fuel pump MAZDA 323 1992 Suplement User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: 323, Model: MAZDA 323 1992Pages: 279, PDF Size: 24.15 MB

Page 56 of 279

TROUBLESHOOTING GUlDE F3

STEP INSPECTION ACTlON

4

Is there buttery voltage at fuel pump connector Yes

* (G/R) with lgnitron switch ON and F/P terminal Check contmurty of fuel pump

between termrnafs G/R and 8

Check ctrcutt openmg relay

5

Is qector operating sound heard whtle engine IS Yes Go to Step 8

being cranked?

No Go to next step

CcI page F3-45

+ If 0K;check for a short cjrcult rn

wiring harness

(Injector reastor-Injector)

=D If not OK, replace Injector reststor

fuel Line pressure: 265-314 kPa

12.7-3.2 kgflcd, 38-46

psi)

if fuel return hose is clogged or

t, replace pressure

CT psge F3-3

F3-2 3

Page 58 of 279

TROUBLESHOOTING GUIDE F3

4 CRANKS NORMALLY 8UT WILL NOT START (PARTfAL COMBUSTION) - AFTER WARM-UP

&RIP-

l Engine cranks at nurmal speed and shows partial combustion but will not Continue running after being hot

soaked

FION

l Battery in normal condltlon

*Engine starts normally when cold

TROUBLESHOOTING

HINTS] 3 Air/Fuel mixture too rich @ Vaporlock

ssure not held in fuel line after engrne IS

GND mth jumper wire tor 3

minutes with ignition

Fuel

line pressure: 265-314 kPs (2.7-3.2 kgflcm2, 38-46 psi 1

c3 If pressure

quickly increases,

check pressure regulator

4 If pressure

gradually increases,

check fuel line and filter lor

clogging

If hose is not clogged. check fuel

pump maximum pressure

High pressure Check if fuel return hose is clogged or

restricted

INSTALL CLAMPS e If rt is not, replace pressure

regulator

@ It It 6. repalr or replace it CT page F3-3

F3-25

Page 59 of 279

F3 TROUBLESHOOTING GUIDE

I- STEP lNSPECTlON ACTION

Yes Go to Step 8

5 In same condition as in Step 2, IS fuel ilne pres-

sfire held after Igrxtbon swatch rs turned OFF?

Fuel line pressure: More than 147 kPa

Il.5 kgflcm’, 21 Psi 1 for 5 min.

6 In same condition as in Step 3, IS fuel line pres-

sure held after lgnltron switch IS turned OFF?

Fuel line pressure: More than 147 kPa

{ t.5 kgf/cm*, 21 psi) for 5 min.

No

I Go to next step

Plug both vcuum ports of pressure regulator; IS

fuel lme pressure held after ignltlon switch is

turned OFF? Yes Replace pressure regulator

r~ page F3-3

Fuel line pressure: More than 147 kPa

{ 1.5 kgf/crn*, 21 psi] for 5 min.

NO Check fuel pump hold pressure

e If OK, check InJector for fuel

leakage

e If not OK reptace fuel pump ZF- page F3-42

T page F3-3

8 Dlscofinect water thermosensor connector, does

engtne start? Yes Check water thermosensor

e ff OK. check connectrons of water

thermosensor and ECU 2Q terminal

Q If not OK, replace water thermo-

sensor

ET page F3-13

No 1 Go to next step --~

Is “00” drsplayea on Self-Diagnosis Checker

with ignition switch ON? 9 Yes Go to next step

NO Service Code No. displayed

Check for cause (Refer to specified

check sequence)

c7 page F3-16 SYSTEM SELECT, 1

“88” flashes

Check ECU terminal IF voltage

KIT page F3-45

Voltage: Battery voltage

(ignition switch ON)

e If OK, replace ECU

ET- page F3-2

e If not OK, check wiring

(ECU - Self-Diagnosis Checker)

Y %EtECT SW: A

Yes 1 Go to next step 10 Are rf ECU termrnaf voltages are OK?

(especjaffy 1C. 2D. and 2Q)

CT page F3-45

NO Check for cause

Yes Replace ECU

=T page F3-2

No Change to another brand of fuel

13EOF3 331 Try known good ECU, does condition improve?

CT page F3-2

F3-26

Page 61 of 279

F3 TROU8LESliOOTING GUIDE

iTEP INSPECTION

ACTtUN

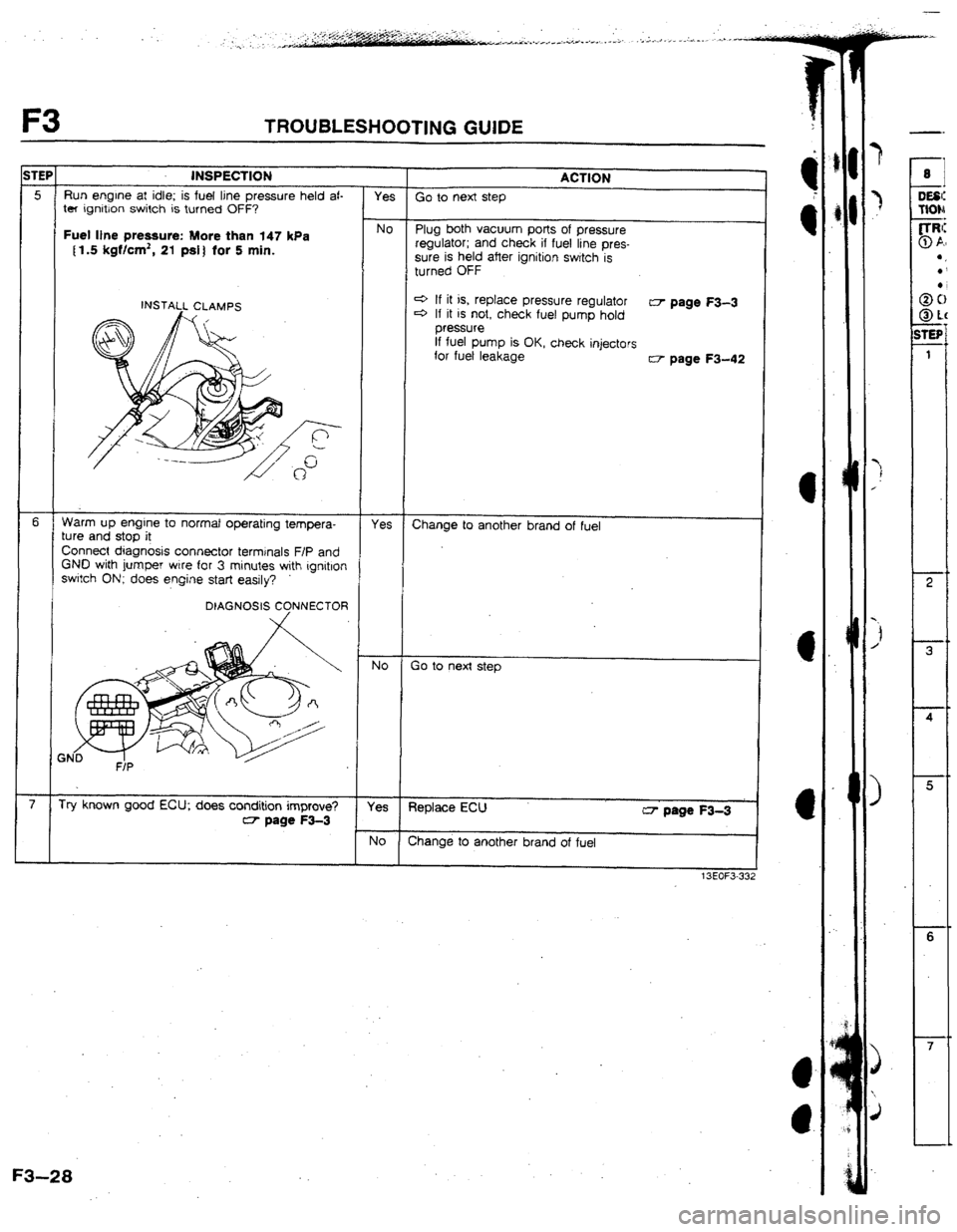

5 Run engine at idle; is fuel line pressure held af-

Yes Go to next step

ter ignition switch is turned OFF?

Fuet Ijne pressure: More than 147 kPa No Plug both vacuum potts of pressure

{1,5 kgflcd, 21 pdf for 5 min. regulator;

and check if fuel line pres-

sure is held after ignition switch is

turned OFF

NSTAtl CLAMPS 4 If it is, replace pressure regulator

c3 If it is not, check fuel pump hold CT page F3-3

pressure

If fuel pump is OK, check injectors

for fuet leakage

CT- page F3-4

6 Warm up engine to normal operating tempera-

Yes

ture and stop it Change to another brand of fuel

Connect diagnosis connector terminals F/P and

GND with jumper wire for 3 minutes with rgnitlon

switch ON; does engine start easily?

No Go to next step

7 Try known good ECU; does condition improve?

Yes Replace ECU

CT page F3-3 w- page F3-3

No Change to another brand of fuel

t3EOF3

F3-28

Page 63 of 279

F3 TROUBLESHUOTING GUIDE

TEPI tNSPECTION ACflON

e If OK, replace injector

4 If not OK, check for cause w Section 82

(Upper vacuum hose to pressure regulator 4

If pressure quickly increases,

check pressure regulator

4 If pressure

gradually increases,

check for clogging between fuel

pump and pressure regulator

if hose is not clogged, check fuel

pump maximum pressure

I

12 Is engine compression correct? Yes Go to next step w Sectlon 82

Engine

compression: 1059 kPa (10.8 kgf/cm2, 152 psi]-300 rpm NO Check for cause w Section B2.

13 Connect System Selector to diagnosis connector

Yes Try known good ECU; does condition

and $et Test Switch to SELF TEST; is ignition improves? w page f3-3 timing correct at idle after warm-up?

ignition timing (BTDC): 10 * to

NO Adjust ignition timing

F3-30

7

*

10

DES&

HON

-*

ITEP

2

3

4

Page 65 of 279

![MAZDA 323 1992 Suplement User Guide F3 TROUBLESHOOTING GUIDE

3TEI ACTION

Is fuel line pressure correct at Idle?

*

Fuel line pressure: 265-314 kPa

12.7-3.2 kgf/cm’, 38-46 psi]

(Two vacuums hose to pressure regulator

disconnected MAZDA 323 1992 Suplement User Guide F3 TROUBLESHOOTING GUIDE

3TEI ACTION

Is fuel line pressure correct at Idle?

*

Fuel line pressure: 265-314 kPa

12.7-3.2 kgf/cm’, 38-46 psi]

(Two vacuums hose to pressure regulator

disconnected](/img/28/57055/w960_57055-64.png)

F3 TROUBLESHOOTING GUIDE

3TEI ACTION

Is fuel line pressure correct at Idle?

*

Fuel line pressure: 265-314 kPa

12.7-3.2 kgf/cm’, 38-46 psi]

(Two vacuums hose to pressure regulator

disconnected)

304-392 kPa [ 3.1-4.0 kgf/cm’, 44-57 psi 1

(Upper vacuum hose to pressure regulator

disconnected)

INSTALL CLAMPS Yes Go to next step

No Low pressure

Check fuel line pressure while pinching

fuel return hose

4 If pressure quickly Increases,

check pressure regulator

e If pressure gradually Increases,

check for clogging between fuel

pump and pressure regulator

If hose is not clogged, check fuel

pump maxrmum pressure

Connect System Selector to diagnosis connector

and set Test Switch to SELF TEST; is ignition

tlmlng at idle correct after warm-up?

Ignition timing (BTDC): 10 f lo Yes Go to next step

No Adjust tgnrtkon system

8 Dtsconnect water thermosensor connector; does

engine condrtlon Improve? Yes Replace water thermosensor

No

Try known good ECU. does condltlon

Improve?

w page F3-13

Go to next step

Check if injector resistance is OK

w page F3-42 9 Is jqector operating sound heard at Idle?

Yes

No

Resistance: Approx. 2.11 Q

(at 20°C 168*F])

4 If it is, check wlnng

(ECU - Injector)

c3 If it Is not, replace injector

Go to next step IO

Yes Is engine compressron cprrect?

w Section G

No

Engine compression:

1059 kPa 110.8 kgf/cm2, 152 psi)-300 rDm

is strong blue spark vrslble at each disconnected

hrgh-tension lead?’ Check engine

3 Section B2

17

Yes Go to next step

No Check high-tension lead

w Section G

c3 If UK, check distrrbutor cap and

rotor

3 If not OK, replace htgh-tensron lead

Try known good ‘ECU: does condrtron

Improve7

w page F3-3 12 Are spark plugs.OK?

w Section G

l Wear and carbon butld up l Piug gap l Damage Yes

NO

Clean, adjust

13EOi3.334

F3-32.

Page 73 of 279

F3 FUEL SYSTEM

t 3EoF3-344

1

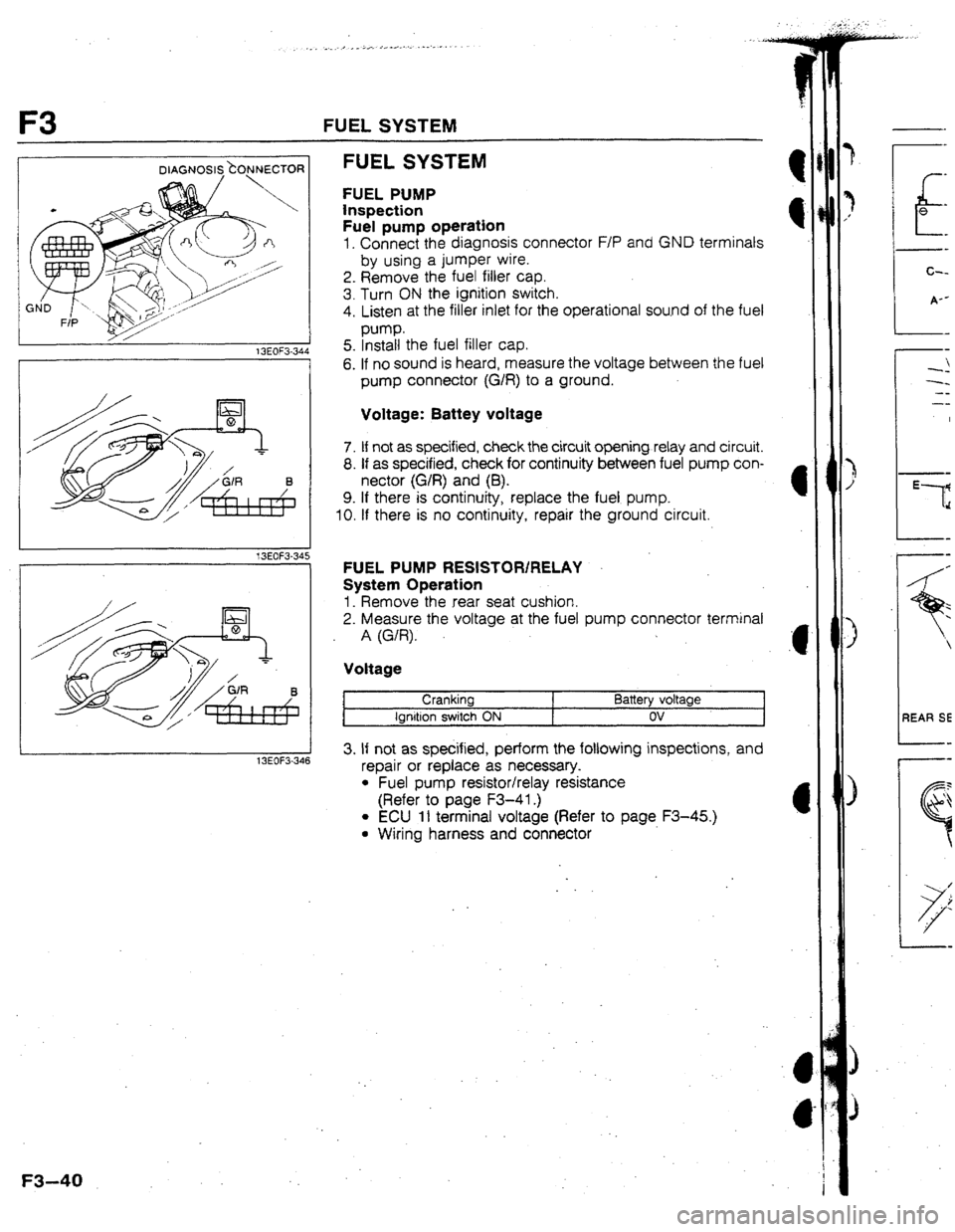

FUEL SYSTEM

FUEL PUMP

inspection

Fuel pump operation

1. Connect the diagnosis connector F/P and GND terminals

by using a jumper wire.

2. Remove the fuel filler cap.

3. Turn ON the ignition switch.

4.

Listen at the filler inlet for the operational sou.nd of the fuel

pump.

5. Install the fuel filler cap.

6. If no sound is heard, measure the voltage between the fuel

pump connector (G/R) to a ground.

Voltage: 8attey vo kage

7. If not as specified, check the circuit opening relay and circuit.

8. ff as specified, check fur continuity between fuel pump con-

nector (G/R) and (B).

9. If there is continuity, reptace the fuel pump.

10. If there is no continuity, repair the ground circuit.

f3EOF3.345

13EOF3-346 FUEL PUMP RESlSTORlRELAY

System Operation

1. Remove the rear seat cushion.

2. Measure the voltage at the fuel pump connector terminal

A (G/R).

Voltage

I

Cranking

1 Battery voltage

Ignition switch ON ov 3. If not as specified, perform the following inspections, and

repair or replace as necessary.

l Fuel pump resistor/relay resistance

(Refer to page F3-41.)

l ECU 11 terminal voltage (Refer to page F3-45.)

l Wiring harness and connector

F3-40

ii e -

*

_~ --

C --

A-'

-,

-,

--

--

-1

E

7

2

I

i 3EAR SE

--

Page 74 of 279

FUEL SYSTEM F3

13EOF3.34

c I 13EOF3-364 FUEL PUMP CONNECTOR

/

!NSTALL CLAMPS

I

l nspection

1, Disconnect the resistor/relay connector.

2. Ground the fuel pump resistor relay terminal D.

3. Apply battery voltage and check for continuity as shown.

Terminal C

Continuity between A and I3

Battery voltage applied NO

ov Yes

4. Measure the resistance between terminals E and F.

Resistance : 0.38--0.42Q (at 2O*C {6S°F 1)

PRESSURE REGULATOR

Inspection

Fuel line pressure

Warning

l Before performing the following operation, release

the fuel pressure from the fuel system to reduce the

possibility of injury or fire. (Refer to page F3-21.)

1. Disconnect the negative battery terminal.

2. Connect a fuel pressure gauge between the fuel filter and

the fuel main hose. (install clamps as shown.) , .

I

3. Connect the negative battery terminal.

/t.

4, Start the engine and run it at idle.

5. Measure the fuel line pressure.

Fuel line pressure:

206-255 kPa [ 2.1-2.6 kgflcml, 30-37 psi )

6. Disconnect the upper vacuum hose from the pressure regu-

lator and measure the fuel line pressure.

Fuel line pressure:

304-392 kPa (3.1-4.0 kgf/cm2, 44-57 psi )

F3-41

Page 79 of 279

F3 CONTROL SYSTEM

Terminal voltage

Reference date

Vs: Battery voltage

‘em&al Input Output Connected to Test condition Correct voltage Remark

1A - - Battery Constant VB

For backup

18 0 Main relay

Ignition switch OFF ov

(FUEL INJ relay) -

ON

V8

1C 0 lgnitlon switch While cranking Approx. 1 OV

(START) -

Ignition switch ON ov

10 0 Self-Diagnosis Test switch at SELF TEST

Wtth Self-

Checker Lamp illuminated for 3 sec. after ignition Approx. 5V

(monitor lamp) switch OFFdON Diagnosis Check-

er and System

lamp not iltuminated after 3 sec. V8 Selector

Test switch at 02 MONITOR with engine

idling Approx. 5V

Monitor lamp illuminated

Test switch at 02 MONITOR with engine

idling Vi3

Monitor lamp not illuminated

IE - - - - - -

IF

0 Self-Diagnosis Buzzer sounded for 3 sec. after ignition

Below 2SV

l With Seif-

Checker switch OFF-+ON

Diagnosis

(service code)

Buzzer not sounded after 3 set V0 ’ Checker and

Buzzer sounded Below 2.5V System Selector

l With System

Buzzer not sounded VB Selector test

switch at SELF

TEST

1G 0 igniter tgnition switch ON

ov

-

Idte

Approx. 0.2V

It-l 0

Solenoid valve Ignition switch ON

VB

(wastegate)

Idle

Approx. 2V ’ -

II

0 Fuel pump While cranking

Approx. 1 OV

resistor/relay -

Idle

8etow 1.5V

IJ 0 NC relay Ignition switch ON

VB

A/C switch UN at idle

Below 2.5V

. NC switch OFF at idle V3

-

IK 0 Diagnosis

connector

(TEN terminal) System Selector test switch at

02 MONITOR

System Selector test switch at

SELF TEST V0

-

8elow l*OV

1L - - - - - -

I

1M - - - - -

I -

lr ‘- l-7

f L.-

r

20 20 2M 2K 21 2G 2E 2c 2A IU 1S 10 10 ltvl tK II Ir; tE 1~ IA

1

22 2x 2v 2T ZR 2P 2N 2L 25 2H 2F 20 2B 1V IT 1R tP 1N IL 1J 1H IF 1~ 1~

1

J=3-46 --

4lways 4

--

AIways 4

--

Atways 1

--

Always 1

-a

Always ’

--

Always i

-e

Always I

2.5v

Always

Always (

-m

Always f

-a

Always 1

Always (

--

Always I

2.5V

Always 1

Always t

Always

--

Page 80 of 279

,,1

CONTROL SYSTEM F3 ‘1

Va: Battew voltage

Incorrect voltage Possible cause

Always OV

l ROOM IOA fuse burned l Open circuit In wiring from ROOM 10A fuse to ECU termina! 1A

Always OV

l Main relay malfunction l Open or short circuit in wiring from main relay to ECU terminal IB

Always OV (starter turns)

l Open or short circuit in wiring from ignition switch to ECU terminal IC

Always OV

Always VB

l Maln relay (FUEL INJ relay) malfunction l Open circuit in wiring from main relay to diagnosis connector terminal +B l Open or short circuit in wiring from diagnosis connector terminal MEN to

ECU terminal 1 D

l Poor connection at ECU connector l ECU malfunction

Always approx. 5V . ECU malfunction

Always below

2.5v

Always Ve -

-

No display on Self- * Main relay (FUEL INJ relay) malfunction

Diagnosis Checker

l Open circuit in wiring from main relay to diagnosis connector terminal + B

“88” displayed and

l Open or short clrcurt in wiring from diagnosis connector terminal FEN to

buzzer sounds con- ECU terminal tF

ti nuousl y

l Poor connection at ECU connector l ECU malfunction

Always QV

l Short circuit in wiring from igniter to ECU terminal 16

Always OV or VB

l Refer to Code No.42 Troubleshooting

(Refer to 323 4-Wheel Drtve Workshop Manual (12?9-IO-89L))

Always VB

Always OV

Always below

2.5V

Atways Ve I ’

l Fuel pump resistor/relay malfunction

l Open or short circurt in wiring from ECU terminal II to fuel pump resis-

tor/relay

A/C does not operate

l A/C reiay malfunction l Open circuit in wiring from ignition switch to A/C relay l Open circuit in wiring from A/C relay to ECU terminal 1J

A/C switch

OFF but l Short circuit in wiring from AIC relay to ECU terminal 1 J

A/C operates . ECU malfunction

l Poor connection at ECU connector l ECU malfunction

Always below 1 .OV a Short circuit in wiring from diagnosis connector terminal TEN to ECU termi-

nal 1K

Always Vs

l Open circuit In wiring from diagnosis connector terminal TEN to ECU terml-

nal IK

-

-

l Open circuit in winrig from diagnosis connector terminal GND to ground’

-

I -

.

. .

-. F3-47