fuse MAZDA 323 1992 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: 323, Model: MAZDA 323 1992Pages: 279, PDF Size: 24.15 MB

Page 17 of 279

..,. .

a

._

GI CAUTKN

PRECAUTIONS TO TAKE WHEN SERVICING AN ELECTRICAL SYSTEM l Note the following items when servicing the electrical system.

l Do not alter the wiring or electrical equipment in any way; this may damage the vehicle or cause a fire

from short-circuiting a circuit or overloading it.

l The negatrve (-) battery cable must be removed first and

rnstalled last. l Do not reptace with fuses exceedrng specified capacity

Cautron

l 8e sure that the ignitton and other switches are off

before disconnectrng or connecting the battery cables.

Failure to do so may damage the semrconductor

components. Caution l Repfacing a fuse with one of a larger capacrty than

desrgnated may damage components or cause a frre.

l Secure harnesses with provrded clamps to take up slack. l Tape areas of the harness

that may rub or bump l When mounting

components, be sure the

against sharp edges to

protect rt from damage. harness IS not caught or

damaged.

Caution

l Clamp all harnesses near vibratrng components (for

example, the engine) to remove slack and to prevent

contact resultrng from vibration. i Drsconnect heatsensitive l Make sure that the

parts (for example, relays

and ECU) when performing connectors are securely

connected when installed.

l Do not handle electrical components roughly or drop

them. maintenance (such as

weldrng) where

temperatures may exceed

80°C [176OFj.

-*

HI

Page 21 of 279

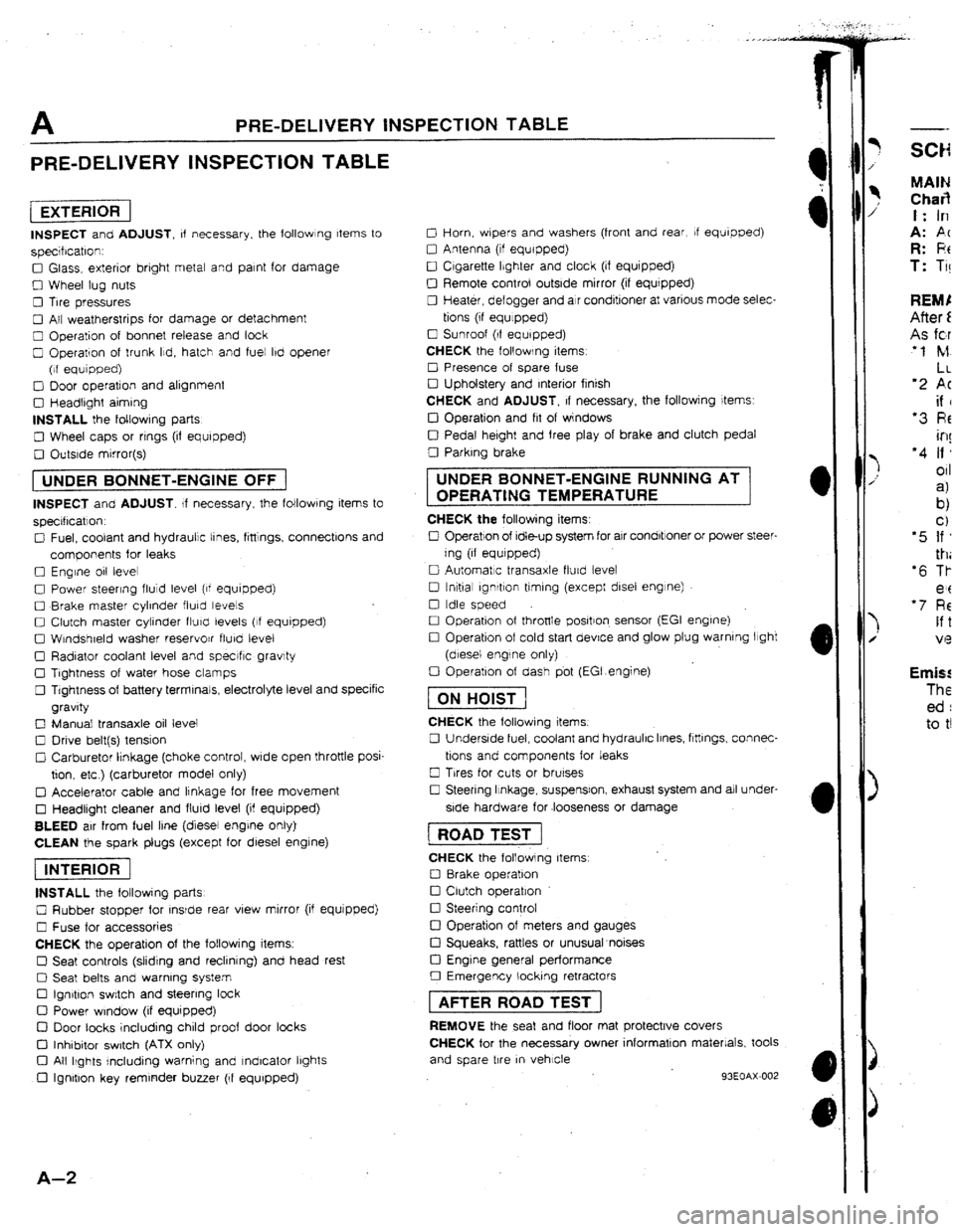

A PRE-DELIVERY INSPECTION TABLE

PRE-DELIVERY INSPECTION TABLE

[EXTERlORI

INSPECT and ADJUST, of necessary. the followlng Items to

specrfrcatron:

0 Glass, exterior bright metal and paint for damage

0 Wheel lug nuts

0 Tire pressures

0 All weatherstrips for damage or detachment

0 Operation of bonnet release and look

0 Operation of trunk Ild, hatch and fuel lbd opener

(of equipped)

0 Door operation and alignment

0 Headtrght aiming

INSTALL the foltowrng parts

0 Wheel caps or rrngs (if equipped)

0 Outsrde mirror(s)

1 UNDER BONNET-ENGINE OFF j

INSPECT and ADJUST. If necessary, the following items to

specrflcatlon.

0 Fuel, coolant and hydraulic tines, fittings, connectlons and

components for leaks

0 Engine 011 level

0 Power steering fluid level (of equipped)

0 Brake master cylinder fluky levels

0 Clutch master cylinder fturcl levels (If equipped)

0 Wtndshreld washer reservojr flurd level

0 Radiator coolant level and specrfic gravity

0 Tightness of water hose clamps

0 Tightness of battery terminals, electrolyte level and specific

gravity

0 Manual transaxle oil level

0 Drive belt(s) tension

Cl Carburetor lrnkage (choke control, wrde open throttle posi-

tion. etc ) (carburetor model only)

q Accelerator cable and linkage for free movement

0 Headlight cleaner and flurd level (if equipped)

BLEED air from fuel line (diesel engrne only)

CLEAN the spark plugs (except for diesel engine)

piEi6F]

INSTALL the following parts

0 Rubber stopper for rnsrde rear view mirror (if equjpped)

0 Fuse for accessories

CHECK the operation of the following items.

0 Seat controls (sliding and reclining) and head rest

0 Seat belts and warning system

Cl Ign&on switch and steering lock

0 Power window (if equipped)

D Door tacks including child proof door locks

Cl Inhibitor switch (ATX only)

Cl All Ikghts rncluding warning and Indicator lbghts

0 Ignition key reminder buzzer (If equipped)

A-Z

0 Horn, wbpers and washers (front and rear, If equipped)

0 Antenna (tf equipped)

0 Cigarette Ibghter and clock (if equipped)

0 Remote control outside mirror (if equrpped)

0 Heater, defogger and air conditioner at various mode selec-

tions (if equlppedj

0 Sunroof (If equipped)

CHECK the following items

0 Presence of spare fuse

0 Upholstery and Interior finish

CHECK and ADJUST, If necessary, the followjng items:

IJ Operation and fit of windows

0 Pedal height and free play of brake and clutch pedal

0 Parking brake UNDER BONNET-ENGINE RUNNING AT

OPERATING TEMPERATURE

CHECK the following items:

0 Operation of Idle-up system for air condbtroner or power steer-

ing (if equrpped)

0 Automatic transaxle flurd levet

0 tnltial ignrtlon timing (except disel engine)

0 Idle speed

0 Operation of throttle positron. sensor (EGI engrne)

0 Operation of cold start device and glow plug warning light

(diesel engine only)

0 Operation of dash pbt (EGI.engine)

fTiGGJ

CHECK the following items.

0 Underside fuel, coolant and hydraulic Irnes, ftttlngs, connec-

tions and components for leaks

0 Trres for cuts or brurses

0 Steering Itnkage, suspensron, exhaust system and all under-

side hardware for .looseness or damage 1 ROAD TEST j

CHECK the following items

0 8rake operation

0 Clutch operation

0 Steering control

!ZI Operation of meters and gauges

Cl Squeaks, rattles or unusual noises

Cl Engine general performance

0 Emergency locking retractors 1 AFTER ROAD TEST ]

REMOVE the seat and floor mat protective covers

CHECK for the necessary owner information materials, took

and spare tire

m vehicle

93EOAX-002

-- MAIN Char3 t: In

A: PC R: F!t T: Ti! Emis! The ed : to t!

Page 80 of 279

,,1

CONTROL SYSTEM F3 ‘1

Va: Battew voltage

Incorrect voltage Possible cause

Always OV

l ROOM IOA fuse burned l Open circuit In wiring from ROOM 10A fuse to ECU termina! 1A

Always OV

l Main relay malfunction l Open or short circuit in wiring from main relay to ECU terminal IB

Always OV (starter turns)

l Open or short circuit in wiring from ignition switch to ECU terminal IC

Always OV

Always VB

l Maln relay (FUEL INJ relay) malfunction l Open circuit in wiring from main relay to diagnosis connector terminal +B l Open or short circuit in wiring from diagnosis connector terminal MEN to

ECU terminal 1 D

l Poor connection at ECU connector l ECU malfunction

Always approx. 5V . ECU malfunction

Always below

2.5v

Always Ve -

-

No display on Self- * Main relay (FUEL INJ relay) malfunction

Diagnosis Checker

l Open circuit in wiring from main relay to diagnosis connector terminal + B

“88” displayed and

l Open or short clrcurt in wiring from diagnosis connector terminal FEN to

buzzer sounds con- ECU terminal tF

ti nuousl y

l Poor connection at ECU connector l ECU malfunction

Always QV

l Short circuit in wiring from igniter to ECU terminal 16

Always OV or VB

l Refer to Code No.42 Troubleshooting

(Refer to 323 4-Wheel Drtve Workshop Manual (12?9-IO-89L))

Always VB

Always OV

Always below

2.5V

Atways Ve I ’

l Fuel pump resistor/relay malfunction

l Open or short circurt in wiring from ECU terminal II to fuel pump resis-

tor/relay

A/C does not operate

l A/C reiay malfunction l Open circuit in wiring from ignition switch to A/C relay l Open circuit in wiring from A/C relay to ECU terminal 1J

A/C switch

OFF but l Short circuit in wiring from AIC relay to ECU terminal 1 J

A/C operates . ECU malfunction

l Poor connection at ECU connector l ECU malfunction

Always below 1 .OV a Short circuit in wiring from diagnosis connector terminal TEN to ECU termi-

nal 1K

Always Vs

l Open circuit In wiring from diagnosis connector terminal TEN to ECU terml-

nal IK

-

-

l Open circuit in winrig from diagnosis connector terminal GND to ground’

-

I -

.

. .

-. F3-47

Page 183 of 279

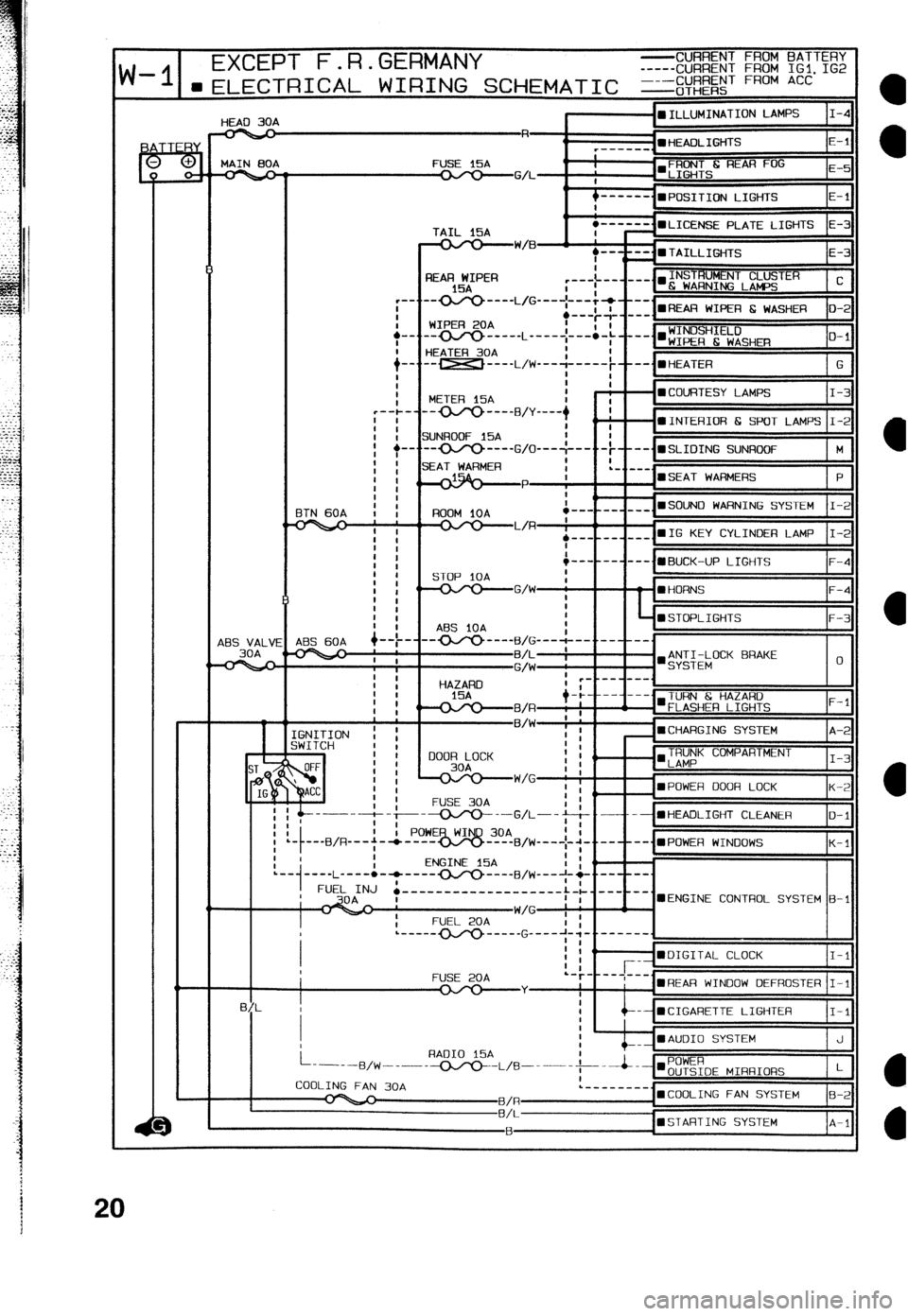

GI Wiring Diagrams

Contents of wiring diagrams

l This document comprises the 8 groups shown below. The main components are summarized in the

components location diagram at the

end of the document.

I I Gi General information A how-to on using and reading wiring diagrams, 1

using test equipment, checking harnesses and

connectors, and findrng trouble spots

Y , Ground points

- Ground routes from and to the battery

W Electrical wiring Shows main fuses and other fuses for each

schematics system

A-U Circuit diagrams for

~ individual systems Shows circuit and connector diagrams and

component and connector location diagrams

X Common connectors Shows connectors common throughout system

~ JB i Joint box complete

wiring system

I Shows internal circuits and connectors

PL Parts location

Pi index Shows location of major electrical parts

Gives page number of circuit diagram for each

component

Using wiring diagrams

l The use of the wiring diagram depends on its application. Application

-or checking

:ircuits of

ndividual

systems

For checking

ground circuit

of individual

systems Use

II Application For checking

fuse

connections

Open to page with circuit diagram and

harness routing to be used and fold out

common connector diagram or joint box

diagram.

II

For finding

page numbers

of systems and

components

Open to page with ground point diagram

and fold out common connector diagram

or joint box diagram. Use

3pen to electrical wiring schematic.

Parts Index System Index

or

Open to parts index or system index.

Page 189 of 279

GI Reading Wiring Diagrams

Symbols

Symbol Meaning Symbol Meaning

Battery

l Generates electricity through

Resistance 0 A resistor with a constant value.

chemical reaction. l Mainly used to protect electrical

l Supplies direct current to circuits. components in circuits by maintaining

rated voltage.

l Reading resistance values.

Ground (1)

l Connecting point to vehicle body or No.1 color band other ground wire where current flows No.2 color band

-A-

from positive to negative terminal of No.3 mbr band

battery. No.4 color band

1 l Ground (1) indicates a ground point to

body through wire harness.

Ground (2)

l Gound (2) indicates point where

component is grounded directly to

body.

Remarks

l Current will not flow through a circuit if

ground is faulty.

Fuse (1)

0 Melts when current flow exceeds that

specified for circuit, interrupts current

I__q/y)__ now.

Precautions

(box)

l Do not replace with fuses exceeding

Fuse (2) specified capacity.

(Cartridge)

Main fuse/Fusible

Transistor (1)

l Electrical switching component. l Turns on when voltage is applied to Motor

0 Converts electrical energy into

mechanical energy.

Transistor (2)

0 Reading code. a Pulls in and discharges gases and

liquids.

Number of temtinak

Lamp l Emits light and generates heat when Current flows through filament. Cigarette lighter l Electrical coil that generates heat.

Page 192 of 279

Troubleshooting GI

Precautions to take when servicing an electrical system

l Note the following items when servicing the electrical system.

l Do not alter the wiring or electrical equipment in any way; this may damage the vehicle or cause a fire from

short-circuiting a circuit or overloading it. l

The negative (-) battery cable must be removed first and

installed last. l Do not replace with fuses exceeding specified capacity.

1OA

f5A

Zaution

o Be sure that the ignition and other switches are off

Caution

before disconnecting or connecting the battery

l Replacing a fuse with one of a larger capacity than

cables.

designated may damage components or cause a fire.

Failure to do so may damage the semiconductor

components.

0 Tape areas of the

l When mounting l Secure harnesses with provided clamps to take up slack.

harness that may rub or

components, be sure the

bump against sharp

harness is not caught or

edges to protect it from

damaged.

damage.

Zaution

B Clamp all harnesses near vibrating components

(for example, the engine) to remove slack and to

prevent contact resulting from vibration.

D Do not handle electrical components roughly or drop

them.

l Disconnect heat-

sensitive parts (for

example, relays and

ECU) when performing

maintenance (such as

welding) where

temperatures may exceed

80°C (176°F). l Make sure that the

connectors are securely

connected when

installed.

11

Page 197 of 279

GI Troubleshooting

FindIng short circuits

Shorts occur between the power (positive) and ground (negative) sides of a circuit.

Therefore, finding a short circuit requires determining how the circuit is routed.

Circuits

not connected to control unit

I

Examples

ihort location 1 SvmWom

I Battery

,pOSlhl

terminal) lgnitbn switch

I Finding short circuit

4

1. Remove the fuse and

main fuse of the circuit.

2. Disconnect ail connecton

Of electrical components in the circuit.

3. Attach a voltmeter or test

Motor

M

Qi!

Short (A)

Short (8)

Short (C)

Short (0) l The motor operates

regardless of whether the

thermoswitch is ON or OFF

when the ignition switch is ..-..

ON. -

@The fuse is not melted.

0 The main fuse melts when the

ignition switch and thermo-

switch are ON and the relay is

operating.

lgnitlon switch

Switch short locatior

Short (A)

Short (B)

Short (C) Test lamp lamp to the fuse box and

reconnect each connector, beginning

nearest the power

, source. Circuits connected to control unit

1 Examples

Symptom

l Fuse melts.

Short (D)

Short (E) 14. Check the voltmeter

reading or test lamp as

the connectors are

connected.

l solenoid A operates when the

ignition switch is ON.

l The CPU transistor burns out

when the ignition switch is

turned ON.

l The CPU thinks the switch is

ON because the same

conditions exist as when the

switch is ON.

@The CPU senses the sensor

to be 0 Q because the same

conditions exist as when the

resistance value is 0 Q.

l The CPU equipped with the

self-diagnosis function outputs

the code. l-

Finding short circuit

1. Remove the fuse and main

fuse of the circuit.

2. Disconnect ail connectors oi

electrical components in the

circuit.

rest lamp 3. Attach a voltmeter or test

lamp to the fuse box and

reconnect each connector,

beginning nearest to the

power source.

Check the voltmeter reading

or test lamp as the

connectors are connected.

Sensor/switch

1. Attach the test lamp or

voltmeter to the CPU

connector.

2. Connect to the switch/

sensor connector.

3. Check the voltmeter reading

voltmeter reads OV or the test lamp

16

Page 201 of 279

d-II __ EXCEPT F.R.GERMANY -CURRENT FROM BATTERY

-----CURRENT FROM IGl. IG2

-I 1--~-l-l-a-r-~ A, ,.,TiTl-TLITr r-.-a ar.1. ?I,-% ----CIJARENT FROM ACC

“-‘e 30A

I -mILLUMINATION LAMPS I-4

HiZP

r--- “f E-l

MAIN 00A FUSE l5A

q

-GA- I’LIE iHTS

---mm_

n POSITION LIGHTS E-l

TAIL 15A

-W/B

I

+-.

i-. I

i REAR WIPER

15A

-0J‘o ---- L/G _--- ;-.-&+v ---.

WIPER 20A .---$- ---. l REAR WIPER E WASHER o-2

m--c____ L _____ ;--:-; ____. l ;:E;H;E:;SHm

O-l

HEATER 30A

-- _-__ ,,,-j __-__; --me., HEATER

G

t

METER 15A : - - l COURTESY LAMPS I-3

-------B/y ---- + I

ZiUNROOF 15A : --•INTERIOR 6 SPOT LAMPS I-2

t

-oJy)--

G/O---:--- -t----.mSLIOING SUNROOF M

~~~~ .--- __ ___ n SOUN0 WARNING SYSTEM I-2

48s VALV

30A I

i

AES 60A +--t-

I mSTOF’LIGHTS F-3

ABS iOA

--- ’ ‘I ---

GNITION ! ;

iWITCH 1 I

TRUNK COMPARTMENT

‘LAMP I-3

‘mPOWER DOOR LOCK A

K-2

FUSE 30A

y-------t- --~--G/!---j--& .--- - l HEADLIGHT CLEANER O-l

I

’ . ---B/R---+-* ----

K-l

I PowE~~om!,IJ,+~~ -..---- -...;PO,.,ER WI,.,,,OWS

! I ENGINE 15A

’ I (’ I :

:.

.--

1 ----L ---- l -* ---- OJY) ---- FJ,w----l-q -..--

FUEL INJ ’ .-------------------:-L.---

’ I UENGINE CONTROL SYSTEM B-l

FUSE 20A

l REAR WINOOW DEFROSTER I-l

-- mCIGARETTE LIGHTER I-l

mAUOI0 SYSTEM J

aSTARTING SYSTEM A-l

Page 206 of 279

FUSE BOX -

MAIN FUSE

25

Page 208 of 279

---

HARNESS SYYBOL : E (F) m (E) ;HH (I) m (R) +++ (DR) c (IN) e (Ffl)G (EM)- (IN.0

A-2

FUSE BOX

FUSE BOX

-/x-all