power steering MAZDA 323 1992 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1992, Model line: 323, Model: MAZDA 323 1992Pages: 279, PDF Size: 24.15 MB

Page 21 of 279

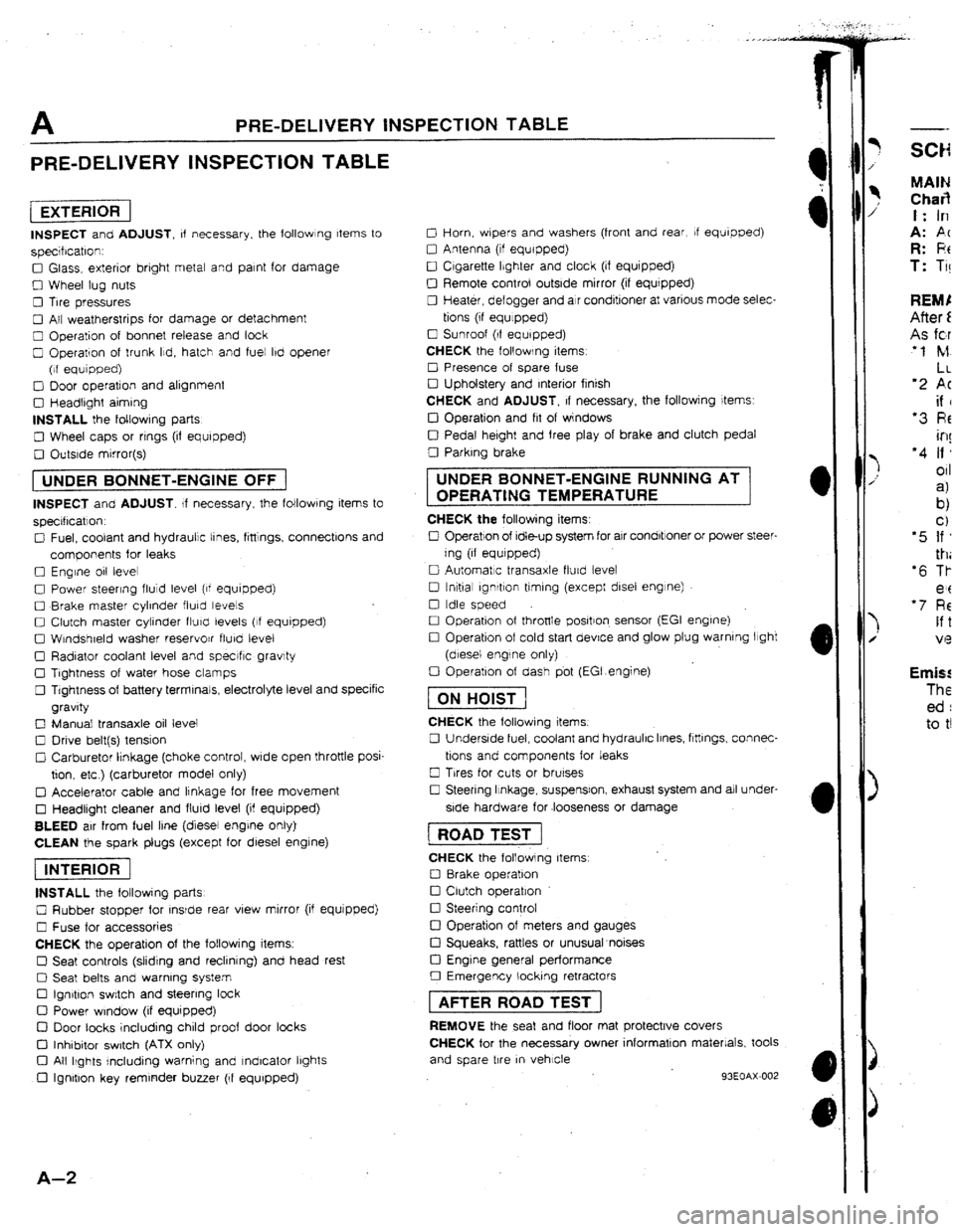

A PRE-DELIVERY INSPECTION TABLE

PRE-DELIVERY INSPECTION TABLE

[EXTERlORI

INSPECT and ADJUST, of necessary. the followlng Items to

specrfrcatron:

0 Glass, exterior bright metal and paint for damage

0 Wheel lug nuts

0 Tire pressures

0 All weatherstrips for damage or detachment

0 Operation of bonnet release and look

0 Operation of trunk Ild, hatch and fuel lbd opener

(of equipped)

0 Door operation and alignment

0 Headtrght aiming

INSTALL the foltowrng parts

0 Wheel caps or rrngs (if equipped)

0 Outsrde mirror(s)

1 UNDER BONNET-ENGINE OFF j

INSPECT and ADJUST. If necessary, the following items to

specrflcatlon.

0 Fuel, coolant and hydraulic tines, fittings, connectlons and

components for leaks

0 Engine 011 level

0 Power steering fluid level (of equipped)

0 Brake master cylinder fluky levels

0 Clutch master cylinder fturcl levels (If equipped)

0 Wtndshreld washer reservojr flurd level

0 Radiator coolant level and specrfic gravity

0 Tightness of water hose clamps

0 Tightness of battery terminals, electrolyte level and specific

gravity

0 Manual transaxle oil level

0 Drive belt(s) tension

Cl Carburetor lrnkage (choke control, wrde open throttle posi-

tion. etc ) (carburetor model only)

q Accelerator cable and linkage for free movement

0 Headlight cleaner and flurd level (if equipped)

BLEED air from fuel line (diesel engrne only)

CLEAN the spark plugs (except for diesel engine)

piEi6F]

INSTALL the following parts

0 Rubber stopper for rnsrde rear view mirror (if equjpped)

0 Fuse for accessories

CHECK the operation of the following items.

0 Seat controls (sliding and reclining) and head rest

0 Seat belts and warning system

Cl Ign&on switch and steering lock

0 Power window (if equipped)

D Door tacks including child proof door locks

Cl Inhibitor switch (ATX only)

Cl All Ikghts rncluding warning and Indicator lbghts

0 Ignition key reminder buzzer (If equipped)

A-Z

0 Horn, wbpers and washers (front and rear, If equipped)

0 Antenna (tf equipped)

0 Cigarette Ibghter and clock (if equipped)

0 Remote control outside mirror (if equrpped)

0 Heater, defogger and air conditioner at various mode selec-

tions (if equlppedj

0 Sunroof (If equipped)

CHECK the following items

0 Presence of spare fuse

0 Upholstery and Interior finish

CHECK and ADJUST, If necessary, the followjng items:

IJ Operation and fit of windows

0 Pedal height and free play of brake and clutch pedal

0 Parking brake UNDER BONNET-ENGINE RUNNING AT

OPERATING TEMPERATURE

CHECK the following items:

0 Operation of Idle-up system for air condbtroner or power steer-

ing (if equrpped)

0 Automatic transaxle flurd levet

0 tnltial ignrtlon timing (except disel engine)

0 Idle speed

0 Operation of throttle positron. sensor (EGI engrne)

0 Operation of cold start device and glow plug warning light

(diesel engine only)

0 Operation of dash pbt (EGI.engine)

fTiGGJ

CHECK the following items.

0 Underside fuel, coolant and hydraulic Irnes, ftttlngs, connec-

tions and components for leaks

0 Trres for cuts or brurses

0 Steering Itnkage, suspensron, exhaust system and all under-

side hardware for .looseness or damage 1 ROAD TEST j

CHECK the following items

0 8rake operation

0 Clutch operation

0 Steering control

!ZI Operation of meters and gauges

Cl Squeaks, rattles or unusual noises

Cl Engine general performance

0 Emergency locking retractors 1 AFTER ROAD TEST ]

REMOVE the seat and floor mat protective covers

CHECK for the necessary owner information materials, took

and spare tire

m vehicle

93EOAX-002

-- MAIN Char3 t: In

A: PC R: F!t T: Ti! Emis! The ed : to t!

Page 22 of 279

SCHEDULED MAINTENANCE SERVICES A

SCHEDULED MAINTENANCE SERVICES

MAINTENANCE TABLE

Chafi symbols:

1 : Inspect: Visual examination and/or functional measurement of system’s operation or

performance , A: Adjust: Examination resulting in adjustment or replacement

n

R: Replace or change

T: Tighten

REMARKS

After 80,000 km or 48 months, continue to follow the described maintenance at the recommended intervals.

As for * marked items in this maintenance chart, note the following points.

+ 1 Major service interval at 12 months/20,000 km (12,000 miles).

Lubrication service based on distance only 10,000 km (6,000 miles) not time.

l 2 Adjust or inspect alternator and water pump drive belt, and power steering and air conditioner drive belt

if equipped.

‘3 Replacement of the timing belt is required at every 100,000 km (60,000 mile). Failure to replace the tim-

ing bett may result in damage to the engine.

‘4 tf the vehicle is operated under any of the following conditions, it is suggested that the engine oil and

oil filter be changed more often than the recommended intervals.

a) Driving in dusty conditions. I

:

b) Extended periods of idling or low speed operation. i

i!

c) Driving for a prolonged periods in cold temperatures or regularly driving onty short distances.

*5 If the vehicle is operated in very dusty or sandy areas, inspect and, if necessary, replace more often

than at usual recommended intervals.

l 6 This IS a full function check of all electrical systems, i.e, atl

ltghts. washers (including condition of blades)

electric windows, sunroof, horn etc.

‘7 Replace every two years. $1

‘I

If there has been continuous hard driving, mountain

drivtng, or if the brakes are used extensively or the

vehicle is operated in extremely humid climates, the brake fluid should be changed annually.

Emission Control and Related Systems

The ignition and fuel systems are vitally important to the proper operation of the-emission control and relat-

ed system, as well as for efficient engine operation. It is strongly recommended that all servicing related

to these systems be done by your Authorised Mazda Dealer.

13EOAX-302 -4

I!

A-3

Page 111 of 279

N OUTLJNE

UUTLJNE

OUTLINE Of CONSTRUCTION

l EncJine speed sensing power steering (ESPS) is standard equipment for all models. The construction and

operation are basically the same as for previous models.

l The lock-to-lock specification of the steering wheel is reduced from 2.76 to 2.51.

13EONX-302

SPECIFICATIONS

hem Specifications

Steermg wheel Outer diameter mm {in] 370 { 14.57)

Lock-to-lock turns :i-‘~~:~.~~~~~~:~~;~~~~ :;‘:.. .‘:I .:::::.::~::::,:.:::.i: ,,,,.,:, :‘,:,,.:,: .,: I. . ..- :.~6:.n.:::;,:~~:~~~~~~~.~::~,:~:.: :: :

” .: ‘-.: .:.:::~:‘::.‘.::‘:‘:.I;:.‘,.: >.. .: :” 3 :. ,;:.+..i<.I. ‘_ : ; t:

. . ..: :: ::.:. .:::. ::r .;

. . . . . . . . . .y : :.: ,. .: ,_ : ., :

Me Collapsible

Steering shaft and joint Joint type

Tilt stroke

J 2-cross joint

mm {in] 30 11.18)

Type Rack-and-pinion

I

Steering gear Gear ratio

Rack stroke mm [in] 00 (infinite)

121 f4.761

Capacity

Power steertng fluid 1 (US qt Imp qt) 018 (0.85, 0.701

We ATF DexrorPlI or M-ID

,

Shaded area rndicates new specrfcatlon. t3EONX-303

N-2

Page 173 of 279

‘T 1 SPECIAL TOOLS

STEERING

rONT AND REAR AXLES (CUNT’D)

3 FO27 005

ttachment @62

9 F027 009

ttachment

68 and $77

9 Vool 795

staller. ort seal

9 BOO1 795

xtafter, oil seal 3 HO02 671

dapter

bwer steer1

9 8032 3ti

lemover ,

rearing & oI

Power steer

19 B032 3’

‘m3ctor trc

d seal

--

3 B032 3t

older, pot

leering pu

‘ower stt:c

--

9 8032 3

Votector ,

her bw

--

$9 8032 :

Mench, r

[Power stl

-- TOOL NUMBER

& DESCRIPTION PRiORlTY

ILLUSTRATION

49 HO34 201

Support blczk

49 HO27 002

Remover, bearing

49 F026 103

Puller, wheel hub

49 F026 102

Installer, bearing A

fEERING

I’OdL NUMBER

L DESCRIPTION PRIORITY ILLUSTRATION

PRIORITY ) ILLUSTRATION TOOL NUMBER

& DESCRlPTtON

49 GO33 108 19 0180 510B

Utachment

Ireload B

Adapter, caster

camber gauge A

19 8032

adapter

,Power 31

--

49 GO32

House

power 5 49 HO32 301 $9 0118 850C

Uler, ball joint

I A Wrench

(Power steering)

49 1232 670A

Gauge set,

power steering 49 1243 785

installer.

dust boot A

Page 174 of 279

SPECIAL TOOLS ST

STEERING (CONT’D)

PRIORITY TOOL NUMBER

et QESCRlPTlUN ILLUSTRATION

19 HO02 671

4dapter

Power steering) A

(Power steering)

(Power steering)

49 6032 3t2

(Power steering)

49 6032 323

Remover body,

rod seal

49 8032 316

Support block,

PM

(Power steering)

49 B032..327

Wrench,

outer box

49 9032 315

Installer, oil seal A

(Power steering)

0

19 8032 317

qemover ,

Dearing & oil seal

:Power steermg) B

49 8032 324

Protector body,

rod seal A

49 8032 305

Holder, power

steering pump

(Power steermg) A

49 8032 326

Protector,

outer box A

49 8032 306

Wrench, plug

(Power steermg) A

49 8032 321

Adapter

(Power steering) A

A

n

49 GO32 317

House (Power steering)

ST-7

Page 175 of 279

ST SPECIAL TOOLS --

BRAKIN

STEERING (CONT’D)

--

TOOL fi

h DESC

--

19 1285

Wer,

Qeedle :

--

49 8065

Harness;

--

49 cw:

Setting

retainer

--

49 804

Socke: PRIORITY / ILLUSTRATJUN TOOL NUMBER

& DEScCRIPTION TOOL NUMBER

& DESCRIPTION PRlORITY

ILLUSTRATION

A

(IlIP

A

0

A

c!iz9 49 B032 310

49 8032 320

0

Wrench

A

(Power steermg)

jq

49 F032 303

Handle

(Power steering)

Protector, pmon seal

(Power steermg)

49 B032 311

Protector,

Jipper seat

(Power steering)

49 8032 325

Guide. rod seal

BRAKING

PRIORITY

ILLUSTRATION TOOL NUMBER

b DESCRlPTlON TOOL NUMSER

& DESCRIPTION PRIORITY

ILLUSTRATION

49 8043 001

Adjust gauge

I A 49 0259 770B

Wrench, flare nut

A

49 0221 60X

Expand tool,

disc brake 49 8043 002

Installer, bearing A

TOOL

& DES

--

49 BC:

Replac

rubber

InstallE

dust 3 49 0208 701A

Atr out tool, boot 49 8043 003

Turning, lock tool A

49 FAt8 602

49 U043 OAO

I

Gauge set,

I A

oil pressure Wrench ,disc

brake piston

Page 185 of 279

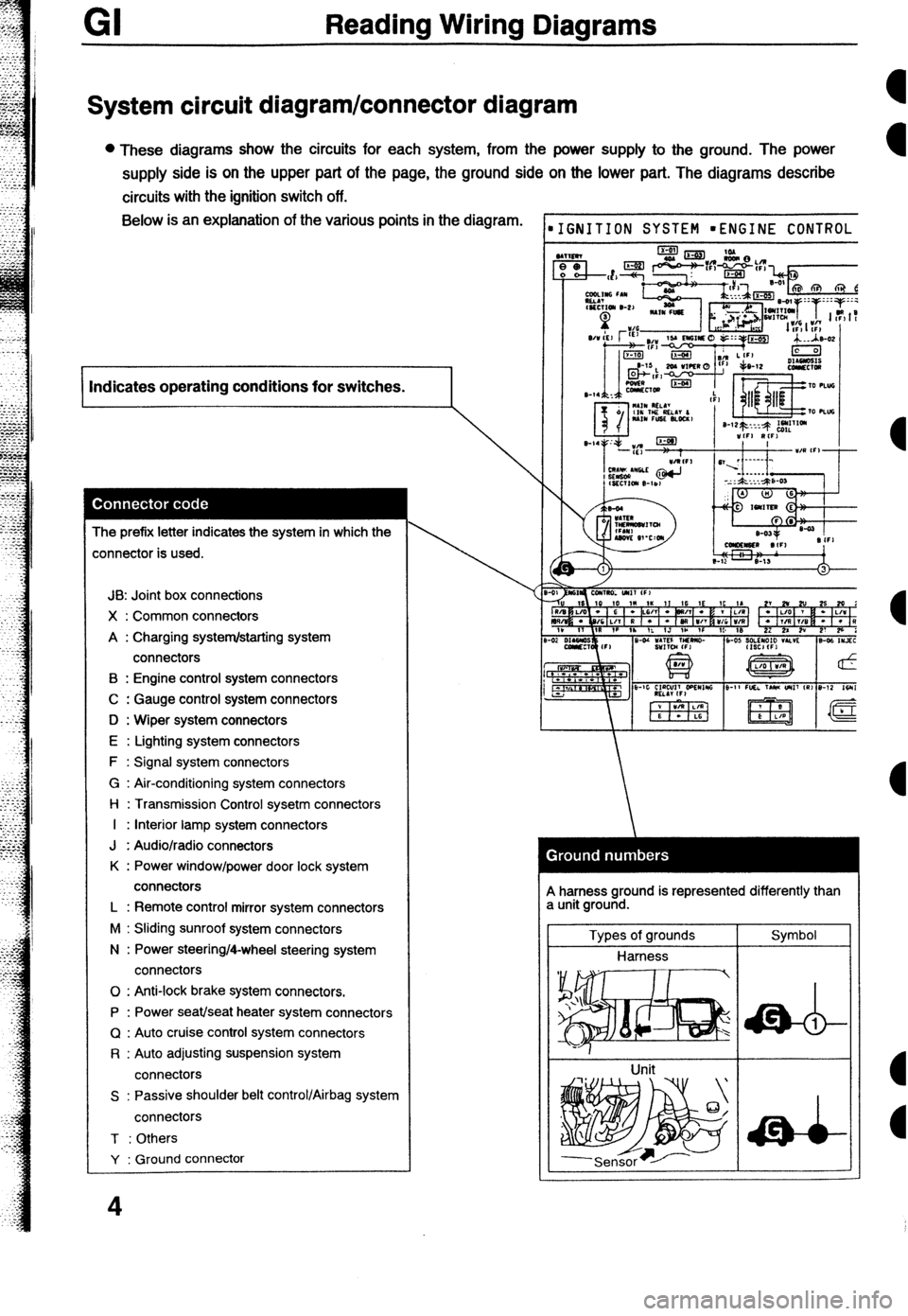

GI Reading Wiring Diagrams

System circuit diagram/connector diagram

l These diagrams show the circuits for each system, from the power supply to the ground. The power

supply side is on the upper part of the page, the ground side on the lower part. The diagrams describe

circuits with the ignition switch off. Below is an explanation of the various points in the diagram.

I Indicates operating conditions for switches.

I

The prefix letter indicates the system in which the

:onnector is used.

JB: Joint box connections

X : Common connectors

A : Charging system/starting system

connectors

B : Engine control system connectors

C : Gauge control system connectors

D : Wiper system connectors

E : Lighting system connectors

F : Signal system connectors

G : Air-conditioning system connectors

l-l : Transmission Control sysetm connectors

I : Interior lamp system connectors

J : Audio/radio connectors

K : Power window/power door lock system

connectors

L : Remote control mirror system connectors

M : Sliding sunroof system connectors

N : Power steering/4-wheel steering system

connectors

0 : Anti-lock brake system connectors.

P : Power seat/seat heater system connectors

Q : Auto cruise control system connectors

R : Auto adjusting suspension system

connectors

S : Passive shoulder belt control/Airbag system

connectors

T : Others

Y : Ground connector

4

IGNITION SYSTEM mENGINE CONTROL

A harness ground is represented differently than

a unit ground.

Types of grounds

Harness

Unit Symbol

Page 191 of 279

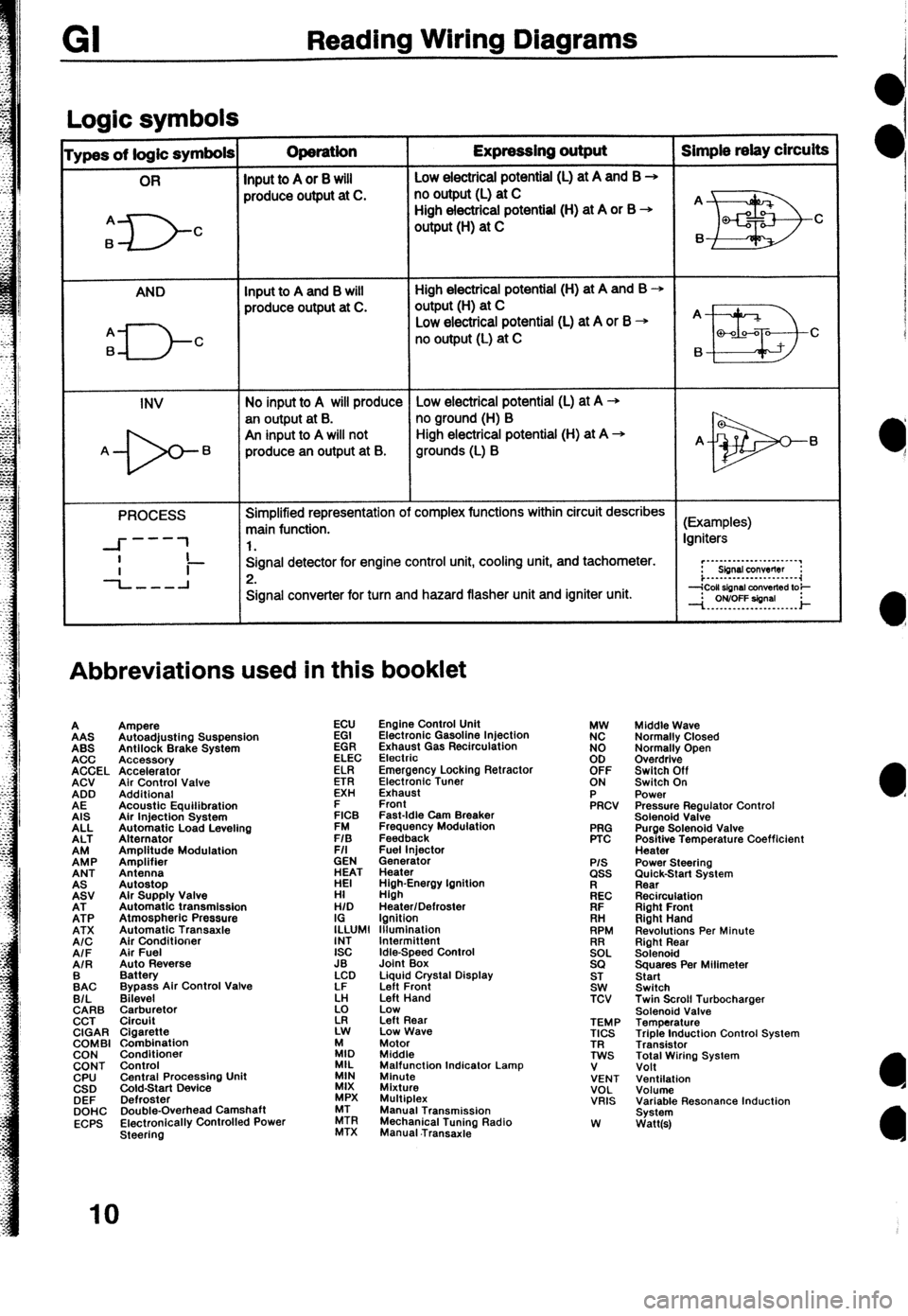

Reading Wiring Diagrams

Loaic symbols I

ypes of logic symbols Operation Expressing output Simple relay circuits

OR

Input to A or 8 will Low electricai potential (L) at A and B +

produce output at C. no output (L) at C

A

6

D- High electrical potential (H) at A or B +

C output (H) at C

AND Input to A and B will High electrical potential (H) at A and B +

produce output at C. output(H) at C

q---J-c

Low electrical potential (L) at A or B + A

no output (L) at C

B a-00-a C

6

INV No input to A will produce Low electrical potential (L) at A -+

an output at B. no ground (H) B

An input to A will not High electrical potential (H) at A +

A- 6 produce an output at B. grounds (L) B A- 6

PROCESS Simplified representation of complex functions within circuit describes

main function. (Examples)

---

--I- 1 1. Igniters

I

-L-l Signal detector for engine control unit, cooling unit, and tachometer.

Ii- 2. r”~“-‘-‘-““‘~~‘.“’

Sbnsl conwflw :

i...-..--.---......-.~~

Signal converter for turn and hazard flasher unit and igniter unit.

Abbreviations used in this booklet

A

AAS

ABS

ACC

ACCEL

ACV

ADD

AE

AIS

ALL

ALT

EP

ANT

EV

EP

ATX

A/C

AIF

AIR

:AC

B/L

CARB

CCT

CIGAR

COMBI

CON

CONT

CPU

CSD

DEF

DOHC

ECPS Ampere

Autoadjusting Suspension

Antilock Brake System

Accessory

Accelerator

Air Control Valve

Additional

Acoustic Equilibration

Air Injection System

Automatic Load Leveling

Alternator

Amplitude Modulation

Amplifier

Antenna

Autostop

Alr Supply Valve

Automatic transmission

Atmospheric Pressure

Automatic Transaxle

Air Conditioner

Air Fuel

Auto Reverse

Battery

Bypass Air Control Valve

Bilevel

$rr$:,tor

Cigarette

Combination

Conditioner

Control

Central Procassino Unit

&Id-Start Device -

Defroster

Double-Overhead Camshaft

Electronically Controlled Power

Steering ECU

EGI

EGR

ELEC

ELR

ETR

EXH

E

FICB

FM

F/S

F/I

GEN

ET

HI

H/D

I;LUMl

INT

ISC

JB

LCD

LF

k!

z Engine Control Unit

Electronic Gasoline Injection

Exhaust Gas Recirculation

Electrio

Emergency Locking Retractor

Electronic Tuner

Exhaust

Front

Fast-Idle Cam Breaker

Frequency Modulation

Feedback

Fuel lniector

Generator

Heater

High-Energy Ignition

High

Heater/Defroster

Ignition

lllumlnation

Idle-Speed Control

Joint Box

Liquid Crystal Display

Left Front

Left Hand

Low

Left Rear

Low Wave

:I, Motor

Middle

MIL

MIN Malfunction Indicator Lamp

Minute

MIX

Mixture

MPX Multiplex

ZR Manual Transmission

MTX Mechanical Tuning Radio

Manual .Transaxie PRG

PTC

P/S ass

kc

FIF

. . .

RH

RPM

!2EL

SQ

ST

SW

TCV

TEMP

TICS

TR

TWS

V

VENT

VOL

VRIS

W Middle Wave

Normally Closed

Normally Open

Overdrive

Switch Off

Switch On

Power

Pressure Regulator Control

Solenoid Valve

Purge Solenoid Valve

Positive Temperature Coefficient

Heater

Power Steering

;im&k-Start System

Recirculation

Right Front

Right Hand

Revolutions Per Minute

Right Rear

Solenoid

Squares Per Milimeter

Start

Switch

Twin Scroll Turbocharger

Solenoid Valve

Temperature

Triple Induction Control System

Transistor

Total Wiring System

Volt

Ventilation

Volume

Variable Resonance Induction

System

Watt(s)

IO

Page 213 of 279

-” ‘ENGINE CONTROL SYSTEM (3/3)

FRM\IT FOG LIGHT RELAY REAR WINDOW

INsTF%+ffNT CLUSTER BLOWER

SWITCH

(SECTION G1

B/O B/O E/LG B/BA L/Y t

(EM) (EM) (EMI (EM)

I

%P

:;~~~=====~::~~~~=~~=~~

POWER STEERING

PRESSURE SWITCH

8

2-01 ENGINE CONTROL UNIT (EM) El-10 POWER STEERING PRESSURE SWITCH(F)

I” IS 10 ID 1M IK iI IG IE 1C ,A 2Y 2W 2U 25 20 20 2H 2K 21 26 2E

2C 2A

R/B O/L G/B G * -G/Y L G/W * v L/R LG L/O Y R/Y L/W R -G/d-G/F * Y/L P/B 3/LG B/O

BR/ B/L B/G L/Y R/W * L/B O/B W/B W/Y W/R G W/L Y/B G/O W R/B R/L G/R R/Y * x B/BqE/O

1” ,T

IR II’ 1N IL 1.J 1H 1F 10 16 2X 2V 2T 2R 2P 2N 2L 2J 2H 2F 2D 28

1-20 AIRFLOW METER (EM) 81-21 THROTTLE SE%;; 81-22 CLUTCH SWITCH (F) 81-23 NEUTRAL SWITCH (EM)

ii

32

Page 277 of 279

a

l

a

.Sc+wCi!J VALVE(PRC HIGH TEMp)

R THERMOSENSOR

POWER STEERING P

ABS WHEEL

SPEED SENSOR Rk

OXYGEN &OR

RUNNlNG LIGHT RELAY No.2

RUNNINGLIGMR

PavERDooR

HEADLIGHT RELAY

ENGINE CONTROL UNIT

STOPUGHT SWITCH

HORN RELAY SEAT WARMER RELAY