check oil MAZDA 323 1992 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: 323, Model: MAZDA 323 1992Pages: 279, PDF Size: 24.15 MB

Page 21 of 279

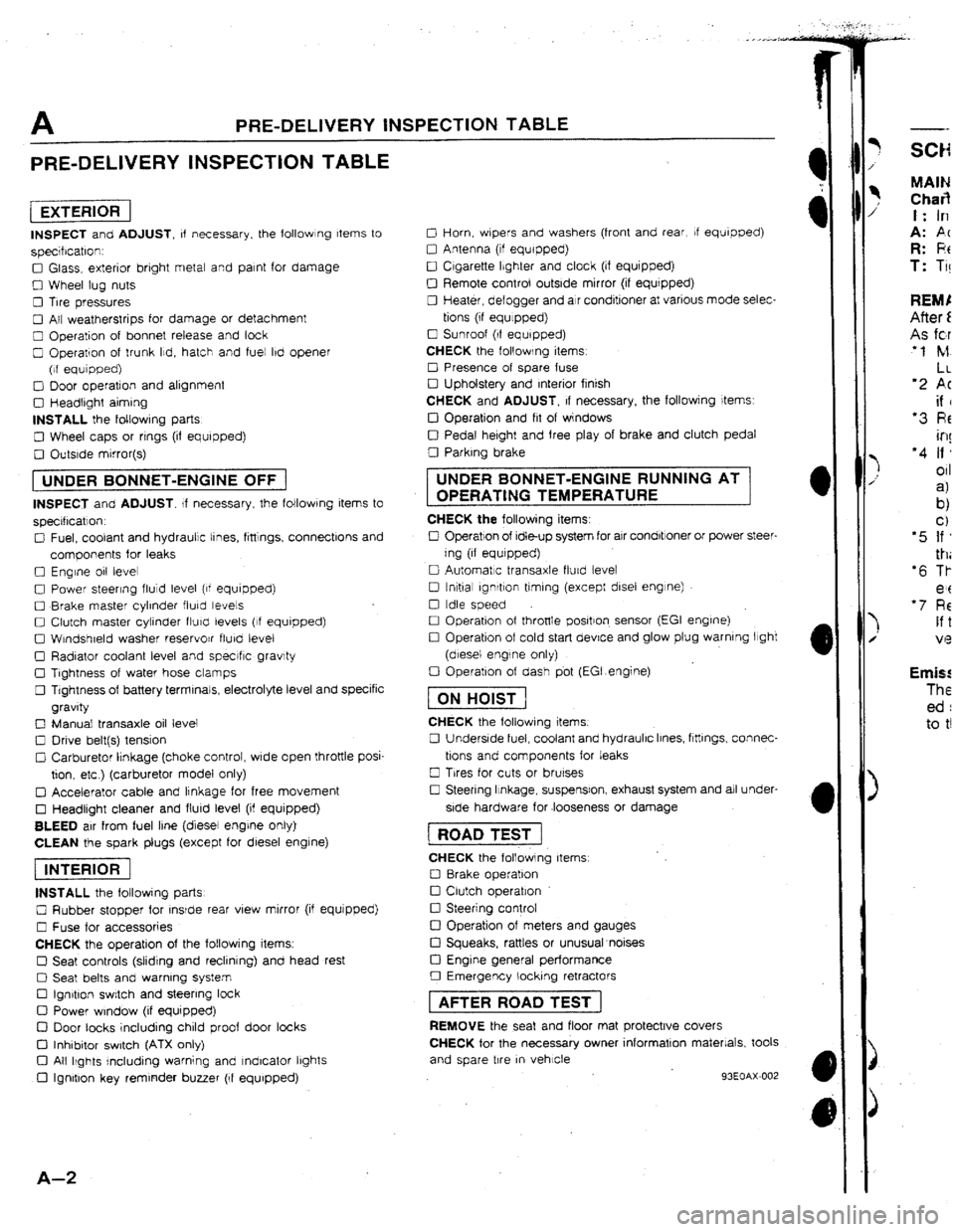

A PRE-DELIVERY INSPECTION TABLE

PRE-DELIVERY INSPECTION TABLE

[EXTERlORI

INSPECT and ADJUST, of necessary. the followlng Items to

specrfrcatron:

0 Glass, exterior bright metal and paint for damage

0 Wheel lug nuts

0 Tire pressures

0 All weatherstrips for damage or detachment

0 Operation of bonnet release and look

0 Operation of trunk Ild, hatch and fuel lbd opener

(of equipped)

0 Door operation and alignment

0 Headtrght aiming

INSTALL the foltowrng parts

0 Wheel caps or rrngs (if equipped)

0 Outsrde mirror(s)

1 UNDER BONNET-ENGINE OFF j

INSPECT and ADJUST. If necessary, the following items to

specrflcatlon.

0 Fuel, coolant and hydraulic tines, fittings, connectlons and

components for leaks

0 Engine 011 level

0 Power steering fluid level (of equipped)

0 Brake master cylinder fluky levels

0 Clutch master cylinder fturcl levels (If equipped)

0 Wtndshreld washer reservojr flurd level

0 Radiator coolant level and specrfic gravity

0 Tightness of water hose clamps

0 Tightness of battery terminals, electrolyte level and specific

gravity

0 Manual transaxle oil level

0 Drive belt(s) tension

Cl Carburetor lrnkage (choke control, wrde open throttle posi-

tion. etc ) (carburetor model only)

q Accelerator cable and linkage for free movement

0 Headlight cleaner and flurd level (if equipped)

BLEED air from fuel line (diesel engrne only)

CLEAN the spark plugs (except for diesel engine)

piEi6F]

INSTALL the following parts

0 Rubber stopper for rnsrde rear view mirror (if equjpped)

0 Fuse for accessories

CHECK the operation of the following items.

0 Seat controls (sliding and reclining) and head rest

0 Seat belts and warning system

Cl Ign&on switch and steering lock

0 Power window (if equipped)

D Door tacks including child proof door locks

Cl Inhibitor switch (ATX only)

Cl All Ikghts rncluding warning and Indicator lbghts

0 Ignition key reminder buzzer (If equipped)

A-Z

0 Horn, wbpers and washers (front and rear, If equipped)

0 Antenna (tf equipped)

0 Cigarette Ibghter and clock (if equipped)

0 Remote control outside mirror (if equrpped)

0 Heater, defogger and air conditioner at various mode selec-

tions (if equlppedj

0 Sunroof (If equipped)

CHECK the following items

0 Presence of spare fuse

0 Upholstery and Interior finish

CHECK and ADJUST, If necessary, the followjng items:

IJ Operation and fit of windows

0 Pedal height and free play of brake and clutch pedal

0 Parking brake UNDER BONNET-ENGINE RUNNING AT

OPERATING TEMPERATURE

CHECK the following items:

0 Operation of Idle-up system for air condbtroner or power steer-

ing (if equrpped)

0 Automatic transaxle flurd levet

0 tnltial ignrtlon timing (except disel engine)

0 Idle speed

0 Operation of throttle positron. sensor (EGI engrne)

0 Operation of cold start device and glow plug warning light

(diesel engine only)

0 Operation of dash pbt (EGI.engine)

fTiGGJ

CHECK the following items.

0 Underside fuel, coolant and hydraulic Irnes, ftttlngs, connec-

tions and components for leaks

0 Trres for cuts or brurses

0 Steering Itnkage, suspensron, exhaust system and all under-

side hardware for .looseness or damage 1 ROAD TEST j

CHECK the following items

0 8rake operation

0 Clutch operation

0 Steering control

!ZI Operation of meters and gauges

Cl Squeaks, rattles or unusual noises

Cl Engine general performance

0 Emergency locking retractors 1 AFTER ROAD TEST ]

REMOVE the seat and floor mat protective covers

CHECK for the necessary owner information materials, took

and spare tire

m vehicle

93EOAX-002

-- MAIN Char3 t: In

A: PC R: F!t T: Ti! Emis! The ed : to t!

Page 22 of 279

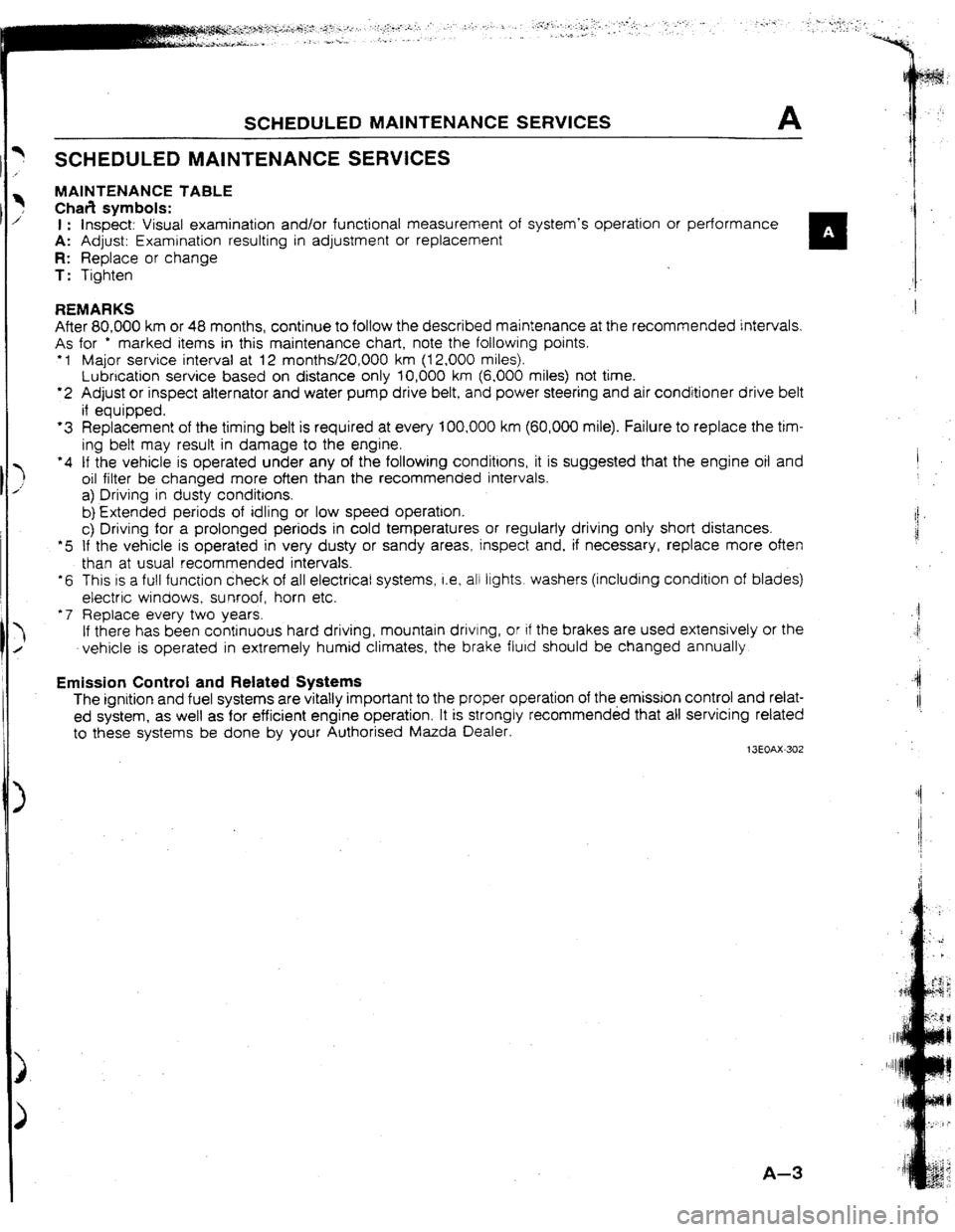

SCHEDULED MAINTENANCE SERVICES A

SCHEDULED MAINTENANCE SERVICES

MAINTENANCE TABLE

Chafi symbols:

1 : Inspect: Visual examination and/or functional measurement of system’s operation or

performance , A: Adjust: Examination resulting in adjustment or replacement

n

R: Replace or change

T: Tighten

REMARKS

After 80,000 km or 48 months, continue to follow the described maintenance at the recommended intervals.

As for * marked items in this maintenance chart, note the following points.

+ 1 Major service interval at 12 months/20,000 km (12,000 miles).

Lubrication service based on distance only 10,000 km (6,000 miles) not time.

l 2 Adjust or inspect alternator and water pump drive belt, and power steering and air conditioner drive belt

if equipped.

‘3 Replacement of the timing belt is required at every 100,000 km (60,000 mile). Failure to replace the tim-

ing bett may result in damage to the engine.

‘4 tf the vehicle is operated under any of the following conditions, it is suggested that the engine oil and

oil filter be changed more often than the recommended intervals.

a) Driving in dusty conditions. I

:

b) Extended periods of idling or low speed operation. i

i!

c) Driving for a prolonged periods in cold temperatures or regularly driving onty short distances.

*5 If the vehicle is operated in very dusty or sandy areas, inspect and, if necessary, replace more often

than at usual recommended intervals.

l 6 This IS a full function check of all electrical systems, i.e, atl

ltghts. washers (including condition of blades)

electric windows, sunroof, horn etc.

‘7 Replace every two years. $1

‘I

If there has been continuous hard driving, mountain

drivtng, or if the brakes are used extensively or the

vehicle is operated in extremely humid climates, the brake fluid should be changed annually.

Emission Control and Related Systems

The ignition and fuel systems are vitally important to the proper operation of the-emission control and relat-

ed system, as well as for efficient engine operation. It is strongly recommended that all servicing related

to these systems be done by your Authorised Mazda Dealer.

13EOAX-302 -4

I!

A-3

Page 68 of 279

![MAZDA 323 1992 Workshop Manual Suplement TROUBLESHOOTING GUiDE F3

15 ENGINE STALLS ON DECELERATION

IESCRIP-

l Engrne unexpectedly stops running dunng or after deceleration

[iON l Idle condition normal.

TROUBLESHOOT1NG HtNTS]

ingrne spe MAZDA 323 1992 Workshop Manual Suplement TROUBLESHOOTING GUiDE F3

15 ENGINE STALLS ON DECELERATION

IESCRIP-

l Engrne unexpectedly stops running dunng or after deceleration

[iON l Idle condition normal.

TROUBLESHOOT1NG HtNTS]

ingrne spe](/img/28/57055/w960_57055-67.png)

TROUBLESHOOTING GUiDE F3

15 ENGINE STALLS ON DECELERATION

IESCRIP-

l Engrne unexpectedly stops running dunng or after deceleration

[iON l Idle condition normal.

TROUBLESHOOT1NG HtNTS]

ingrne speed drops too much when releasrng accelerator

3 Idle-speed misadjustment @I Loose connector disconnected by force of deceleration

3 Fuel-cut contrd malfunction

TEP lNSPECTlON ACTION

1 1s idle condition normal? Yes Go to next step

tdle speed: 800 f 50 rpm (in neutral)

NO Adjust or perform Troubleshooting, Nos.

8-I 1 “ROUGH IDLE”

(Refer to Workshop Manual

(1203-I o-89F))

2 Is “00” displayed on Self-Diagnosis Checker Yes Go to next step

with ignition switch ON?

SYSTEM SELECT: 1 NO Service Code No. displayed

Check for cause (Refer to specified

check sequence) ET page F3-16

“88” flashes

Check ECU termrnal 1 F voltage

Voltage: Battery voltage

(ignition switch ON) r;r page F346

W:SELFTEST

e If OK, replace ECU CI page F3-3

4 If not OK, check wirtng

(ECU - Self-Diagnosis Checker)

3 Does Self-Diagnosis Checker Monitor Lamp with Yes Go to next step

lgnttlon switch UN show that switches operate

correctly?

NO Lamp not ON or OFF with specified

switch

Check for cause (Refer to specified

check sequence)

W: SEtF TEST Lamp slways ON

Check wiring between

(ECU terminal 1 D - Self-Diagnosis

Checker)

4 Are ECU ?erminal voltages OK? Yes Go to next step

(especially IV, 20, 20, ZU, 2V.

and 20) v page F346 No

Check for cause

5 Check for poor connection of foltowing parts YC?S Repair or replace

l ignrtion coil l Igniter l Olstribdor l High-tension lead

NO Go to next step l Injector. l Injector resistor l Ctrcuit-opening relay . l ECU

F3-35

Page 69 of 279

F3 TROUBLESHOOTING GUIDE

STEP INSPECTION ACTlON

6 Is dashpot correctly adjusted? Yes Go to next step

c

Dashpot set speed: Approx. 3,500 rpm

No Adjust dashpot

7

Try known good ECU; does condition

Improve?

w page F3-3

13EOF3-336

16 ENGINE STALLS SUDDENLY (INTERMITTENT)

DESCRIP.

l Engine intermittently stops running

TION l Before stalling, engine conditron is OK

TROUBLESHOOTING HINTS]

@ intermittently no spark or no fuel injection caused by ve-

hlcle vibratron, acceleratton, or deceleration

l Poor connectlon in wiring harness

iTEP INSPECTION ACTfON

1 Is “00” displayed on Self-Oiagnoss Checker Yes Go to next step

with lgnltlon swrtch ON?

NO Service Code No. displayed

Check for cause (Refer to speclfled

check sequence).

Note CT page F3-16

l When checking wiring harness and

connectors, tap, move, and wiggle

suspect sensor and/or harness to

recreate problem

“88” flashes ’

Check ECU terminal IF voltage

Voltage: Battery voltage

{ignition swttch ON) w page F3-45

4 If OK, replace ECU

4 If not OK, check wiring

(ECU - Self-Diagnosis Checker)

2 Check for poor connection of foliowrng parts

Yes Reparr or replace

l lgnltfon coil l Igniter l Distributor l t-flgh-tensron lead

No Go to next step l Injector l Injector reststor l Circutt-opening relay l ECU

3 Are ECU terminal voltages OK? Yes Go to Troubleshbotrng No. 2

(especially 16, 2A, 2B, and 2C) .“CRANKS NORMALLY BUT WILL NOT

w page F3-45 START (NO COMBUSTION)”

w page F3-20

Note

. No Check for cause

l When. checking voltages, tap, move, and

wiggle harness and connector to recreate

problem

* lrlrl m-7

F3-36

7.8-l

Page 278 of 279

PARTS INDEX

PARTS NAME PAGE

PARTS NAME PAGE

I KNOCK CONTROL UNIT...................30

KNOCK SENSOR.........................30 .82

.82

.82

.82

.82

.32

.26

.72

a LICENSE PLATE LIGHT...............48.5 0

B MAIN RELAY(FUEL INJ)

............... ..2 8

1 NEUTRAL SWITCH.......................3 2

$3 OIL PRESSURE SWITCH..................3 8

OXYGEN SENSOR........................2 8

J PANEL LIGHT CONTROL..................7 0

PARKING BRAKE SWITCH.................3 8

POSITION LIGHT....................44,5 0

POWER DDOR LOCK SWITCH...............7 6

POWER DDOR LOCK TIMER UNIT...........7 6

POWER DOOR LOCK ACTUATOR.............7 6

POWER OUTSIDE MIRROR MOTOR...........7 0

POWER OUTSIDE MIRROR SWITCH..........7 8

POWER STEERING PRESSURE SWITCH.......3 2

POWER WINDOW MAIN SWITCH.............7 4

POWER WINDOW MOTOR...................7 4

e

1 BACK-UP LIGHT SWITCH.................60

BACK-UP LIGHT....

BLOWER MOTOR.....:::::::::::::::::::’

.E

BLOWER SWITCH........................62

BRAKE FLUID SWITCH...................38

POWER WINDOW SWITCH..................74

J D REAR FOG LIGHT RELAY.

REAR FOG LIGHT SWITCH

REAR FOG LIGHT.......

REAR SPEAKER......... ................

................ zz

................

52

................

................ E

................ 42

............... .

..: 2

.Riik+‘::::::::..6 4

SWITCH.........6 4

................

................ :z

................ 62

............. 44, 48

I CIGARETTE LIGHTER..

CIRCUIT OPENING REL

CLUTCH SWITCH...

COMBINATION SWITCH:

CONDENSER.......

COOLING FAN MOTOR::

COOLING FAN RELAY..

COURTESY LAMP.....,

CPU................ . .64

/ii’::::::::::::::..2 8

..................

... 44, 46, 48, 50, 52, %

..................

.................. 2:

..................

.................. 2:

............... 42, 66

B DIAGNOSIS CONNECTOR.....

DIGITAL CLOCK...........

n-rnnc ............

............ E

............

............ %

............

............ ZE

TURN LIGHT....

WASHER MOTOR.. REAR

REAR

REAR

REAR

REAR

REAR

REAR

REAR

-ih .ER

-ER

RESISTOR ASSEMBLY..

RUNNING LIGHT RELAY

il SEAT WARMER...........

SEAT WARMER REALY.....

SEAT WARMER SWITCH....

SHORT CONNECTOR.......

SLIDING SUNROOF MOTOR.

SLIDING SUNROOF RELAY.

SLIDING SUNROOF SWITCH

SLIDING SUNROOF.......

SOLENOID RESISTOR.....

SOLENOID VALVES

PRC HIGH TEMP........

PRC LOW TEMP.........

PURGE CONTROL........

WASTEGATE............

SPEED SENSOR..........

SPOT LAMP.............

STARTER...............

STOPLIGHT CHECKER..... ........

........

........

........

........

........

........

........

........ ....... 84

.......

....... ::

.......

.... 66.2

.......

.... 66, Ei

.......

....... ........

........

........

........

........

........

........

........

........

........

.

. . . . . . z:

. . .

. . . . zoo

. 1 .

. . . . E

. . . .

56, ::

. . 56, 58

. . 56, 58

“J.“LJL................. DISTRIBUTOR ............

DOOR SPEAKER ........... .

DOOR SWITCH........: .... 8

3 ENGINE CONTROL UNIT............ ,28, 30. 32

3 FLASHER UNIT...

FRONT FOG LIGHT

FRONT FOG LIGHT

FRONT FOG LIGHT

FRONT SIDE TURN

FRONT TURN LIGH

FUEL METER.....

FUEL PUMP REALY

FUEL PUMP UNIT.

FUEL PUMP......

-. -- ............

............ 22 .

. . RiiA‘i 1

SWITCH

i&ii 1 ............ 52

............ .

............ 22

.....................

..................... %

.....................

..................... %

..................... 28 -

tust ....................

B

G SENSOR ................

13 HAZARD SWITCH............

HEADLIGHT CLEANER MOTOR..

HEADLIGHT CLEANER SWITCH.

HEADLIGHT LEVELING ACTUAT

HEADLIGHT LEVELING SWITCH

HEADLIGHT RELAY..........

ENI- IGHT. . . . . .

HORN RELAY...............

HORN SWITCH.............. ...

40, 46, 52, 64

: ........... 82

............ 54

........... .

..: ii

&::::::::..4 6

HORN..................I 1

HYDRAULIC UNIT ..........

01 IC REGURATOR ............

IG KEY CYLINDER LAMP ....

IGNITER .................

IGNITION COIL ...........

ILLUMINATION LAMP .......

AUDIO SYSTEM ...........

BLOWER SWITCH .......... ............

46

............ 44

......... 44, 46

............

............ E

............

............ E

...........

........... 2:

...........

........... 2

...........

........... 5:

...........

........... 5:

...........

........... 5::

...........

........... 5:

..........

.%

;ci:::::::.;;

........... CIGARETTE LIGHTER: ;.I:;::

FRONT FOG LIGHT SWITCH...

HAZARD SWITCH...........

HEADLIGHT CLEANER SWITCH:

HEADLIGHT LEVELING SWITCH

INSTRUMENT CLUSTER.......

REAR FOG LIGHT SWITCH....

REAR WINDOW DEFROSTER SW1

SEAT WARMER SWITCH.......

INDICATOR LAMP...........

...........

........... 33:: ...........

30 STOPLIGHT SWITCH ......

STOPLIGHT .............

0 TAChOMETER...........................3 8

TAILLIGHT.........................48,5 0

TEMP METER...........................3 8

THROTTLE SENSOR......................3 2

TRANSFER PUMP........................2 8

TRUNK COMPARTMENT LAMP SWITCH........6 8

TRUNK COMPARTMENT LAMP...............6 8

TURN SWITCH..........................5 4

q WARNING LAMP.........................3 8

WASHER LEVEL SENSOR..................3 8

WATER THERMOSENSOR................30,3 8

WATER THERMOSWITCH................... 6

WINDSHIELD WASHER MOTOR..............4 0

WINDSHIELD WASHER SWITCH.............4 0

WINDSHIELD WIPER MOTOR...............4 0

WINDSHIELD WIPER SWITCH..............4 0 INJECTOR..........:;.:::::

INJECTOR RESISTOR .........

INSTRUMENT CLUSTER .....

INTERIOR LAMP..........:::

ISC VALVE .................

. . . . . , . . . . .

. . . . . . . . . . . iz:

,..........

30