lock LINCOLN NAVIGATOR 2018 Owners Manual

[x] Cancel search | Manufacturer: LINCOLN, Model Year: 2018, Model line: NAVIGATOR, Model: LINCOLN NAVIGATOR 2018Pages: 649, PDF Size: 4.96 MB

Page 378 of 649

Note:For flexible fuel vehicles, if you areoperating on E85, you may experience poorstarts or an inability to start the engine anddriveability problems until the fuel trim andethanol content have been relearned.

Make sure that you dispose of old batteriesin an environmentally friendly way. Seekadvice from your local authority aboutrecycling old batteries.

If storing your vehicle for more than 30 dayswithout recharging the battery, werecommend that you disconnect the negativebattery cable to maintain battery charge forquick starting.

Battery Management System (If Equipped)

The battery management system monitorsbattery conditions and takes actions toextend battery life. If excessive battery drainis detected, the system temporarily disablessome electrical systems to protect thebattery.

Systems included are:

•Heated rear window.

•Heated seats.

•Climate control.

•Heated steering wheel.

•Audio unit.

•Navigation system.

A message may appear in the informationdisplays to alert you that battery protectionactions are active. These messages are onlyfor notification that an action is taking place,and not intended to indicate an electricalproblem or that the battery requiresreplacement.

After battery replacement, or in some casesafter charging the battery with an externalcharger, the battery management systemrequires eight hours of vehicle sleep time torelearn the battery state of charge. Duringthis time your vehicle must remain fullylocked with the ignition switched off.

Note:Prior to relearning the battery state ofcharge, the battery management systemmay temporarily disable some electricalsystems.

Electrical Accessory Installation

To make sure the battery managementsystem works correctly, do not connect anelectrical device ground connection directlyto the battery negative post. This can causeinaccurate measurements of the batterycondition and potential incorrect systemoperation.

Note:If you add electrical accessories orcomponents to the vehicle, it may adverselyaffect battery performance and durability.This may also affect the performance ofother electrical systems in the vehicle.

CHECKING THE WIPER BLADES

375

Navigator (TB9) Canada/United States of America, enUSA, Edition date: 201708, Third-Printing-

MaintenanceE142463

Page 379 of 649

Run the tip of your fingers over the edge ofthe blade to check for roughness.

Clean the wiper blades with washer fluid orwater applied with a soft sponge or cloth.

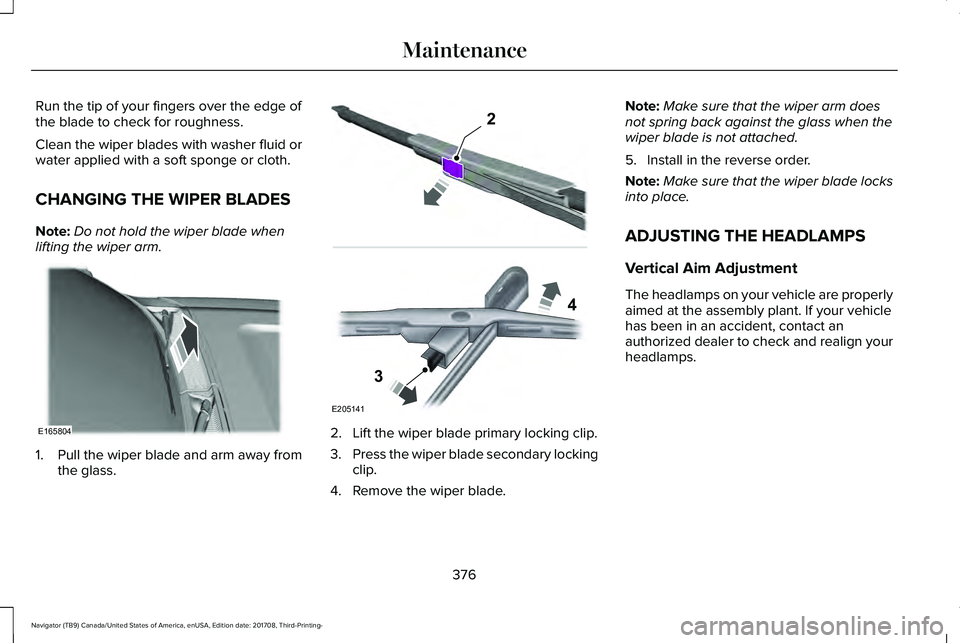

CHANGING THE WIPER BLADES

Note:Do not hold the wiper blade whenlifting the wiper arm.

1. Pull the wiper blade and arm away fromthe glass.

2. Lift the wiper blade primary locking clip.

3.Press the wiper blade secondary lockingclip.

4. Remove the wiper blade.

Note:Make sure that the wiper arm doesnot spring back against the glass when thewiper blade is not attached.

5. Install in the reverse order.

Note:Make sure that the wiper blade locksinto place.

ADJUSTING THE HEADLAMPS

Vertical Aim Adjustment

The headlamps on your vehicle are properlyaimed at the assembly plant. If your vehiclehas been in an accident, contact anauthorized dealer to check and realign yourheadlamps.

376

Navigator (TB9) Canada/United States of America, enUSA, Edition date: 201708, Third-Printing-

MaintenanceE165804 E205141

2

3

4

Page 380 of 649

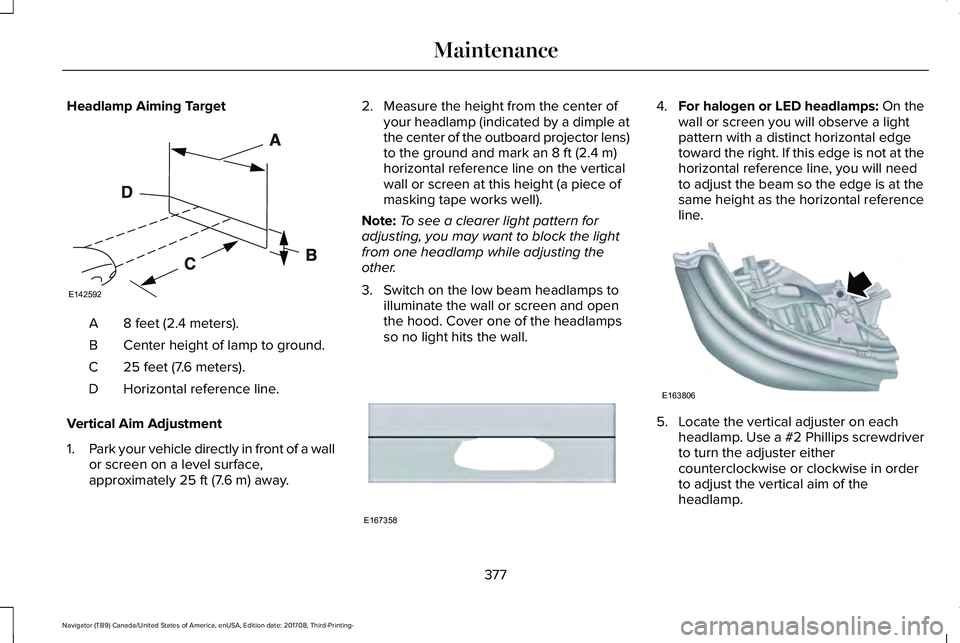

Headlamp Aiming Target

8 feet (2.4 meters).A

Center height of lamp to ground.B

25 feet (7.6 meters).C

Horizontal reference line.D

Vertical Aim Adjustment

1.Park your vehicle directly in front of a wallor screen on a level surface,approximately 25 ft (7.6 m) away.

2. Measure the height from the center ofyour headlamp (indicated by a dimple atthe center of the outboard projector lens)to the ground and mark an 8 ft (2.4 m)horizontal reference line on the verticalwall or screen at this height (a piece ofmasking tape works well).

Note:To see a clearer light pattern foradjusting, you may want to block the lightfrom one headlamp while adjusting theother.

3. Switch on the low beam headlamps toilluminate the wall or screen and openthe hood. Cover one of the headlampsso no light hits the wall.

4.For halogen or LED headlamps: On thewall or screen you will observe a lightpattern with a distinct horizontal edgetoward the right. If this edge is not at thehorizontal reference line, you will needto adjust the beam so the edge is at thesame height as the horizontal referenceline.

5. Locate the vertical adjuster on eachheadlamp. Use a #2 Phillips screwdriverto turn the adjuster eithercounterclockwise or clockwise in orderto adjust the vertical aim of theheadlamp.

377

Navigator (TB9) Canada/United States of America, enUSA, Edition date: 201708, Third-Printing-

MaintenanceE142592 E167358 E163806

Page 388 of 649

•Do not allow wax to come in contact withany non-body (low-gloss black) coloredtrim. The wax will discolor or stain theparts over time.

•Roof racks.

•Bumpers.

•Grained door handles.

•Side moldings.

•Mirror housings.

•Windshield cowl area.

•Do not apply wax to glass areas.

•After waxing, your car's paint should feelsmooth, and be free of streaks andsmudges.

CLEANING THE ENGINE

Engines are more efficient when they areclean because grease and dirt buildup keepthe engine warmer than normal.

When washing:

•Take care when using a power washerto clean the engine. The high-pressurefluid could penetrate the sealed partsand cause damage.

•Do not spray a hot engine with cold waterto avoid cracking the engine block orother engine components.

•Spray Motorcraft Engine Shampoo andDegreaser on all parts that requirecleaning and pressure rinse clean. InCanada, use Motorcraft Engine Shampoo.

•Never wash or rinse the engine while itis hot or running; water in the runningengine may cause internal damage.

•Never wash or rinse any ignition coil,spark plug wire or spark plug well, or thearea in and around these locations.

•Cover the battery, power distribution box,and air filter assembly to prevent waterdamage when cleaning the engine.

CLEANING THE WINDOWS AND

WIPER BLADES

Car wash chemicals and environmentalfallout can result in windshield and wiperblade contamination. Dirty windshield andwipers will result in poor windshield wiperoperation. Keep the windshield and wiperblades clean to maintain windshield wiperperformance.

To clean the windshield and wiper blades:

•Clean the windshield with a non-abrasiveglass cleaner. When cleaning the interiorof the windshield, avoid getting any glasscleaner on the instrument panel or doorpanels. Wipe any glass cleaner off thesesurfaces immediately.

•For windshields contaminated with treesap, chemicals, wax or bugs, clean theentire windshield using steel wool (nogreater than 0000 grade) in a circularmotion and rinse with water.

•Clean the wiper blades with isopropylrubbing alcohol or windshield washerconcentrate.

385

Navigator (TB9) Canada/United States of America, enUSA, Edition date: 201708, Third-Printing-

Vehicle Care

Page 419 of 649

LocationItem

Under the vehicle, just forward of the rear bumperSpare tire

Under the access panel located in the floor compartment behind therear seatJack and tool kit bag

Tire Change Procedure

WARNING: Only use replacementtires and wheels that are the same size,load index, speed rating and type (such asP-metric versus LT-metric or all-seasonversus all-terrain) as those originallyprovided by Ford. The recommended tireand wheel size may be found on either theSafety Compliance Certification Label(affixed to either the door hinge pillar,door-latch post, or the door edge thatmeets the door-latch post, next to thedriver's seating position), or the Tire Labelwhich is located on the B-Pillar or edge ofthe driver's door. If this information is notfound on these labels, then you shouldcontact your authorized dealer as soon as

possible. Use of any tire or wheel notrecommended by Ford can affect thesafety and performance of your vehicle,which could result in an increased risk ofloss of vehicle control, vehicle rollover,personal injury and death.

WARNING: When one of the frontwheels is off the ground, the transmissionalone will not prevent the vehicle frommoving or slipping off the jack, even if thetransmission is in park (P).

WARNING: To help prevent yourvehicle from moving when changing awheel, shift the transmission into park (P),set the parking brake and use anappropriate block or wheel chock tosecure the wheel diagonally opposite tothe wheel being changed. For example,when changing the front left wheel, placean appropriate block or wheel chock onthe right rear wheel.

WARNING: Do not attempt to changea tire on the side of the vehicle close tomoving traffic. Pull far enough off the roadto avoid the danger of being hit whenoperating the jack or changing the wheel.

416

Navigator (TB9) Canada/United States of America, enUSA, Edition date: 201708, Third-Printing-

Wheels and Tires

Page 420 of 649

WARNING: Always use the jackprovided as original equipment with yourvehicle. If using a jack other than the oneprovided, make sure the jack capacity isadequate for the vehicle weight, includingany vehicle cargo or modifications. If youare unsure if the jack capacity is adequate,contact the authorized dealer.

WARNING: Switch off the runningboards before jacking or placing any objectunder your vehicle. Never place your handbetween the extended running board andyour vehicle. A moving running board maycause injury.

WARNING: Only use the spare wheelcarrier to stow the wheel provided withyour vehicle. Other wheel sizes couldcause the spare wheel carrier to fail if itdoes not fit securely or is too heavy.

1.Park the vehicle on firm, level ground andactivate the hazard flashers.

2. Apply the parking brake, place thetransmission in park (P) and switch theignition off.

3.Block the wheels diagonally opposite theflat tire, for example, if the left front tireis flat, block the right rear wheel.

Removing the Jack and Tools

Note:Pay close attention to the orientationof the jack and tool kit bag, because it needsto be reinstalled after changing the tire.

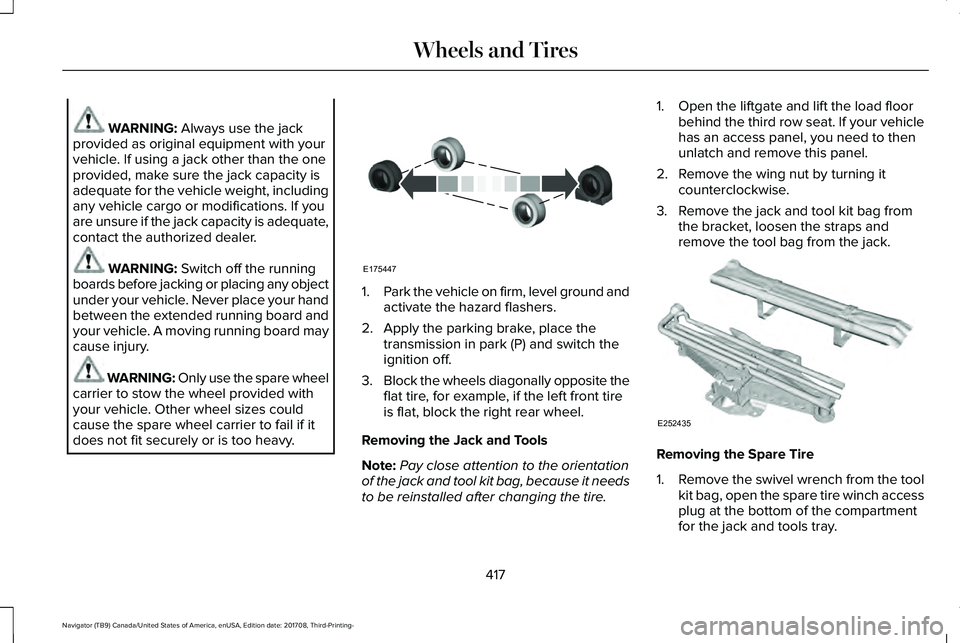

1. Open the liftgate and lift the load floorbehind the third row seat. If your vehiclehas an access panel, you need to thenunlatch and remove this panel.

2. Remove the wing nut by turning itcounterclockwise.

3. Remove the jack and tool kit bag fromthe bracket, loosen the straps andremove the tool bag from the jack.

Removing the Spare Tire

1.Remove the swivel wrench from the toolkit bag, open the spare tire winch accessplug at the bottom of the compartmentfor the jack and tools tray.

417

Navigator (TB9) Canada/United States of America, enUSA, Edition date: 201708, Third-Printing-

Wheels and TiresE175447 E252435

Page 421 of 649

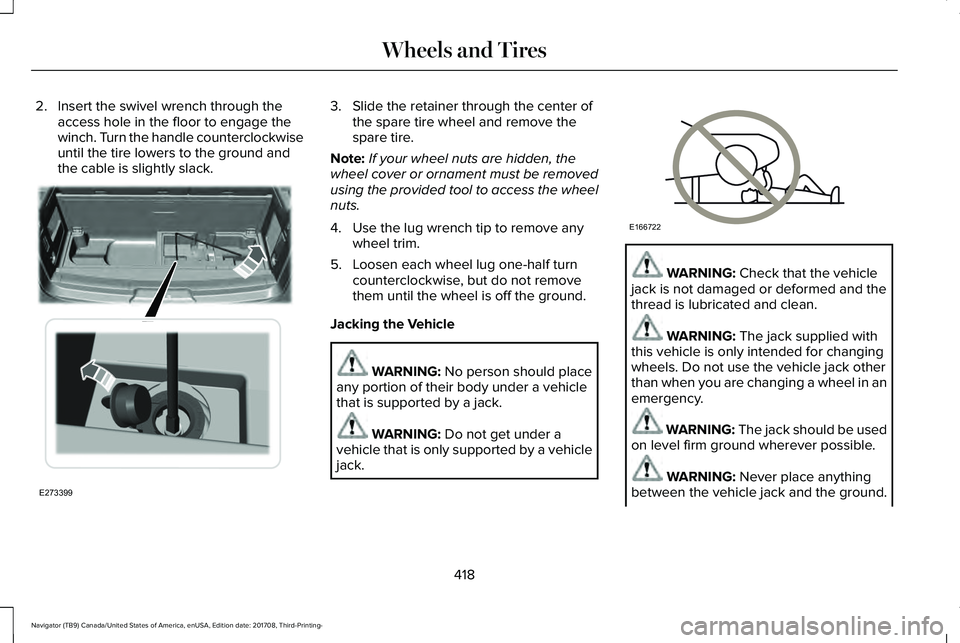

2. Insert the swivel wrench through theaccess hole in the floor to engage thewinch. Turn the handle counterclockwiseuntil the tire lowers to the ground andthe cable is slightly slack.

3. Slide the retainer through the center ofthe spare tire wheel and remove thespare tire.

Note:If your wheel nuts are hidden, thewheel cover or ornament must be removedusing the provided tool to access the wheelnuts.

4. Use the lug wrench tip to remove anywheel trim.

5. Loosen each wheel lug one-half turncounterclockwise, but do not removethem until the wheel is off the ground.

Jacking the Vehicle

WARNING: No person should placeany portion of their body under a vehiclethat is supported by a jack.

WARNING: Do not get under avehicle that is only supported by a vehiclejack.

WARNING: Check that the vehiclejack is not damaged or deformed and thethread is lubricated and clean.

WARNING: The jack supplied withthis vehicle is only intended for changingwheels. Do not use the vehicle jack otherthan when you are changing a wheel in anemergency.

WARNING: The jack should be usedon level firm ground wherever possible.

WARNING: Never place anythingbetween the vehicle jack and the ground.

418

Navigator (TB9) Canada/United States of America, enUSA, Edition date: 201708, Third-Printing-

Wheels and TiresE273399 E166722

Page 422 of 649

WARNING: Never place anythingbetween the vehicle jack and your vehicle.

WARNING: It is recommended thatthe wheels of the vehicle be chocked, andthat no person should remain in a vehiclethat is being jacked.

WARNING: Failure to follow theseguidelines could result in an increased riskof loss of vehicle control, injury or death.

Note:The jack does not requiremaintenance or additional lubrication overthe service life of your vehicle.

Note:Jack at the specified locations to avoiddamaging your vehicle.

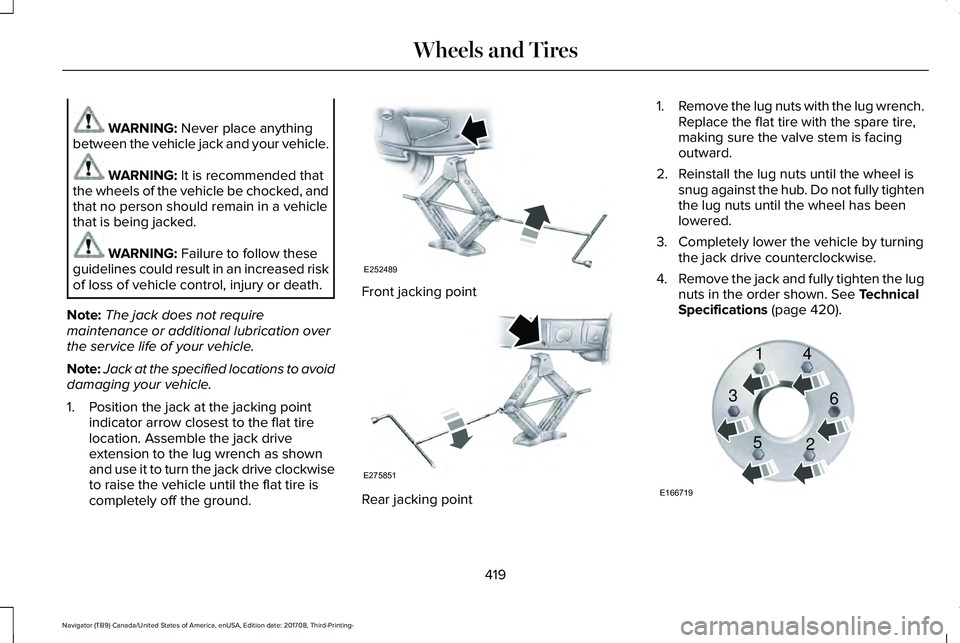

1. Position the jack at the jacking pointindicator arrow closest to the flat tirelocation. Assemble the jack driveextension to the lug wrench as shownand use it to turn the jack drive clockwiseto raise the vehicle until the flat tire iscompletely off the ground.

Front jacking point

Rear jacking point

1.Remove the lug nuts with the lug wrench.Replace the flat tire with the spare tire,making sure the valve stem is facingoutward.

2. Reinstall the lug nuts until the wheel issnug against the hub. Do not fully tightenthe lug nuts until the wheel has beenlowered.

3. Completely lower the vehicle by turningthe jack drive counterclockwise.

4.Remove the jack and fully tighten the lugnuts in the order shown. See TechnicalSpecifications (page 420).

419

Navigator (TB9) Canada/United States of America, enUSA, Edition date: 201708, Third-Printing-

Wheels and TiresE252489 E275851 E166719

1

3

5 4

6

2

Page 423 of 649

Stowing the Flat or Spare Tire

1.Lay the tire on the ground, near the rearof the vehicle, with the valve stem sidefacing up.

2. Slide the wheel partially under thevehicle and install the retainer throughthe wheel center. You may have toremove the wheel center cap prior topushing the retainer through the centerof the wheel. To remove the center cap,press it off with the jack tool from theinner side of the wheel. Pull on the cableto align the components at the end of thecable.

3.Using the swivel wrench, insert it throughthe access hole behind the third row seatand engage the winch.

4. Turn the swivel wrench clockwise untilthe tire is raised to its stowed positionunderneath the vehicle. The wrenchbecomes harder to turn and the sparetire winch ratchets or slips when the tireis raised to maximum tightness. A clickingsound can be heard from the winchindicating that the tire is properly stowed.

5.Carefully place all tools back into the toolkit bag.

6.Reinstall the tool kit bag on the jack andtighten the straps.

7.Reinstall the jack properly on the bracketand secure with the wing nut.

8. Close the access hole with the rubberplug.

9. If the vehicle has an access panel,reinstall.

10. Unblock the wheel.

TECHNICAL SPECIFICATIONS

Wheel Lug Nut Torque Specifications

WARNING: When you install a wheel, always remove any corrosion, dirt or foreign materials present on the mounting surfaces of thewheel or the surface of the wheel hub, brake drum or brake disc that contacts the wheel. Make sure to secure any fasteners that attachthe rotor to the hub so they do not interfere with the mounting surfaces of the wheel. Installing wheels without correct metal-to-metal contactat the wheel mounting surfaces can cause the wheel nuts to loosen and the wheel to come off while your vehicle is in motion, resulting inloss of vehicle control, personal injury or death.

420

Navigator (TB9) Canada/United States of America, enUSA, Edition date: 201708, Third-Printing-

Wheels and Tires

Page 434 of 649

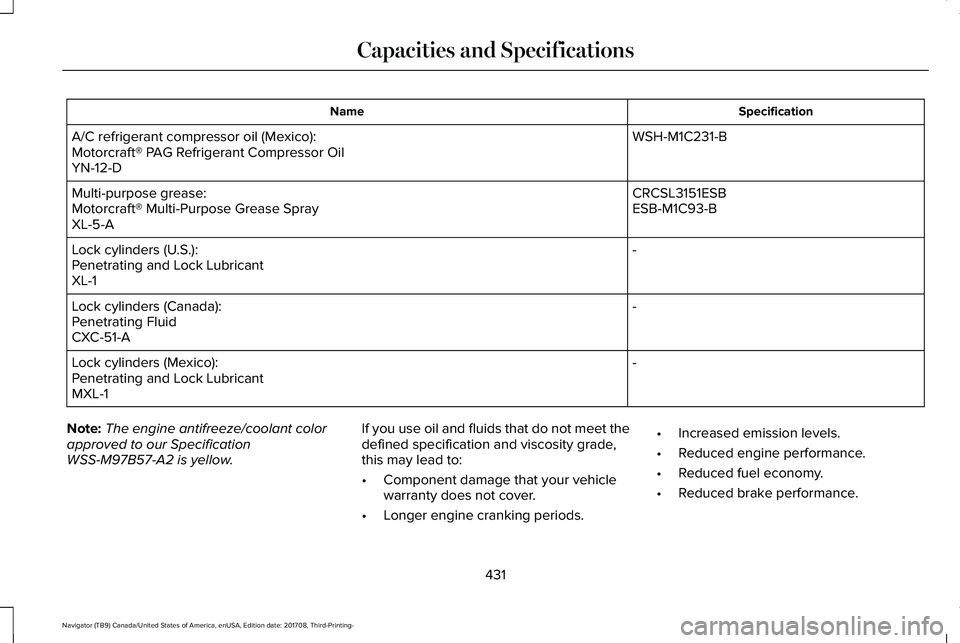

SpecificationName

WSH-M1C231-BA/C refrigerant compressor oil (Mexico):Motorcraft® PAG Refrigerant Compressor OilYN-12-D

CRCSL3151ESBMulti-purpose grease:ESB-M1C93-BMotorcraft® Multi-Purpose Grease SprayXL-5-A

-Lock cylinders (U.S.):Penetrating and Lock LubricantXL-1

-Lock cylinders (Canada):Penetrating FluidCXC-51-A

-Lock cylinders (Mexico):Penetrating and Lock LubricantMXL-1

Note:The engine antifreeze/coolant colorapproved to our SpecificationWSS-M97B57-A2 is yellow.

If you use oil and fluids that do not meet thedefined specification and viscosity grade,this may lead to:

•Component damage that your vehiclewarranty does not cover.

•Longer engine cranking periods.

•Increased emission levels.

•Reduced engine performance.

•Reduced fuel economy.

•Reduced brake performance.

431

Navigator (TB9) Canada/United States of America, enUSA, Edition date: 201708, Third-Printing-

Capacities and Specifications