air filter MAZDA 232 1990 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1990, Model line: 232, Model: MAZDA 232 1990Pages: 677, PDF Size: 61.19 MB

Page 23 of 677

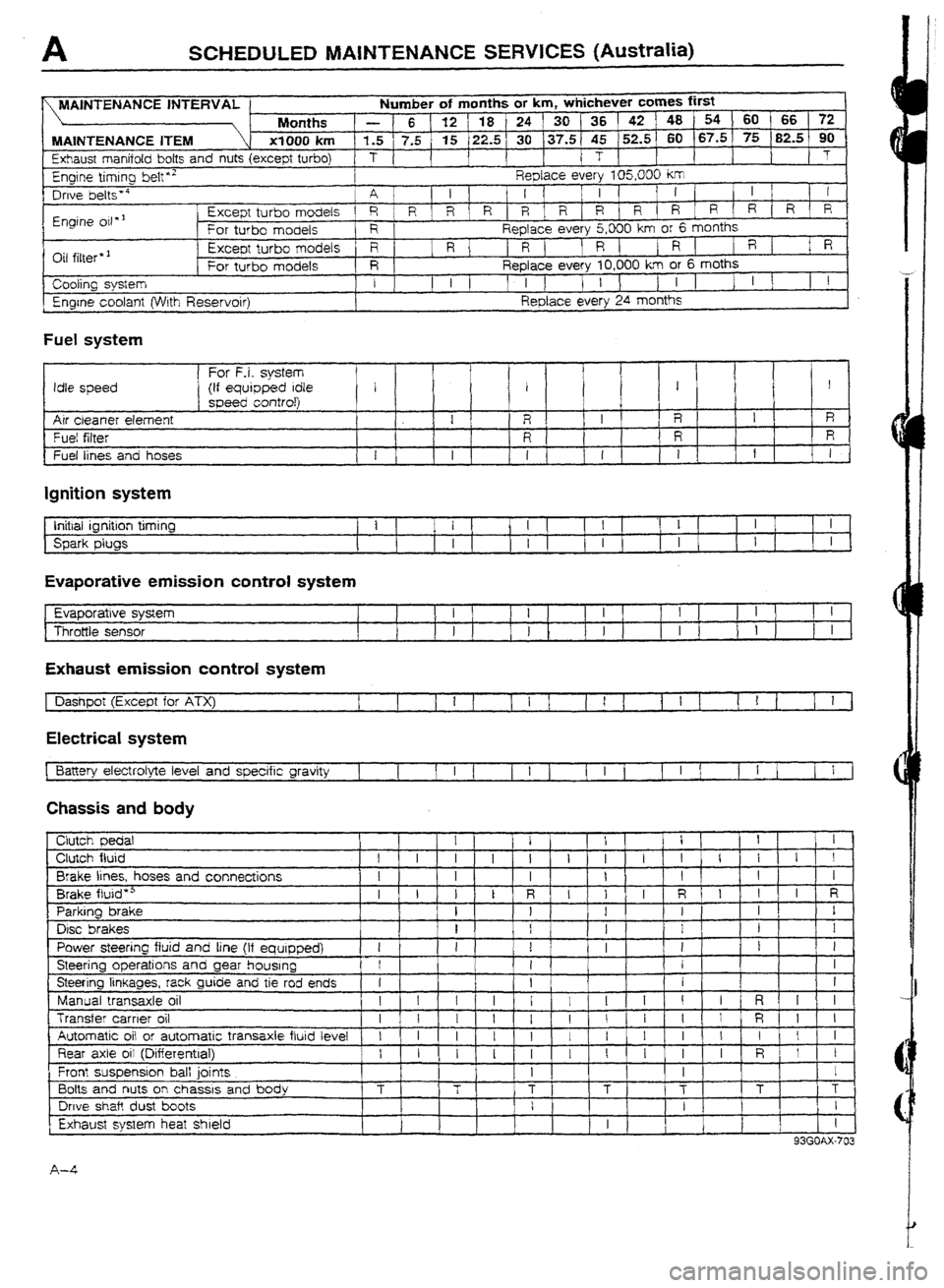

A SCHEDULED MAINTENANCE SERVICES (Australia)

lumber of months or km, whichever cumes first

P

_ 48 54 60 1 66 72

5

60 67.5 75 90 .--- .-- -

.-m-w --v-w _ _ -_-- - - _ _ - -

_ -- - - --- __-

_-

-- -- (82.5

Exhaust manifold bolts and nuts (except turbo) T 1

I i T 1

1 T

Engine timlrtg belt”’ Replace every 105,000 km

Drwe belts * a

A I 1 I 1 1 I 1

! ’ I I 1 1

Engine oil * ’ Except turbo models 1 RIR\R/RIRIRIR R R,R R R/R

For turbo models R

Replace every 5,000 km or 6 months

r-k:1 c:t+*-* 1 Except turbo models

R 1 R 1 1 R ( ) R ( 1 R ( 1

R 1 f R

-

1 VII IIIIc;I 1 For turbo models I R 1 ReDlace everv IO.000 km or E

Engine coolant (Wrth Reservoir)

Fuel

system

Replace e&y 24 months

For F-i. system

Idle speed (if equipped Idle 1 1 1 I

I speed controf)

Air cleaner element 1

R , I R I R

Fuet filter

I I? R R

~ Fuel lines and hoses

1 I 1 I I 1 I I 1 1

Ignition system

t Initial ignition timing

Spark plugs i I I I -1 I I

I I I I I

f

Evaporative emission control system

Evaporative system

Throttle sensor

Exhaust emission contra! system

[ Dashpot

(Except for ATX) I 1 I

1 1 I 1 1 t 1 1 1 1 1 ! 1 1 I 1

Electrical system

Battery electrolyte level and specific gravity ]

I 1 1 I 1 t I ’ 1 1 I 1 f I ( 1

I 1

Chassis and body

Brake lines, hoses and connections

Brake fluid * a

Parking brake

Disc brakes

1 Power steering fluid and line Ilf &uiDDedl

I 1 1 I I I

I 1 1 III II

I ’

I I

Steering operations and gear housing

I

1 1 I --r--j- 1 I

I

Steerino linkanes. rack auide and tie rod pnds .-- --

----.“.a ..‘-~--, J- -.-- _.- .-- -..-- I I I t I 1 1 I I I I I I I 1

Manual transaxle oil I \\!‘I rl\jl I 1 I R III

1 Transfer Automatic carrier oil or 09 automatic transaxle fluid level

1 1 I 1 111 I 1 I l 1 I 1 I 1[11i t I 1 I 1 I I 1 I

R 1 Iii 1 I

1 Rear axle oil (Differential) 1 t I I I I I I I I

t ’ I r . ’ 1 . I I I I I R I 1

I

I I

i T

1 T T T 1 T [ T I 1 T

Front suspension ball joints

Bolts and nuts on chassis and body

I I I . I ! ,

I 1 I . I 1 ’ I I ’

Drive shaft dust boots

I

I 1 I 1

I 1 1 I

~~

- - ’ C1utcl-1 pedat

Clutch fluid

1

A-4

Page 24 of 677

!

i

i

I

i

t-

I

i

i

e

-1

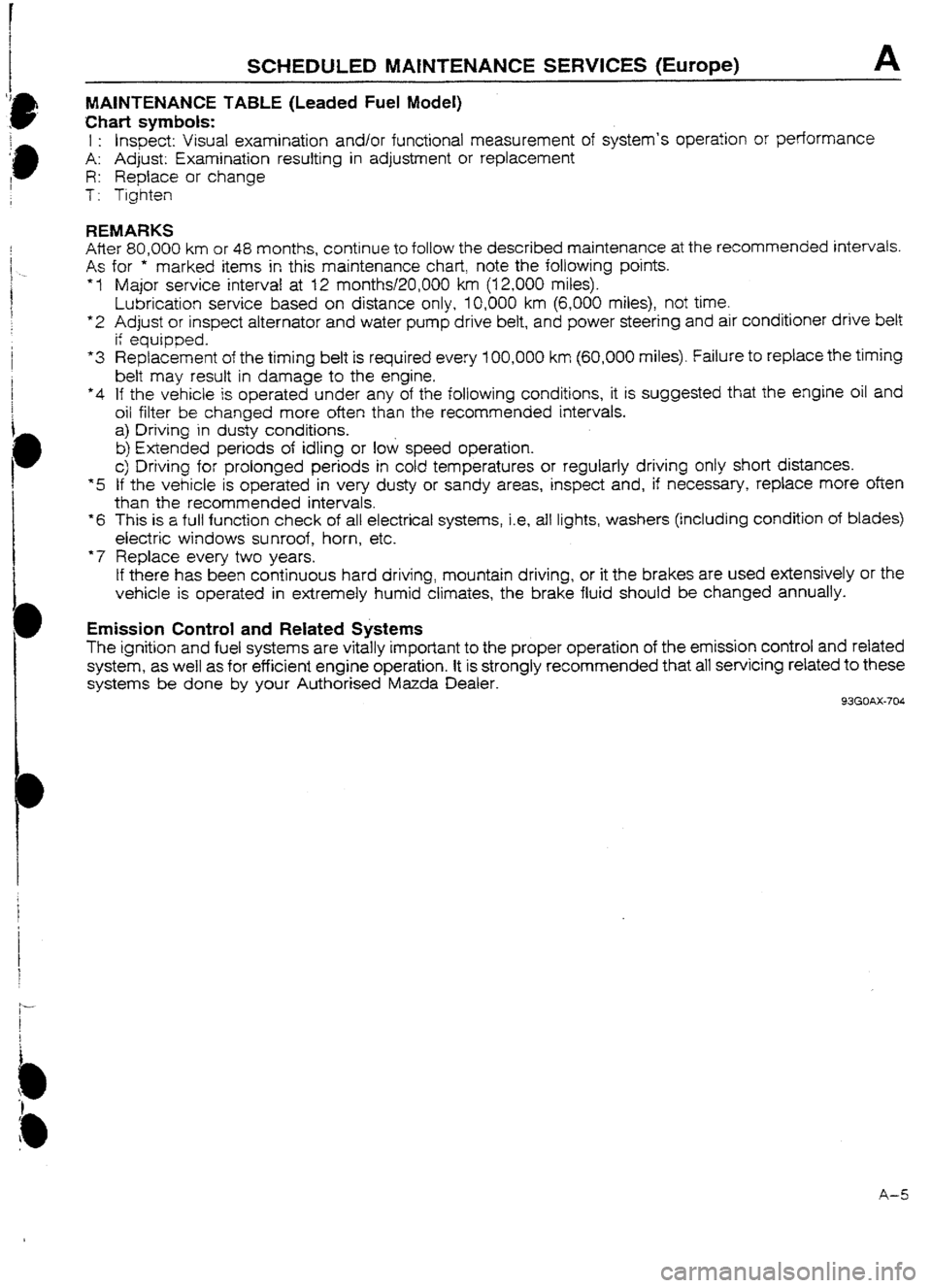

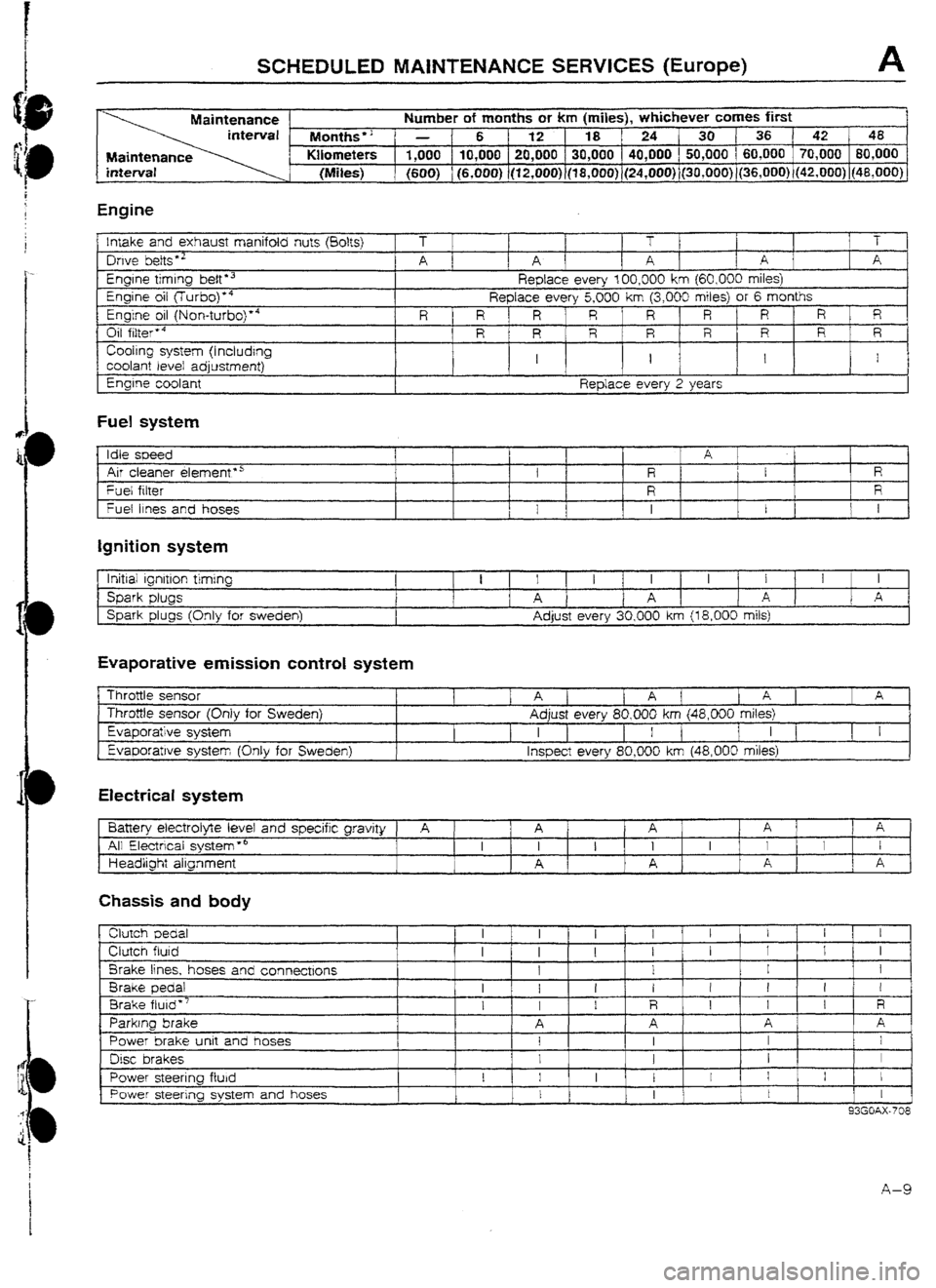

SCHEDULED MAfNTENANCE SERVICES (Europe) A

MAINTENANCE TABLE (Leaded Fuel Model)

Chart symbols:

1 : Inspect: Visual examination and/or functional measurement of system’s operation or performance

A: Adjust: Examination resulting in adjustment or replacement

R: Replace or change

T: Tighten

REMARKS

After 80.000 km or 48 months, continue to foltow the described maintenance at the recommended intervals.

As

*I

*2

“3

*4

*5

*6

*7 for *’

marked items in this’ maintenance chart, note the following points.

Major service interval at 12 months!ZO,OOO km (I 2,000 miles).

Lubrication service based on distance only, 10,000 km (6,000 miles), not time.

Adjust or inspect alternator and water pump drive belt, and power steering and air conditioner drive belt

ii equipped.

Replacement of the timing belt is required every ICQOUO km (60,000 miles). Failure to replace the timing

belt may result in damage to the engine.

If the vehicle is operated under any of the following conditions, it is suggested that the engine

oil and

oil filter be changed more often than the recommended intervals.

a) Driving in dusty conditions.

b) Extended periods of idling or low speed operation.

c) Driving for prolonged periods in cold temperatures or regularly driving only short distances.

If the vehicle is operated in very dusty or sandy areas, inspect and, if necessary, replace more often

than the recommended intervals.

This is a full function check of all electrical systems, i.e, afl lights, washers (inctuding condition of blades)

electric windows sunroof, horn, etc.

Replace every two years.

tf there has been continuous hard driving, mountain driving, or it the brakes are used extensively or the

vehicle is operated in extremely humid climates, the brake fluid should be changed annually.

Emission Control and Related Systems

The ignition and fuel systems are vitally important to the proper operation of the emission control and related

system, as well as for efficient engine operation. It is strongly recommended that all servicing related to these

systems be done by your Authorised Mazda Dealer.

93GOAX-704

A-5

Page 25 of 677

SCHEDULED MAlNTENANCE SERVICES (Europe)

Maintenance Number of months or km (miles), whichever comes first

Months” - 6 1 12 18 24 1 30

36 1 42 48

Maintenance Wometers 1,000 10,000 20,000 30,000 40,000 50,000 60,000 1 70,000 80,000

interval

(Miles) (600) (6,000) (12,000) (18,000) (24,000) (30,000) (36,000)~(42,000) (48,000)

Engine Intake

and exhaust manifold nuts (Bolts) Drive belts * 2

Engine ttming belt *’

Engine oi; (Non-Turboj’4

Oil filter * 4

Cooling system (Including coolant

level adjustment)

Enaine coolant T

1 1 1

1 1 ’

A

[ A I A 1 A ] [ A

Replace every t 00,000 km (60,000 miles)

R

R R R R R R R 1 R

R R R R R R R R

I I 1 I

Reolace everv 2 Years

Fuel system

Idle speed

Idle mixture

Air cleaner element *’ Fuel

filter

Fuel lines and hoses

I A I * A 1 A 1 A

I

A A A A

I R I R

R

I R I

1 I

t I 1 [ I

Ignition system

Initial ignition timing

Spark plugs I t I I 1 I 1 I

A A ( A A

Evaporative emission control system

Electrical system

Ejattery electrolyte level and specific gravity A

A 1 A A 1 A

Electrical system

l 6

I I I

I t I 1 I I

Headlight algnment

A A f A 1 A

Chassis and body

Clutch pedal

Clutch fluid

Brake lines, hoses and connections

Brake pedal

Brake flutd *7

Parking brake

Power brake unit and hoses

DGC brakes

Pow& steering fluid

Power steering system and hoses

Steering and front suspension

MTX oil

Rear axle oil

Transfer carrier

ui!

Rear suspension bail joint

Bolts, nuts on chassis and body

8ody condltlon (Visual onty)

-

I I I I I I I I

1 I I I I I I I

I

1 I I

i

1 I I I I I I

I I I

R I 1 I R

A A A 1 A

1

1 i 1 I

I

I I

I

I

I I I I I I I

I 1 I I

I 1 I 1 i

1 A

A R A A A R

iR,i A R A A A R

R ’

A . A R A A A R

f I

T

T T T

T

I Inspect annually

93GOAX-705

A-6

Page 27 of 677

A SCHEDULED MAINTENANCE sERvw3 (Europe)

SCHEDULED MAfNTENANCE SERWCES (Europe)

MAWTENAN CE TABLE (Unlead Fuel Model)

Chati symbols:

I : Inspect: Visual examination and/or functional measurement of system’s operation or performance

A: Adjust: Examination resulting in adjustment or replacement

R: Replace or change

T: Tighten

REMARKS

After 80,000 km or 48 months, continue to follow the described maintenance at the recommended intervals.

As for * marked items in this maintenance chart, note the following points.

* 1 Major service interval at 12 months120,OOO km (12,000 miles).

Lubrication service based on distance only 10,000 km (6,000 miles) not time.

*2 Adjust or inspect alternator and water pump drive belt, and power steering and air conditioner drive belt

if equipped.

“3 Replacement of the timing belt is required at every 100,000 km (60,000 mile). failure to replace the tim-

ing belt may result in damage to the engine.

“4 If the vehicle is operated under any of the following conditions, it is suggested that the engine oil and

oil filter be changed more often than the &commended intervals.

a) Driving in dusty conditions.

b) Extended periods of idling or low speed operation.

c> Driving for a prolonged periods in cold temperatures or regularly driving only short distances.

*5 If the vehicle is operated in very dusty or sandy areas, inspect and, if necessary, replace more oten

than at usual recommended intervals.

*6 This is a full function check of all electrical systems, i.e, all lights, washers (including condition of blades)

electric windows, sunroof, horn etc.

“7 Replace every two years.

If there has been continuous hard driving, mountain driving, or if the brakes are used extensively or the

vehicle is operated in extremely humid climates, the brake fluid should be changed annually.

Emission Control and Related Systems

The ignition and fuel systems are vitally important to the proper operation of the emission control and related

system, as well as for efficient engine operation. It is strongly recommended that all servicing related to these

systems be done by your Authorised Mazda Dealer.

93GOAX-707

A-8

Page 28 of 677

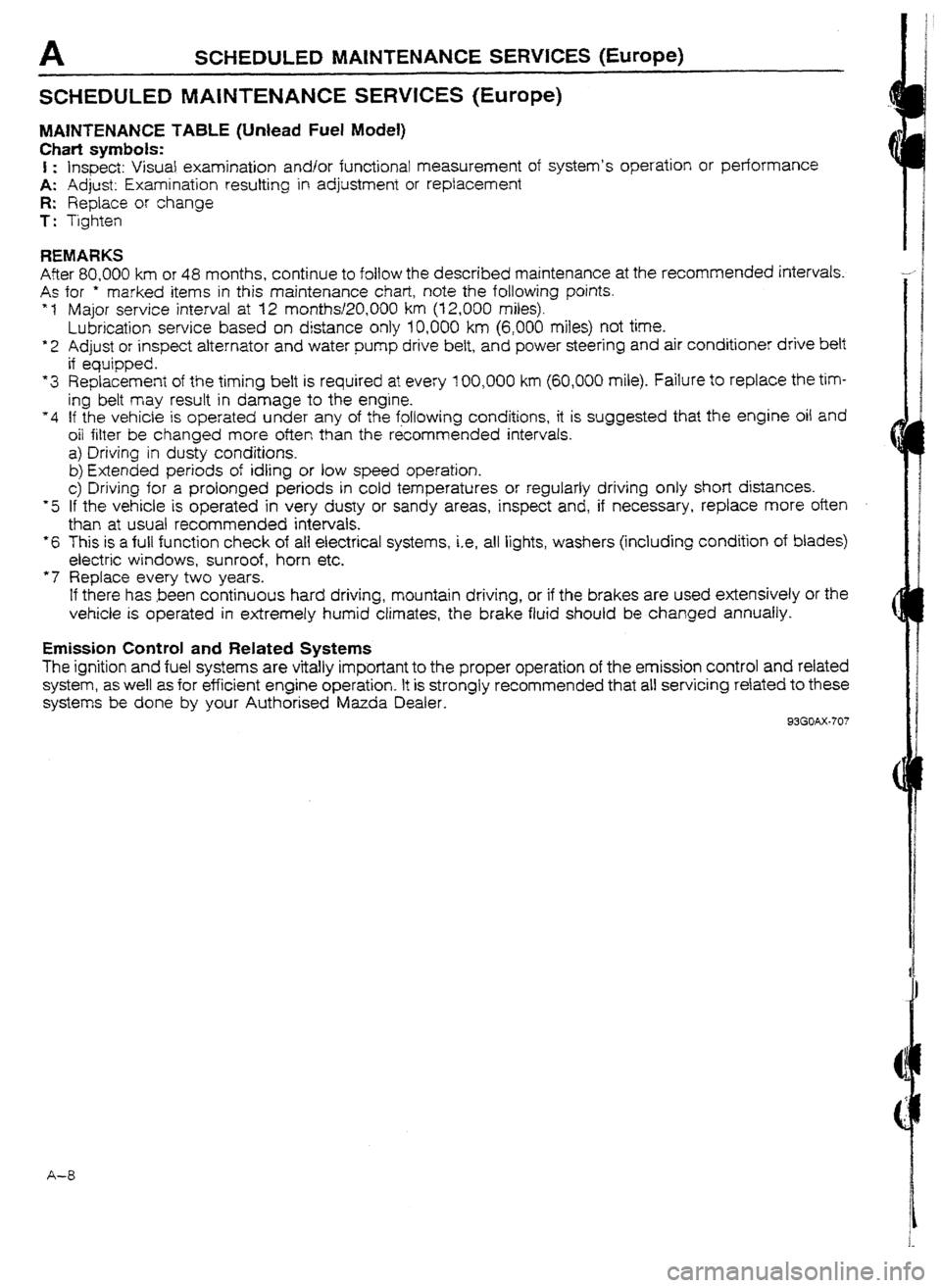

SCHEDULED MAtNTENANCE SERVICES (Europe) A

Maintenance Number of months or km (miles), whichever comes first

Months” - 6 1 12 18 ‘24 30136 42 48

Maintenance Kilometers 1,000 10,000 20,000 30,000 40,000 50,000 ( 60,000 70,000 80,000

(Miles) (600) (6,000) (12,OOO)~(l8,0~0) (24,000) (3O,UOO))(36,000) (42,000) j48,OOU)

Engine

!nrake and exhaust manifold nuts (80&j

Owe belts *’

Engrne timing belt l 3

Engine oil flurbo)‘4

Engine oil (Non-turbo)“4

Oil filter’4

Cooling system (I ncludrng

coolant level adjustment)

Engine coolant T 1 T T

A 1 1 A A 1 A A

Reptace every 100,000 km

{60,000 miles)

Replace every 5,000 km (3,000 miles) or 6 months

R R 1 R R R R ‘ R R R

R R R R R R R ’ R

I I I I

Replace every 2 years

Fuel system

Idle soeed

I A 1

Air cleaner elemenf*5 I f R E

R

Fuel fitter

R R

fuel 11~s and hoses 1

t 1 I I I I

Ignition system

lrritiai ignition timing

Spark plugs

Spark plugs (Only for Sweden) 1 I I I 1 I I 1 I I 1 I

A 1 A A 1 A

Adjust every 30,000 km {

18,000 mils)

Evaporative emission control system

Throttle sensor

Throttle sensor (Only for

Sweden)

Evaporative system Evaporatwe system Khlv

for Sweden) 1 1 Aj 1 A ( [ A ] 1 A

Adjust every 80,000 km (48,000 miles)

I 1 I [ I 1

I I [ 1 I

lnsoect everv 80.000 km (48.000 miles)

Electrical system

Battery electrolyte level and specific gravity

A 1 A A ’ 1 A ; A *

All Electrical system *’ I I 1 I I I I I I

Headlight alignment A A A I

c I A ,

Chassis and body

clutch Dedal

Clutch fluid

Brake lines, hoses and connectrons

Brake pedal

Brake fluid”’

Parking brake

Power brake unit and hoses

Disc brakes

Power steering fluid

Power steering system and hoses I

I I 1 1 1 I I

I I

I

I I I I 1 1 I

1

1 I I

I I I I t ! I I

I I I R I 1 I R

A A A A

I I I I

I 1 I 1

I 1 I I I I j I ,

I

I 1 I 1

I

93GOAX-708

A-9

Page 107 of 677

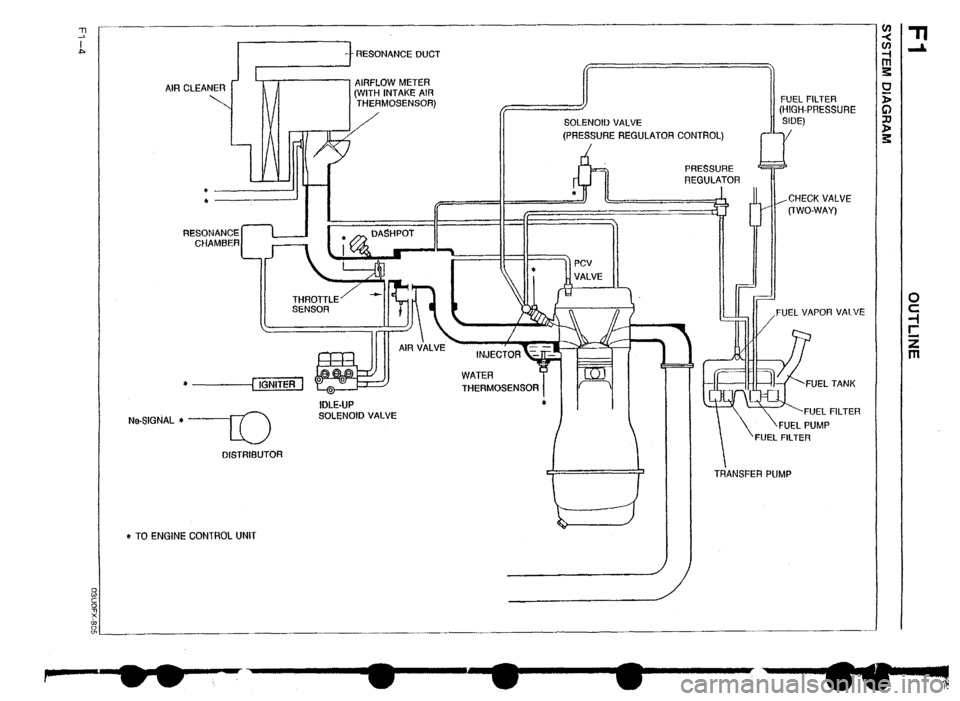

I

(WITH INTAKE AIR

THERMOSENSOR) AIR CLEANER METER

RESONANCE

CHAMBER /

SOLENOID VALVE

(PRESSURE REGULATOR CONTROL) FUEL FILTER

(HIGH-PRESSURE

SIDE)

P-“---j

Ne-S’GtiAL * ----El

DlSTRlfjUTOR IDLE-UP

SOLENOID VALVE

* TO ENGINE CONTROL UNIT ,CHECKVALVE

(TWO-WAY)

FUEL VAPOR VALVE

*

THERMOSENSOR

‘FUEL PUMP

FUEL FILTER

I TRANSFER PUMP

Page 112 of 677

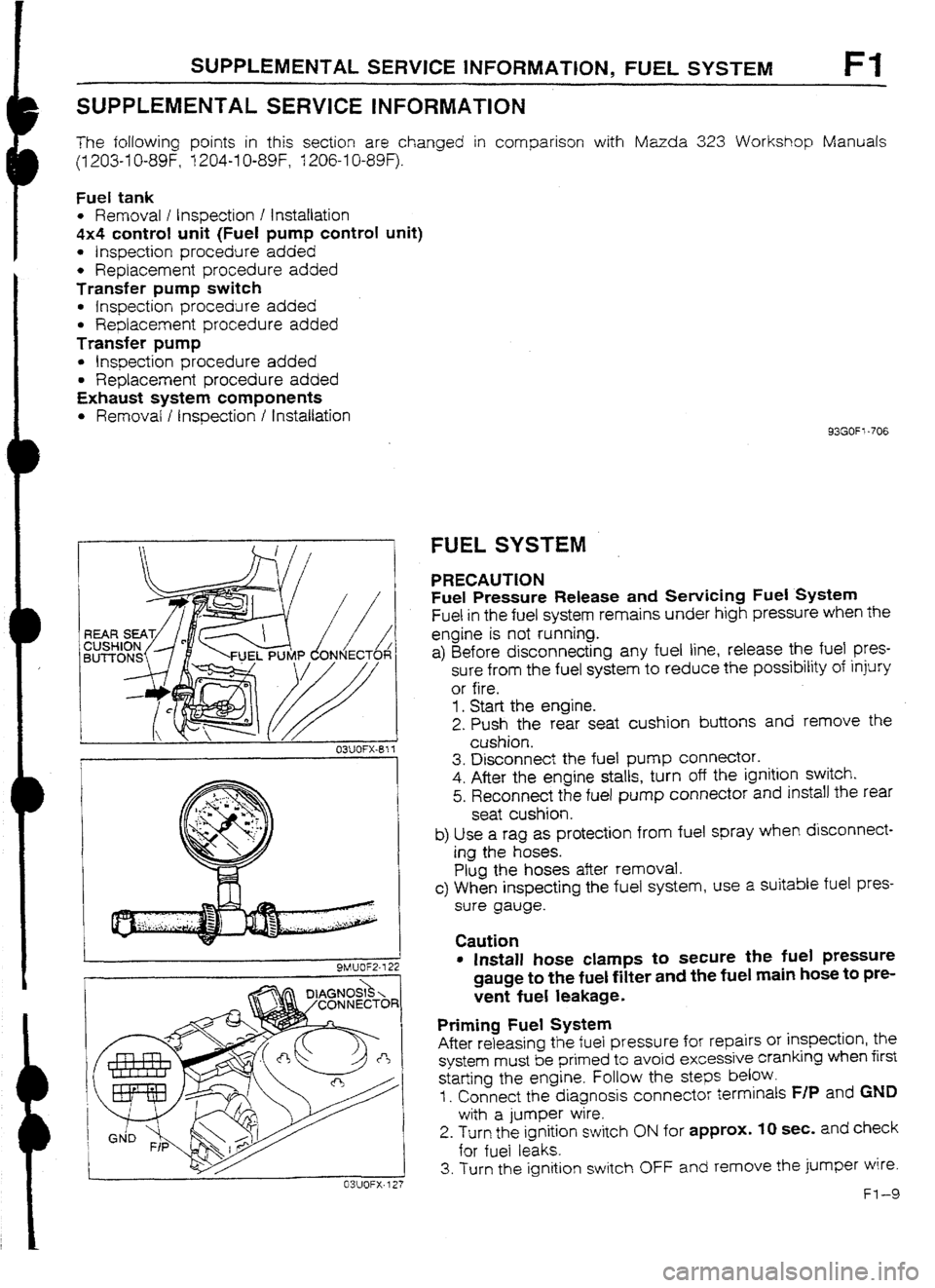

SUPPLEMENTAL SERVICE INFORMATION, FUEL SYSTEM Fl

SUPPLEMENTAL SERVICE INFORMATION

The following points in this section are changed in comparison with Mazda 323 Workshop Manuals

(I 203-I U-89F, 1204-I O-89F, I2061 O-89F).

fuel tank

l Removal I Inspection I Installation

4x4 control unit (Fuel pump control unit)

l Inspection procedure added

l Replacement procedure added

Transfer pump switch

l Inspection procedure added

l Replacement procedure added

Transfer pump

l Inspection procedure added

l Replacement procedure added

Exhaust system components

l Removai I Inspection I installation 93GOF? -706

FUELSYSTEM

PRECAUTION

Fuel Pressure Release and Sewicing Fuel System

Fuel in the fuel system remains under high pressure when the

engine is not running.

a) Before disconnecting any fuel line, release the fuel

pres-

sure from the fuel system to reduce the possibility of injury

or fire.

1. Start the engine.

2. Push the rear seat cushion buttons and remove the

cushion.

3. Disconnect the fuel pump connector.

4. After the engine stalls, turn off the ignition switch.

5. Reconnect the fuel pump connector and install the rear

seat cushion.

b) Use a rag as protection from fuel spray when disconnect-

ing the hoses.

Plug the hoses after removal.

c> When inspecting the fuel system, use a suitable fuel pres-

sure gauge.

Caution

l Install hose clamps to secure tile fuel pressure

gauge to the fuel filter and the fuel main hose to pre-

vent fuel leakage.

Priming Fuel System

After releasing the fuel pressure for repairs or inspection, the

system must be primed to avoid excessive cranking when first

starting the engine. Follow the

steps below.

I. Connect the diagnosis connector terminals F/P and GND

with a jumper wire.

2. Turn the ignition switch ON for approx. IO sec. and check

for fuel leaks.

3. Turn the ignition switch OFF and remove the jumper wire.

Fl-9

Page 123 of 677

SOLENOID VALVE

CHECK VALVE

r----+ (PURGE CONTROL)

CHiRCOAL

I CANISTER

INTERCOOLER 11 ’ 1 ‘I A-4

II II -

AIR , BYPASS

II ,.-ok----,/ ,CHECK VALVE

(TWO-WAY)

1-1

---II

-d KNO&

II II I I II VALVE

VALVE

THERMOSENSOR

c

I 31c

SENSOR 1 k---k FUEL FILTER

TRANSFER

PUMP

WASTEGATE 7

II t I III TURtiOCHARGERI~

I SOLENOID I II - i 1 WASTFGATF II I

AlOCI fuAl RAlz-rCD

VALVE

le-SIGNAL* -

EJ 0

G-SIGNAL-

DISTRIBUTOR

CATALYTIC CONVERTER ftl”FLLt”” IVIL I =r,

(WITH INTAKE THERMOSENSOR)

*TO ENGINE CONTROL UNIT

Page 167 of 677

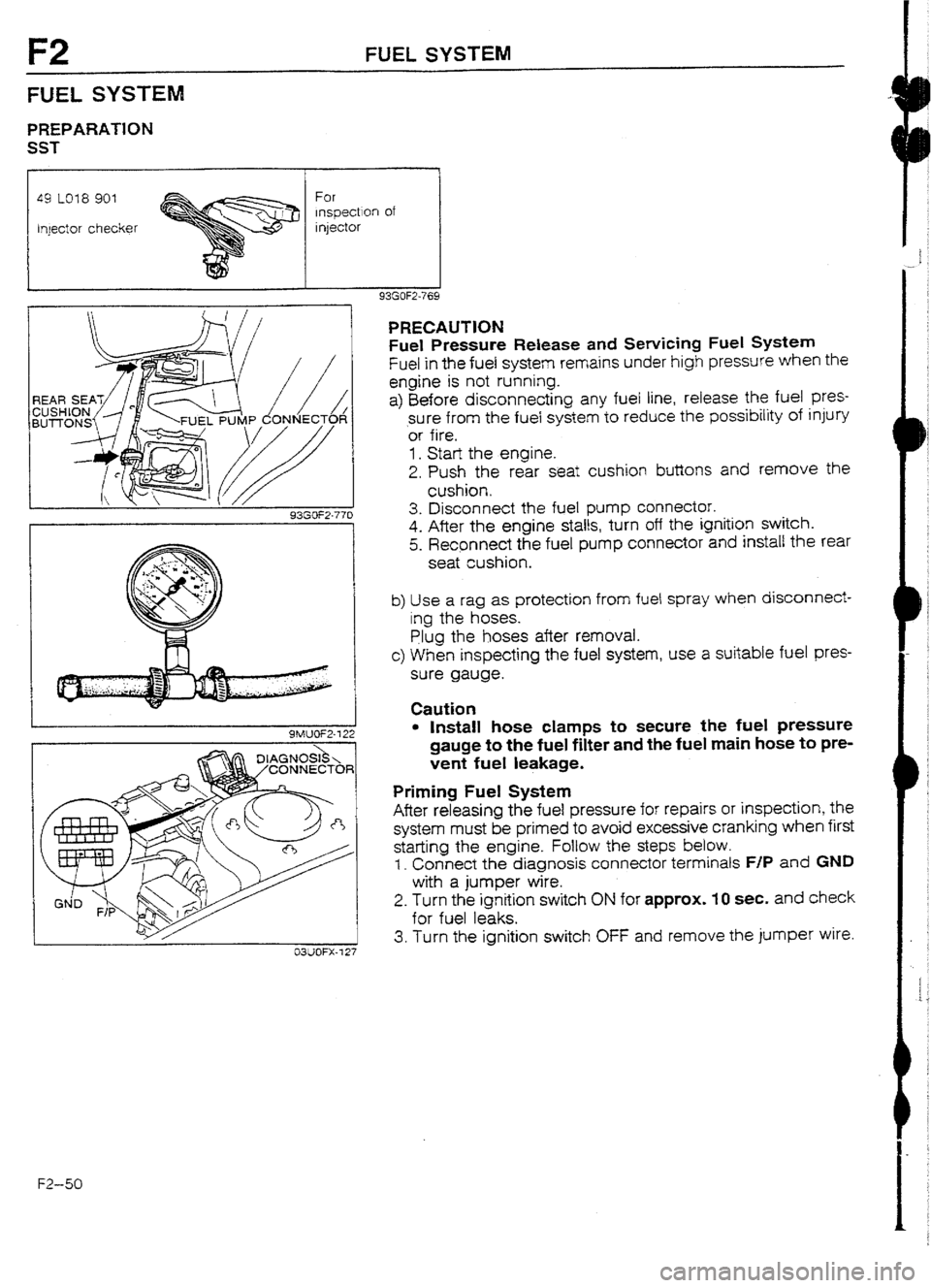

F2 FUEL SYSTEM

FUEL

SYSTEM

PREPARATlON

SST

49 LO18 901

Injector checker For

lnsgectlon of

injector

93GOF2.770

9MUOF2-722

03UOFX-7 27

F2-50

PRECAUTION

Fuel Pressure

Release and Servicing Fuel System

Fuel in the fuel system remains under high pressure when the

engine is not running.

a) Before disconnecting any fuel line, release the fuel pres-

sure from the fuel system to reduce the possibility of injury

‘or fife,

1. Start the engine.

2. Push the rear seat cushion buttons and remove the

cushion,

3. Disconnect the fuel pump connector.

4. After the engine stalts, turn off the ignition switch.

5. Recpnnect the fuel pump connector and install the rear

seat cushion.

b) Use a rag as protection from fuel spray when disconnect-

ing the hoses.

Plug the hoses after

removal.

c) When inspecting the fuel system, use a suitable fuel pres-

sure gauge.

Caution

l Install hose clamps to secure the fuel pressure

gauge to the fuel filter and the fuel main hose to pre-

vent fuet leakage.

Priming Fuel System

After releasing the fuel pressure for repairs or inspection, the

system must be primed to avoid excessive cranking when first

starting the engine. Follow the steps

below.

1. Connect the diagnosis connector terminals F/P and GND

with a jumper wire.

2. Turn the ignition switch

ON for approx. 10 set, and check

for fuel leaks.

3. Turn the ignition switch OFF and remove the jumper wire.