coolant MAZDA 232 1990 Suplement User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1990, Model line: 232, Model: MAZDA 232 1990Pages: 677, PDF Size: 61.19 MB

Page 85 of 677

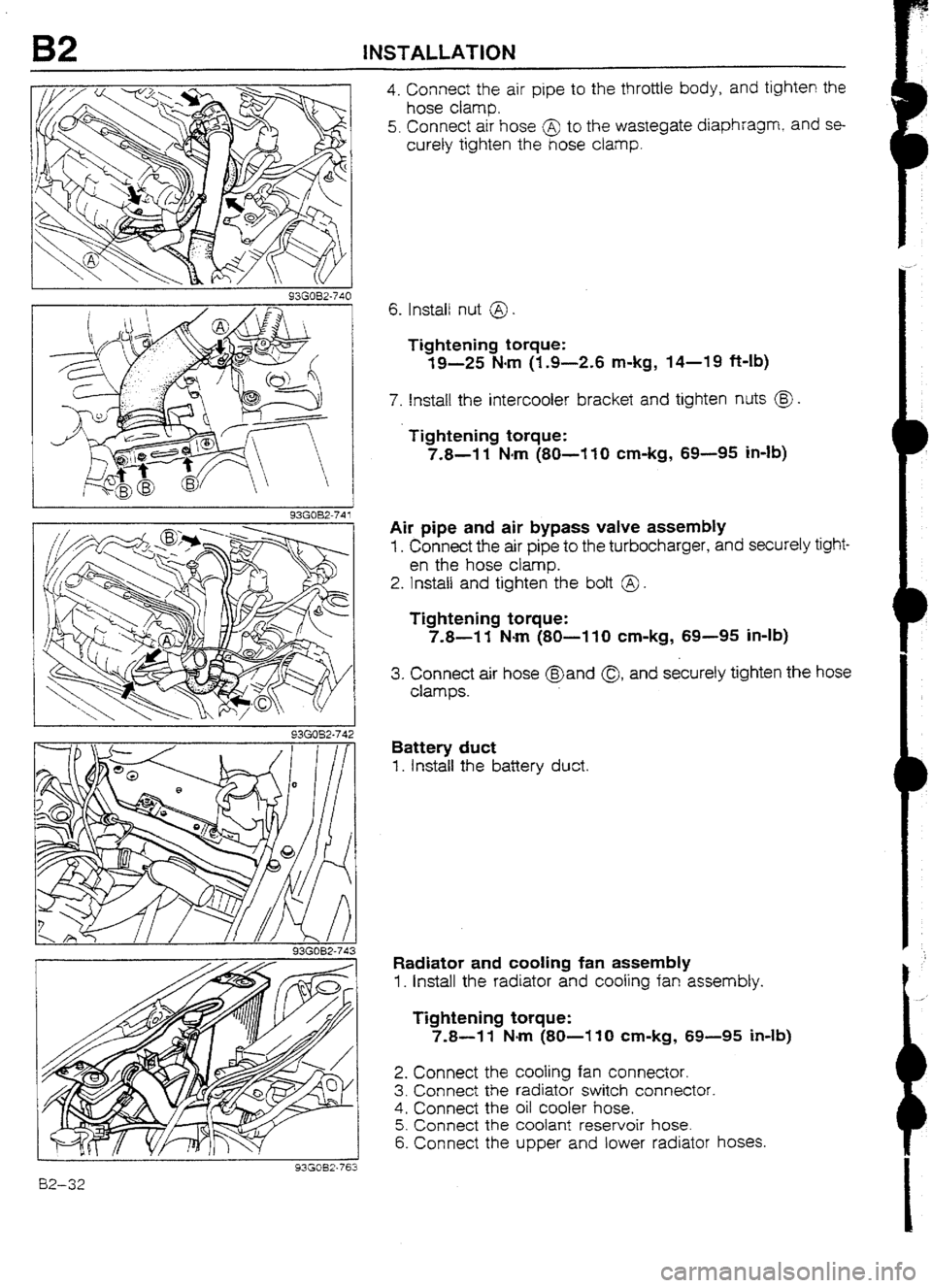

B2 INSTALLATION

93GOB2-74 1

93GOB2-743

82-32

4. Connect the air pipe to the throttle body, and tighten the

hose clamp.

5. Connect air hose @ to the wastegate diaphragm,

and se-

curely tighten the hose clamp.

6. Install nut @

Tightening torque:

19-25 Narn (1.9-2.6 m-kg, 14-19 ft-lb)

7. Install the intercooter bracket and tighten nuts @J .

Tightening torque:

7.8-l 1 Narn (80-I IO cm-kg, 69-95 in-lb)

Air pipe and air bypass valve assembly

1. Connect the air pipe to the turbocharger, and securely tight-

en the hose clamp.

2. Install and tighten the bolt @ .

Tightening torque:

7.8-l 1 Nom (80-I 10 cm-kg, 69-95 in-ib)

3. Connect air hose @and Q1 and securely tighten the hose

clamps.

Battery duct

1. install the battery duct.

Radiator and tooting fan assembly

1. Install the radiator and cooling fan assembly.

Tightening torque:

7.8-l 1 Nm (80-l 10 cm-kg, 69-95 Mb)

2. Connect the tooting fan connector.

3. Connect the radiator switch connector.

4. Connect the oil cooler hose.

5. Connect the coolant reservoir hose.

6. Connect the upper and lower radiator hoses.

Page 87 of 677

82 INSTALLATION

Steps after installation

1. If the engine oil was drained, refill with the specified amount and type of engine oil.

2. Fill the radiator with the specified amount and type of engine coolant.

3. Fill the transaxie with the specified amount and type of transaxle oil. (Refer to page J3-36.)

4. Connect the negative battery cable.

5. Start the engine and check the following:

(I) Engine oiI, transaxle oil, and engine coolant for leakage

(2) Ignition timing and idle speed

(3) Operation of emission control system

6. Perform a road test.

7. Recheck the engine oil and engine coolant levels.

93G032-747

-

BZ-34

Page 90 of 677

E

COOLING SYSTEM

1NDEX . ..*....*~.....*..*~~**~=~~.~~.~...~..**.~.....*...~.. E- 2

OUTLINE .................................................. E- 4

OUTLlNE OF CONSTRUCTION.. ................ E- 4

COOLANT FLOW CHART.. ....................... E- 4

SPECIFICATKINS

.................................... E- 5

TWO-STAGE THERMOSTAT.. .................... E- 6

RADIATOR AND COOLING FAN.. .............. E- 7

ELECTRIC COOLING FAN SYSTEM ........... E- 8

SUPPLEMENTAL SERVICE INFORMATION E- 9

THERMOSTAT

.......................................... E- 9

INSPECTION

.......................................... E- 9

ELECTRIC COOLING FAN SYSTEM ............ E-l 0

SYSTEM INSPECTlON

.............................. E-l 0

FAN MOTOR

............................................. E-If

iNSPECTION .......................................... E-l 1

WATER THERMOSWITCH

.......................... E-l I

INSPECTION .......................................... E-f 1

RADIATOR THERMOSWITCH

..................... E-l 2

REMOVAL I INSPECTION I INSTALLATION.. E-12

FAN RELAY .............................................. E-l 3

REMOVAL I tNSPECTlUN .......................... E-l 3

93GOEX-701

Page 91 of 677

E tNDEX

INDEX

-

- &ANT RESERVOlR

ENGiNE COOLANT

TOTAL CAPACITY

MTX: 5.0 liters (5.3 US qt, 4.4 Imp qt)

ATX: 6.0 liters (6.3 US qt. 5.3

tmp qt)

1. Fan motor

Inspection .._.....,._............._..........

page E-1 I

E-Z

Page 93 of 677

E OUTLINE

OUTLINE

OUTttNE OF CONSTRUCTION

The cooling system in the 323 4WD model is basically the same as in the 323 2WD model.

Although there is no fundamental change from the BP DOHC of the 2WD model, the coolant circulation

path has been changed to direct coolant to the water-cooied turbocharger.

A two-stage thermostat is used in the BP DUHC turbocharged engine to stabilize the engine coolant tem-

peratu re.

The radiator and cooling fan specifications are different. The BP DOHC turbocharged engine of the 4WD

model uses a two-speed electric cooling fan.

93GOEX-704

COOLANT FLOW CHART (BP DOHC TURBO)

E-4

Page 94 of 677

![MAZDA 232 1990 Suplement User Guide SPECIFICATlONS

-

km

Cootlng system

Coolant camacltv

EnginelTtansaxte

lrters [US Qt. Imo at)

8P SOHC ] 8P DOW Turbo

MTX ATX

I MTX

Water-cooled, forced crrculation

5.0 (5.3, 4.4)

I 6.0 t&3,5 MAZDA 232 1990 Suplement User Guide SPECIFICATlONS

-

km

Cootlng system

Coolant camacltv

EnginelTtansaxte

lrters [US Qt. Imo at)

8P SOHC ] 8P DOW Turbo

MTX ATX

I MTX

Water-cooled, forced crrculation

5.0 (5.3, 4.4)

I 6.0 t&3,5](/img/28/57056/w960_57056-93.png)

SPECIFICATlONS

-

km

Cootlng system

Coolant camacltv

EnginelTtansaxte

lrters [US Qt. Imo at)

8P SOHC ] 8P DOW Turbo

MTX ATX

I MTX

Water-cooled, forced crrculation

5.0 (5.3, 4.4)

I 6.0 t&3,5.3) -

1 Type

Water puma 1

I Water seal Centrifugal

Unified mechanical

seal

: Type I Wax,single stage”‘, Wax, two-stage*’ 1 Wax, two-stage

80.5-83.5 (177-182)“1

Opening temperature

“C (OF)

Main: 86.5-89.5 (188-l 93) *’ Main: 86.5-89.5 (lSS--193)

The:mosta! 1 Sub : 83.5-86.5 (182-188) Sub 83.G86.5 (182-188)

1 Full-open temperature OC

(OF) 95 (203)*‘, 100 (212)*’ i 100 (212)

L I

“...Except cold area, *2...Cotd area only

1 r 1 93GOEX-706 j Full-open lift mm (in) 8.5 (0.335) or more’l

Main: 8.0 (0.31).mln.‘2

Sub : 1.5 10.061 min * Main: 8.0 (0.31) min.

Sub : I.5 (0.06) mm.

Radiator 1 Type

Cap vaive opening-pressure ’

kPa (kglcm2, psi) Corrugated fin

74-l 03 (0.75-I .05, 11-l 5) j Tvm?

EIectnc I

Coohg fan f Outer drameter mm (in) 320 (12.6) 340 (13.4)

Blade

Number 4 5

Motor

/ Current A

6.6 * 1 Hi : 13.3 + 10% max.

Lo: 8.8 + 10% max. E-5

Page 95 of 677

E OUTlANE

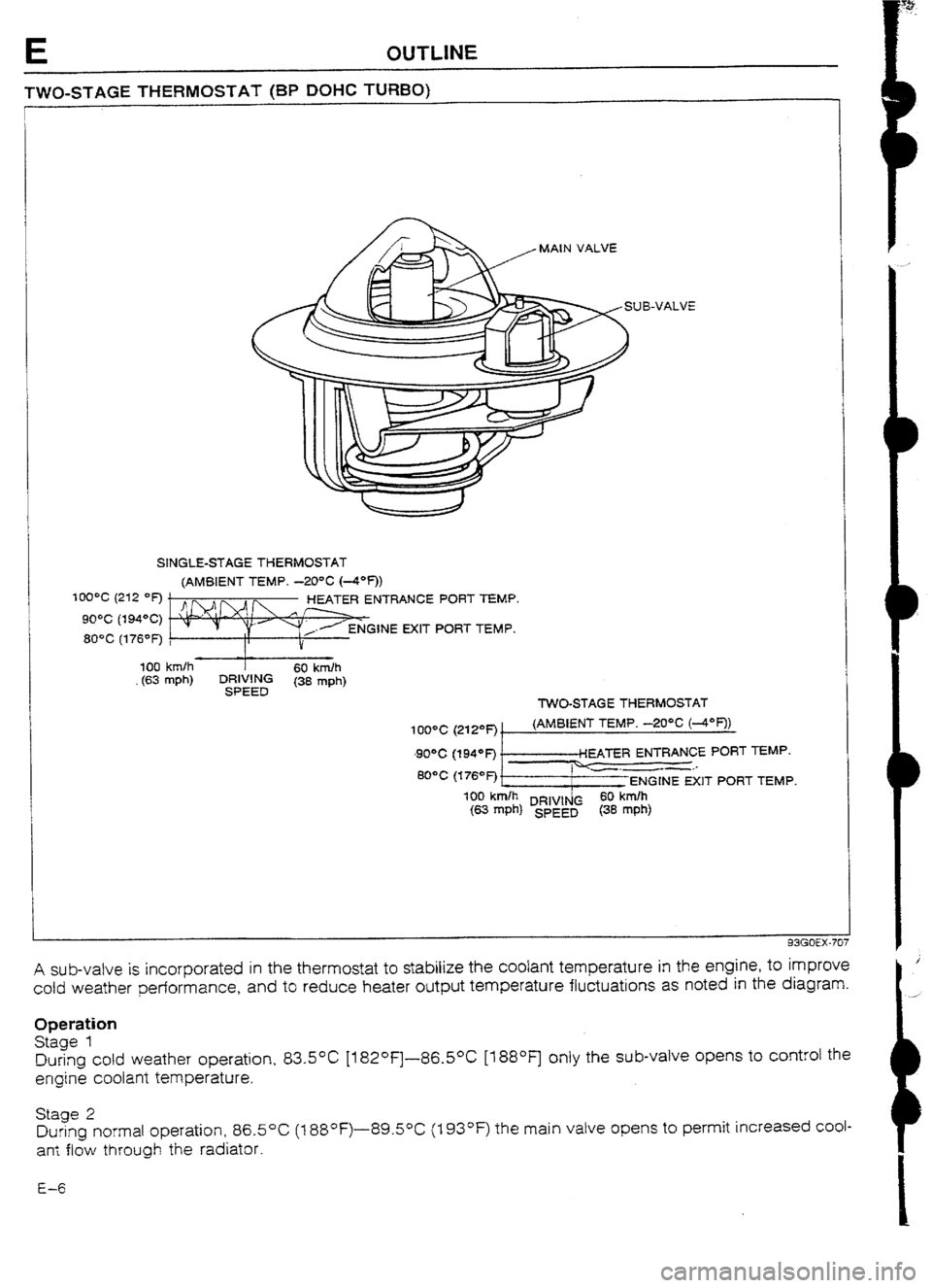

TWO-STAGE THERMOSTAT (BP DOHC TURBO)

MAIN VALVE

SINGLE-STAGE THERMOSTAT

(AMBIENT fEMP. -20% (4*f))

NTRANCE PORT TEMP

GINE EXIT PORT TEMP.

- 100 km/h

60 kndh

(63 mph) ~~~~~ (38 mph)

TWO-STAGE THERMOSTAT

A sub-valve is incorporated in the thermostat to stabilize the coolant temperature in the engine, to improve

cold weather performance, and to reduce heater output temperature fluctuations as noted in the diagram.

Operation

Stage 1

During cold weather operation, 83.5*C [182°F]-86.50C [t 88OF] only the sub-valve opens to control the

engine coolant temperature.

Stage 2

During normal operation, 86.5OC (1 88°F)-89.50C (I 93OF) the main valve opens to permit increased coul-

an: flow through the radiator.

E-6

Page 97 of 677

E OUTLINE

ELECTRIC COCUNG FAN SYSTEM (BP DOHC TURBO)

System Circuit

I I

WITH A/C

r----‘-- -___- ---------.--------;

ADDITIONAL

FAN

MOTOR

I

II 1 A/C RELAY

RAD1ATdTHERMOSWITCH

ABOVE 105% I221 OF-): ON +IIAGNOSlS

CONNECTOR

WATER

THERMOSWlTCH

ABOVE 97% (207OF): ON

Operation 1. When the coolant temperature exceeds 97OC (207*F), the water thermoswitch turns ON to close the No.7

relay, and connects the + I and -1 terminals of the fan motor

connector. The fan motor turns at low

speed (about 1,660 rpm).

2. When the coolant temperature exceeds 105OC (221 OF), the radiator thermoswitch turns ON, to close the

No.2 and No.3 relays, and connects

the +2 and -2 terminals of the fan motor connector. The fan mo-

tor turns at high speed (about 2,200 rpm).

3. if the vehicle is equipped with air conditioning, the cooling fan motor operates whenever the

NC switch

and the blower switch are on, regardless of

the coolant temperature. Also, when the A/C switch and the blower switch are on, the A/C retay closes

to operate the additional fan

motur.

Note

l The water thermoswitch and the cooling fan reIay are normally-open switches.

Checking cooling fan operation 1. Jump across the TFA and the GND terminals

of the diagnosis connector with a jumper wire.

2. Turn the ignition switch to ON and verify that the cooling fan operates smoothly.

Note

l When the water thermoswitch connector is disconnected, the cooling fan wiif not operate.

E-8

Page 99 of 677

E ELECTRIC COOLING FAN SYSTEM

ELECTRIC COOLING FAN SYSTEM (BP

DUHC TURBO)

SYSTEM ClRCUIT

r

WITH A/C

r-- _______ ------

I ADDITIONAL

1 FAN

I PRESSL

SWITCH

I WATER

THERMOSWfTCtl

ABOVE 87OC (207OF): ON

RADlATOjl THERMOSWITCH

ABOVE 105*C (221 “I=): ON

8 93GOEX-719

-

%

J--- QY- -THERMOME?ERsi-=i

--

--------L-

93GOEX-7 i 2

E-10 SYSTEM INSPECTION

1. Jump across the test fan (TFA) terminal and the ground

(GN D) terminal of the diagnosis connector.

2. Turn the ignition switch ON and verify that the fan operates.

If the fan does not operate, inspect the cooling fan system

components and wiring harness.

3. Remove the radiator cap and place a thermometer in the

radiator filler neck.

4. Start the engine.

5. Verify that the fan operates when the coolant temperature

reaches approx. 97*C (207°F).

If it does, check the water thermoswitch.

(Refer to page

E--i I.)

Page 100 of 677

FAN MOTOR, WATER THERMOSWITCH E

93GOEX-71:

93GOEX-714

93GOEX-720

tNSPECTlON

Single-speed Type (For BP SOW MTX)

I. Verify

that the battery is fully charged.

2. Disconnect the fan motor connector.

3. Connect the battery and an ammeter to the fan motor

con-

nector.

4. Verify that current is as specified.

Current (A): 6.6 k 1

5. If current is not within specification and/or the fan does not

turn smoothly, replace the fan motor.

Two-speed Type (Except BP SUHC MTX)

I. Verify that the battery is fully charged.

2. Disconnect the fan motor connector.

3. Connect the battery and an ammeter to the fan motor con-

nectors for low-speed inspection.

4. Verify that the fan motor operates smoothly at the standard

cu vent.

Current (A): 8.8 + 10% max.

5. Connect the battery, an ammeter, and switch to the fan mo-

tor connectors for high-speed inspection.

6. Verify that the fan motor operates smoothly

at the standard

current or less with the switch ON.

Current (A): 13.3 + 10% max.

7. If not as specified, replace the fan motor.

WATER THERMOSWITCH

(BP DOHC TURBO)

INSPECTlUN

I . Place the switch and a thermometer in water.

2. Heat the water gradually and check continuity of the switch

with an ohmmeter.

Coolant temperature OC (OF) 1 Contrdy

I

More than 97 (207) Yes

Less than 90 (194)

NO

3. If not as specified, replace the water thermoswitch.

93GOEX.715