave the engine running so the compressor does not drain the

vehicle’s battery.

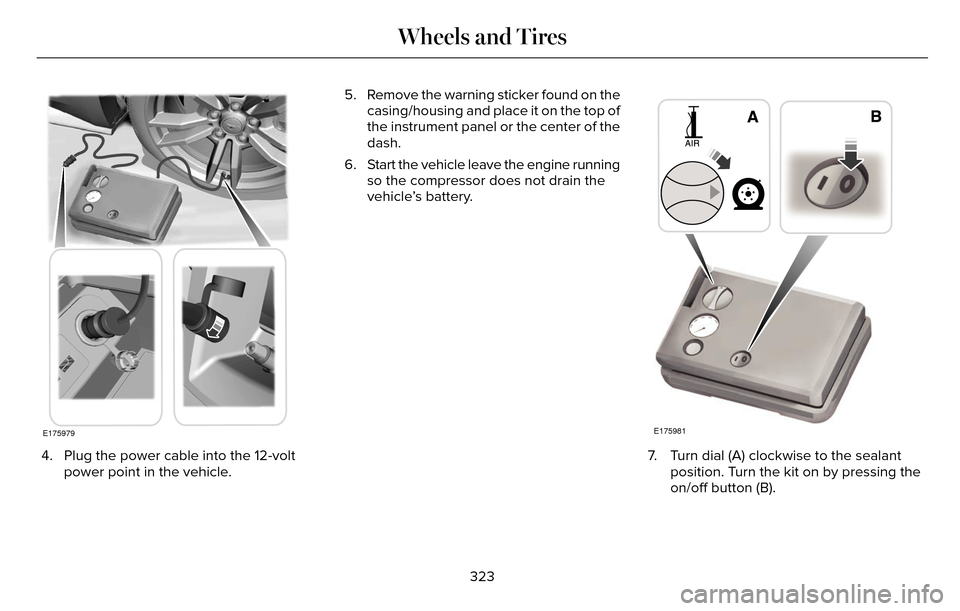

E175981

7. Turn dial (A) clockwise to the sealantposition. Turn the kit on by pressing the

on/off button (B).

323

Wheels and Tires

Page 328 of 544

Second Stage: Checking Tire Pressure

WARNINGS

If you are proceeding from the First

Stage: Re-inflating the Tire with Sealing

Compound and Air section and have injected

sealant in the tire and the pressure is below

20 psi (1.4 bar), continue to the next step.

The power plug may get hot after use

and should be handled carefully while

unplugging.

Check the air pressure of your tires as

follows:

E175983

1. Remove the valve cap from the tire valve. 2. Firmly screw the air compressor hose

onto the valve stem by turning clockwise.

3. Push and turn the dial clockwise to the air position.

4. If required, turn on the compressor and adjust the tire to the recommended

inflation pressure shown on the tire label

located on the driver's door or door jamb

area. The tire pressure should be

checked with the compressor turned OFF

in order to get an accurate pressure

reading.

5. Unplug the hoses, re-install the valve cap on the tire and return the kit to the

stowage area.

What to do after the Tire has been

Sealed

After using the kit to seal your tire, you will

need to replace the sealant canister. Sealant

canisters and spare parts can be obtained

at an authorized Ford dealer. Empty sealant

canisters may be disposed of at home.

However, canisters still containing liquid

sealant should be disposed of by your local

authorized Ford dealer or tire dealer, or in

accordance with local waste disposal

regulation.

Note: After the sealing compound has been

used, the maximum vehicle speed is 50 mph

(80 km/h) and the maximum driving distance

is 120 mi (200 km). The sealed tire should

be inspected immediately.

You can check the tire pressure any time

within the 120 mi (200 km) by performing the

steps listed previously in the Second stage:

Checking Tire Pressure procedure.

325

Wheels and Tires

Page 331 of 544

Tire Quality Grades apply to new

pneumatic passenger car tires. The

Quality grades can be found where

applicable on the tire sidewall between

tread shoulder and maximum section

width. For example: Treadwear 200

Traction AA Temperature A.

These Tire Quality Grades are

determined by standards that the United

States Department of Transportation has

set.

Tire Quality Grades apply to new

pneumatic passenger car tires. They do

not apply to deep tread, winter-type

snow tires, space-saver or temporary

use spare tires, light truck or LT type

tires, tires with nominal rim diameters of

10 to 12 inches or limited production tires

as defined in Title 49 Code of Federal

Regulations Part 575.104 (c)(2).

U.S. Department of Transportation Tire

quality grades: The U.S. Department of

Transportation requires Ford Motor

Company to give you the following

information about tire grades exactly as

the government has written it.Treadwear

The treadwear grade is a comparative

rating based on the wear rate of the tire

when tested under controlled conditions

on a specified government test course.

For example, a tire graded 150 would

wear 1 ½ times as well on the

government course as a tire graded 100.

The relative performance of tires

depends upon the actual conditions of

their use, however, and may depart

significantly from the norm due to

variations in driving habits, service

practices, and differences in road

characteristics and climate.

Traction AA A B C

WARNING

The traction grade assigned to this

tire is based on straight-ahead

braking traction tests, and does not

include acceleration, cornering,

hydroplaning or peak traction

characteristics.

The traction grades, from highest to

lowest are AA, A, B, and C. The grades

represent the tire’s ability to stop on wet

pavement as measured under controlled

conditions on specified government test

surfaces of asphalt and concrete. A tire

marked C may have poor traction

performance.

Temperature A B C

WARNING

The temperature grade for this tire

is established for a tire that is

properly inflated and not overloaded.

Excessive speed, underinflation, or

excessive loading, either separately or

in combination, can cause heat buildup

and possible tire failure.

The temperature grades are A (the

highest), B and C, representing the tire’s

resistance to the generation of heat and

its ability to dissipate heat when tested

under controlled conditions on a

specified indoor laboratory test wheel.

Sustained high temperature can cause

328

Wheels and Tires