bolt LOTUS ELISE 2005 Owners Manual

[x] Cancel search | Manufacturer: LOTUS, Model Year: 2005, Model line: ELISE, Model: LOTUS ELISE 2005Pages: 205, PDF Size: 4.51 MB

Page 6 of 205

Transmission Oil .....................................................103

Cooling System .......................................................

106

Anti-Freeze/Corrosion Inhibitor ...............................

107

Coolant Drain/Refill Procedure ................................

108

Washer Reservoir ...................................................

109

Wiper Blade .............................................................

109

Brake Fluid Reservoir ............................................... 110

Brake Pads ............................................................... 111

Brake Pipes and Hoses ............................................112

Air Cleaner Element ................................................. 113

Auxiliary Drive Belt ................................................... 114

Sparking Plugs ......................................................... 114

14. TIRES & WHEE

LS

Tires ................................................................ 115

Glossary of Terms .................................................... 115

T

ire Safety ................................................................ 115

Tire Care ................................................................ 117

Replacement Tires ................................................... 118

Tire Characteristics .................................................. 119

Winter T

ires .............................................................. 119

Tire Cha

ins ..............................................................120

Uniform T

ire Quality Grading ...................................120

Tire Placard

/Label ...................................................121

Steps

for Determining Correct Load Limit ...............122

Tire Ma

rkings ..........................................................123

T ire Inflator Aerosol .................................................

124

Wheels ...............................................................

126

Wheel Bolts .............................................................

126

Wheel Alignment & Tire Balance .............................

126

Wheel Replacement ................................................

127

15. ELECTRICAL

Battery ...............................................................129

Battery Access ........................................................

129

Disconnecting the Battery .......................................

129

Reconnecting the Battery ........................................

131

Battery Charging .....................................................

131

‘Jump’ Starting ........................................................

133

Electrical Accessories ...................................................

134

Inertia Switch ...............................................................

135

Fuses ...............................................................

135

Contents

4

oh_croft_InD.indd 420/05/2004 07:58:40ProCarManuals.com

Page 88 of 205

b330

FRONT SPIGOT BRACKET

Hard Top - Fitting

1. Open both doors, and preferably with the aid of an assistant, lower the roof onto the car holding aside the loose tethered

fixings to avoid their entrapment or their causing paint damage. Position the rear edge of the roof first before locating the front

edge against the windscreen header rail.

2. Locate a front spigot bracket into its latch plate lower slot (lifting the roof slightly to allow this) and retain to the roof with the Torx bolt. Use only the special Torx tool supplied in the car tool kit (stowed in the battery cover pocket), and do not

fully tighten at this stage.

3. Repeat step (2) for the opposite front spigot bracket.

External Operations

86

oh_croft_InD.indd 8620/05/2004 07:59:02ProCarManuals.com

Page 89 of 205

4. Engage a rear hook bracket with the lower tongue on its rear latch plate, and retain to the roof with the Torx bolt. Use only

the special tool supplied, and do not fully tighten at this stage.

Ensure that the hook is fully located onto the tongue.

5. Repeat step (4) for the opposite rear hook bracket. 6. Push the roof fully forwards before tightening the front spigot brackets using only the special Torx tool supplied. Hold each

rear hook bracket in alignment whilst tightening the single

fixing screw for each bracket. Do not overtighten.

h2

FITTING REAR HOOK BRACKET

External Operations

87

oh_croft_InD.indd 8720/05/2004 07:59:02ProCarManuals.com

Page 120 of 205

Use a good quality proprietary tire pressure gauge and always replace the tire valve dust cap to prevent the

ingress of dirt and moisture into the valve, which could cause leakage. Many fuel filling stations provide tire inflation facilities,

which specific usage instructions should be carefully fol

-

lowed. For tire pressure information, refer to ‘Technical

Data’ or the Certification Label on the driver’s door jamb

(see page 121).

Replacement Tires When replacing tires, refer to the ‘Technical Data’ sec

-

tion in this handbook, or consult your dealer to check the current Lotus specification and recommendations. Do not

use tires which differ from these specifications.

WARNING: Note that some tread patterns are directional, so

that the tire must be fitted onto the wheel with regard

to which side of the car the wheel is to be used. In

these cases, a direction of rotation arrow is included in the tire sidewall markings.

When balancing the wheel and tire assemblies, the

wheels should be located by the centre spigot hole - NOT by the wheel bolt holes. In order to maintain the correct

ohs115b

Direction of rotation arrow

Tires & Wheels

118

oh_croft_InD.indd 11820/05/2004 07:59:10ProCarManuals.com

Page 128 of 205

WheelsEnsure that only original equipment, or Lotus approved wheel

and tire combinations are fitted. After the car has been used

on track, or in competition conditions, the wheels should be removed and thoroughly inspected for damage.

WARNING: After striking a pothole or kerb, the wheels should be

removed and the wheel and tire thoroughly inspected for

damage. Renew the wheel and /or tire if necessary. Safety

considerations should always be paramount and new parts

fitted in any cases of doubt.

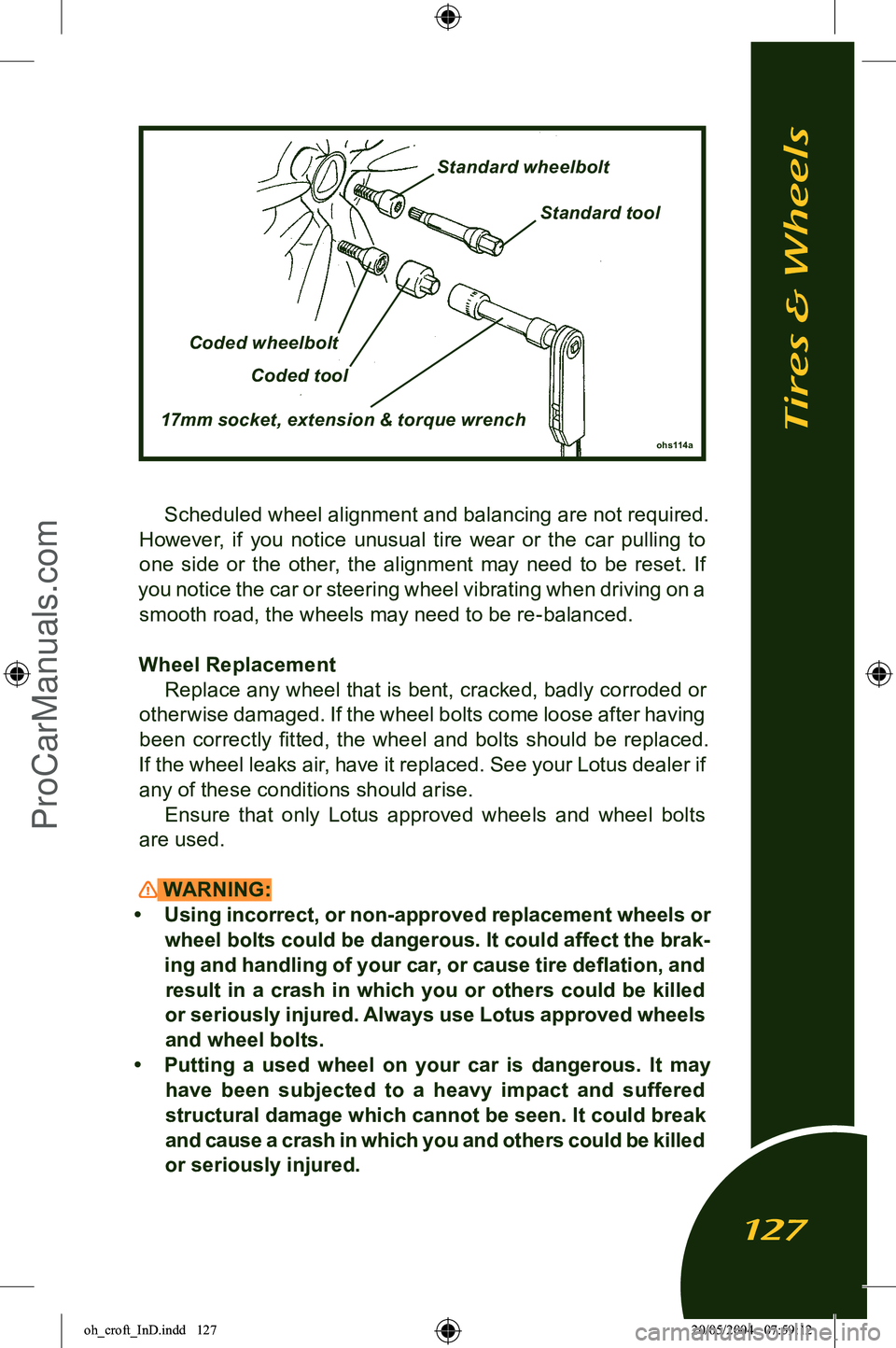

Wheel Bolts The wheel bolts used on the Elise are of a special design to

suit the small diameter fixing tunnels in the wheel centres. The bolts have a 10 spline socket head, for which a special extension

tool is supplied with the car. A 17mm a/f deep socket and 1/2

inch square drive wrench should be applied to the extension tool,

with a tightening torque of 77 lbf.ft (105 Nm) required. To protect against wheel theft, one of the four bolts securing

each wheel is key coded, and requires a corresponding coded

socket wrench and 1/2 inch square drive extension. Rotate the coded socket until full engagement with the bolt head is ensured and take care to maintain the extension tool perpendicular to

the wheel face before applying release torque.

NOTICE: It is not recommended to use hammer action air tools on the coded bolts - use only manual tools.

Both the standard extension and coded socket tools are

stowed in the car tool kit, and should remain with the car at all

times to ensure that servicing may be performed. The key code

included in the tool kit should be recorded and kept safely with

the car documents, in case a replacement socket tool needs

to be ordered.

Wheel Alignment and Tire Balance The wheels on your car were aligned and balanced carefully

during the manufacture of your car to give you the longest tire

life and best overall performance.

Tires & Wheels

126

oh_croft_InD.indd 12620/05/2004 07:59:12ProCarManuals.com

Page 129 of 205

Scheduled wheel alignment and balancing are not required.

However, if you notice unusual tire wear or the car pulling to one side or the other, the alignment may need to be reset. If

you notice the car or steering wheel vibrating when driving on a smooth road, the wheels may need to be re-balanced.

Wheel Replacement Replace any wheel that is bent, cracked, badly corroded or

otherwise damaged. If the wheel bolts come loose after having been correctly fitted, the wheel and bolts should be replaced.

If the wheel leaks air, have it replaced. See your Lotus dealer if any of these conditions should arise.

Ensure that only Lotus approved wheels and wheel bolts

are used.

WARNING:

• Using incorrect, or non-approved replacement wheels or wheel bolts could be dangerous. It could affect the brak

-

ing and handling of your car, or cause tire deflation, and result in a crash in which you or others could be killed

or seriously injured. Always use Lotus approved wheels

and wheel bolts.

• Putting a used wheel on your car is dangerous. It may have been subjected to a heavy impact and suffered

structural damage which cannot be seen. It could break

and cause a crash in which you and others could be killed

or seriously injured.

ohs114a

Coded wheelbolt

Coded tool

17mm socket, extension & torque wrench

Standard wheelbolt

Standard tool

Tires & Wheels

127

oh_croft_InD.indd 12720/05/2004 07:59:12ProCarManuals.com

Page 130 of 205

NOTICE: Using incorrect wheel/tire equipment can also cause problems with wheel bearing life, brake cooling, speedo and

odometer calibration, headlamp aim, ground clearance and tire

clearance to the body.

WARNING: Dirt or corrosion on a wheel or hub mounting flange or

wheel bolts, can result in the wheel bolts coming loose.

The wheel could come off and cause a crash in which you and others could be killed or seriously injured. Thoroughly

clean these components or fit new Lotus approved replace

-

ments before fitting a wheel. Never use oil or grease on the wheel bolts or hub threads.

If you do, the bolts could come loose and the wheel could

come off, causing a crash in which you and others could be killed or seriously injured. Using incorrect wheel bolts, or the wrong tightening

torque could cause the bolts to come loose and the wheel to come off, resulting in a crash in which you and others could be killed or seriously injured. Use only the correct Lotus

approved wheel bolts tightened to 77 lbf.ft (105 Nm).

NOTICE: Improperly tightened wheel bolts, or dirt on the wheel

to hub mounting face can cause brake pulsation and judder, and damage the brake discs. To avoid expensive brake repairs,

ensure complete cleanliness on assembly and tighten the wheel

bolts in a diagonal sequence to the correct torque.

For advice and information on lifting the Elise, refer to ‘Lifting

Points’ on page 148Tires & Wheels

128

oh_croft_InD.indd 12820/05/2004 07:59:12ProCarManuals.com

Page 142 of 205

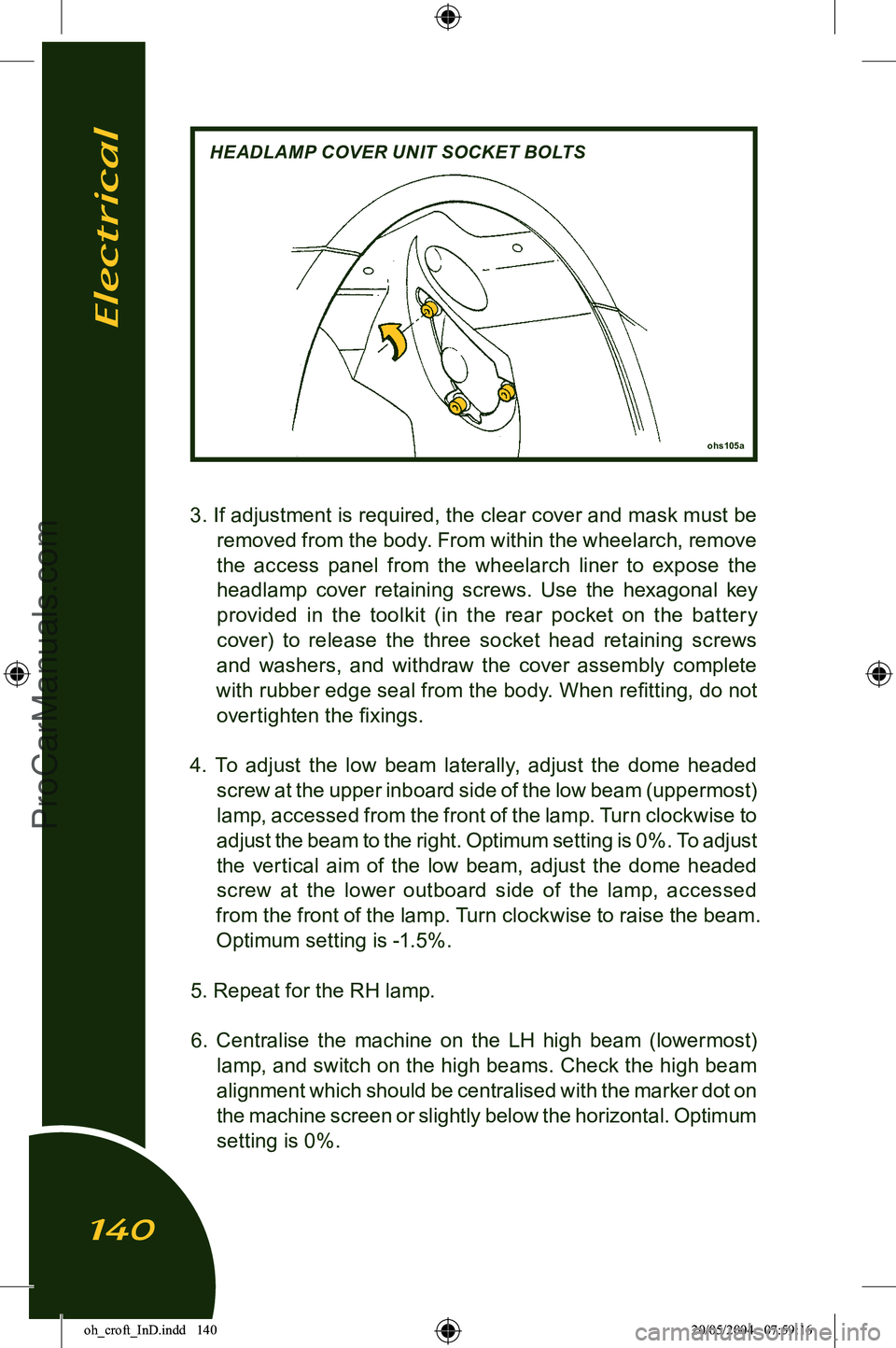

3. If adjustment is required, the clear cover and mask must be removed from the body. From within the wheelarch, remove

the access panel from the wheelarch liner to expose the

headlamp cover retaining screws. Use the hexagonal key provided in the toolkit (in the rear pocket on the batter y

cover) to release the three socket head retaining screws and washers, and withdraw the cover assembly complete

with rubber edge seal from the body. When refitting, do not overtighten the fixings.

4. To adjust the low beam laterally, adjust the dome headed screw at the upper inboard side of the low beam (uppermost)

lamp, accessed from the front of the lamp. Turn clockwise to

adjust the beam to the right. Optimum setting is 0%. To adjust

the vertical aim of the low beam, adjust the dome headed screw at the lower outboard side of the lamp, accessed

from the front of the lamp. Turn clockwise to raise the beam.

Optimum setting is -1.5%.

5. Repeat for the RH lamp. 6. Centralise the machine on the LH high beam (lowermost) lamp, and switch on the high beams. Check the high beam

alignment which should be centralised with the marker dot on

the machine screen or slightly below the horizontal. Optimum

setting is 0%.

ohs105a

HEADLAMP COVER UNIT SOCKET BOLTS

Electrical

140

oh_croft_InD.indd 14020/05/2004 07:59:16ProCarManuals.com

Page 157 of 205

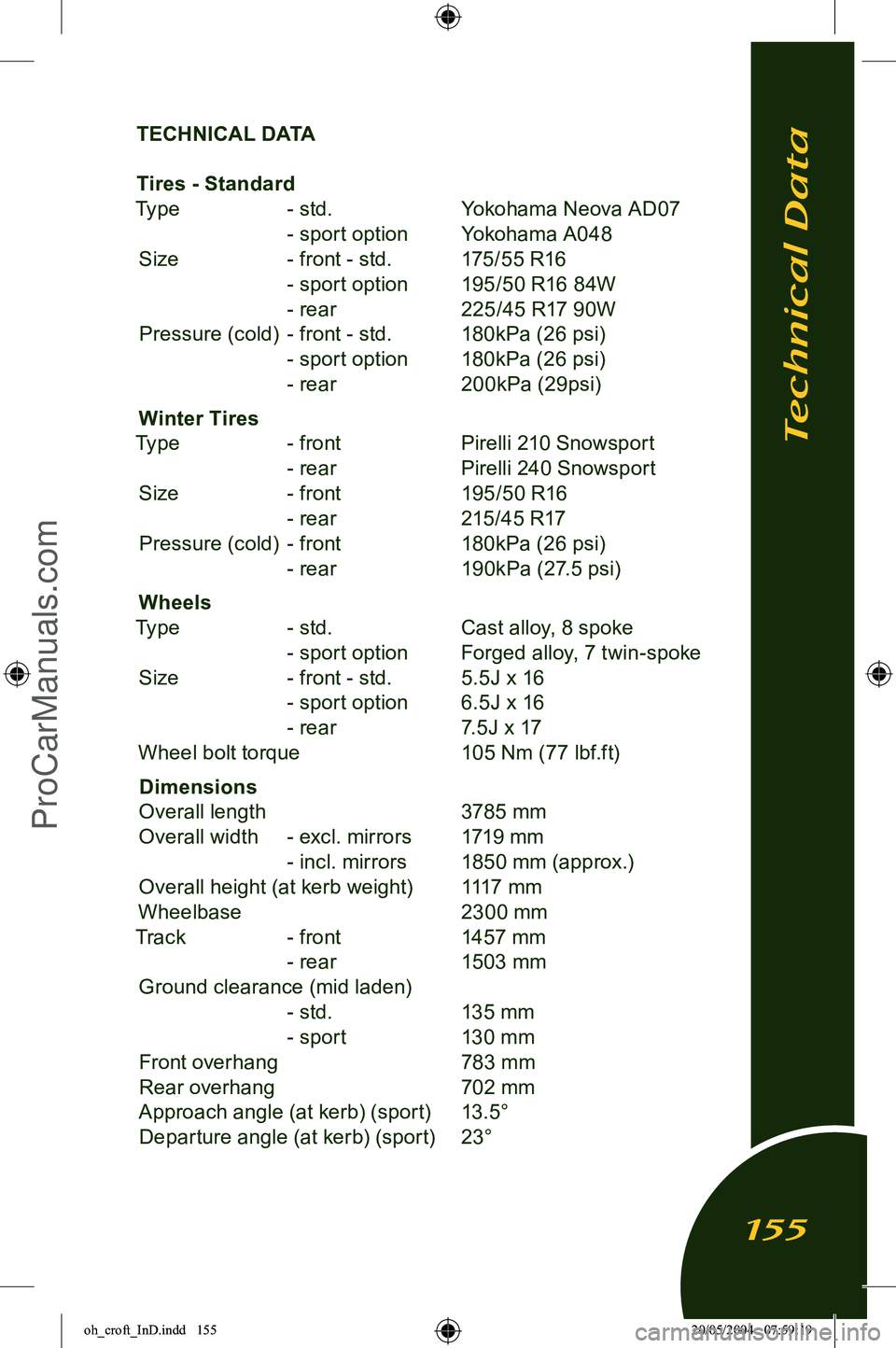

TECHNICAL DATA

Tires - Standard

Type - std. Yokohama Neova AD07

- sport option Yokohama A048

Size - front - std. 175/55 R16

- sport option 195/50 R16 84W

- rear 225/45 R17 90W

Pressure (cold) - front - std. 180kPa (26 psi)

- sport option 180kPa (26 psi)

- rear 200kPa (29psi)

Winter Tires

Type - front Pirelli 210 Snowsport

- rear Pirelli 240 Snowsport

Size - front 195/50 R16

- rear 215/45 R17

Pressure (cold) - front 180kPa (26 psi)

- rear 190kPa (27.5 psi)

Wheels

Type - std. Cast alloy, 8 spoke

- sport option Forged alloy, 7 twin-spoke

Size - front - std. 5.5J x 16

- sport option 6.5J x 16

- rear 7.5J x 17

Wheel bolt torque 105 Nm (77 lbf.ft)

Dimensions

Overall length 3785 mm

Overall width - excl. mirrors 1719 mm

- incl. mirrors 1850 mm (approx.)

Overall height (at kerb weight) 1117 mm

Wheelbase 2300 mm

Track - front 1457 mm

- rear 1503 mm

Ground clearance (mid laden)

- std. 135 mm

- sport 130 mm

Front overhang 783 mm

Rear overhang 702 mm

Approach angle (at kerb) (sport) 13.5° Departure angle (at kerb) (sport) 23°

Technical Data

155

oh_croft_InD.indd 15520/05/2004 07:59:19ProCarManuals.com

Page 192 of 205

Steering Lock ........................................................................44

Storing Your Elise ................................................................ 152

Sun Visors .............................................................................. 41

Tachometer ............................................................................. 51

Technical Data ..................................................................... 155

Tell Tale Lamps ...................................................................... 46

Tie Down, car securing ......................................................... 147

Towing Eye ........................................................................... 146

Trip Re corder ......................................................................... 53

Turn Indicators Switch ........................................................... 58

Tires ...................................................................................... 115

Tire Inflator Aerosol .............................................................. 124

Tire Chains ........................................................................... 120

Identification, car ................................................................... 15

Warning ‘Tell Tale ’ Lamps ..................................................... 46

Warranty ............................................................................... 161

Washer Reservoir ................................................................ 109

Washing, bodycare ................................................................ 93

Wheelbolts ........................................................................... 126

Wheels ................................................................................ 126

Windows, door ...................................................................... 42

Windscreen Wiper/ Washer Control ...................................... 59

Wiper Blade ......................................................................... 109

Index

190

oh_croft_InD.indd 19020/05/2004 07:59:26ProCarManuals.com