wheel LINCOLN MKZ 2017 Owners Manual

[x] Cancel search | Manufacturer: LINCOLN, Model Year: 2017, Model line: MKZ, Model: LINCOLN MKZ 2017Pages: 564, PDF Size: 5.54 MB

Page 363 of 564

3.

Block both the front and rear of the wheel

diagonally opposite the flat tire. For

example, if the left front tire is flat, block

the right rear wheel.

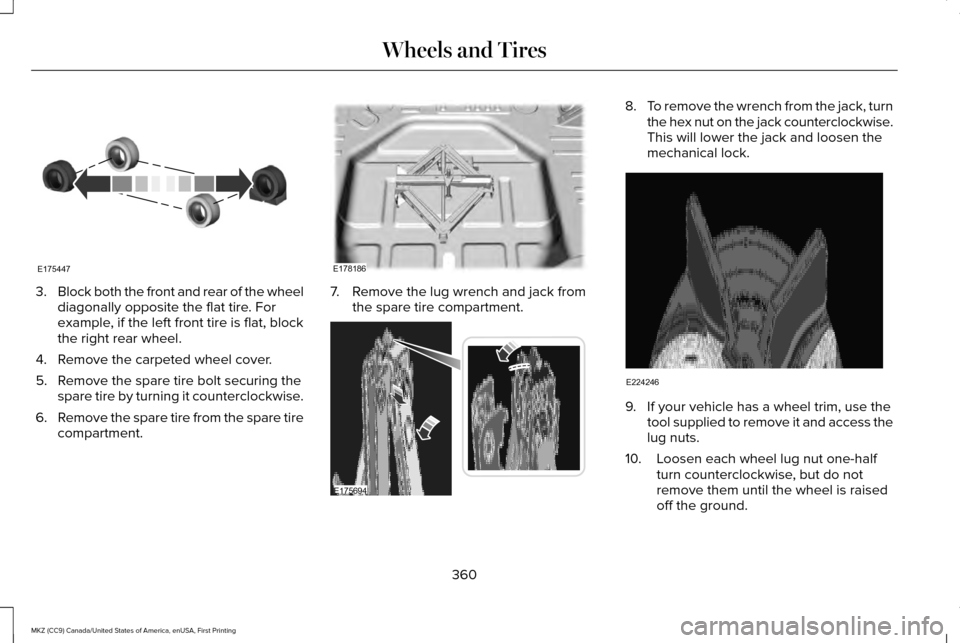

4. Remove the carpeted wheel cover.

5. Remove the spare tire bolt securing the spare tire by turning it counterclockwise.

6. Remove the spare tire from the spare tire

compartment. 7. Remove the lug wrench and jack from

the spare tire compartment. 8.

To remove the wrench from the jack, turn

the hex nut on the jack counterclockwise.

This will lower the jack and loosen the

mechanical lock. 9. If your vehicle has a wheel trim, use the

tool supplied to remove it and access the

lug nuts.

10. Loosen each wheel lug nut one-half turn counterclockwise, but do not

remove them until the wheel is raised

off the ground.

360

MKZ (CC9) Canada/United States of America, enUSA, First Printing Wheels and TiresE175447 E178186 E175694 E224246

Page 364 of 564

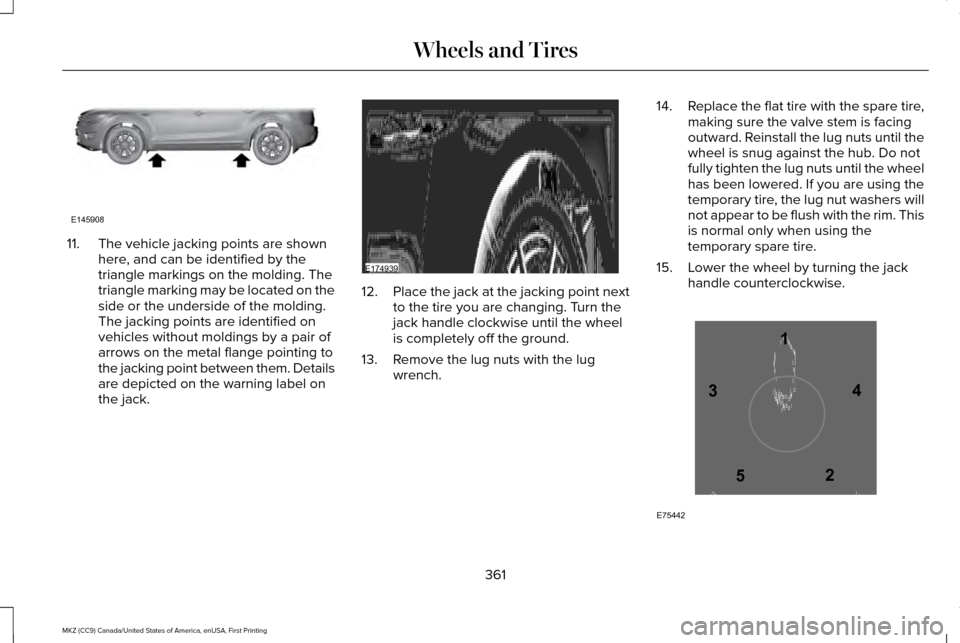

11. The vehicle jacking points are shown

here, and can be identified by the

triangle markings on the molding. The

triangle marking may be located on the

side or the underside of the molding.

The jacking points are identified on

vehicles without moldings by a pair of

arrows on the metal flange pointing to

the jacking point between them. Details

are depicted on the warning label on

the jack. 12.

Place the jack at the jacking point next

to the tire you are changing. Turn the

jack handle clockwise until the wheel

is completely off the ground.

13. Remove the lug nuts with the lug wrench. 14.

Replace the flat tire with the spare tire,

making sure the valve stem is facing

outward. Reinstall the lug nuts until the

wheel is snug against the hub. Do not

fully tighten the lug nuts until the wheel

has been lowered. If you are using the

temporary tire, the lug nut washers will

not appear to be flush with the rim. This

is normal only when using the

temporary spare tire.

15. Lower the wheel by turning the jack handle counterclockwise. 361

MKZ (CC9) Canada/United States of America, enUSA, First Printing Wheels and TiresE145908 E174939 12

3

4

5

E75442

Page 365 of 564

16. Remove the jack and fully tighten the

lug nuts in the order shown. See Technical Specifications (page 365).17.

To store the folded wrench on the jack,

engage the bracket of the jack base on

the wrench feature as shown. Swing

the wrench upward and adjust the

height of the jack until the pin engages

the hole. Tighten the hex nut clockwise

by hand until secure. 18. Put the flat tire, jack and lug wrench

away. Make sure the jack is fastened

securely before you drive.

19. Unblock the wheel.

362

MKZ (CC9) Canada/United States of America, enUSA, First Printing Wheels and TiresE176165

Page 366 of 564

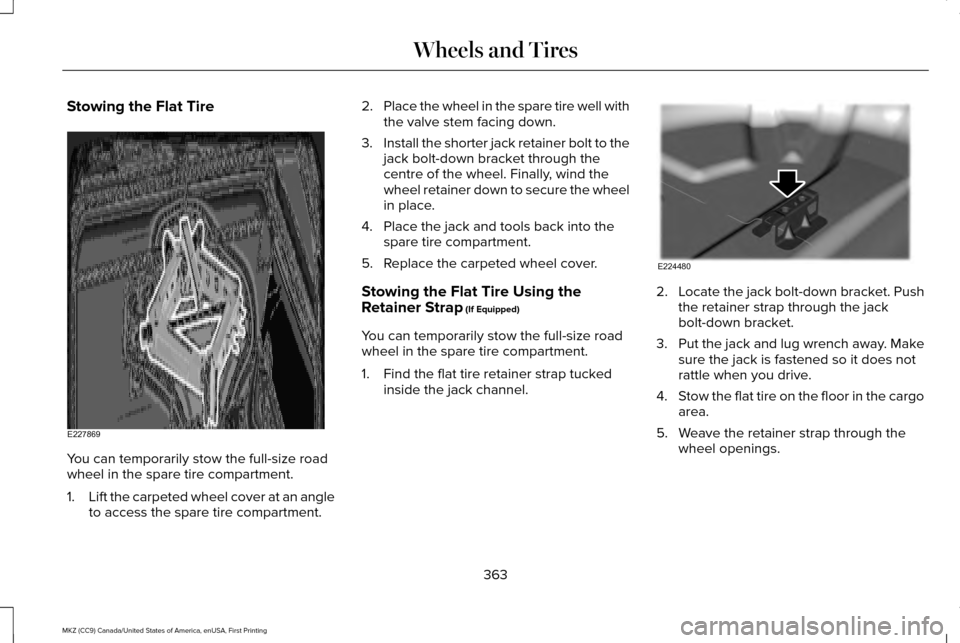

Stowing the Flat Tire

You can temporarily stow the full-size road

wheel in the spare tire compartment.

1.

Lift the carpeted wheel cover at an angle

to access the spare tire compartment. 2.

Place the wheel in the spare tire well with

the valve stem facing down.

3. Install the shorter jack retainer bolt to the

jack bolt-down bracket through the

centre of the wheel. Finally, wind the

wheel retainer down to secure the wheel

in place.

4. Place the jack and tools back into the spare tire compartment.

5. Replace the carpeted wheel cover.

Stowing the Flat Tire Using the

Retainer Strap (If Equipped)

You can temporarily stow the full-size road

wheel in the spare tire compartment.

1. Find the flat tire retainer strap tucked inside the jack channel. 2.

Locate the jack bolt-down bracket. Push

the retainer strap through the jack

bolt-down bracket.

3. Put the jack and lug wrench away. Make

sure the jack is fastened so it does not

rattle when you drive.

4. Stow the flat tire on the floor in the cargo

area.

5. Weave the retainer strap through the wheel openings.

363

MKZ (CC9) Canada/United States of America, enUSA, First Printing Wheels and TiresE227869 E224480

Page 367 of 564

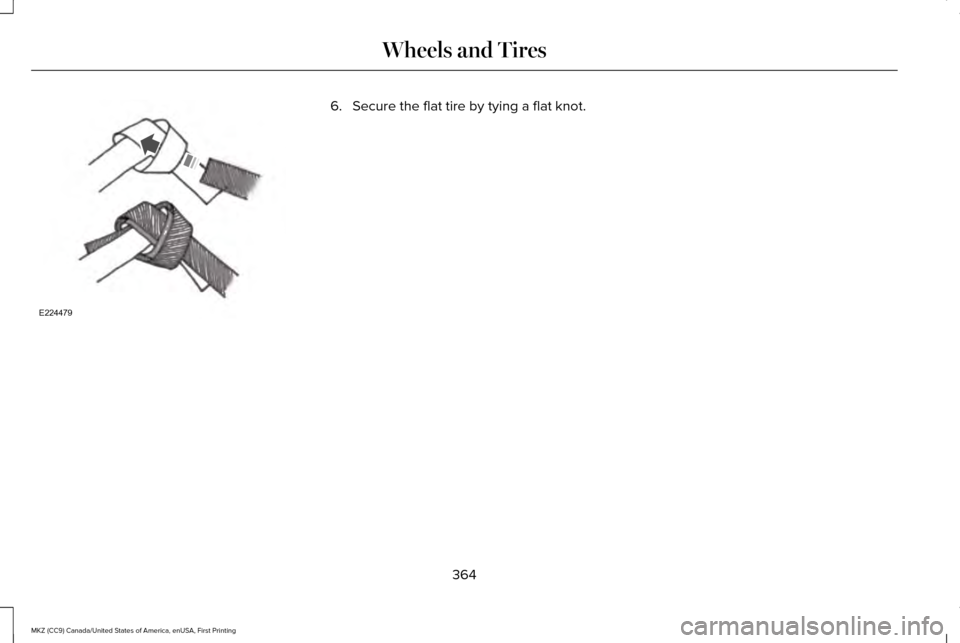

6. Secure the flat tire by tying a flat knot.

364

MKZ (CC9) Canada/United States of America, enUSA, First Printing Wheels and TiresE224479

Page 368 of 564

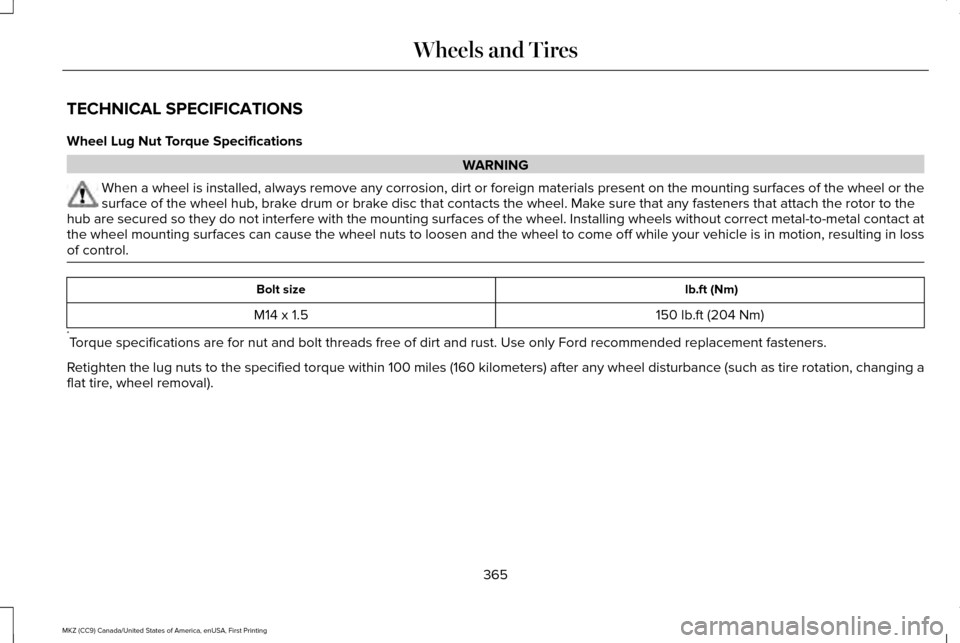

TECHNICAL SPECIFICATIONS

Wheel Lug Nut Torque Specifications

WARNING

When a wheel is installed, always remove any corrosion, dirt or foreign \

materials present on the mounting surfaces of the wheel or the

surface of the wheel hub, brake drum or brake disc that contacts the wheel. Make sure that any fasteners that attach the rotor to the

hub are secured so they do not interfere with the mounting surfaces of t\

he wheel. Installing wheels without correct metal-to-metal contact at

the wheel mounting surfaces can cause the wheel nuts to loosen and the w\

heel to come off while your vehicle is in motion, resulting in loss

of control. lb.ft (Nm)

Bolt size

150 lb.ft (204 Nm)

M14 x 1.5

* Torque specifications are for nut and bolt threads free of dirt and rust.\

Use only Ford recommended replacement fasteners.

Retighten the lug nuts to the specified torque within 100 miles (160 kil\

ometers) after any wheel disturbance (such as tire rotation, changing \

a

flat tire, wheel removal).

365

MKZ (CC9) Canada/United States of America, enUSA, First Printing Wheels and Tires

Page 369 of 564

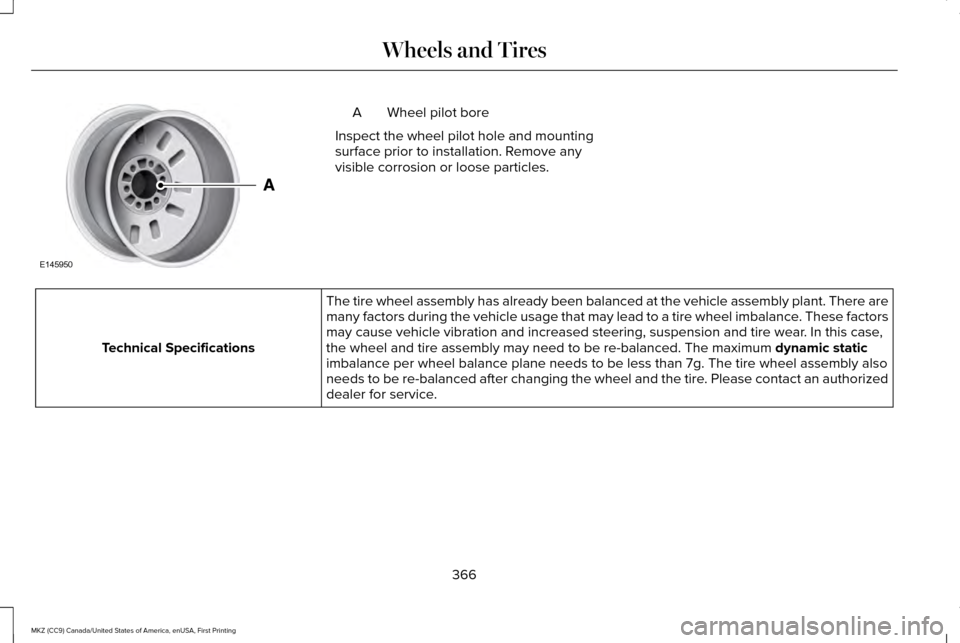

Wheel pilot bore

A

Inspect the wheel pilot hole and mounting

surface prior to installation. Remove any

visible corrosion or loose particles. The tire wheel assembly has already been balanced at the vehicle assembl\

y plant. There are

many factors during the vehicle usage that may lead to a tire wheel imba\

lance. These factors

may cause vehicle vibration and increased steering, suspension and tire \

wear. In this case,

the wheel and tire assembly may need to be re-balanced. The maximum dynamic static

imbalance per wheel balance plane needs to be less than 7g. The tire whe\

el assembly also

needs to be re-balanced after changing the wheel and the tire. Please contact an authorized

dealer for service.

Technical Specifications

366

MKZ (CC9) Canada/United States of America, enUSA, First Printing Wheels and TiresE145950

Page 377 of 564

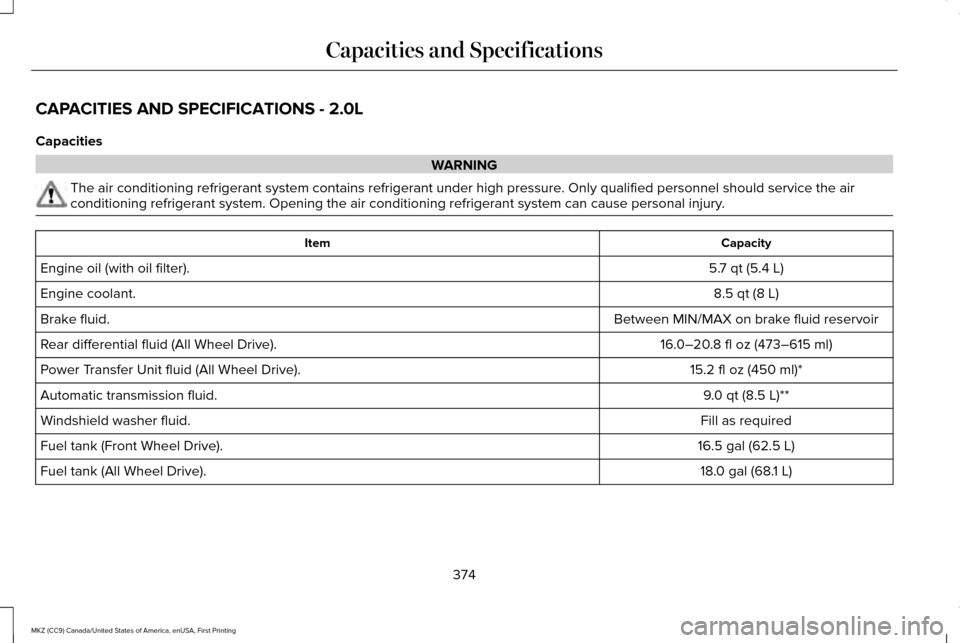

CAPACITIES AND SPECIFICATIONS - 2.0L

Capacities

WARNING

The air conditioning refrigerant system contains refrigerant under high \

pressure. Only qualified personnel should service the air

conditioning refrigerant system. Opening the air conditioning refrigeran\

t system can cause personal injury.

Capacity

Item

5.7 qt (5.4 L)

Engine oil (with oil filter).

8.5 qt (8 L)

Engine coolant.

Between MIN/MAX on brake fluid reservoir

Brake fluid.

16.0–20.8 fl oz (473–615 ml)

Rear differential fluid (All Wheel Drive).

15.2 fl oz (450 ml)*

Power Transfer Unit fluid (All Wheel Drive).

9.0 qt (8.5 L)

**

Automatic transmission fluid.

Fill as required

Windshield washer fluid.

16.5 gal (62.5 L)

Fuel tank (Front Wheel Drive).

18.0 gal (68.1 L)

Fuel tank (All Wheel Drive).

374

MKZ (CC9) Canada/United States of America, enUSA, First Printing Capacities and Specifications

Page 379 of 564

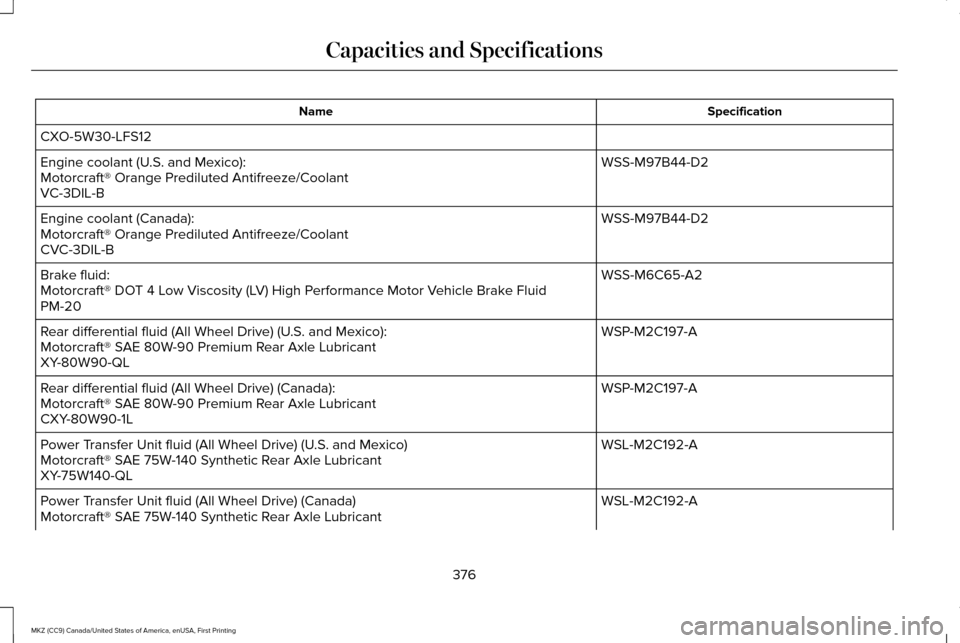

Specification

Name

CXO-5W30-LFS12 WSS-M97B44-D2

Engine coolant (U.S. and Mexico):

Motorcraft® Orange Prediluted Antifreeze/Coolant

VC-3DIL-B

WSS-M97B44-D2

Engine coolant (Canada):

Motorcraft® Orange Prediluted Antifreeze/Coolant

CVC-3DIL-B

WSS-M6C65-A2

Brake fluid:

Motorcraft® DOT 4 Low Viscosity (LV) High Performance Motor Vehicle Brake Fluid

PM-20

WSP-M2C197-A

Rear differential fluid (All Wheel Drive) (U.S. and Mexico):

Motorcraft® SAE 80W-90 Premium Rear Axle Lubricant

XY-80W90-QL

WSP-M2C197-A

Rear differential fluid (All Wheel Drive) (Canada):

Motorcraft® SAE 80W-90 Premium Rear Axle Lubricant

CXY-80W90-1L

WSL-M2C192-A

Power Transfer Unit fluid (All Wheel Drive) (U.S. and Mexico)

Motorcraft® SAE 75W-140 Synthetic Rear Axle Lubricant

XY-75W140-QL

WSL-M2C192-A

Power Transfer Unit fluid (All Wheel Drive) (Canada)

Motorcraft® SAE 75W-140 Synthetic Rear Axle Lubricant

376

MKZ (CC9) Canada/United States of America, enUSA, First Printing Capacities and Specifications

Page 382 of 564

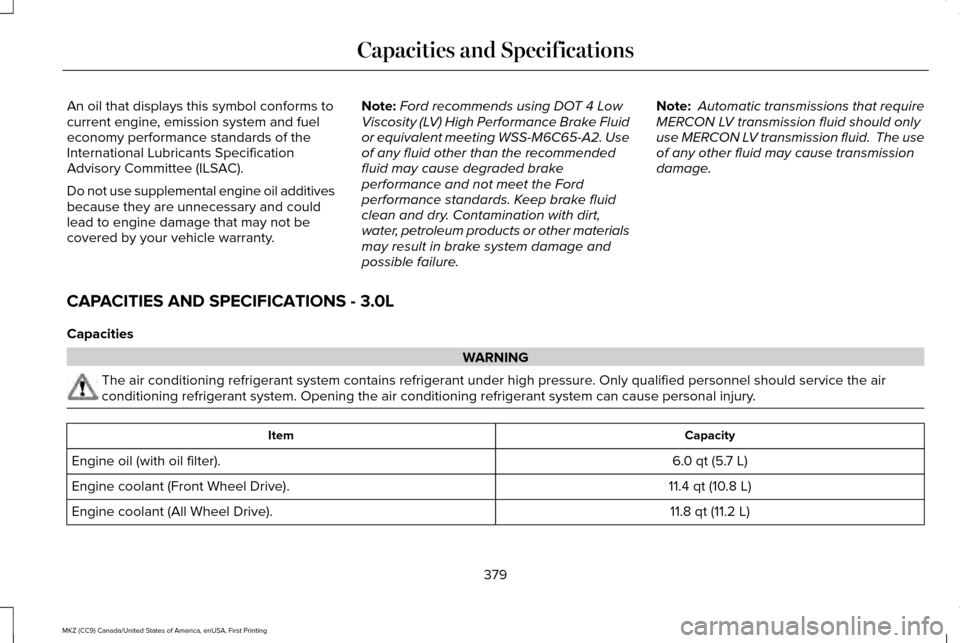

An oil that displays this symbol conforms to

current engine, emission system and fuel

economy performance standards of the

International Lubricants Specification

Advisory Committee (ILSAC).

Do not use supplemental engine oil additives

because they are unnecessary and could

lead to engine damage that may not be

covered by your vehicle warranty.

Note:

Ford recommends using DOT 4 Low

Viscosity (LV) High Performance Brake Fluid

or equivalent meeting WSS-M6C65-A2. Use

of any fluid other than the recommended

fluid may cause degraded brake

performance and not meet the Ford

performance standards. Keep brake fluid

clean and dry. Contamination with dirt,

water, petroleum products or other materials

may result in brake system damage and

possible failure. Note:

Automatic transmissions that require

MERCON LV transmission fluid should only

use MERCON LV transmission fluid. The use

of any other fluid may cause transmission

damage.

CAPACITIES AND SPECIFICATIONS - 3.0L

Capacities WARNING

The air conditioning refrigerant system contains refrigerant under high \

pressure. Only qualified personnel should service the air

conditioning refrigerant system. Opening the air conditioning refrigeran\

t system can cause personal injury.

Capacity

Item

6.0 qt (5.7 L)

Engine oil (with oil filter).

11.4 qt (10.8 L)

Engine coolant (Front Wheel Drive).

11.8 qt (11.2 L)

Engine coolant (All Wheel Drive).

379

MKZ (CC9) Canada/United States of America, enUSA, First Printing Capacities and Specifications