check engine MAZDA 323 1992 Suplement Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: 323, Model: MAZDA 323 1992Pages: 279, PDF Size: 24.15 MB

Page 74 of 279

FUEL SYSTEM F3

13EOF3.34

c I 13EOF3-364 FUEL PUMP CONNECTOR

/

!NSTALL CLAMPS

I

l nspection

1, Disconnect the resistor/relay connector.

2. Ground the fuel pump resistor relay terminal D.

3. Apply battery voltage and check for continuity as shown.

Terminal C

Continuity between A and I3

Battery voltage applied NO

ov Yes

4. Measure the resistance between terminals E and F.

Resistance : 0.38--0.42Q (at 2O*C {6S°F 1)

PRESSURE REGULATOR

Inspection

Fuel line pressure

Warning

l Before performing the following operation, release

the fuel pressure from the fuel system to reduce the

possibility of injury or fire. (Refer to page F3-21.)

1. Disconnect the negative battery terminal.

2. Connect a fuel pressure gauge between the fuel filter and

the fuel main hose. (install clamps as shown.) , .

I

3. Connect the negative battery terminal.

/t.

4, Start the engine and run it at idle.

5. Measure the fuel line pressure.

Fuel line pressure:

206-255 kPa [ 2.1-2.6 kgflcml, 30-37 psi )

6. Disconnect the upper vacuum hose from the pressure regu-

lator and measure the fuel line pressure.

Fuel line pressure:

304-392 kPa (3.1-4.0 kgf/cm2, 44-57 psi )

F3-41

Page 76 of 279

. !I11

PRESSURE REGULATOR CONTROL SYSTEM F3

13EOF3353

(PRC HIGH TEMP.)

13EOF3-35:

BAl-fERY VOLTA

PRESSURE REGULATOR CONTROL

SYSTEM

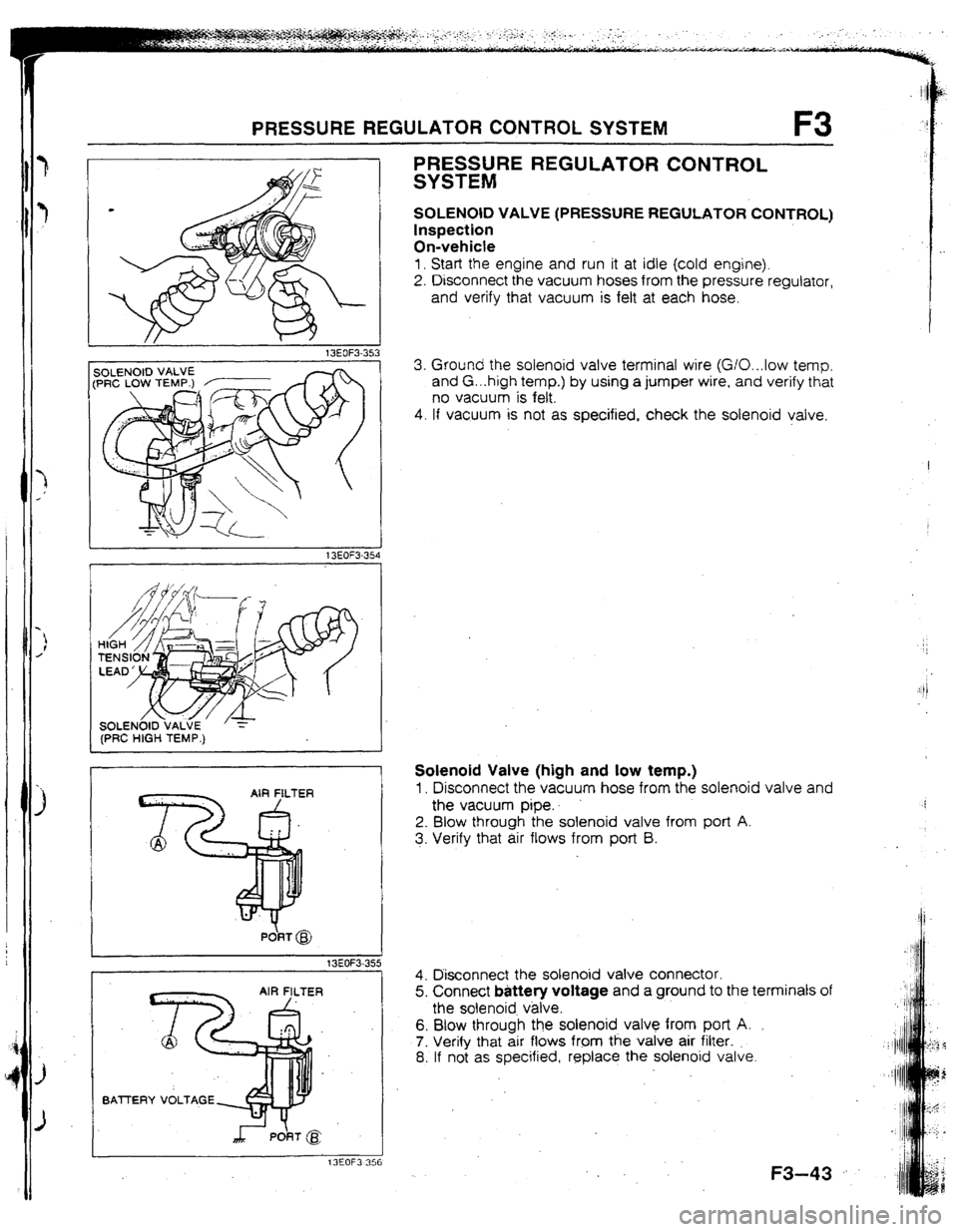

SOLENOID VALVE (PRESSURE REGULATOR CONTROL)

Inspection

On-vehicte

1. Start the engine and run it at idle (cold engine).

2. Disconnect the vacuum hoses from the pressure regulator,

and verify that vacuum is felt at each hose.

3. Ground the solenoid valve terminal wire (G/O...low temp.

and G. ..high temp.) by using a jumper wire, and verify that

no vacuum is felt.

4. If vacuum is not as specified, check the solenoid valve.

Solenoid Valve (high and low temp.)

1, Disconnect the vacuum hose from the solenoid valve and

the vacuum pipe..

2. Blow through the solenoid valve from port A.

3. Verify that air flows from port B.

4. Disconnect the solenoid valve connector.

5. Connect battery voltage and a ground to the terminals of

the solenoid v&e.

6. Blow through the solenoid valve from port A.

7. Verify that air flows from the valve air filter.

8. If not as specified, replace the solenoid valve.

.

F3-43

Page 78 of 279

CONTROL SYSTEM F3

hT==TdI ,

USE CONNECTOR A 1

L

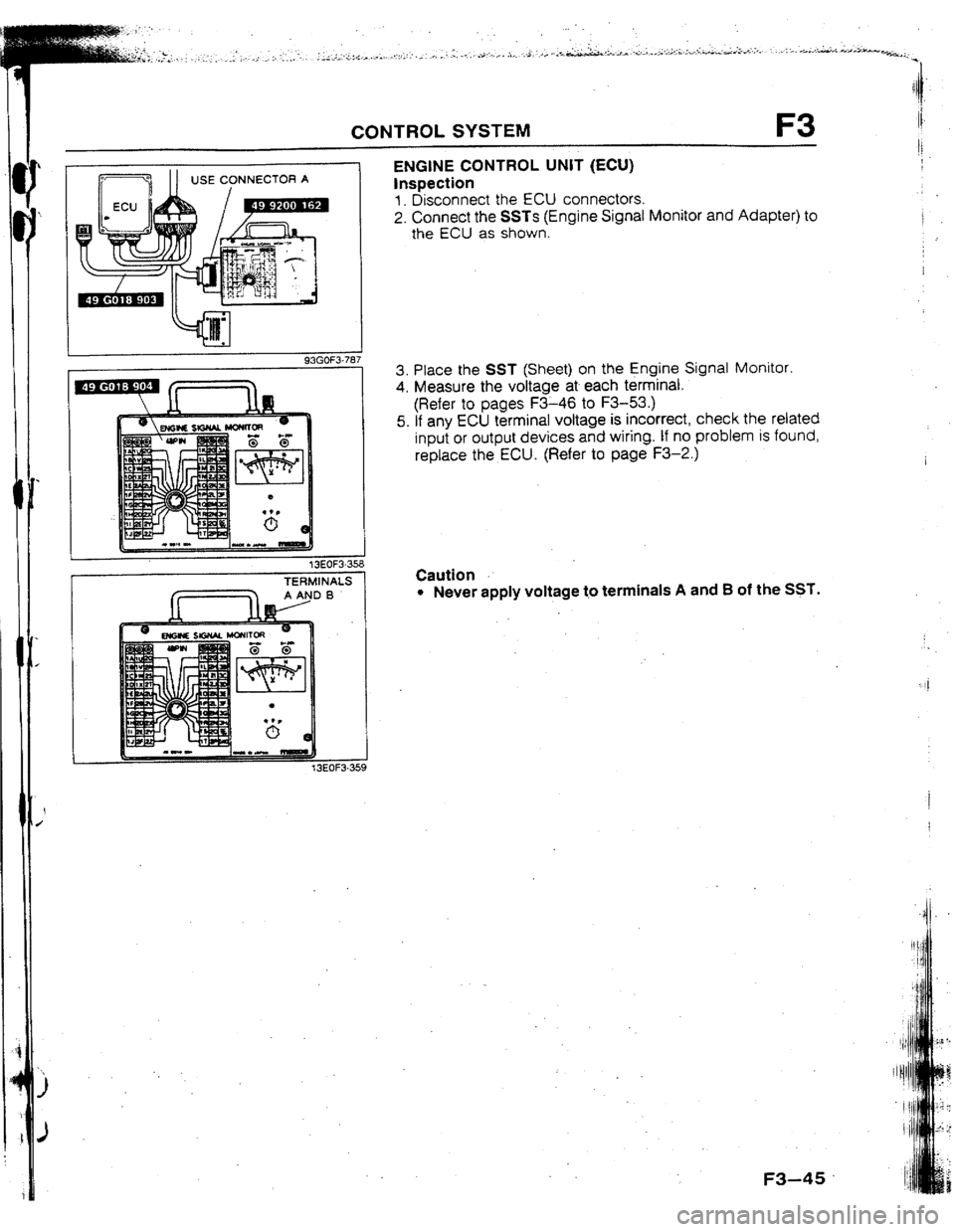

93GOF3-787 ENGINE CONTROL UNIT (ECU)

Inspection

1. Disconnect the ECU connectors.

2. Connect the SSTs {Engine Signat Monitor and Adapter) to

the ECU as shown.

3. Place the SST (Sheet) on the Engine Signal Monitor.

4. Measure the voltage at each terminal.

(Refer to pages F3-46 to F3-53.)

5. If any ECU terminal voltage is incorrect, check the related

input or output devices and wiring. If no problem is found,

replace the ECU. (Refer to page F3-2.)

t

1 13EOF3-358

r

TERMINALS

f. -I AANDB . Caution l Never apply voltage t.o terminals A and 8 of the SST.

! :OF3-359

F3-45

Page 79 of 279

F3 CONTROL SYSTEM

Terminal voltage

Reference date

Vs: Battery voltage

‘em&al Input Output Connected to Test condition Correct voltage Remark

1A - - Battery Constant VB

For backup

18 0 Main relay

Ignition switch OFF ov

(FUEL INJ relay) -

ON

V8

1C 0 lgnitlon switch While cranking Approx. 1 OV

(START) -

Ignition switch ON ov

10 0 Self-Diagnosis Test switch at SELF TEST

Wtth Self-

Checker Lamp illuminated for 3 sec. after ignition Approx. 5V

(monitor lamp) switch OFFdON Diagnosis Check-

er and System

lamp not iltuminated after 3 sec. V8 Selector

Test switch at 02 MONITOR with engine

idling Approx. 5V

Monitor lamp illuminated

Test switch at 02 MONITOR with engine

idling Vi3

Monitor lamp not illuminated

IE - - - - - -

IF

0 Self-Diagnosis Buzzer sounded for 3 sec. after ignition

Below 2SV

l With Seif-

Checker switch OFF-+ON

Diagnosis

(service code)

Buzzer not sounded after 3 set V0 ’ Checker and

Buzzer sounded Below 2.5V System Selector

l With System

Buzzer not sounded VB Selector test

switch at SELF

TEST

1G 0 igniter tgnition switch ON

ov

-

Idte

Approx. 0.2V

It-l 0

Solenoid valve Ignition switch ON

VB

(wastegate)

Idle

Approx. 2V ’ -

II

0 Fuel pump While cranking

Approx. 1 OV

resistor/relay -

Idle

8etow 1.5V

IJ 0 NC relay Ignition switch ON

VB

A/C switch UN at idle

Below 2.5V

. NC switch OFF at idle V3

-

IK 0 Diagnosis

connector

(TEN terminal) System Selector test switch at

02 MONITOR

System Selector test switch at

SELF TEST V0

-

8elow l*OV

1L - - - - - -

I

1M - - - - -

I -

lr ‘- l-7

f L.-

r

20 20 2M 2K 21 2G 2E 2c 2A IU 1S 10 10 ltvl tK II Ir; tE 1~ IA

1

22 2x 2v 2T ZR 2P 2N 2L 25 2H 2F 20 2B 1V IT 1R tP 1N IL 1J 1H IF 1~ 1~

1

J=3-46 --

4lways 4

--

AIways 4

--

Atways 1

--

Always 1

-a

Always ’

--

Always i

-e

Always I

2.5v

Always

Always (

-m

Always f

-a

Always 1

Always (

--

Always I

2.5V

Always 1

Always t

Always

--

Page 119 of 279

P CONVENTIONAL BRAKE SYSTEM

1 t3EOPX.314

@ 66.7 kPa

Iso0 mmHg.

19.7 inHg)

16EOPX-05t

1

13EOPX.315

P-8

POWER BRAKE UNIT

Quick Inspection (On-vehicle)

Power brake unit function check

(Method-using tester)

Connect the SST, vacuum gauge A, and pedal depression

force gauge B as shown in the figure. After bleeding the

air from the SST, conduct the test as described in the 3steps

below.

Note l

Use commercMty available vacuum gauge and ped.

al depression force gauge.

a) Checking for vacuum loss

Unloaded condition

1. Start the engine.

2. Stop the engine when the vacuum gauge reading reaches

66.7 kPa (500 mmHg, 19.7 inHg ) .

3. Observe the vacuum gauge for 15 seconds. If the gauge

shows 63.3-66.7 kPa [475--500 mmHg, 18.7-19.7

inHg 1, the unit is operating.

Loaded condition

1. Start the engine.

2. Depress the brake pedal with a fdrrce of 196 N I20 kgf,

44 Ibfj.

3. With the brake pedal depressed, stop the engine when the

vacuum gauge reading reaches 66.7 kPa {SO0 mmlig,

19.7 inHg].

4. Observe the vacuum gauge for 15 seconds. If the gauge

shows 63.3-66.7 kPa I475--500 mmHg; 18.7-l 9.7

inHg 1, the unit is operating.

b) Checking for hydraulic pressure

1, If with the engine stopped (vacuum 0 kPa (0 mmHg, 0

hltlg 1) the fluid pressure is within specification, the unit is

operating.

Pedal force N fkgf. Ibf]

Fluid pressure kPa (kgf/cm2, psi)

196 LZO. 441 1080 111. 1561 min.

2, Start the engine. Depress the brake pedal when.the vacu-

urn reaches 66.7 kPa 1500 mmHg, 19.7 intlg 1. If the flu-

id pressure is within specification, the unit is operating.

Pedal force N 1 kgf, fbf I Fluid pressure .kPa { kgflcm’. ps 1

196 I20,441 6670 {68, 967

1 min.

-- WlTHOU

&

d

I=-

-

1 MASTER CYUh

.

i_

Page 158 of 279

TECHNICAL DATA TD

Engine

Item BP DOHC turbo

Engine oii

Total (dry engine} 4.0 14.2, 3.5)

Capacity

L IUS qt, Imp qtl Ott pan 3.6 (3.8, 3.2)

011 filter 0.17 (0.18, 0.15)

Grade API Service SD, SE, SF or SG

Above 30°C (86*F) SAE 40

O*C-40*C ~32°F-1040F 1 SAE 30

-1 OOC--2O*C [ 14OF-68OF ] SAE 2OW-20

Viscosity Above -10% [14*Fj SAE ZOW-40 or 2OW-50

number -25*C--3O*C I-1 3OF-86OF ] SAE 1 OW-30

Above -25OC (-13*F1 SAE low-40 or low-50

Below O*C (32*F] SAE 5W-30

Below -2O*C I-4*F] SAE 5W-20

COOLING SYSTEM

L

item

Zooling method - 1 Engine

BP DUHC turbo

I Water-cooled, forced crrcutation

water pump

Type

mpeller diameter

Number of impeller blades

Speed ratio

tiater seal type

rhermostat

bfpe

Opening temperature

Full-open temperature

Full-open lift mm [in)

OC (OF)

*C j*FJ

mm (in] Centrifugal, V-belt driven

75 12.95)

6

1 : 1.05

Unified mechanical seal

Wax, two-stage

Marn: 86.5-89.5 [ 788-I 93 1

Sub: 83.5-86.5 [182-i 88)

loo (212)

Main: 8.0 (0.31 1 min.

Sub: 1.5 IO.061 min.

Radbtor

Type

Cap valve opening pressure kPa { kgflcm2, psi)

Cooling circuit checkrng pressure kPa ( kgflcm2, psi 1

Cooling fan

Type

Number of blades

Outer diameter mm {in 1

Capacity w-v

Current A

Water thermoswitch

OFF-+ON “C 1°F) 1

Radiator thermoswitch

OFFdON OC (OF]

Coolant

Capacity LWS qt,

Imp qt) Coolant protection

Above -16*C (3OF]

Antifreeze solutron

.Above -26*C t-1 5*F ) -

Above -4UOC I-40°F) Corrugated fin

74-103 {0.75--1.05, 11-15)

103 11.05, 15)

Electric

5

340 (13.41

160-12

Hi: 13.3+ 10% max., Lo: 8.8+ 10% max.

97 f207)

105 [221)

6.0 16.3, 5.3)

Specific gravity at 20*C (68*f)

1.054

1.066

1.078 -.ep

1

Page 168 of 279

ST

SPECIAL TOOLS

c 1

GENERAL lNFORMATlON ........................ ST- 2

ENGINE

..................................................

ST- 3

CLUTCH AND MANUAL TRANSAXLE

........

ST- 4

FRONT AND REAR AXLES.

...................... ST-

5

STEERING ..............................................

ST- 6

BRAKING ...............................................

ST- 8

FRONT AND REAR SUSPENSION..

........... ST- 9

CHECKER AND OTHER EQWPMENT..

.......

ST-IO

13ESTX-301

c I

__

c I

Page 169 of 279

ST SPECIAL TOOLS

GENERAL INFORMATION

The letters A and B in the priority column indicate the degree of importance of each tool.

A. . . . . Indispensable

The toots ranked A in this list are indispensable for performing operations satisfactorily, easily, safely, and

efficiently. It is, therefore advisable that all service shops have these tools.

B.. . . .Selective

The tools in this list are not as necessary as tools ranked A, but all service shops should have these tools

to perform repairs more easily and more efficiently.

Note

l When ordering toot sets that consist of several tools, check the List in the Parts Catatogue

to make sure that some tools are not duplicated in other sets you may already have. tf they

are, instead of ordering the set, order only those new tools that are needed.

l There are new SST explanations in this tool chart.

These tools are indicated by “NEW SST” in description column.

13ESTX.302 49 OlC7

Engine

49 LOY~

Hanger

engiN

49 063

Arm, \I lifter

49

BO

Pivot

. .-

49 Sl

Rem

aeaf

Brakl

Page 278 of 279

PARTS INDEX

PARTS NAME PAGE

PARTS NAME PAGE

I KNOCK CONTROL UNIT...................30

KNOCK SENSOR.........................30 .82

.82

.82

.82

.82

.32

.26

.72

a LICENSE PLATE LIGHT...............48.5 0

B MAIN RELAY(FUEL INJ)

............... ..2 8

1 NEUTRAL SWITCH.......................3 2

$3 OIL PRESSURE SWITCH..................3 8

OXYGEN SENSOR........................2 8

J PANEL LIGHT CONTROL..................7 0

PARKING BRAKE SWITCH.................3 8

POSITION LIGHT....................44,5 0

POWER DDOR LOCK SWITCH...............7 6

POWER DDOR LOCK TIMER UNIT...........7 6

POWER DOOR LOCK ACTUATOR.............7 6

POWER OUTSIDE MIRROR MOTOR...........7 0

POWER OUTSIDE MIRROR SWITCH..........7 8

POWER STEERING PRESSURE SWITCH.......3 2

POWER WINDOW MAIN SWITCH.............7 4

POWER WINDOW MOTOR...................7 4

e

1 BACK-UP LIGHT SWITCH.................60

BACK-UP LIGHT....

BLOWER MOTOR.....:::::::::::::::::::’

.E

BLOWER SWITCH........................62

BRAKE FLUID SWITCH...................38

POWER WINDOW SWITCH..................74

J D REAR FOG LIGHT RELAY.

REAR FOG LIGHT SWITCH

REAR FOG LIGHT.......

REAR SPEAKER......... ................

................ zz

................

52

................

................ E

................ 42

............... .

..: 2

.Riik+‘::::::::..6 4

SWITCH.........6 4

................

................ :z

................ 62

............. 44, 48

I CIGARETTE LIGHTER..

CIRCUIT OPENING REL

CLUTCH SWITCH...

COMBINATION SWITCH:

CONDENSER.......

COOLING FAN MOTOR::

COOLING FAN RELAY..

COURTESY LAMP.....,

CPU................ . .64

/ii’::::::::::::::..2 8

..................

... 44, 46, 48, 50, 52, %

..................

.................. 2:

..................

.................. 2:

............... 42, 66

B DIAGNOSIS CONNECTOR.....

DIGITAL CLOCK...........

n-rnnc ............

............ E

............

............ %

............

............ ZE

TURN LIGHT....

WASHER MOTOR.. REAR

REAR

REAR

REAR

REAR

REAR

REAR

REAR

-ih .ER

-ER

RESISTOR ASSEMBLY..

RUNNING LIGHT RELAY

il SEAT WARMER...........

SEAT WARMER REALY.....

SEAT WARMER SWITCH....

SHORT CONNECTOR.......

SLIDING SUNROOF MOTOR.

SLIDING SUNROOF RELAY.

SLIDING SUNROOF SWITCH

SLIDING SUNROOF.......

SOLENOID RESISTOR.....

SOLENOID VALVES

PRC HIGH TEMP........

PRC LOW TEMP.........

PURGE CONTROL........

WASTEGATE............

SPEED SENSOR..........

SPOT LAMP.............

STARTER...............

STOPLIGHT CHECKER..... ........

........

........

........

........

........

........

........

........ ....... 84

.......

....... ::

.......

.... 66.2

.......

.... 66, Ei

.......

....... ........

........

........

........

........

........

........

........

........

........

.

. . . . . . z:

. . .

. . . . zoo

. 1 .

. . . . E

. . . .

56, ::

. . 56, 58

. . 56, 58

“J.“LJL................. DISTRIBUTOR ............

DOOR SPEAKER ........... .

DOOR SWITCH........: .... 8

3 ENGINE CONTROL UNIT............ ,28, 30. 32

3 FLASHER UNIT...

FRONT FOG LIGHT

FRONT FOG LIGHT

FRONT FOG LIGHT

FRONT SIDE TURN

FRONT TURN LIGH

FUEL METER.....

FUEL PUMP REALY

FUEL PUMP UNIT.

FUEL PUMP......

-. -- ............

............ 22 .

. . RiiA‘i 1

SWITCH

i&ii 1 ............ 52

............ .

............ 22

.....................

..................... %

.....................

..................... %

..................... 28 -

tust ....................

B

G SENSOR ................

13 HAZARD SWITCH............

HEADLIGHT CLEANER MOTOR..

HEADLIGHT CLEANER SWITCH.

HEADLIGHT LEVELING ACTUAT

HEADLIGHT LEVELING SWITCH

HEADLIGHT RELAY..........

ENI- IGHT. . . . . .

HORN RELAY...............

HORN SWITCH.............. ...

40, 46, 52, 64

: ........... 82

............ 54

........... .

..: ii

&::::::::..4 6

HORN..................I 1

HYDRAULIC UNIT ..........

01 IC REGURATOR ............

IG KEY CYLINDER LAMP ....

IGNITER .................

IGNITION COIL ...........

ILLUMINATION LAMP .......

AUDIO SYSTEM ...........

BLOWER SWITCH .......... ............

46

............ 44

......... 44, 46

............

............ E

............

............ E

...........

........... 2:

...........

........... 2

...........

........... 5:

...........

........... 5:

...........

........... 5::

...........

........... 5:

..........

.%

;ci:::::::.;;

........... CIGARETTE LIGHTER: ;.I:;::

FRONT FOG LIGHT SWITCH...

HAZARD SWITCH...........

HEADLIGHT CLEANER SWITCH:

HEADLIGHT LEVELING SWITCH

INSTRUMENT CLUSTER.......

REAR FOG LIGHT SWITCH....

REAR WINDOW DEFROSTER SW1

SEAT WARMER SWITCH.......

INDICATOR LAMP...........

...........

........... 33:: ...........

30 STOPLIGHT SWITCH ......

STOPLIGHT .............

0 TAChOMETER...........................3 8

TAILLIGHT.........................48,5 0

TEMP METER...........................3 8

THROTTLE SENSOR......................3 2

TRANSFER PUMP........................2 8

TRUNK COMPARTMENT LAMP SWITCH........6 8

TRUNK COMPARTMENT LAMP...............6 8

TURN SWITCH..........................5 4

q WARNING LAMP.........................3 8

WASHER LEVEL SENSOR..................3 8

WATER THERMOSENSOR................30,3 8

WATER THERMOSWITCH................... 6

WINDSHIELD WASHER MOTOR..............4 0

WINDSHIELD WASHER SWITCH.............4 0

WINDSHIELD WIPER MOTOR...............4 0

WINDSHIELD WIPER SWITCH..............4 0 INJECTOR..........:;.:::::

INJECTOR RESISTOR .........

INSTRUMENT CLUSTER .....

INTERIOR LAMP..........:::

ISC VALVE .................

. . . . . , . . . . .

. . . . . . . . . . . iz:

,..........

30