clock setting LOTUS ELISE 2005 Owners Manual

[x] Cancel search | Manufacturer: LOTUS, Model Year: 2005, Model line: ELISE, Model: LOTUS ELISE 2005Pages: 205, PDF Size: 4.51 MB

Page 67 of 205

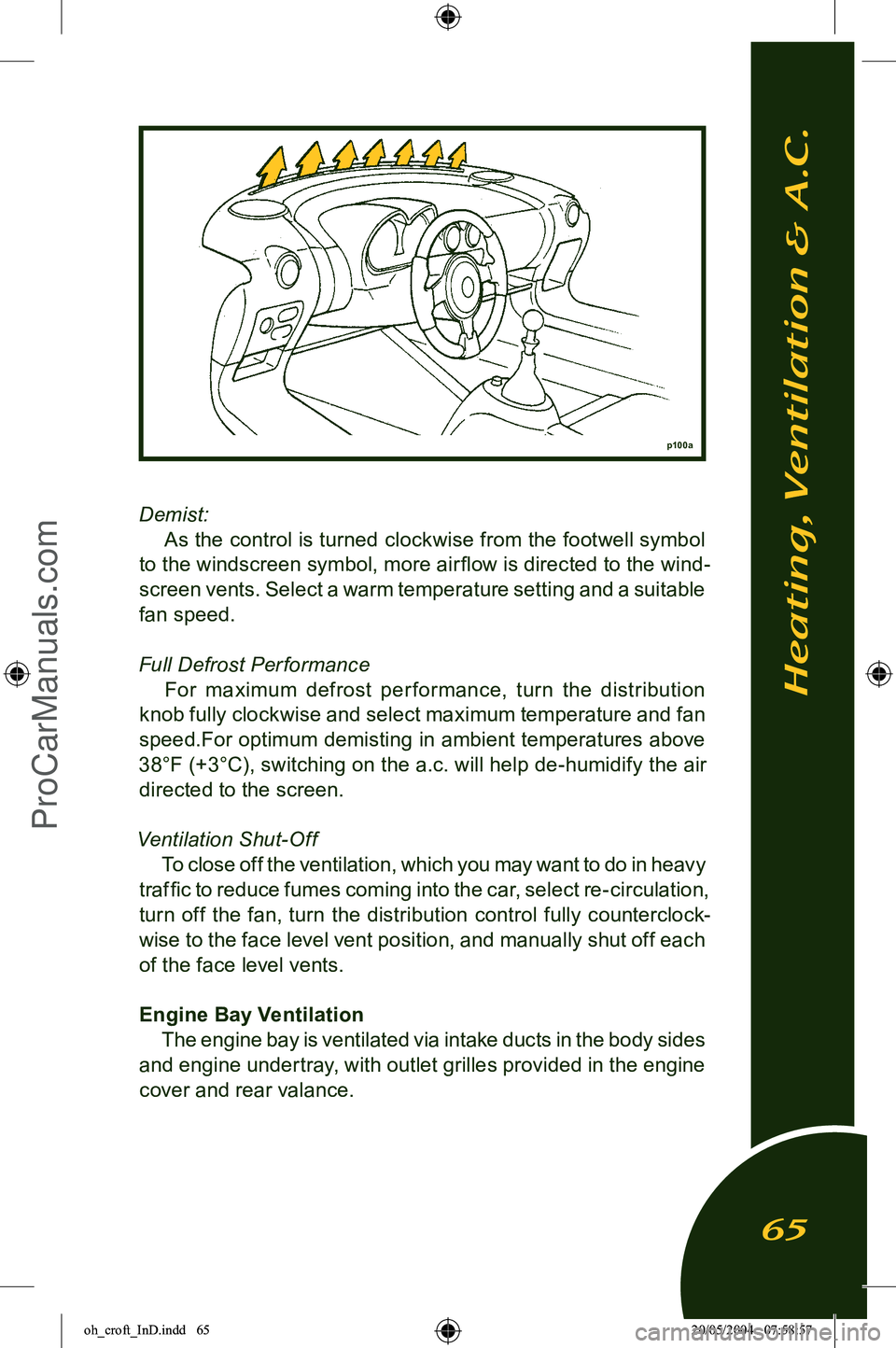

Demist:

As the control is turned clockwise from the footwell symbol

to the windscreen symbol, more air flow is directed to the wind

-

screen vents. Select a warm temperature setting and a suitable

fan speed.

Full Defrost Per formance For maximum defrost per formance, turn the distribution

knob fully clockwise and select maximum temperature and fan

speed.For optimum demisting in ambient temperatures above

38°F (+3°C), switching on the a.c. will help de-humidify the air directed to the screen.

Ventilation Shut-Off To close off the ventilation, which you may want to do in heavy

traffic to reduce fumes coming into the car, select re-circulation,

turn off the fan, turn the distribution control fully counterclock

-

wise to the face level vent position, and manually shut off each of the face level vents.

Engine Bay Ventilation The engine bay is ventilated via intake ducts in the body sides

and engine undertray, with outlet grilles provided in the engine

cover and rear valance.

p100a

Heating, Ventilation & A.C.

65

oh_croft_InD.indd 6520/05/2004 07:58:57ProCarManuals.com

Page 142 of 205

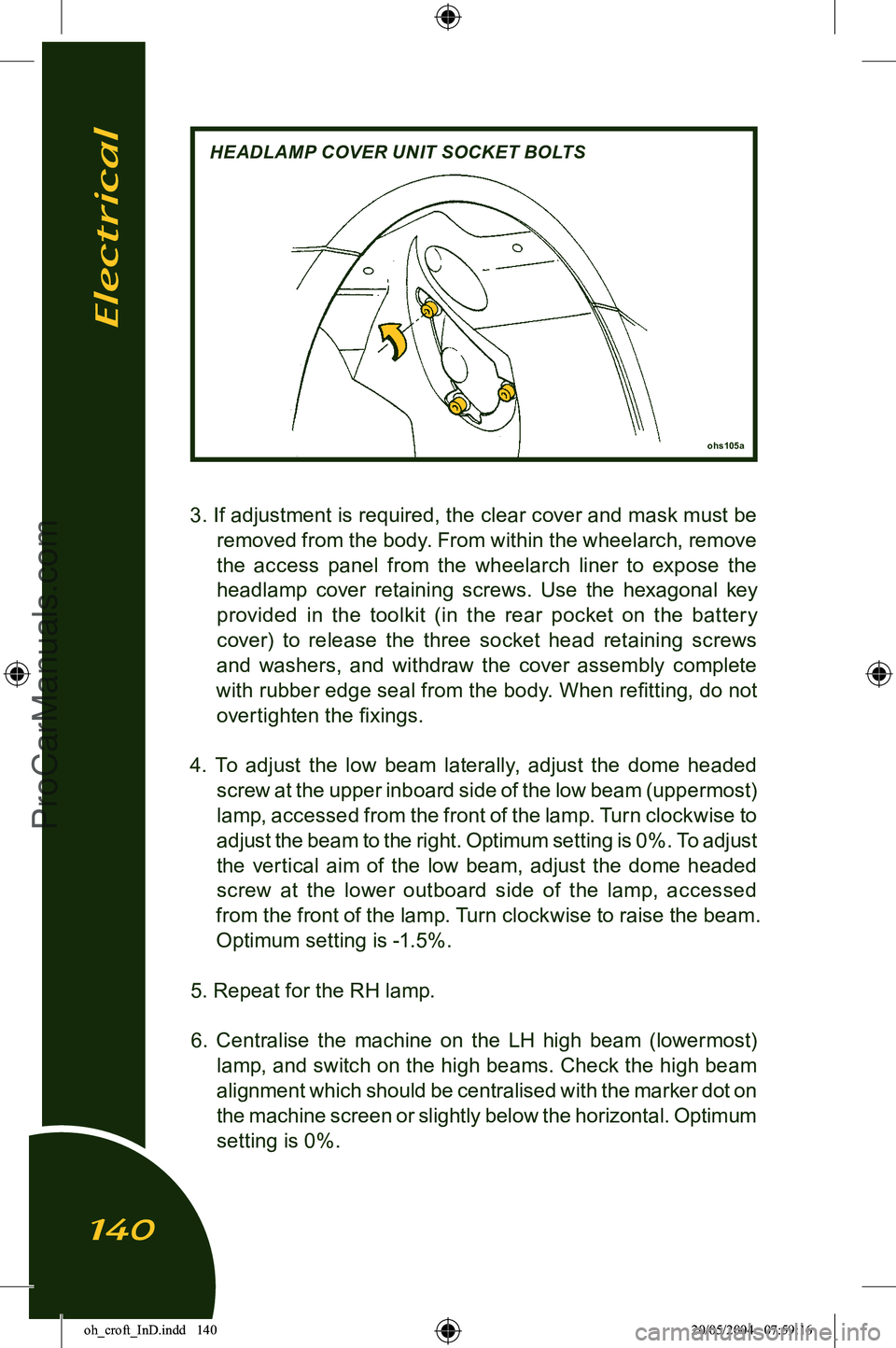

3. If adjustment is required, the clear cover and mask must be removed from the body. From within the wheelarch, remove

the access panel from the wheelarch liner to expose the

headlamp cover retaining screws. Use the hexagonal key provided in the toolkit (in the rear pocket on the batter y

cover) to release the three socket head retaining screws and washers, and withdraw the cover assembly complete

with rubber edge seal from the body. When refitting, do not overtighten the fixings.

4. To adjust the low beam laterally, adjust the dome headed screw at the upper inboard side of the low beam (uppermost)

lamp, accessed from the front of the lamp. Turn clockwise to

adjust the beam to the right. Optimum setting is 0%. To adjust

the vertical aim of the low beam, adjust the dome headed screw at the lower outboard side of the lamp, accessed

from the front of the lamp. Turn clockwise to raise the beam.

Optimum setting is -1.5%.

5. Repeat for the RH lamp. 6. Centralise the machine on the LH high beam (lowermost) lamp, and switch on the high beams. Check the high beam

alignment which should be centralised with the marker dot on

the machine screen or slightly below the horizontal. Optimum

setting is 0%.

ohs105a

HEADLAMP COVER UNIT SOCKET BOLTS

Electrical

140

oh_croft_InD.indd 14020/05/2004 07:59:16ProCarManuals.com